Power seat driving apparatus for vehicle

a driving apparatus and seat technology, applied in the direction of movable seats, transportation and packaging, gearing, etc., can solve the problems of clashing damage, large stress and damage, and generation of stress, and achieve the effect of reducing rigidity and increasing tooth thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

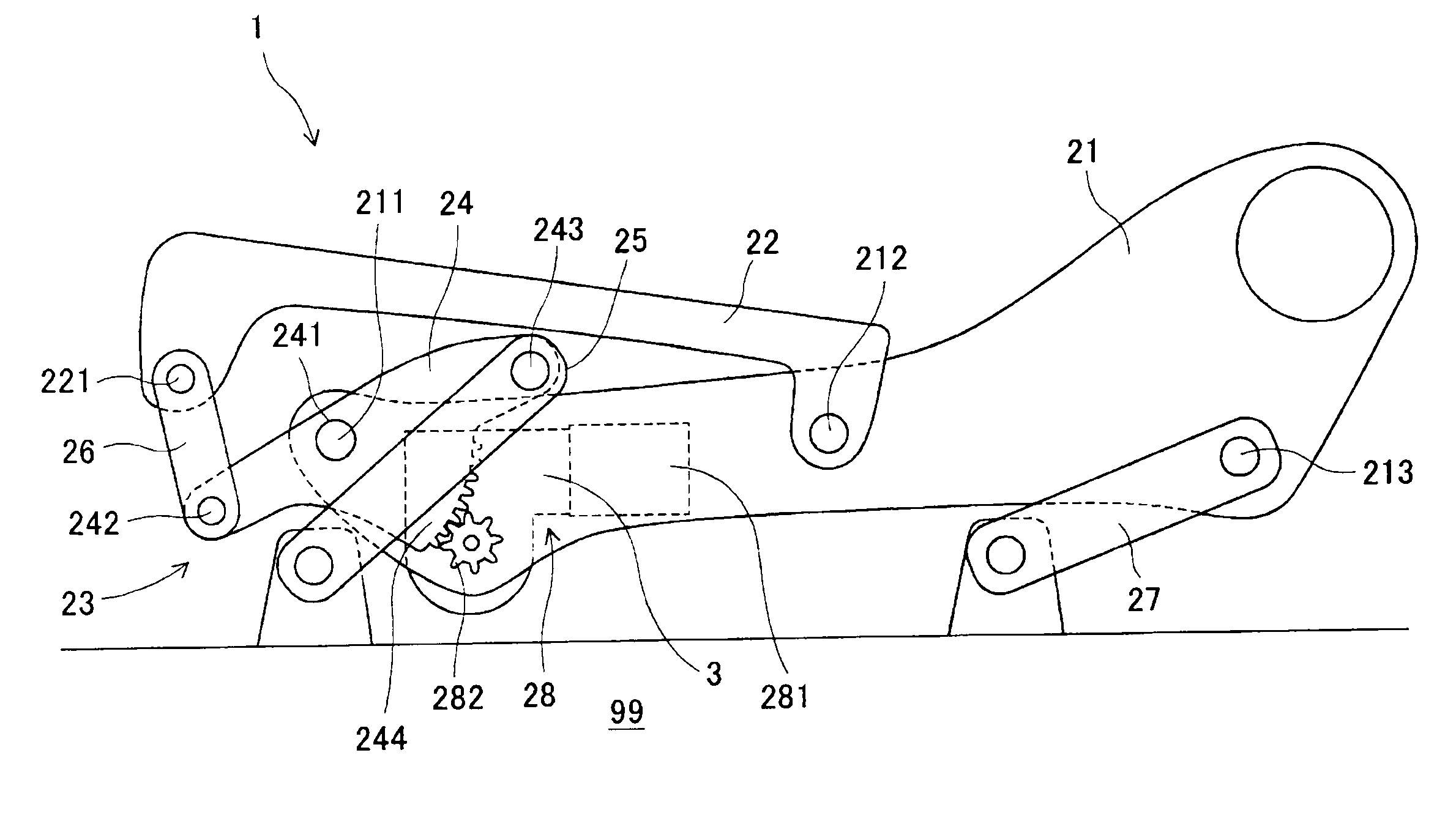

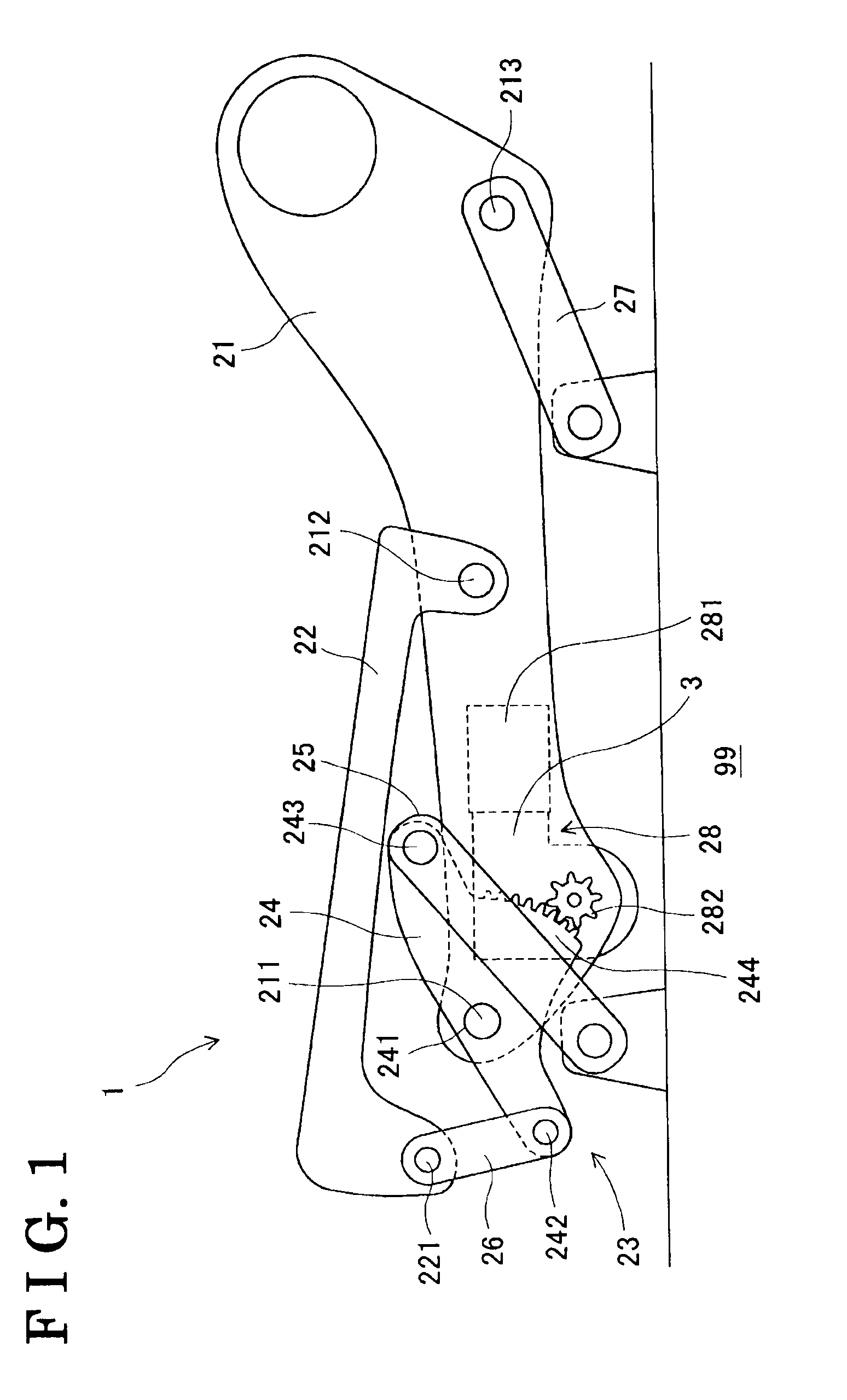

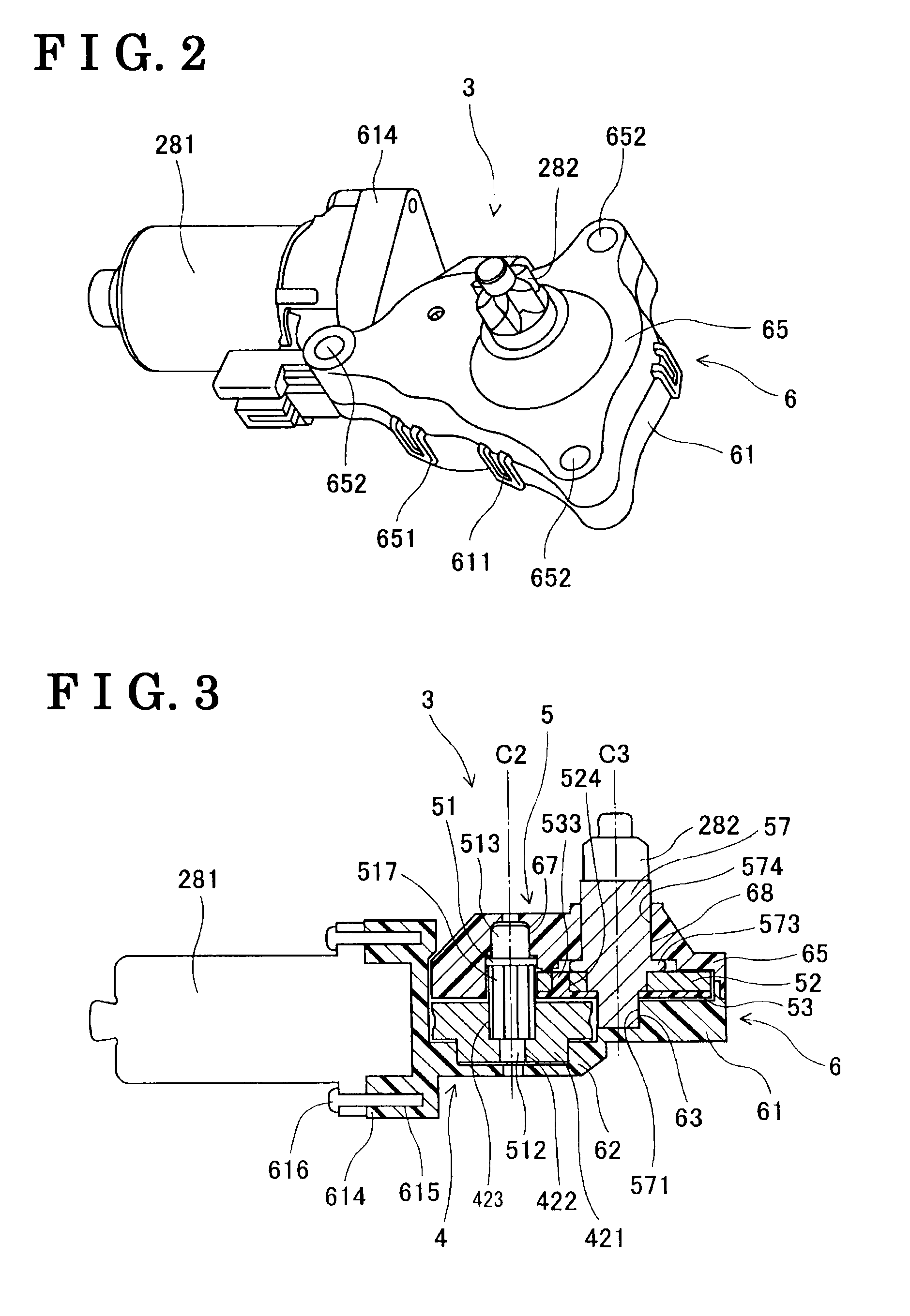

[0018]A first embodiment of a power seat driving apparatus 1 for a vehicle will be provided hereinafter with reference FIGS. 1 to 4. The power seat driving apparatus 1 includes left and right side brackets 21 holding a seat cushion at left and right side surfaces of the seat cushion, a cushion frame 22 holding the seat cushion at a bottom side of the seat cushion, left and right front pivot-link mechanisms 23 rotating in order to operate front portions of the side brackets 21 and the cushion frame 22 so as to pivot, left and right rear pivot links 27 rotating in order to operate rear portions of the side frames 21 so as to pivot, a front driving device 28 and a rear driving device. The