Rolling die

a die and rolling technology, applied in the field of rolling dies, can solve the problems of cracking or localized damage, shortening the life of the die,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

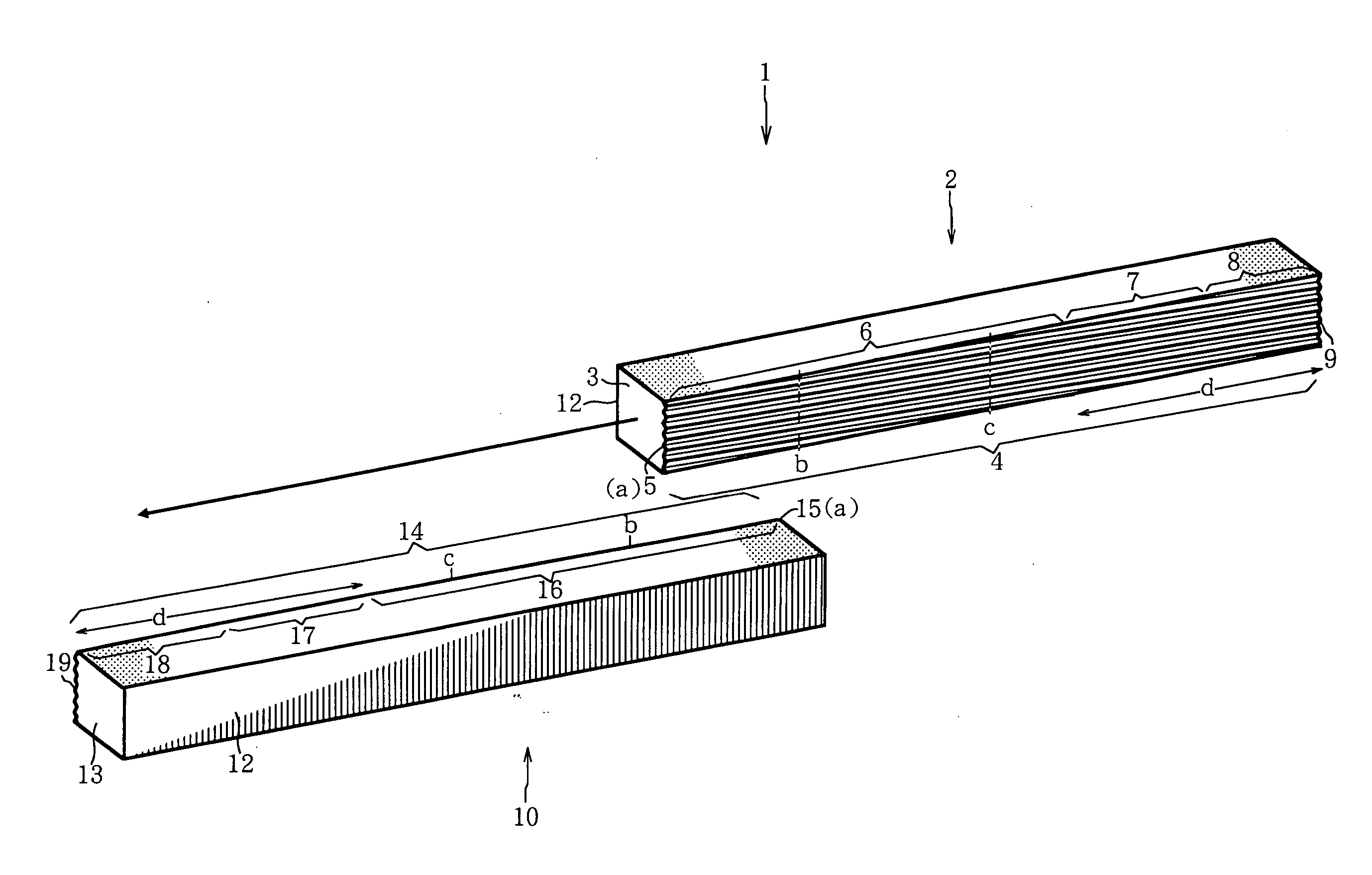

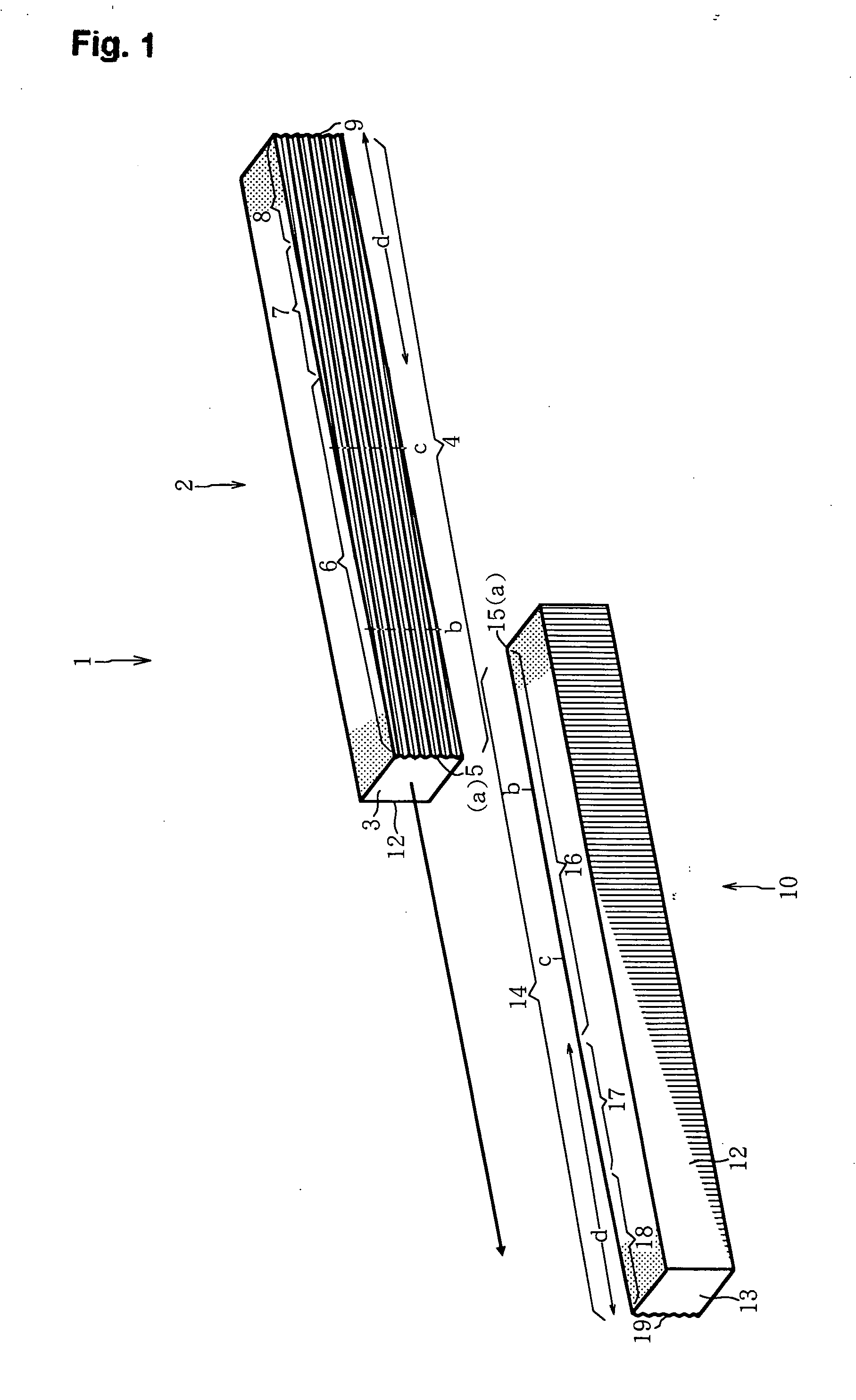

[0028] Reference will now be made in detail to exemplary embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

