Patents

Literature

49results about How to "Reduced brake reaction time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

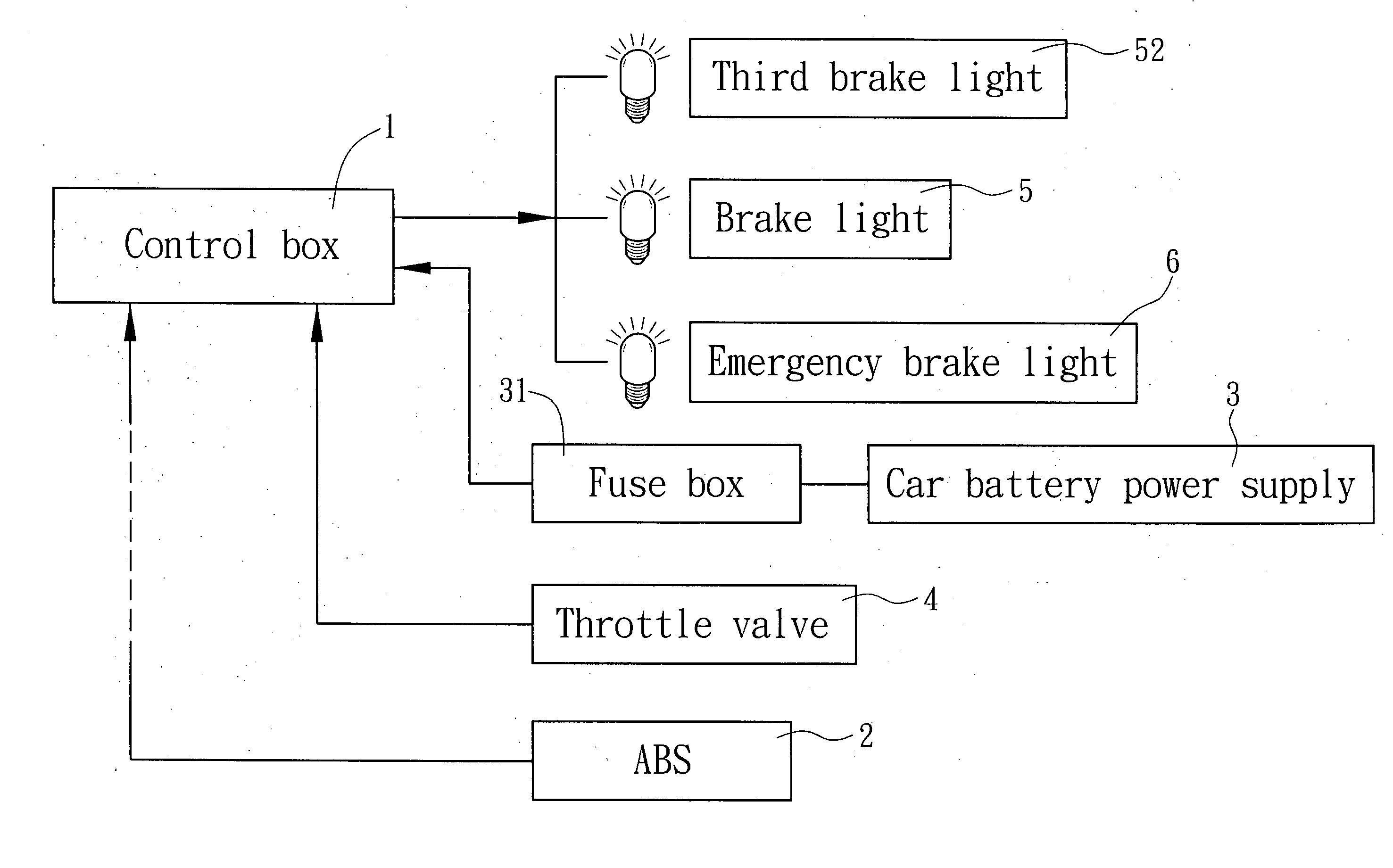

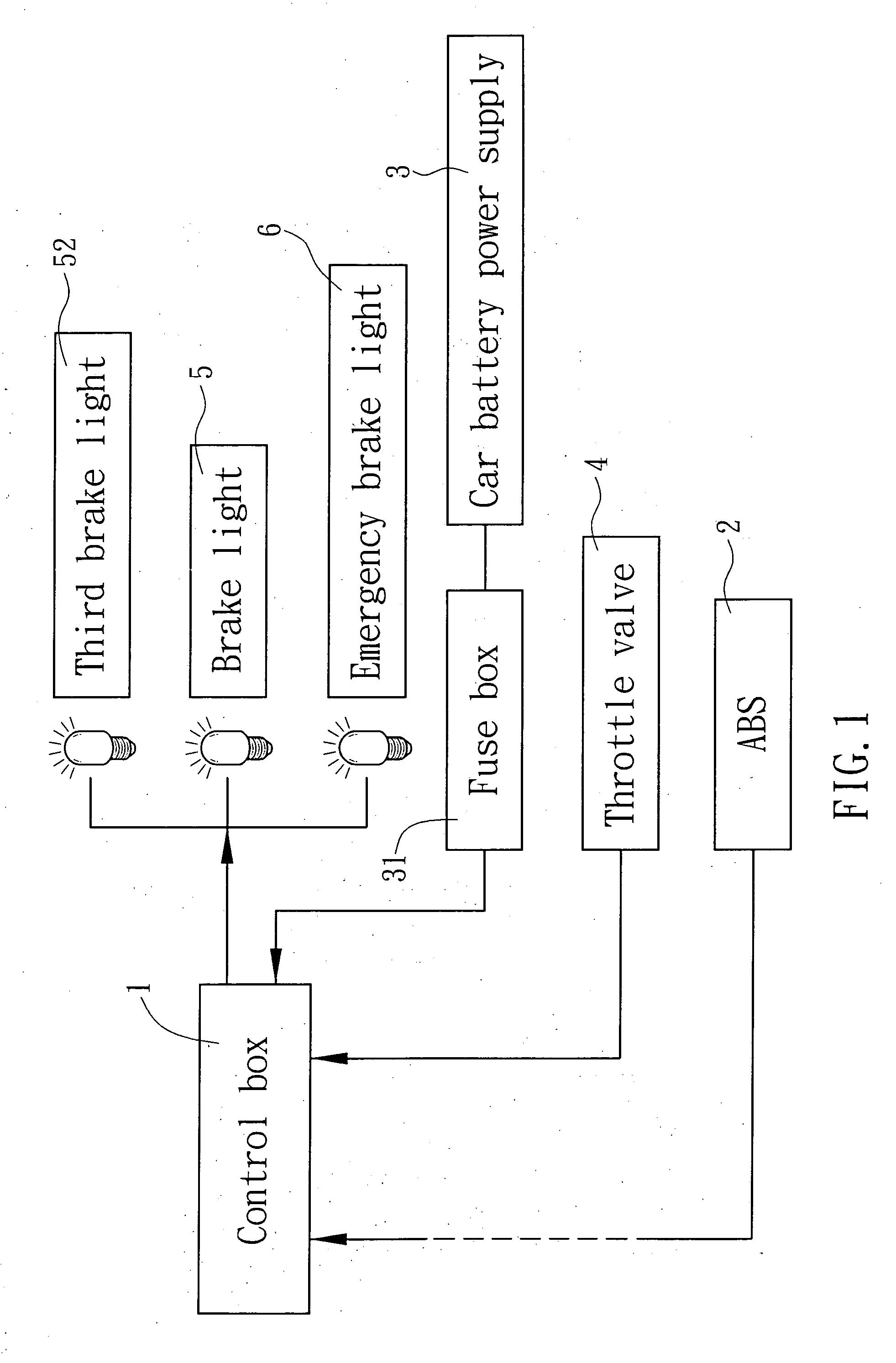

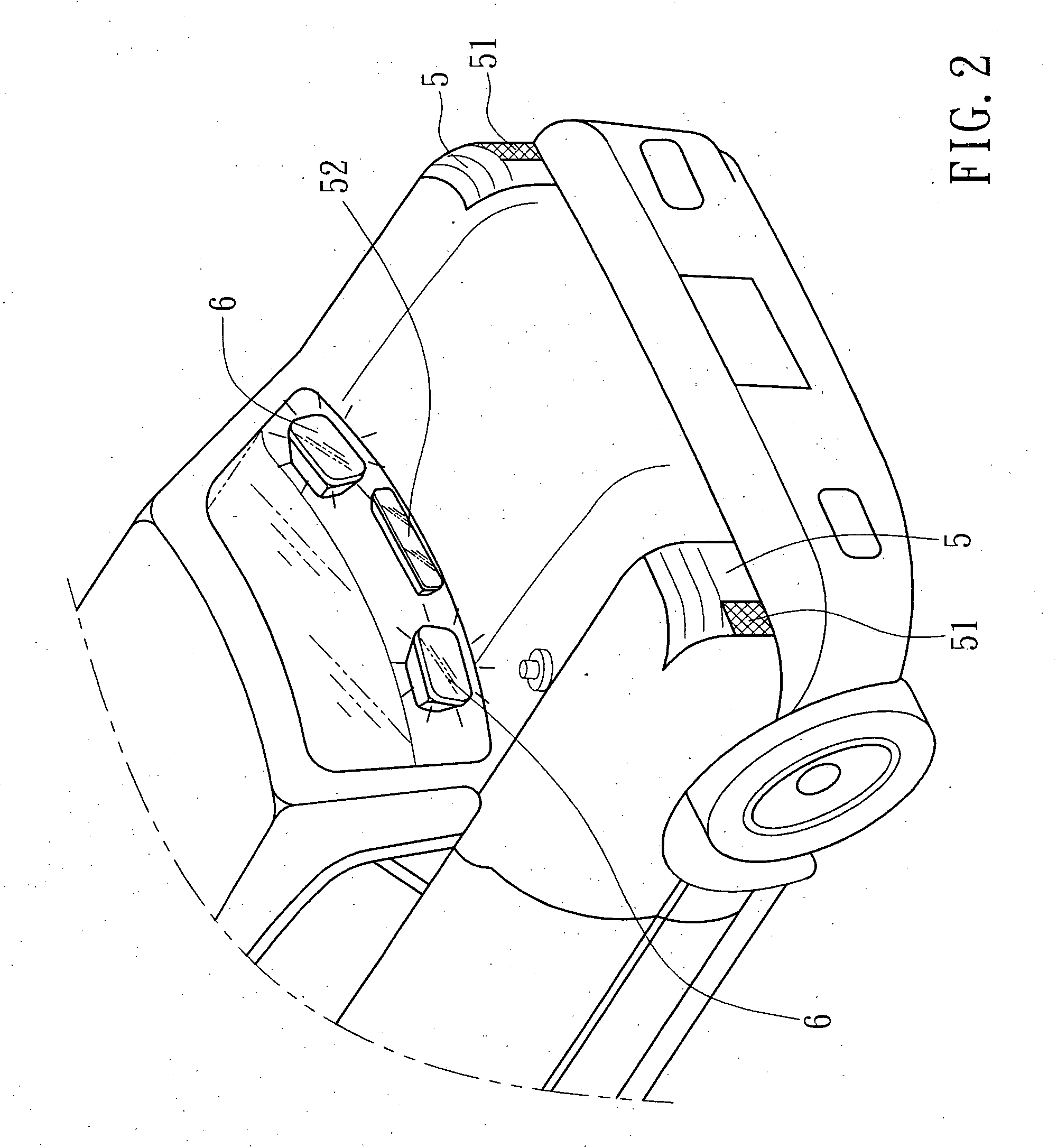

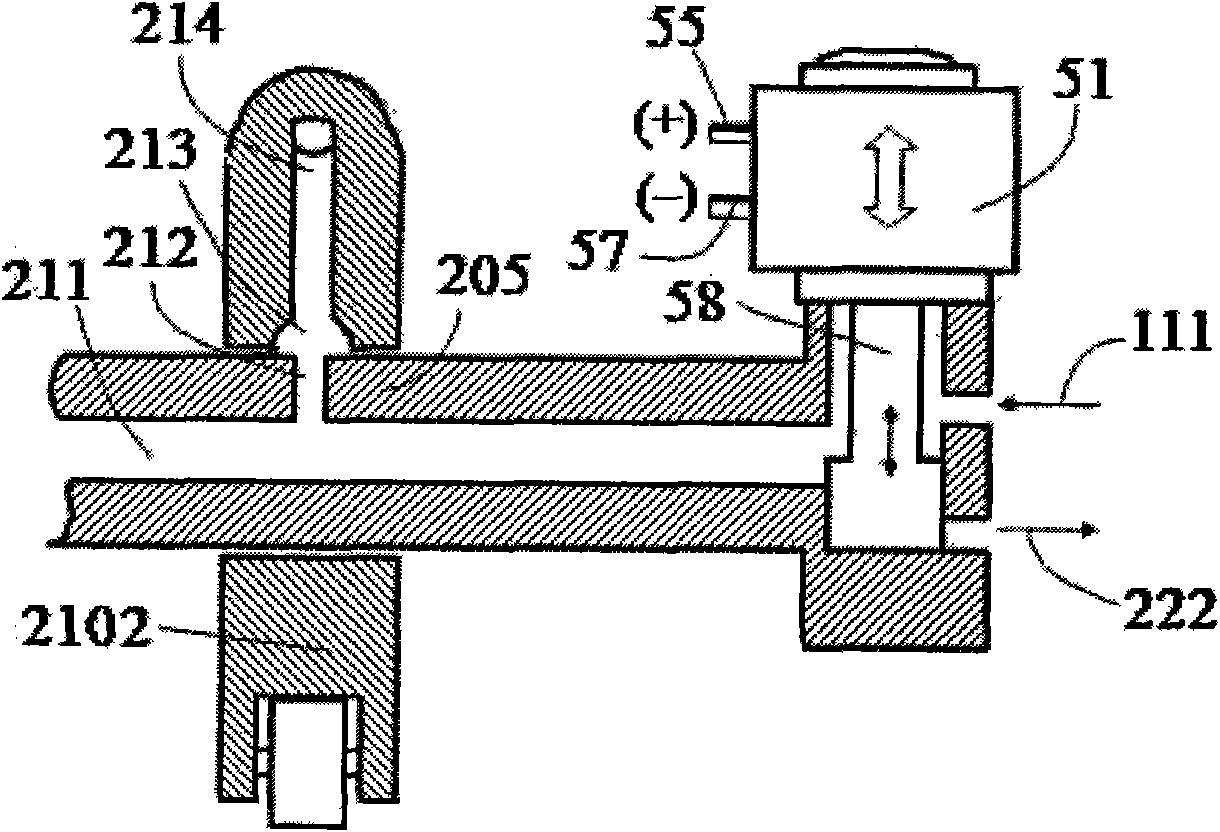

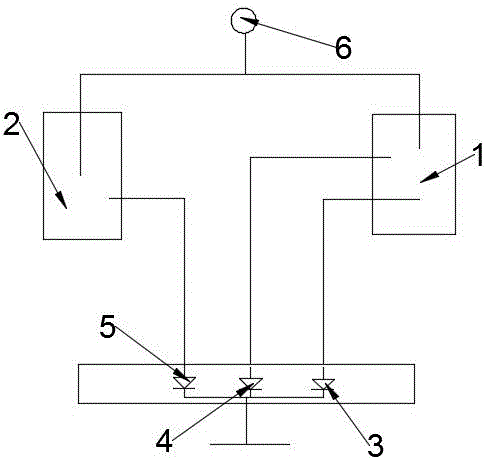

Vehicle emergency brake light control system

InactiveUS20080079555A1Reduced brake reaction timeAvoid collisionOptical signallingAutomotive batteryVehicle driving

A vehicle emergency brake light control system includes a control box installed in a car and electrically connected to the ABS (Anti-lock braking system), a car battery power supply, a throttle valve, a brake light, a third brake light and an emergency brake light of the car such that when the driver of the motor vehicle suddenly steps on the brake pedal to drive on the ABS, the control box is induced by a signal from the ABS to drive the brake light, the third brake light and the emergency brake light to flash; when the ABS is released and the vehicle driver steps on the accelerator pedal of the car to move the car again, the throttle valve gives a signal to the control box, causing the control box to turn off the brake light, the third brake light and the emergency brake light.

