Braking device of toothed solid chain type engine

A technology of engine braking and fixed chain, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of increased engine height and manufacturing cost, large hydraulic deformation, slow braking response, etc., and meet the reduction requirements , Simplify the design and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

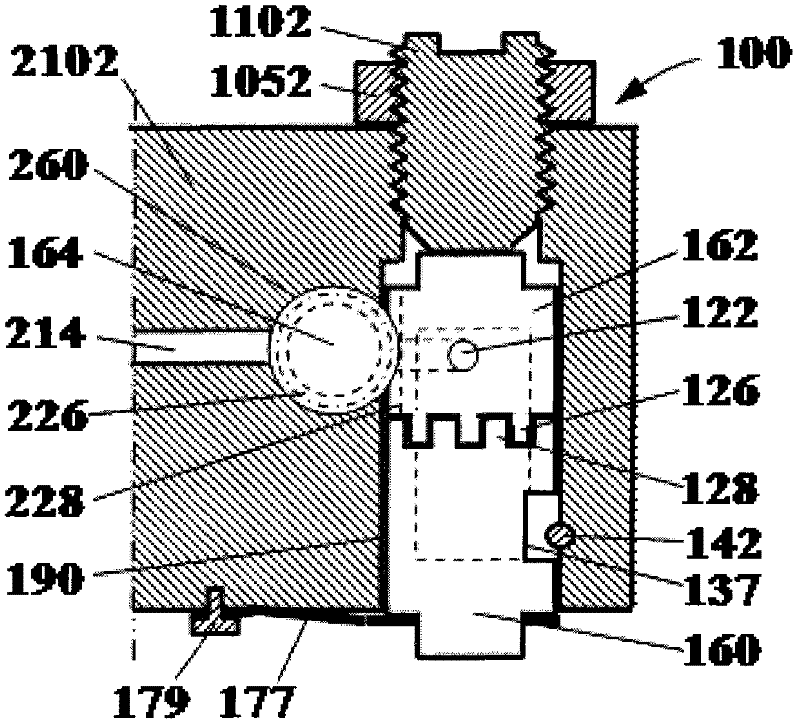

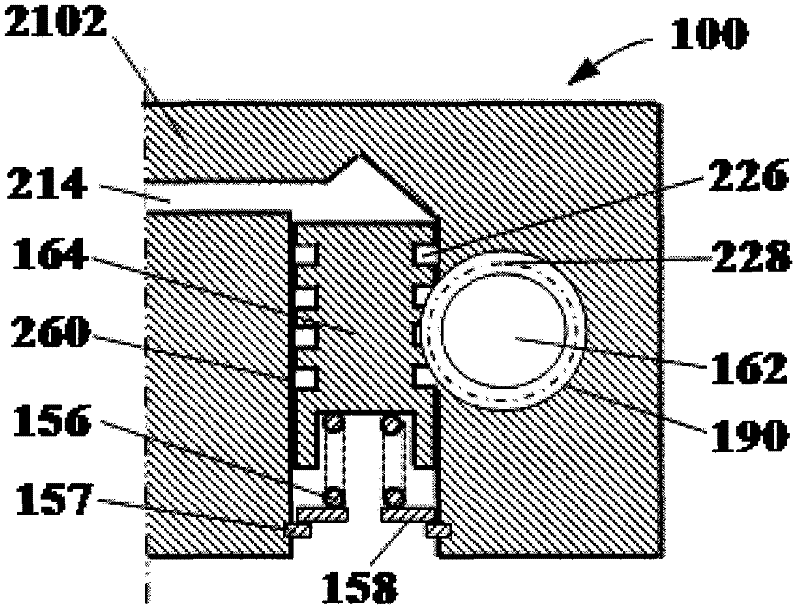

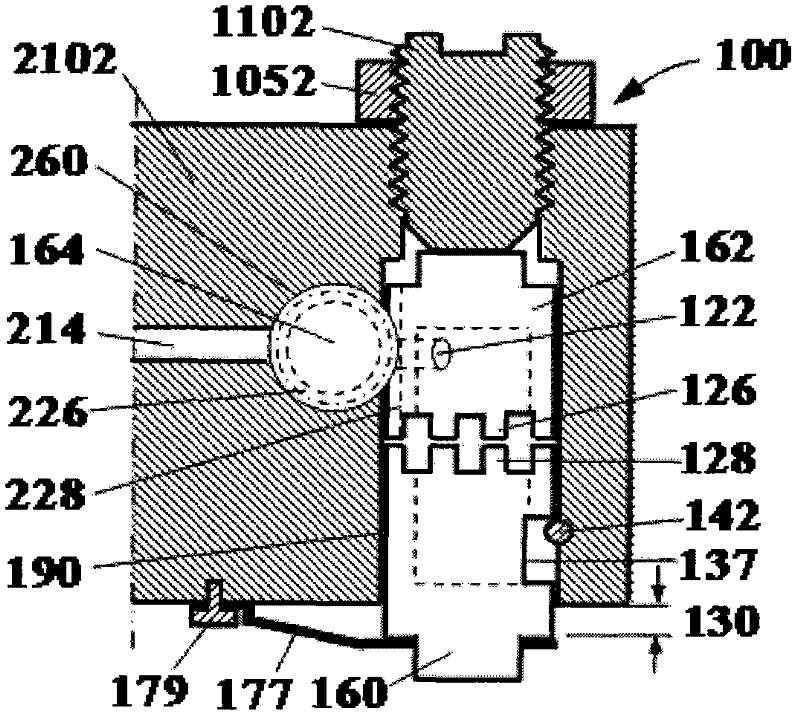

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 9 shown. figure 1 with figure 2 They are respectively a side view and a top view of the first embodiment of the engine braking device of the present invention when it is in the "off" position. The brake device 100 is placed in a brake box 2102, and is composed of a first plunger 160 and a second plunger 162 (braking plunger) in the vertical plunger hole 190, and a plunger rotation drive mechanism. The plunger rotary drive mechanism includes a drive piston 164 positioned in a horizontal piston bore 260, which is normally pushed by a return spring 156 (eg figure 2), stop at one side of the oil supply hole 214. The return spring 156 is located on the spring seat 158 , and the spring seat 158 is positioned by the retaining ring 157 fixed on the brake case 2102 . The drive piston 164 and the first plunger 162 form a translational and variable-rotation mechanism. The drive ...

Embodiment 2

[0046] Such as Figure 7 with Figure 8 as shown, Figure 7 with Figure 8 It is a top view of the second embodiment of the engine braking device of the present invention in the "off" and "on" positions. The working principle of this embodiment is basically the same as that of the first embodiment, and the difference lies in the plunger rotation drive mechanism of translation and rotation. The driving tooth 226 on the driving piston 164 in the first embodiment becomes the driving groove 2263 in this embodiment; the driven tooth 228 on the first plunger 162 becomes the driven pin 2283 in this embodiment. The reciprocating movement of the driving piston 164 in the horizontal piston hole 260 makes the first plunger 162 rotate back and forth in the plunger hole 190 through the driving groove 2263 on the driving piston 164 and the follower pin 2283 on the first plunger 162 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com