Mining differential three-roller tooth crusher

A crusher and differential technology, applied in the direction of grain processing, etc., can solve the problems of inability to use the shearing and crushing principle of ore rock, low material classification and transportation efficiency, and reduced crushing efficiency of the crushing cavity, so as to improve the processing capacity of the whole machine, Increased utilization rate, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

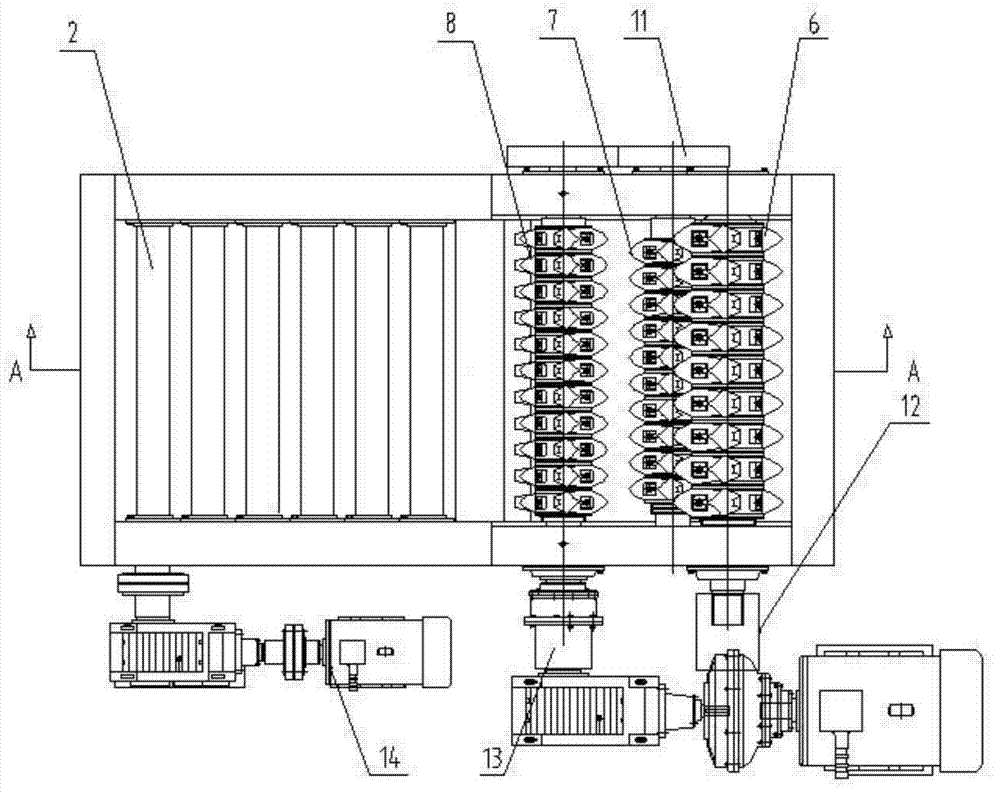

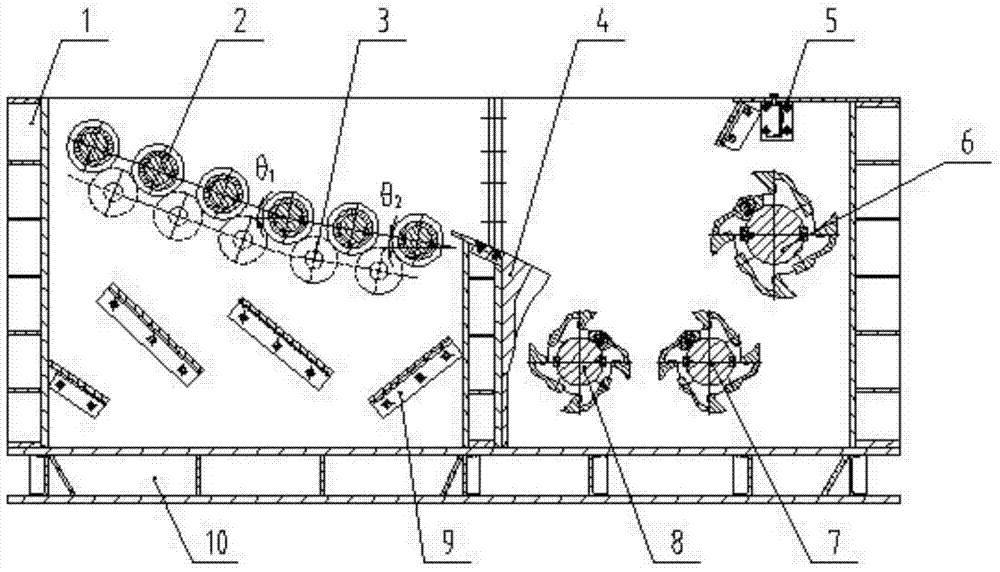

[0020] Such as figure 1 and figure 2 As shown, the mining differential three-roller gear crusher of the present invention includes a front roller screen composed of a roller 2 and a roller idler 3, and the crushing chamber is composed of a left box body and a front roller screen box body. The front roller screen chassis composed of , coal retaining plate 9 and the middle box is composed of the tooth plate 4, the right box body and the crushing chamber box. The front roller screen chassis and the crushing chamber chassis are connected by bolts On the base 10 welded by steel plate and section steel, the front roller screen cabinet and the crushing chamber cabinet form the whole machine cabinet 1; the front roller screen is driven by the roller screen driving device 14, and the adjacent rollers 2 pass through Roller idler gear 3 is meshed and driven; the crushing chamber is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com