Owner:WANG HSU CHENG

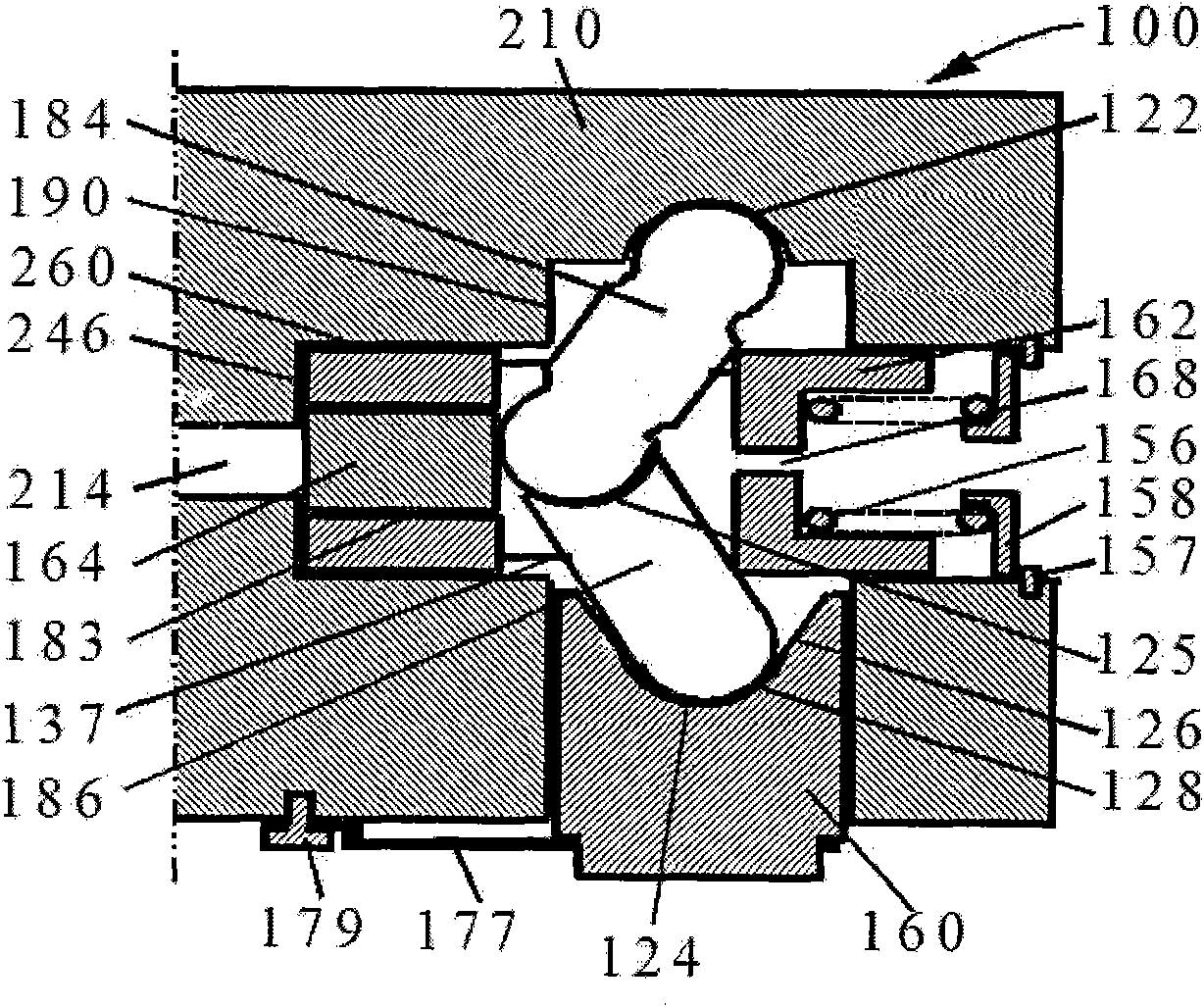

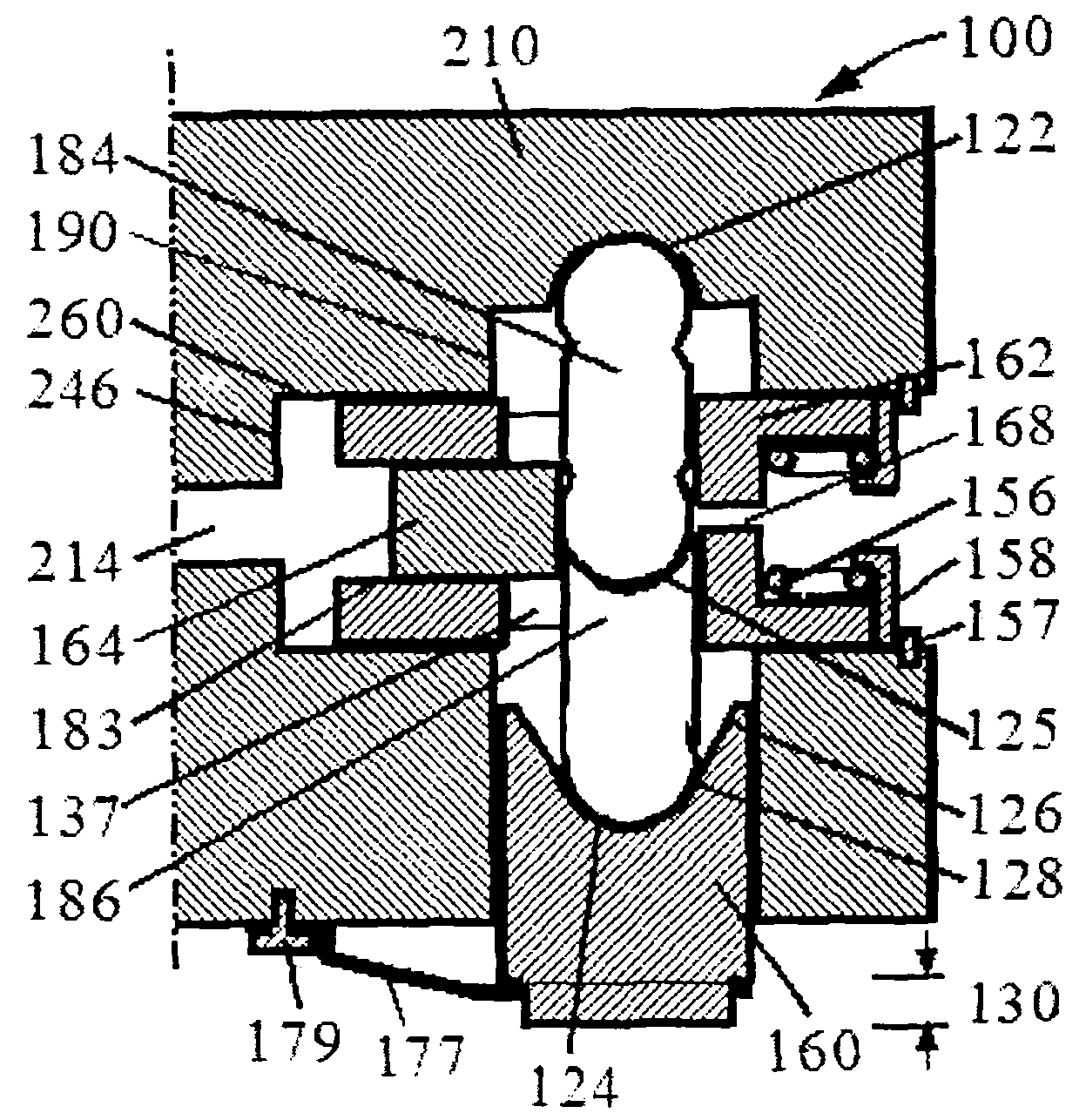

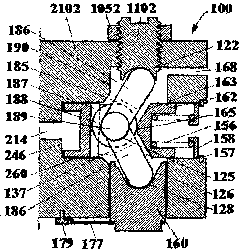

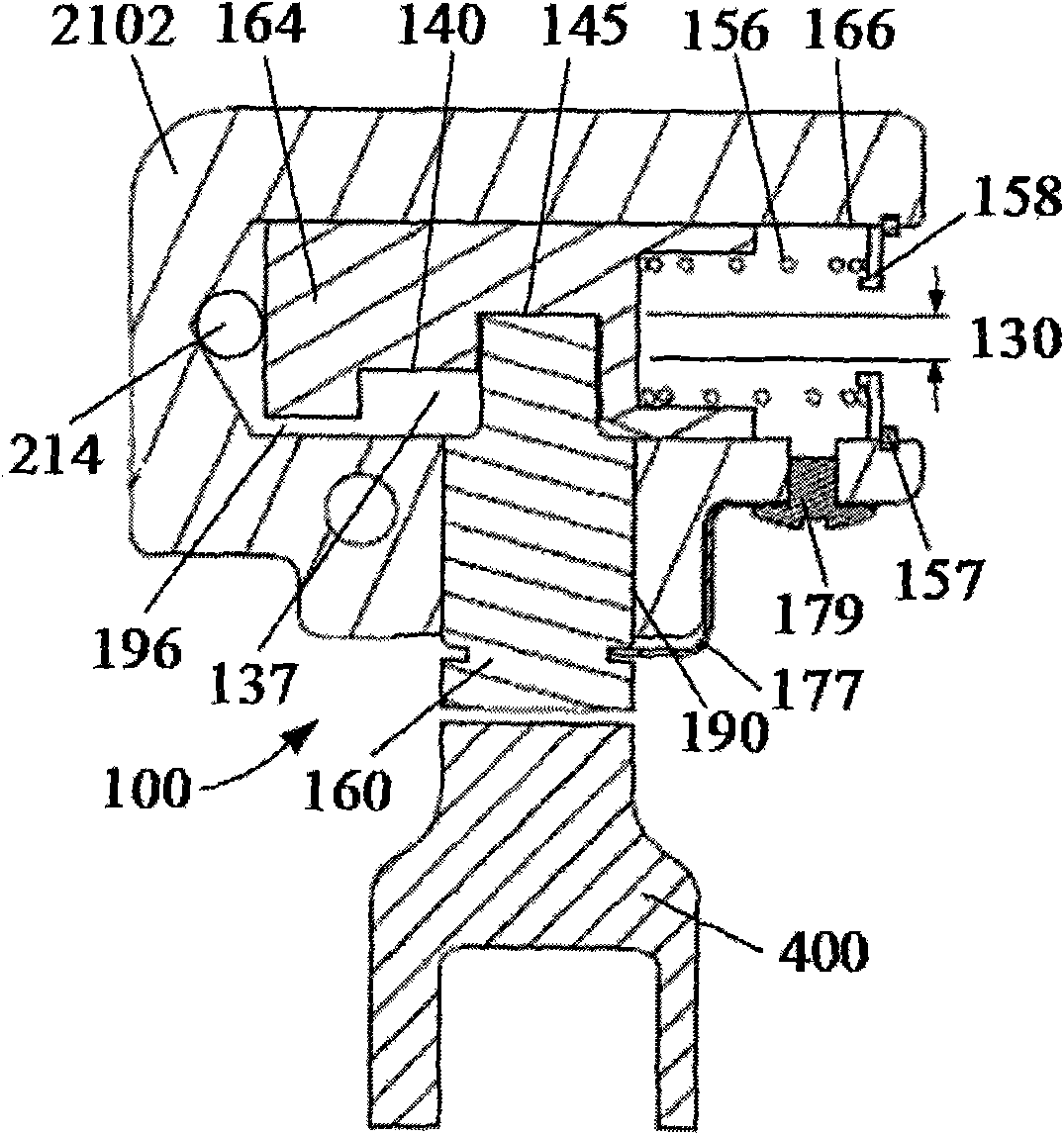

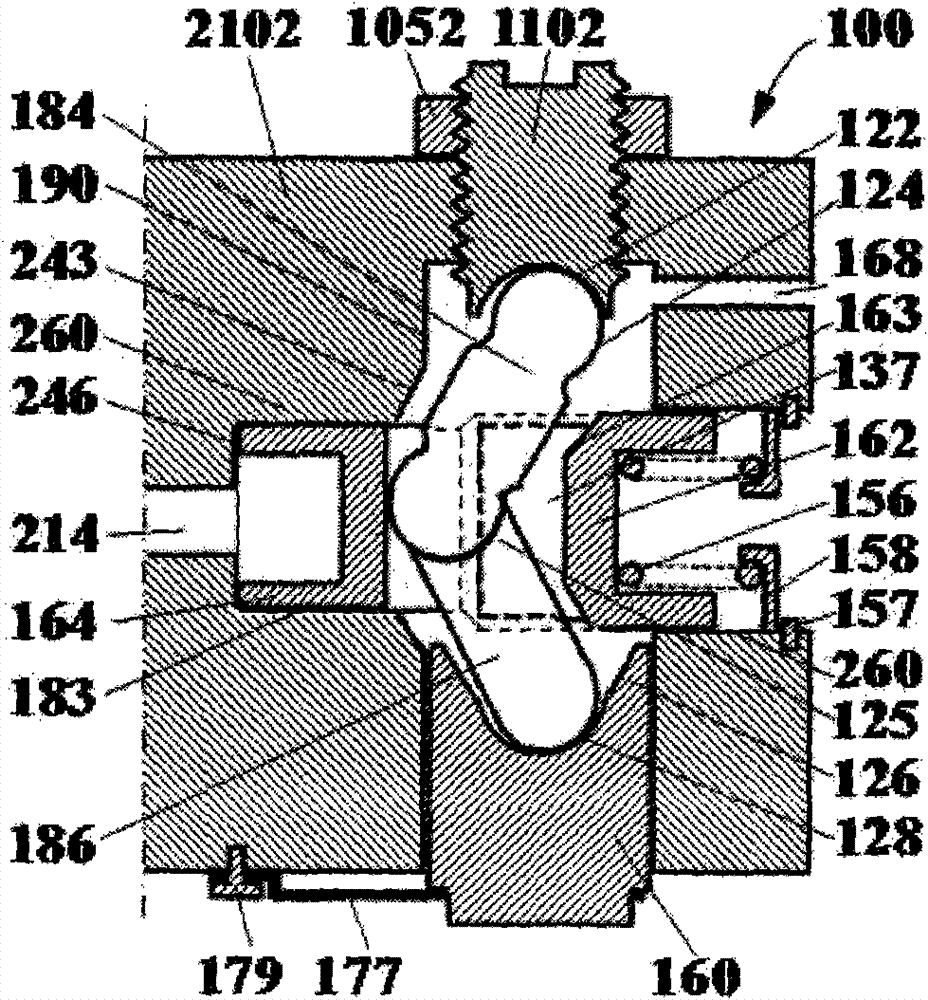

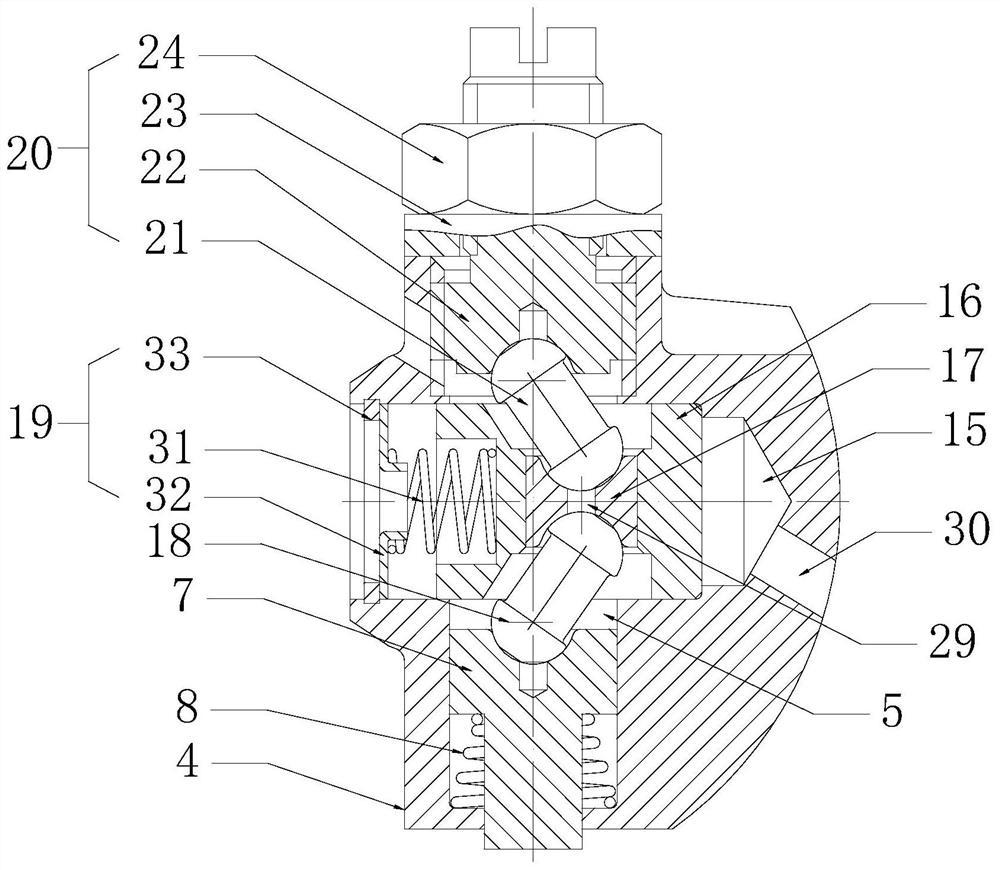

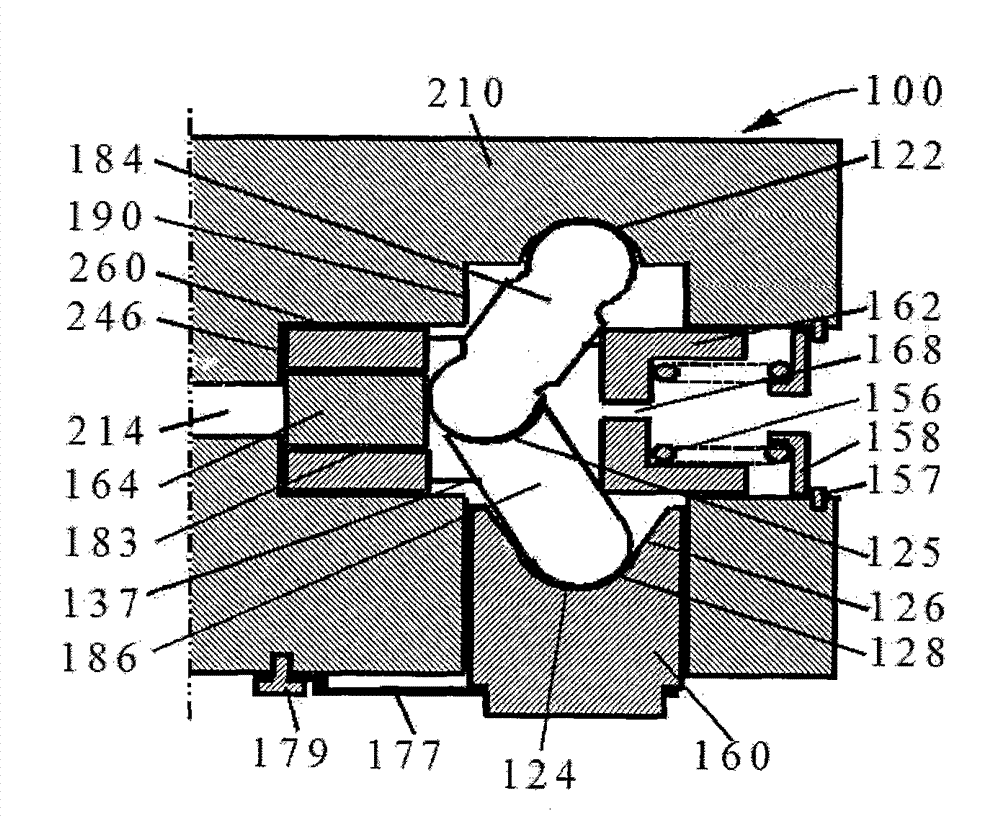

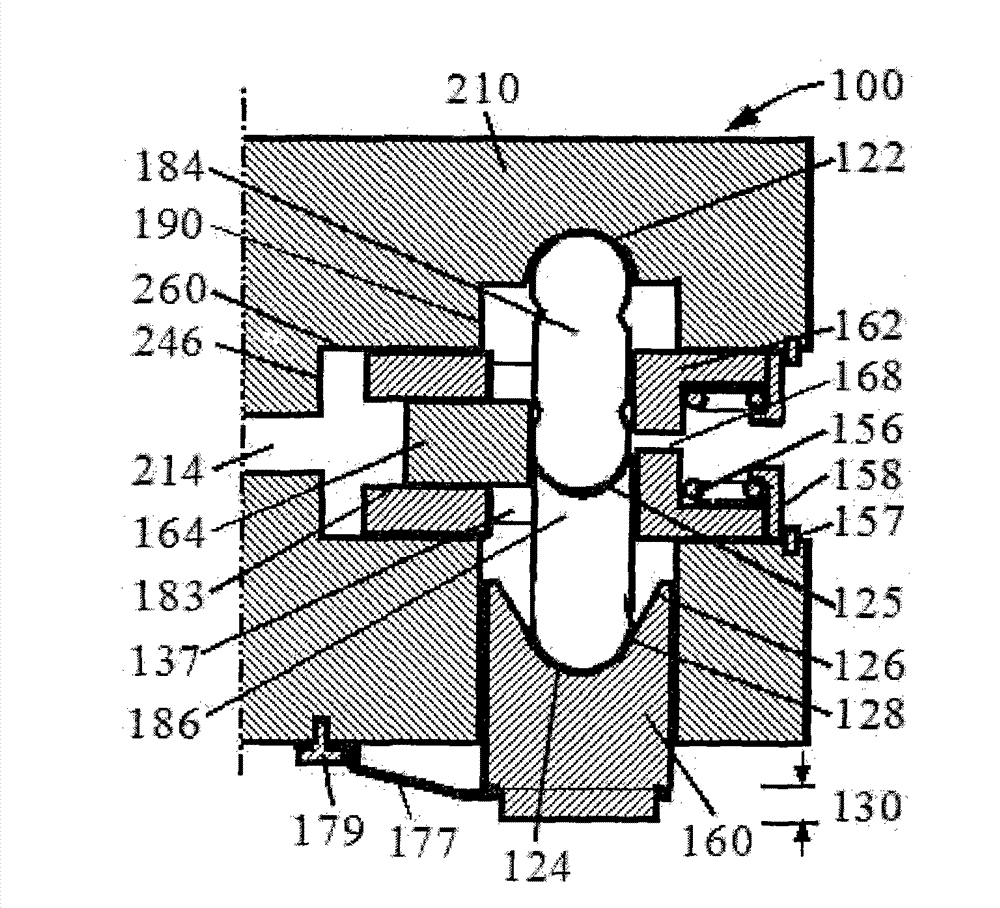

Improved engine brake device

ActiveCN102003242AReduce volumeReduce weightValve arrangementsMachines/enginesDrive wheelExhaust valve

The invention relates to an engine brake device which comprises an exhaust valve control mechanism. The exhaust valve control mechanism comprises a driving force input cam, a cam driven wheel, a push rod, a rocker arm and a rocker arm shaft, wherein one end of the push rod is connected with one end of the rocker arm, the cam driven wheel is arranged on the other end of the push rod, and the driving force input cam is arranged outside the cam driven wheel; the other end of the rocker arm is provided with a horizontal guide piston, a driving piston and a vertical brake plunger piston, two connecting rods are arranged in the guide piston, the convex spherical surface of the upper end of the upper connecting rod is matched with the concave spherical surface of the rocker arm, the convex spherical surface of the lower end of the lower connecting rod is matched with the convex spherical surface of the brake plunger piston, and an exhaust valve rod connecting piece is arranged below the brake plunger piston. The driving force input cam periodically transmits engine power to the rocker arm, the gap between the rocker arm and the exhaust valve rod connecting piece is controlled by using a solenoid valve, the switching between the brake working state and the normal working state is realized, the size and the weight of the brake are reduced, and high oil pressure and leakage, deformationand load fluctuation caused by high oil pressure do not occur.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