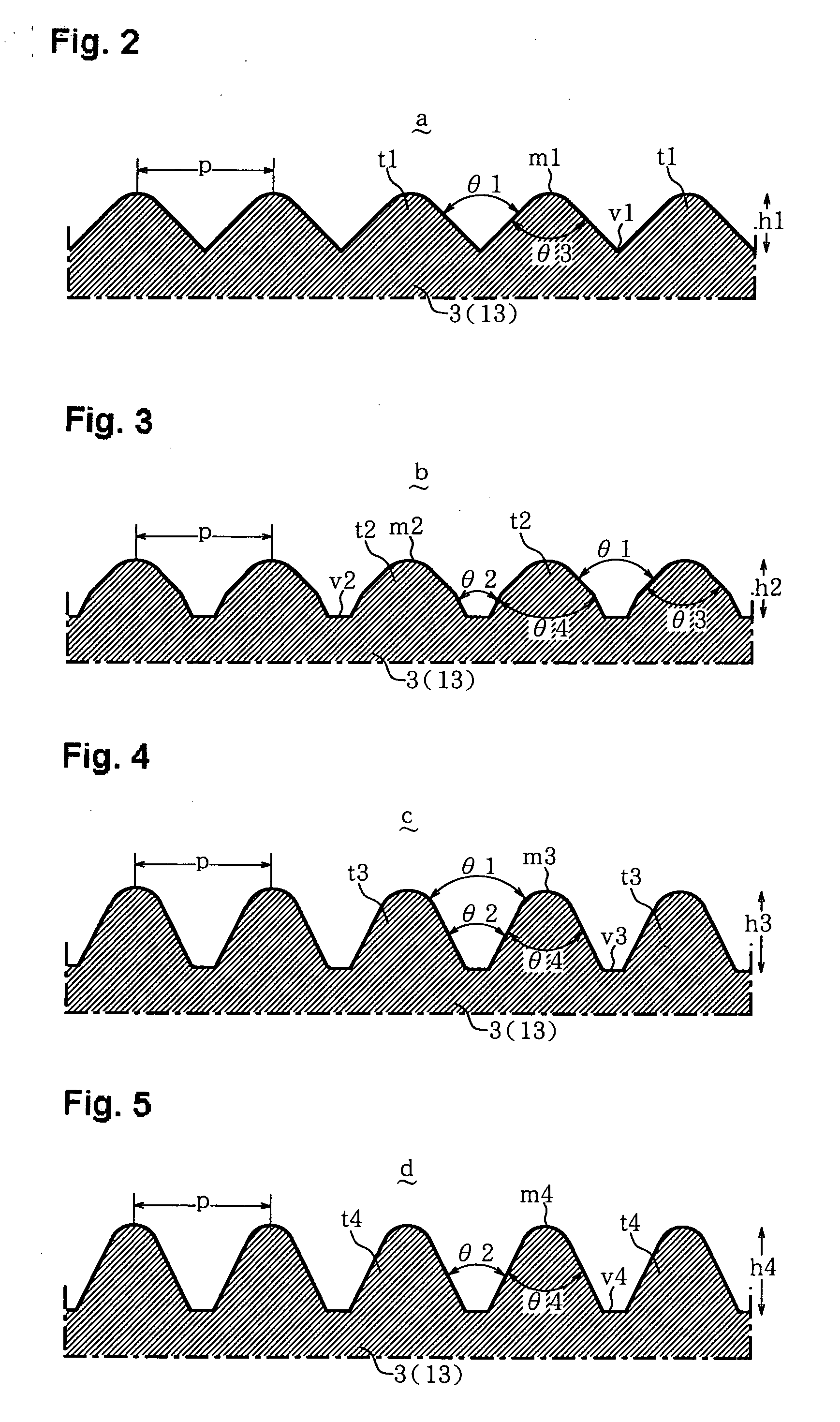

[0029] A rolling die according to one embodiment of the invention includes a bite portion having bite processing teeth and a finishing portion having finishing processing teeth. The bite portion includes bite processing teeth at a bite starting point for a workpiece. The processing teeth at the starting point in the bite portion have a lower tooth height than the processing teeth in the finishing portion, and the bite processing teeth at the starting point in the bite portion have a larger tooth tip angle and a larger trough angle than the finishing processing teeth in the finishing portion.

[0030] In this regard, since the processing teeth of the bite starting point are shallow and have an obtuse angle for the initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| trough angle | aaaaa | aaaaa |

| trough angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com