power seat driving apparatus 1 includes substantially the same structures and functions at left and right sides thereof. Therefore, only one side of the power seat driving apparatus 1 will be described hereinafter, unless otherwise indicated.

[0019]A rear portion of the cushion frame 22 is supported by...

second embodiment

[0032]A second embodiment of the power seat driving apparatus 1 will be described hereinafter with reference to FIGS. 5 and 6. According to the second embodiment, a backlash of a second deceleration portion 50 (a deceleration mechanism) in an axial direction thereof and in a radial direction thereof is reduced. An elastic gear 54 of the second deceleration portion 50, which is different from the first embodiment, will be described mainly hereinafter. In FIG. 6, the output gear member 57 and the housing 61 are illustrated by dashed line.

[0033]The elastic gear 54 according to the second embodiment is made of resin material and is formed into a substantially annular shape. The elastic gear 53 includes elasticity and lower rigidity than the spur gear 52. The elastic gear 54 includes a third gear portion 541, a third shaft hole 542 and connection protruding portions 543. The third gear portion 531 includes a spur gear formed at an outer circumferential surface thereof. The third shaft ho...

third embodiment

[0037]A third embodiment of the power seat driving apparatus 1 will be described hereinafter with reference to FIGS. 7 and 8. According to the third embodiment, a rotational range of the output gear 282 is restricted. Only portions different from the first embodiment will be described mainly hereinafter. Configurations of the housing 6 of a decelerating portion 300 according to the third embodiment and the first deceleration portion 4 are similar to that of the first embodiment.

[0038]A second deceleration portion 7 (a deceleration mechanism) according to the third embodiment includes a pinion gear (a driving gear) 71, a spur gear (a driven gear) 72, and an elastic gear (a supplemental gear) 73. The second deceleration portion 7 further includes a stopper pin 74 and a stopper plate 75. The pinion gear 71, which is a driving portion of the second declaration portion 7, is coaxially integrally formed at an upper end of the helical gear 42 of the first deceleration portion 4. The pinion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com