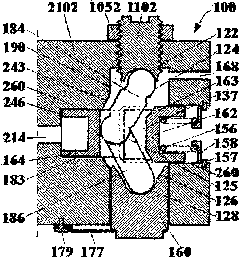

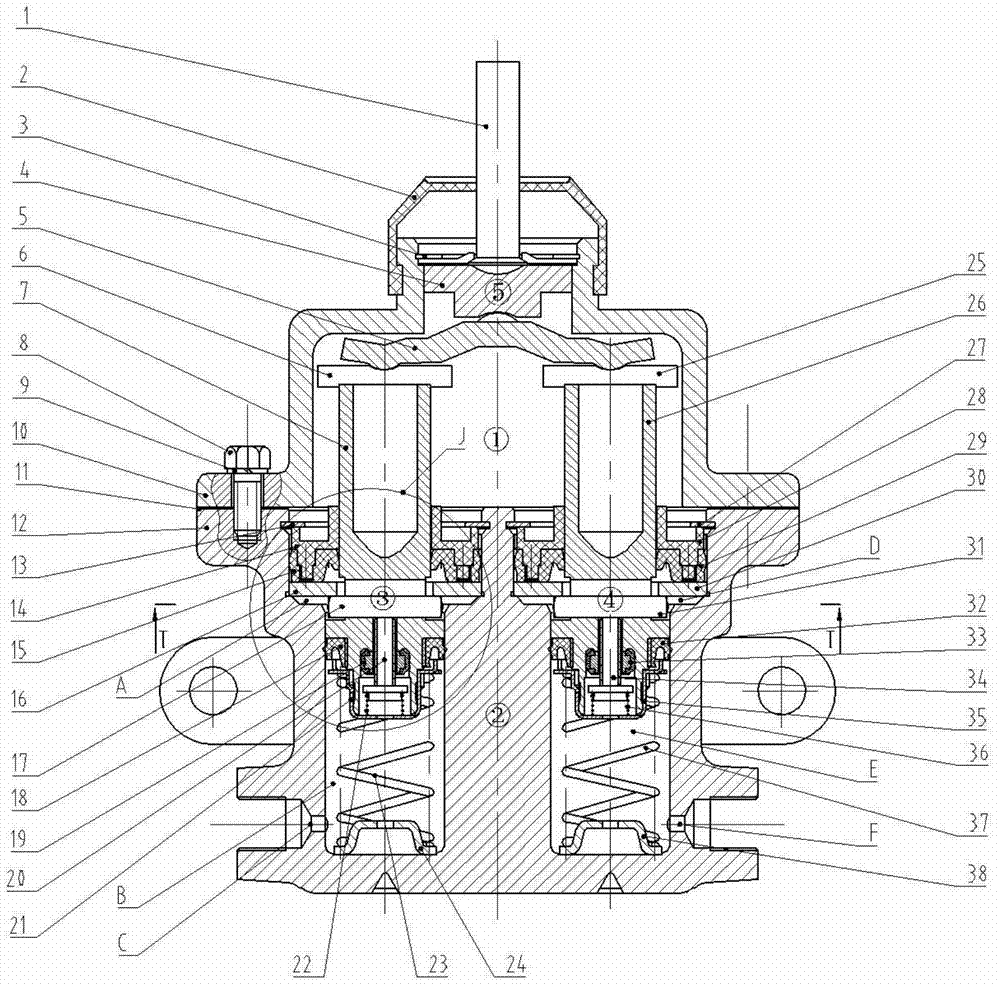

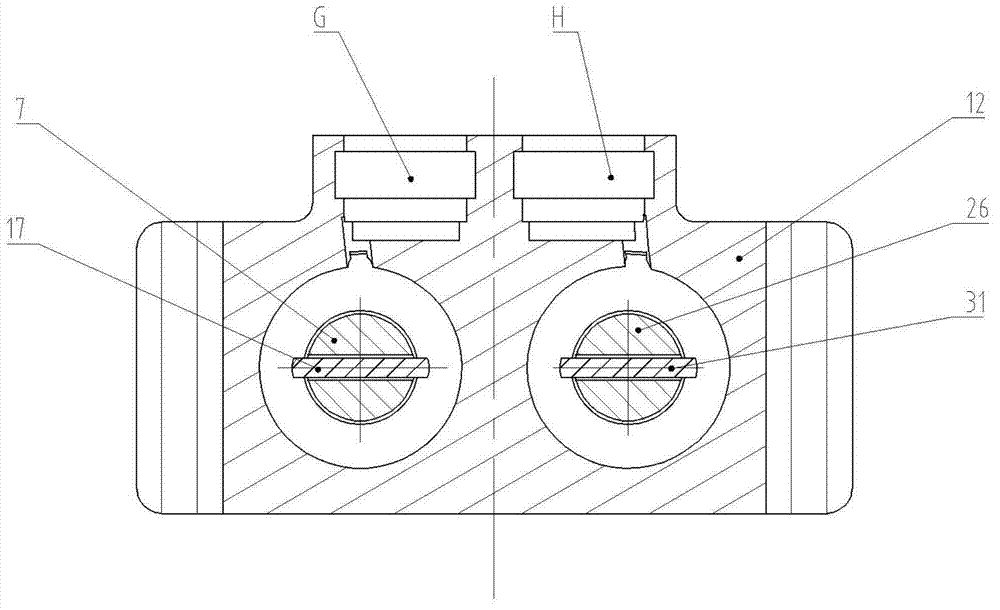

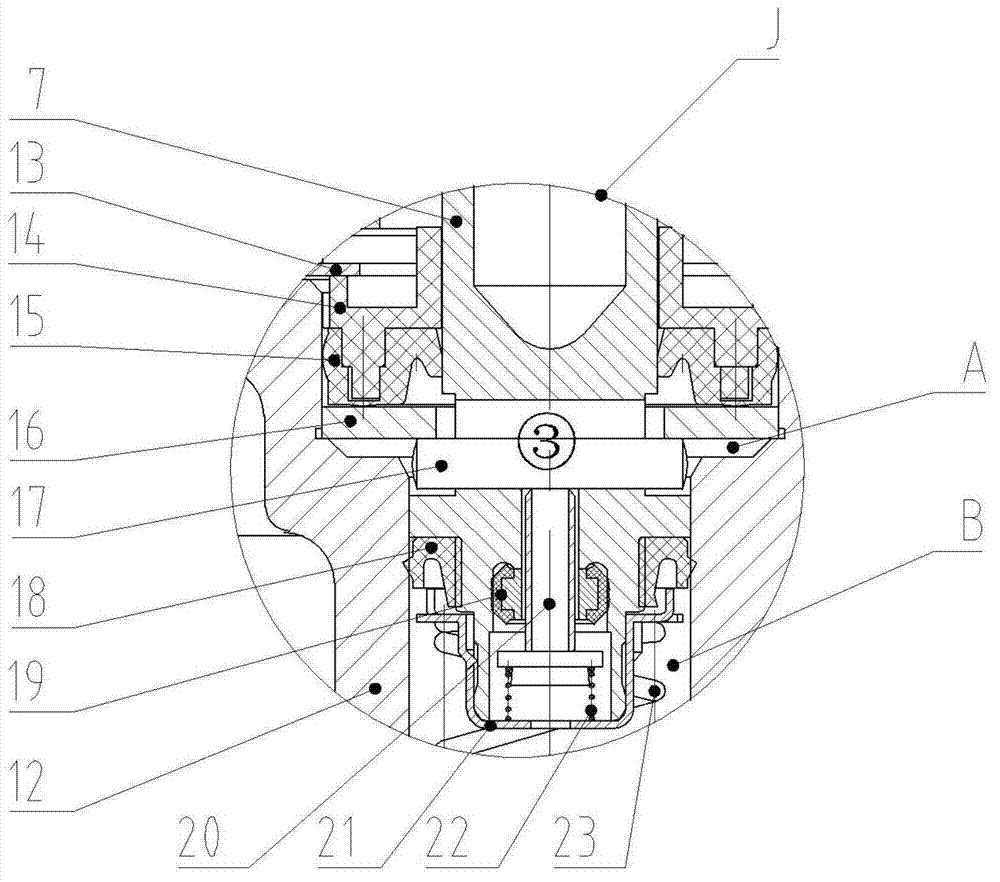

Braking device of engine

ActiveCN101994539AReduce volumeReduce weightValve arrangementsMachines/enginesExhaust valveDrive wheel

The invention relates to a braking device of an engine. The braking device consists of a control mechanism for an exhaust valve, wherein the control mechanism for the exhaust valve consists of a driving force input cam, a cam driven wheel, a push rod, a rocker arm and a rocker arm shaft; one end of the push rod is connected with one end of the rocker arm; the cam driven wheel is arranged at the other end of the push rod; the driving force input cam is arranged outside the cam driven wheel; the other end of the rocker arm is provided with a horizontal driving piston and a vertical braking plunger; an annular groove is formed in the middle of the driving piston; the side face of the annular groove and the side face of the driving piston on the left side of the annular groove, which serve as a non-operative surface and an operative surface, are compressed and contacted with the upper end face of the braking plunger; and a valve rod connecting piece of the exhaust valve is arranged on the lower side of the braking plunger. The driving force input cam periodically transmits the power of the engine to the rocker arm, the gap between the rocker arm and the valve rod connecting piece of the exhaust valve is controlled by an electromagnetic valve, braking and normal working states can be switched, the volume and weight of a brake are reduced, and high oil pressure and leakage, deformation and load fluctuation which are caused by the high oil pressure do not exist.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

