A friction plate return mechanism and an air pressure disc brake with the mechanism

A technology of return mechanism and friction plate, applied in the direction of brake type, axial brake, gear transmission mechanism, etc., can solve the problems of complex assembly of pneumatic disc brakes, increase of air pressure of brake air chambers, difficulty in popularization and use, etc. Achieve simple structure, prolong service life and solve the effect of dragging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

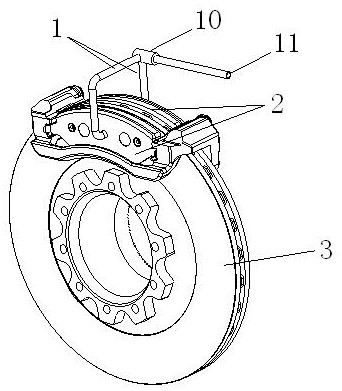

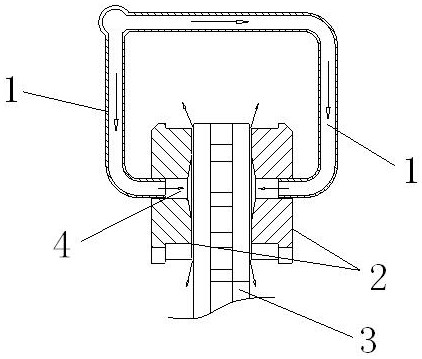

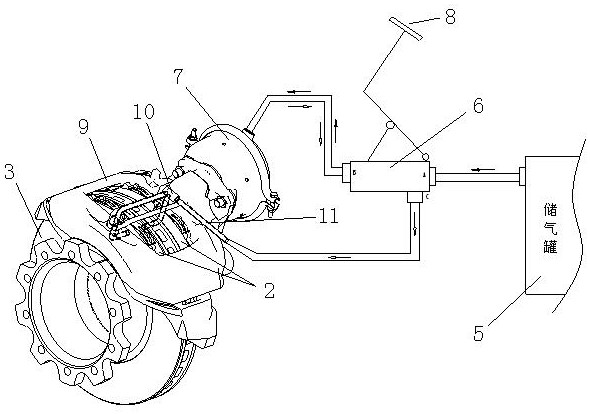

[0026] Such as figure 1 , 2 As shown, the friction plate return mechanism of this embodiment is composed of an air pipe 1, two friction plates 2 that are relatively arranged and movable relative to each other, and a brake disc 3 located between the two friction plates 2; Both are provided with a straight cylinder-shaped ventilation pipeline 4, and the positions of the ventilation pipeline 4 on the two friction plates 2 are opposite; the ventilation pipeline 4 extends along the movement direction of the friction plate 2, and the diameter of the air pipe 1 is slightly smaller than the ventilation pipeline 4 The air pipe 1 extends from the outer side of the friction plate 2 into the ventilation pipeline 4, and the side of the ventilation pipeline 4 facing the brake disc 3 has a trumpet-shaped structure. In this embodiment, the air pipes 1 corresponding to the two friction plates are connected to the main air pipe 11 through the three-way valve 10 .

[0027] The return principle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com