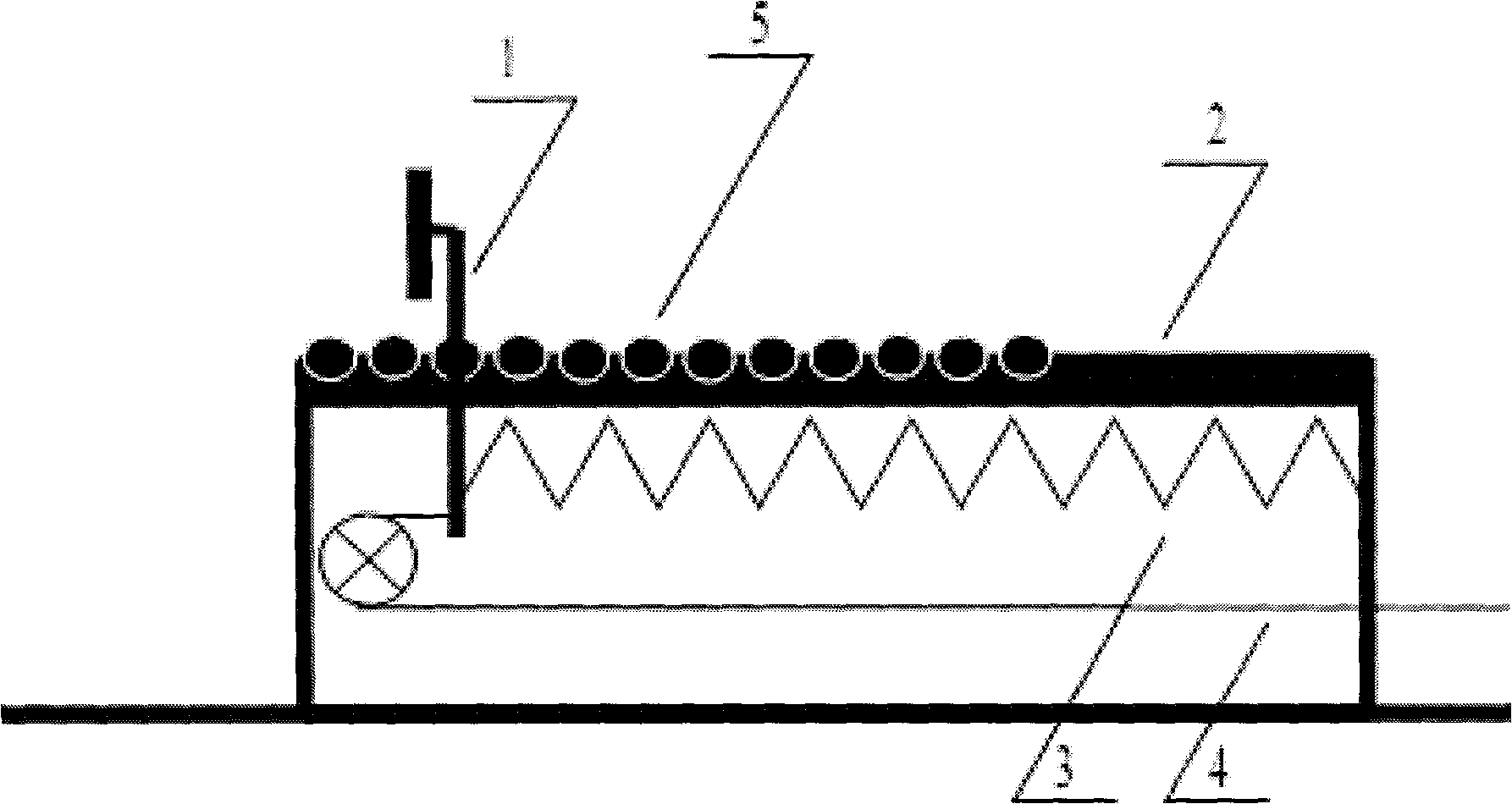

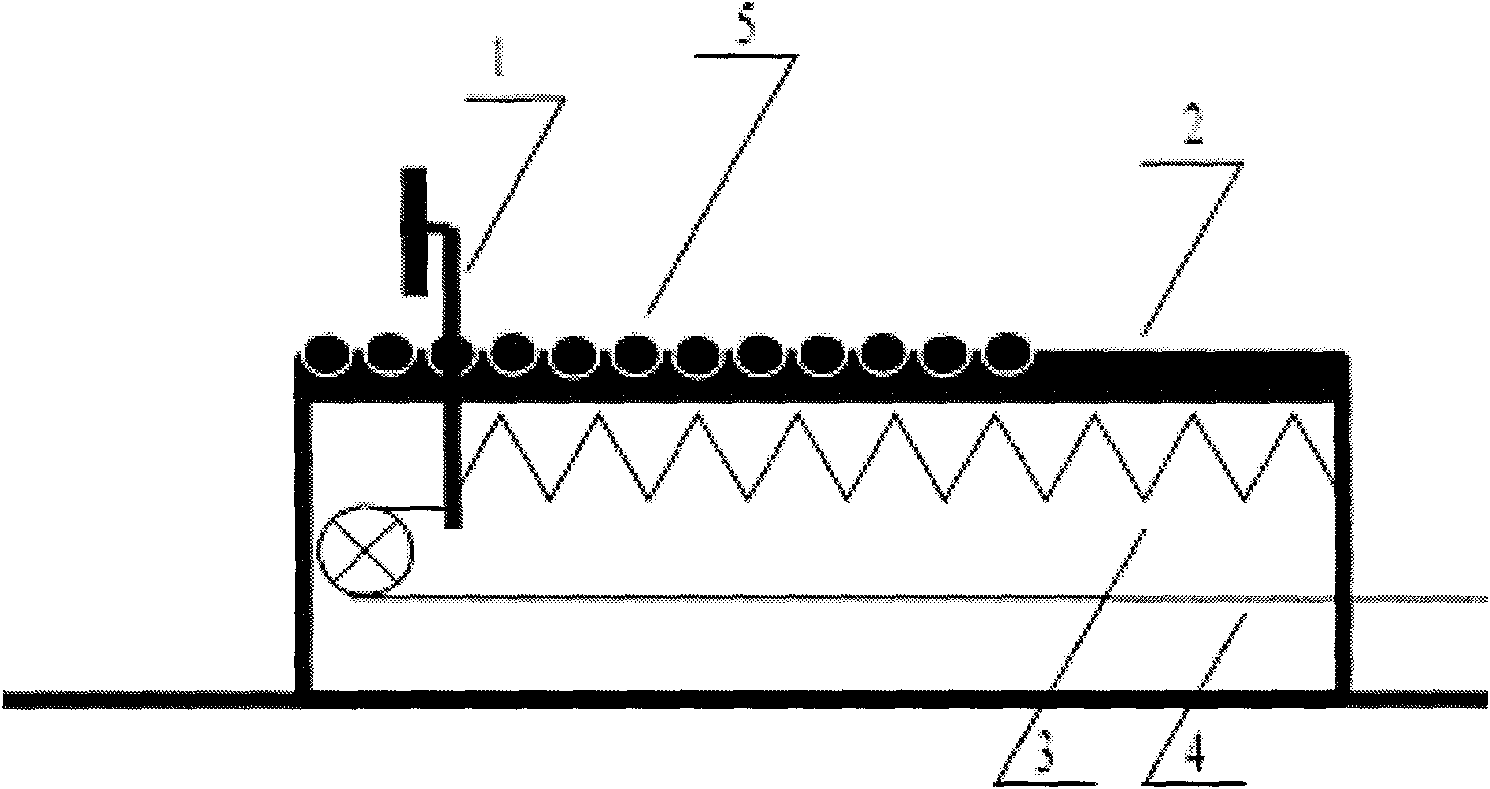

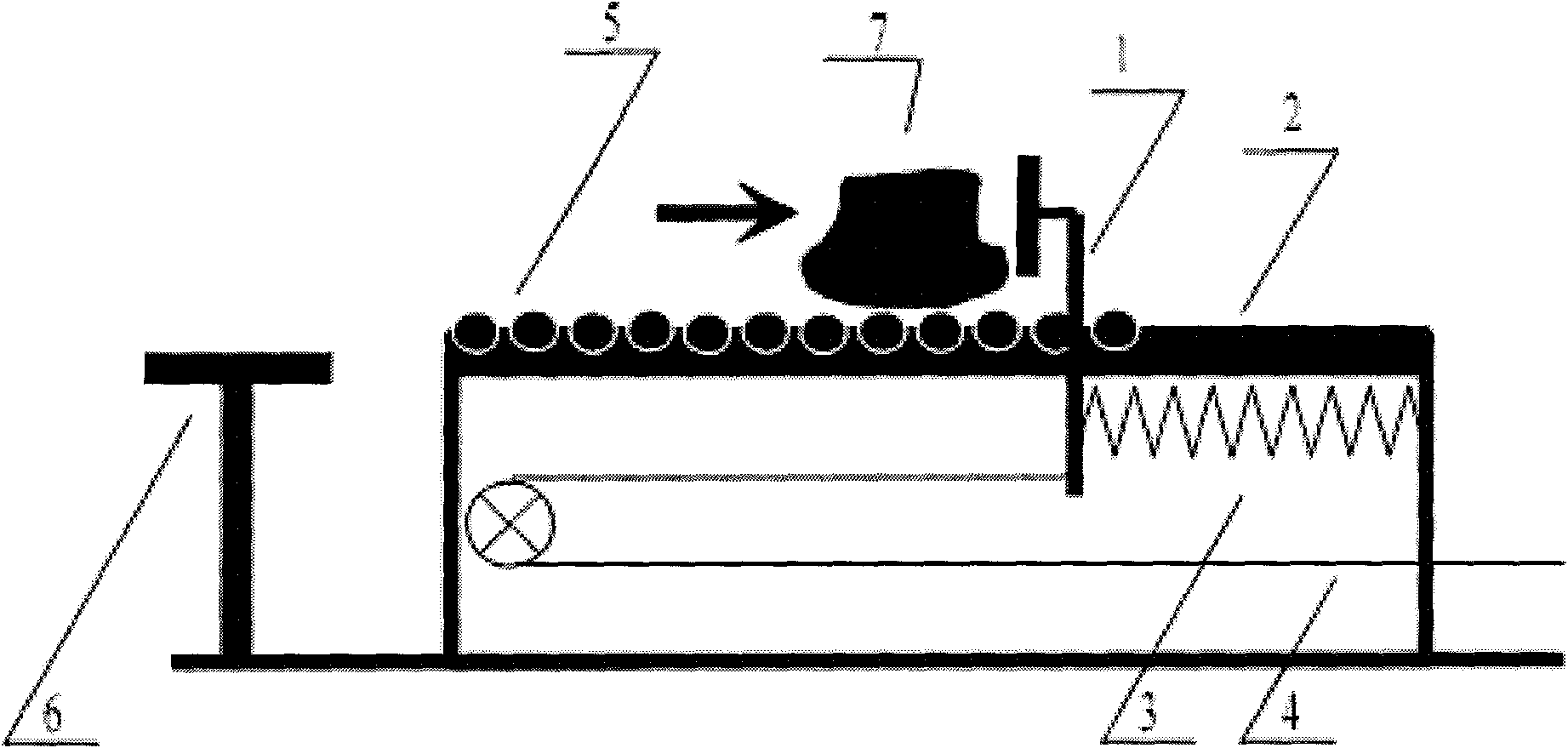

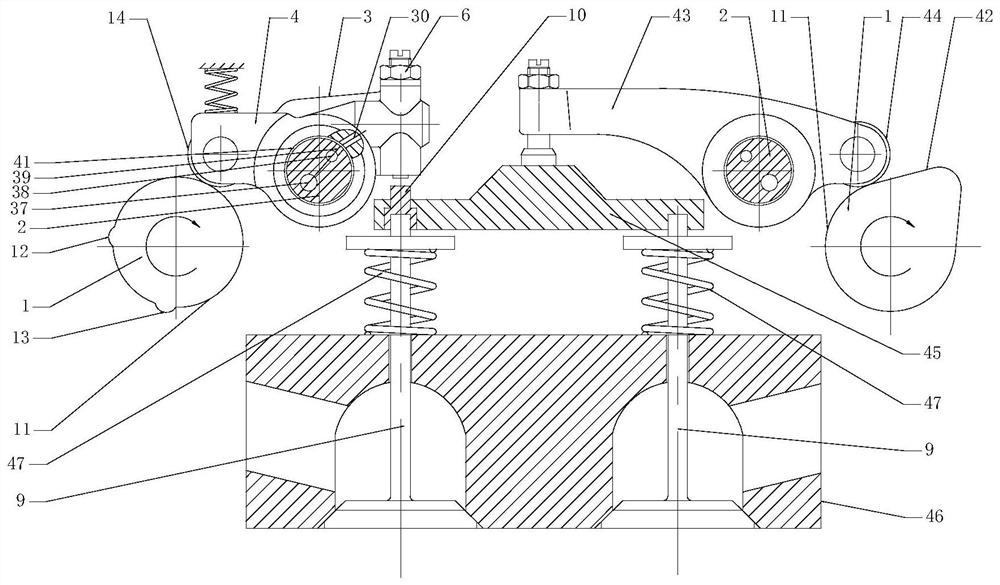

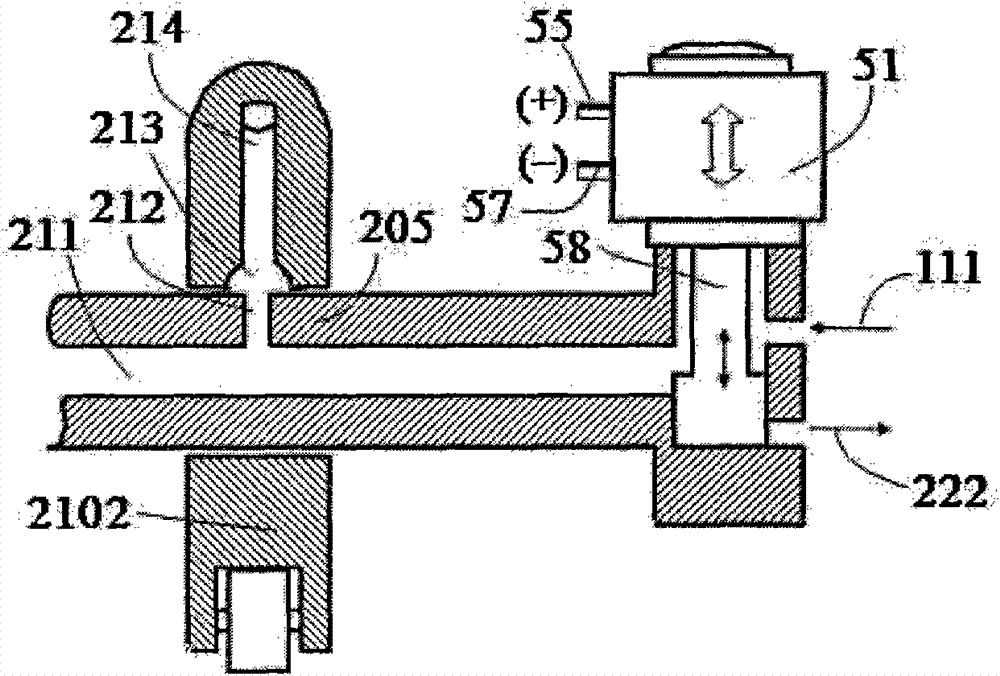

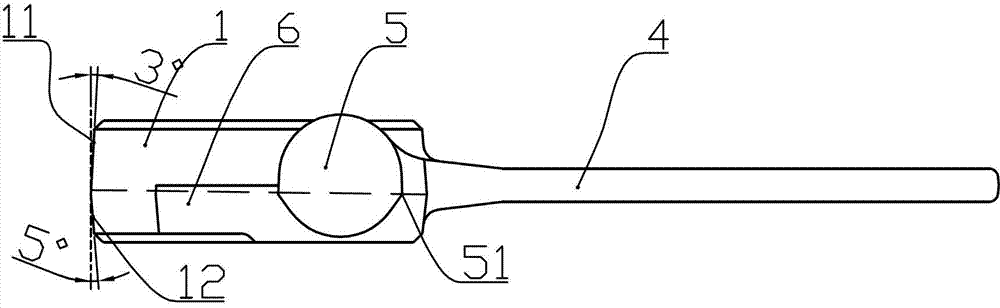

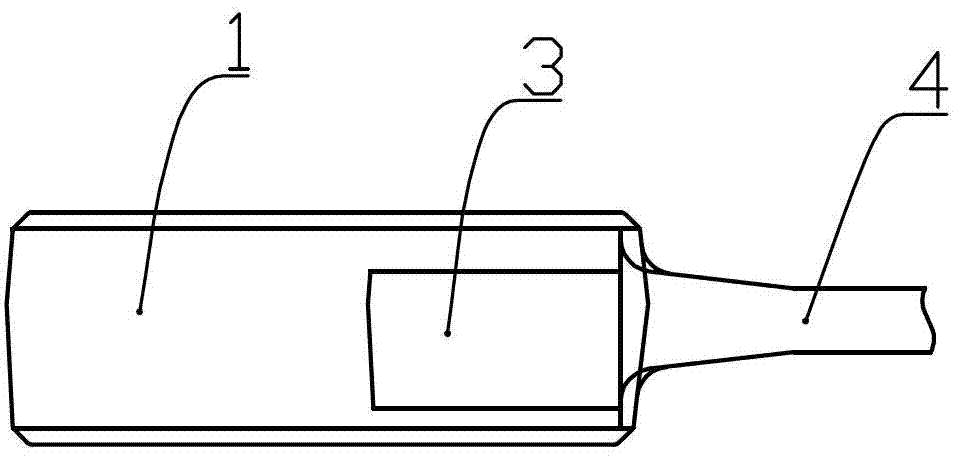

Locomotive accelerator pedal device

InactiveCN101811440AReduced brake reaction timeFoot actuated initiationsPropulsion unit arrangementsDriver/operatorCar manufacturing

The invention relates to a locomotive accelerator pedal device, which belongs to the field of automobile manufacture, in particular to the automotive accelerator device. The locomotive accelerator pedal device comprises a lateral pedal (1) and a base (2), wherein the base (2) is a table top which is arranged on the right side of a locomotive brake pedal and is higher than the brake pedal, a horizontal guide rail notch is arranged on the table top, the lateral pedal (1) which can slide along the notch is arranged in the guide rail notch and is connected with an accelerator cable (4) or an accelerator signal cable, and a reset spring (3) which can make the lateral pedal (1) return to the left end of the notch is arranged in the base (2). The device changes the conventional downward treadingof the accelerator to the rightward pushing of the accelerator, thereby completely separating locomotive acceleration from locomotive braking in operation, that is, when the locomotive accelerates, the accelerator is pushed rightwards with the right foot, and when the locomotive brakes, the brake is treaded downwards with the right foot. Therefore, the driver can not tread the accelerator as the brake by mistake even under the most nervous situation.

Owner:黄祥林

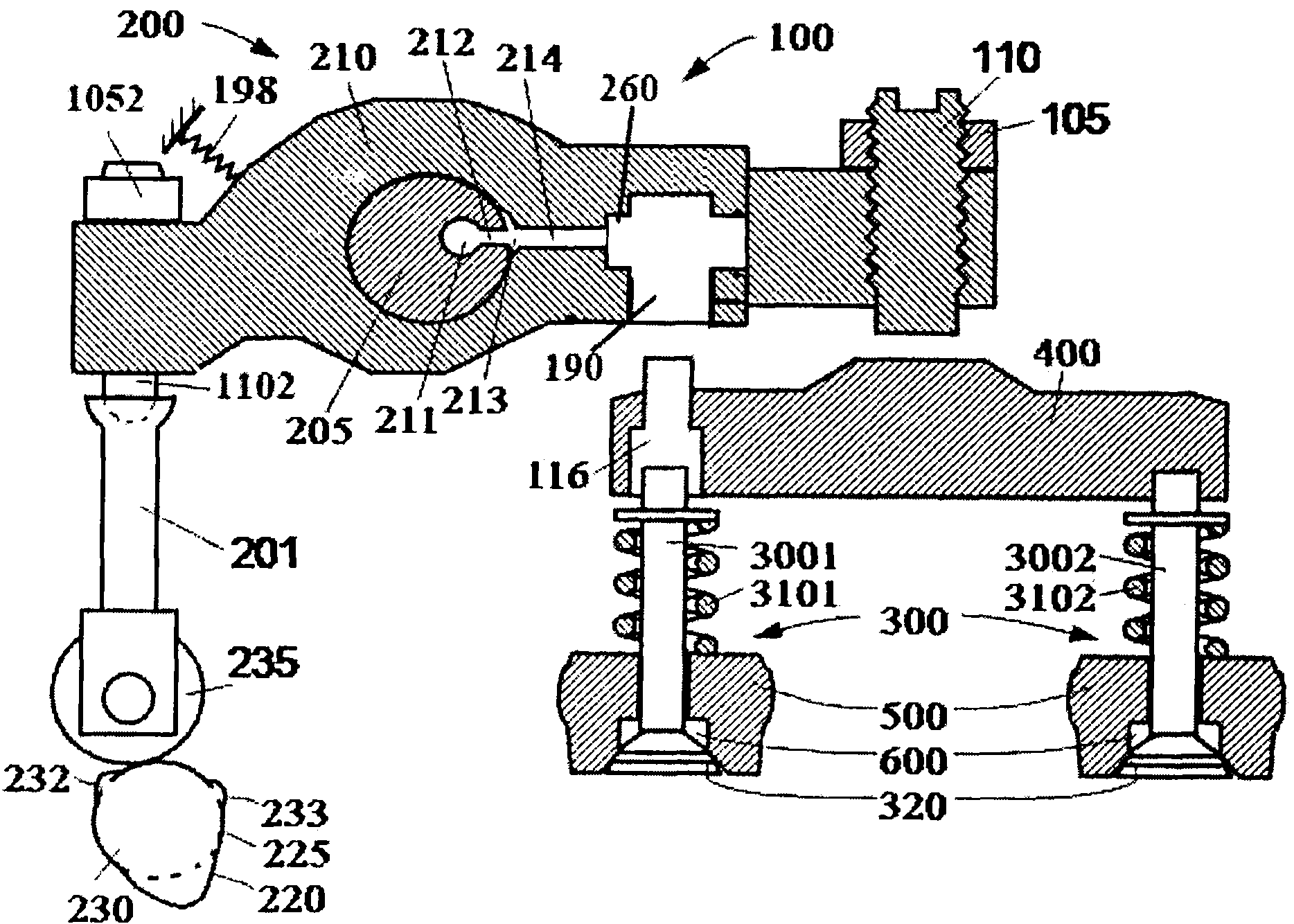

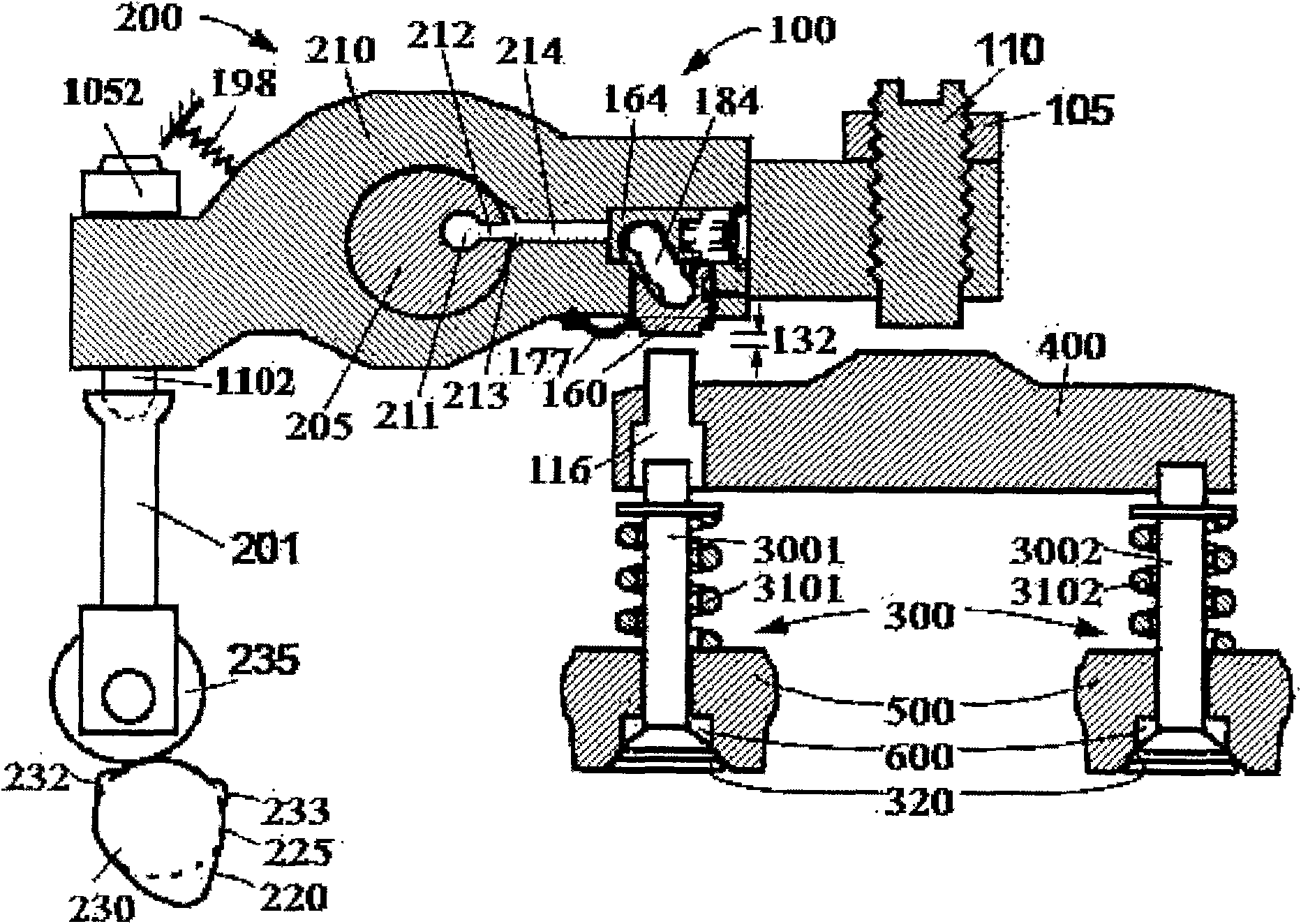

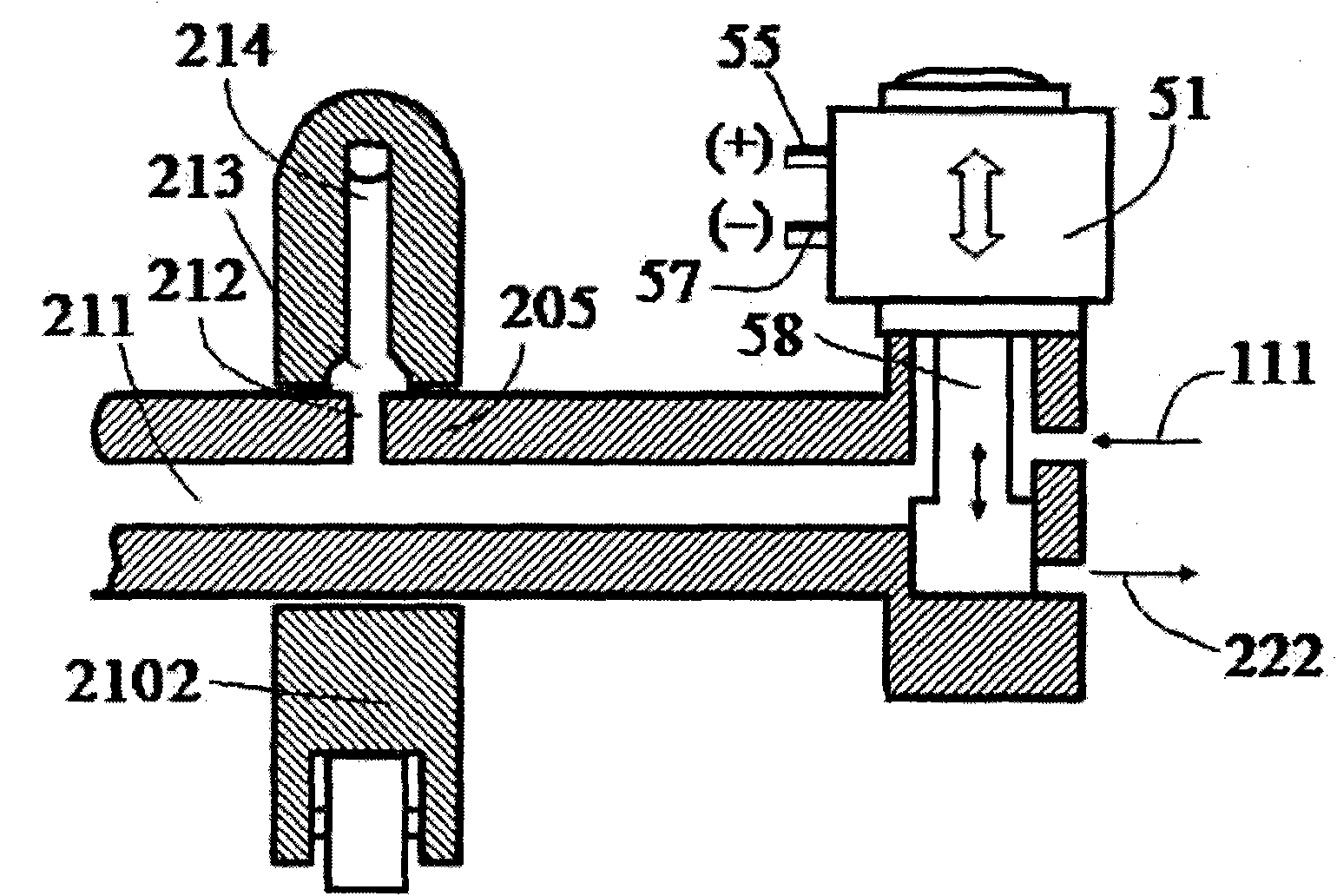

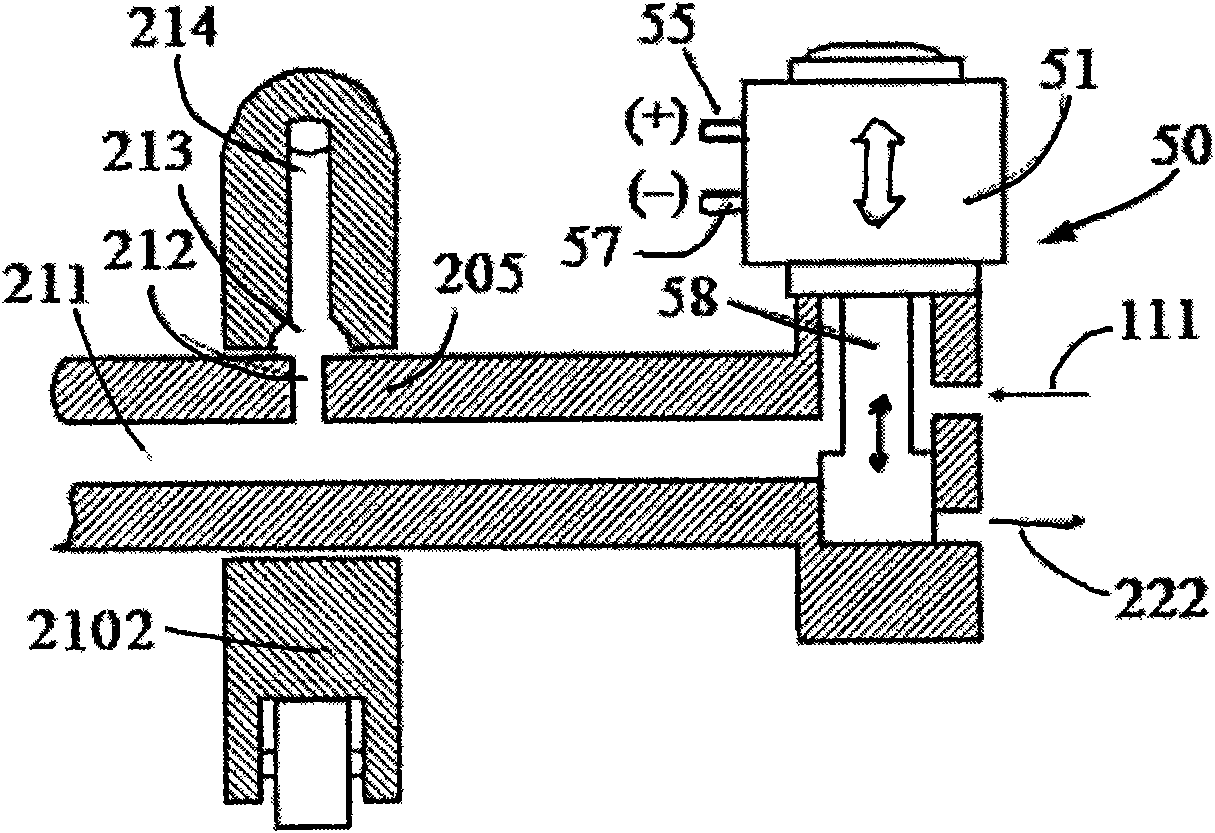

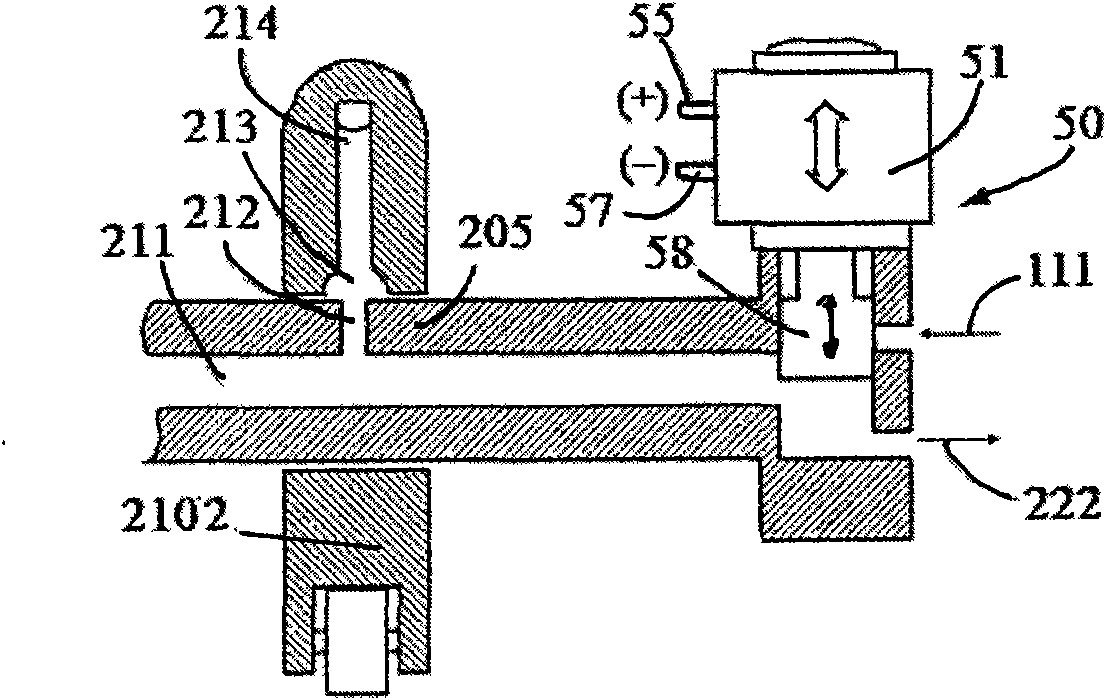

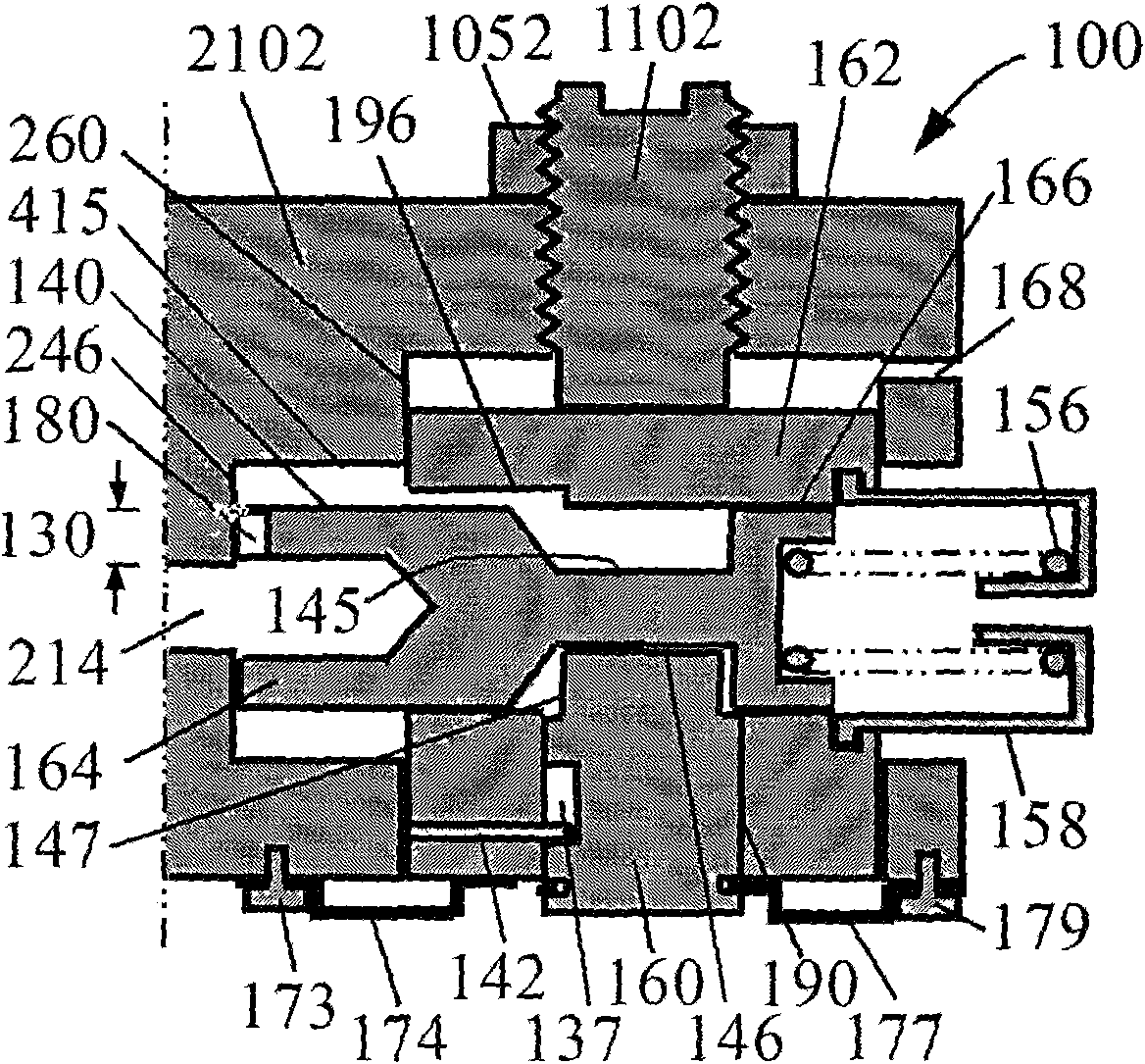

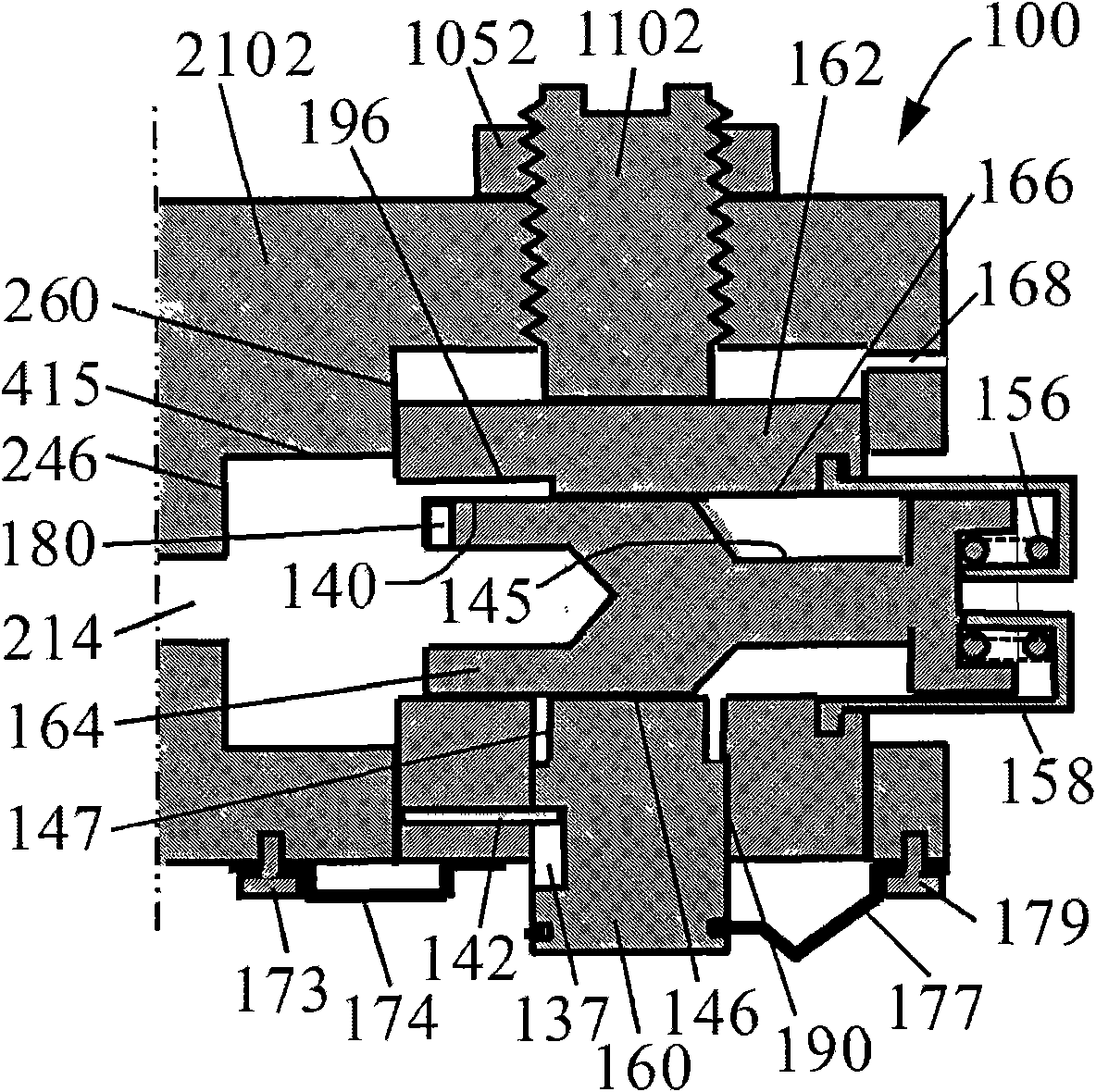

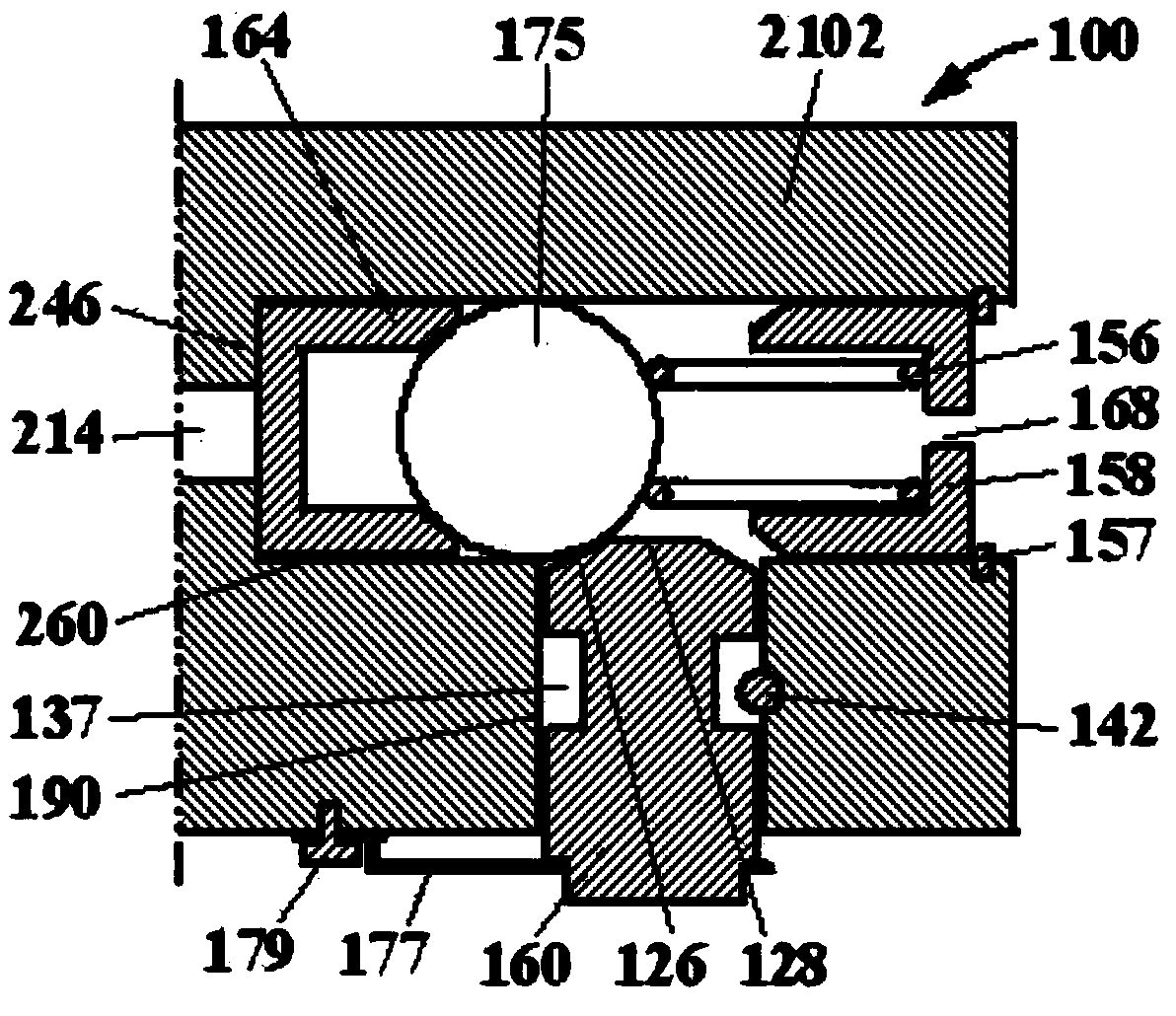

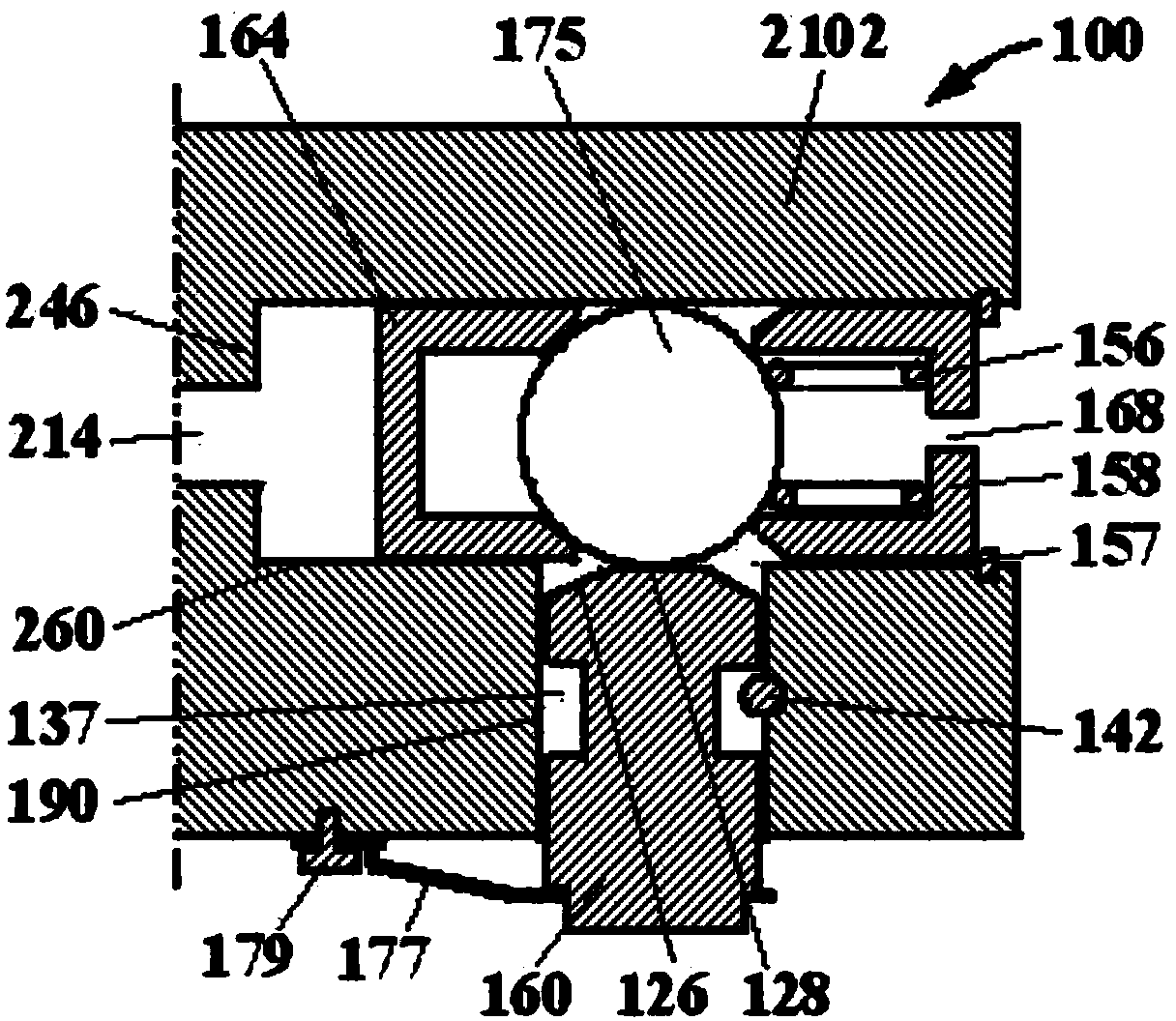

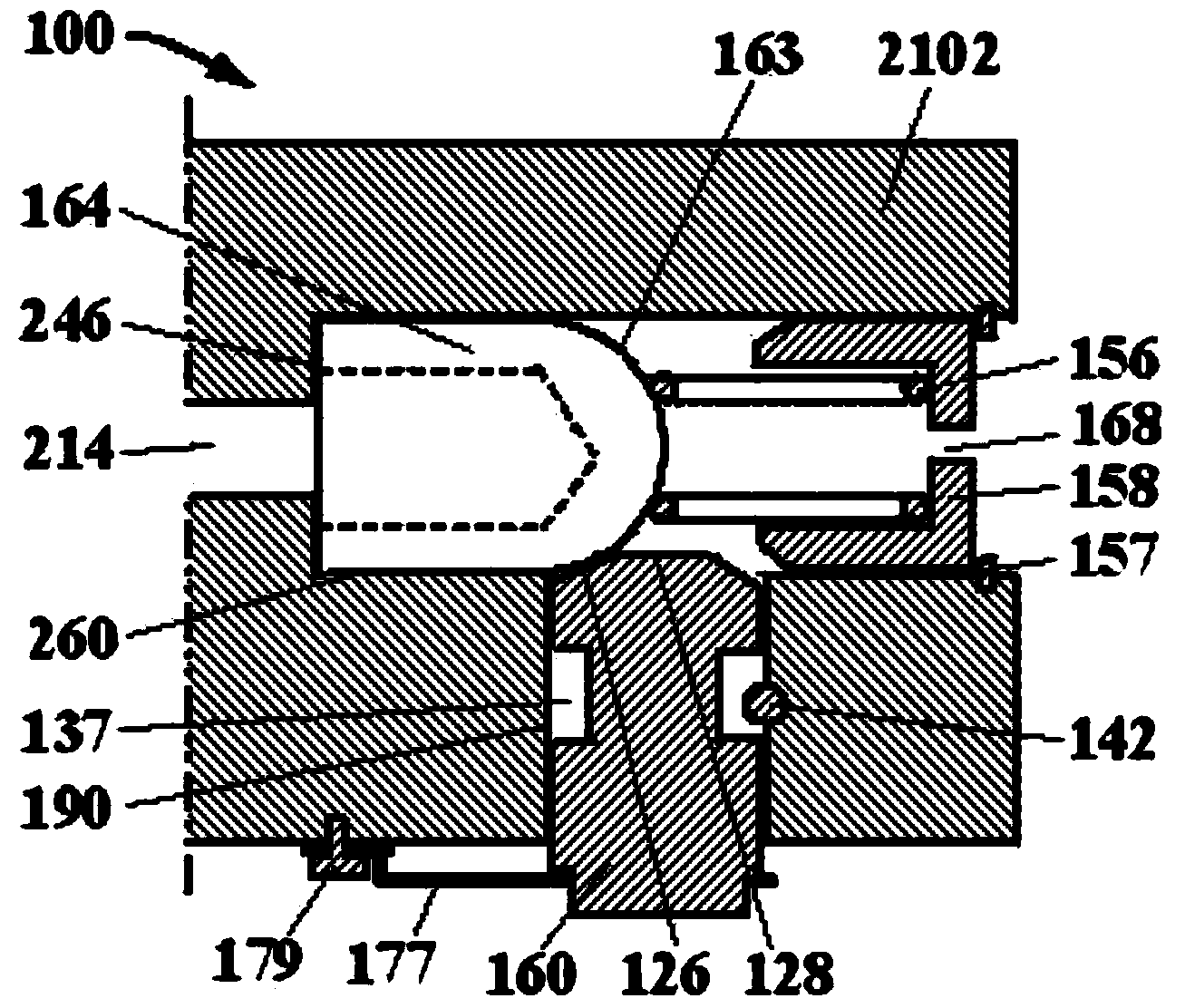

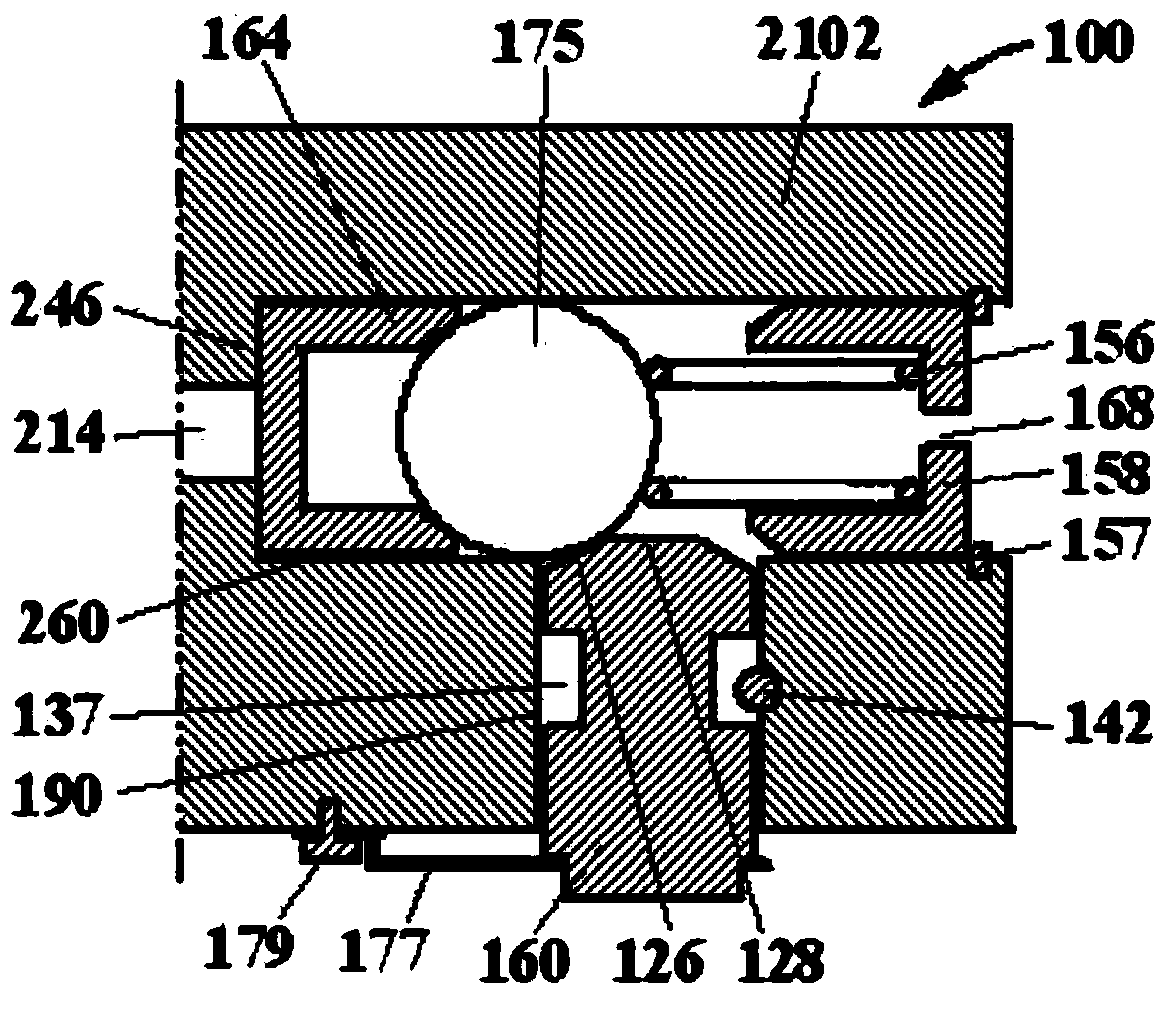

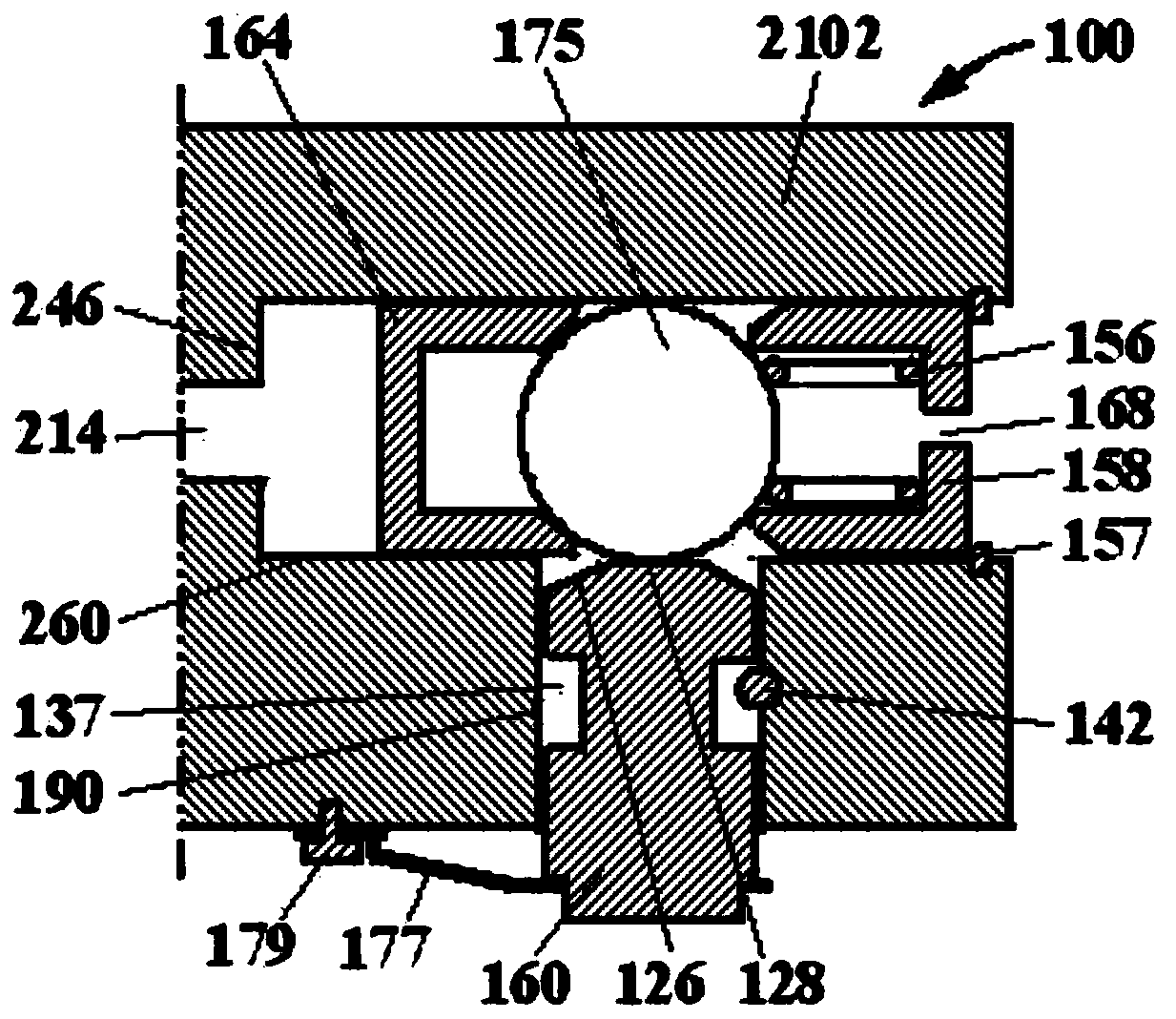

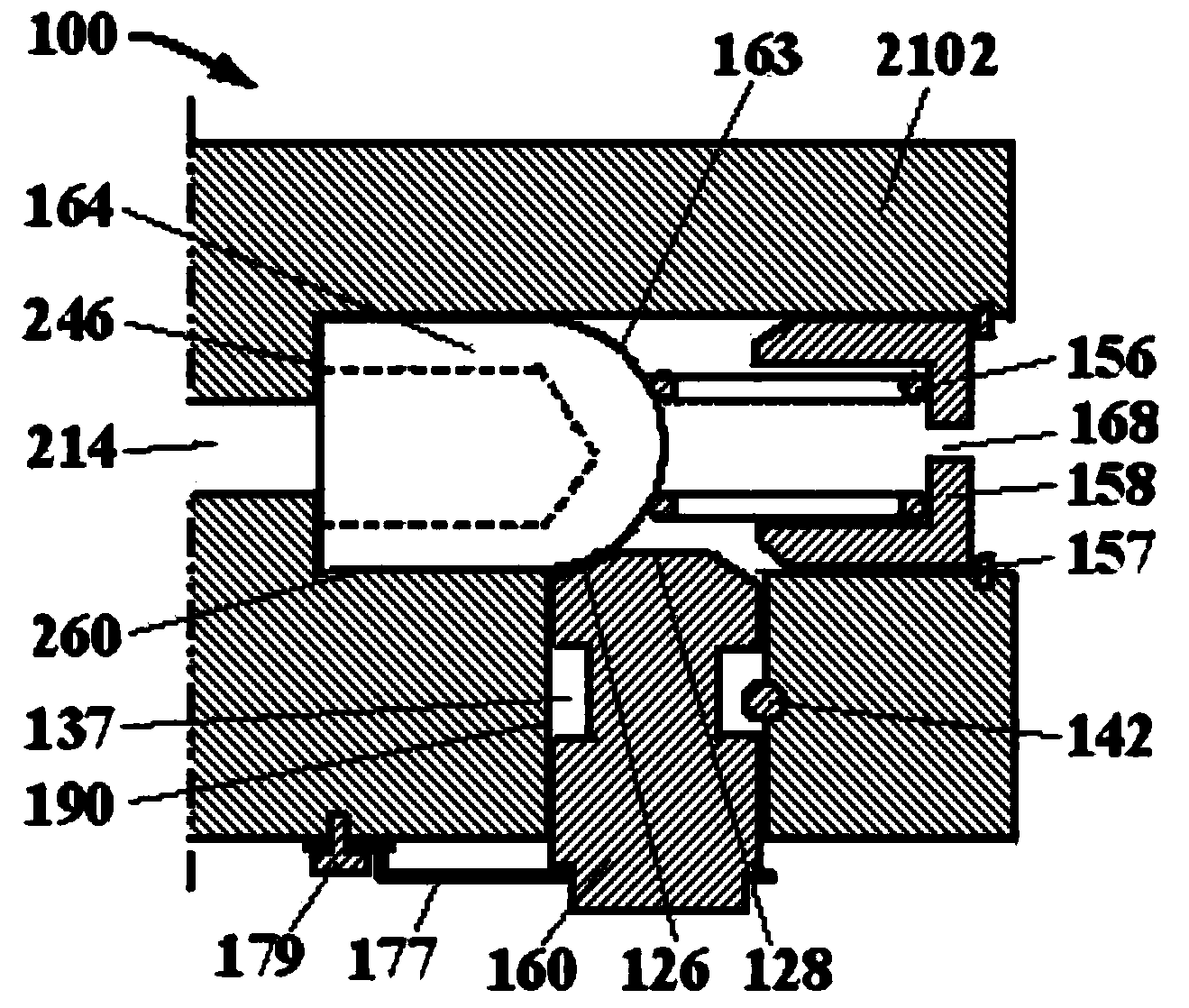

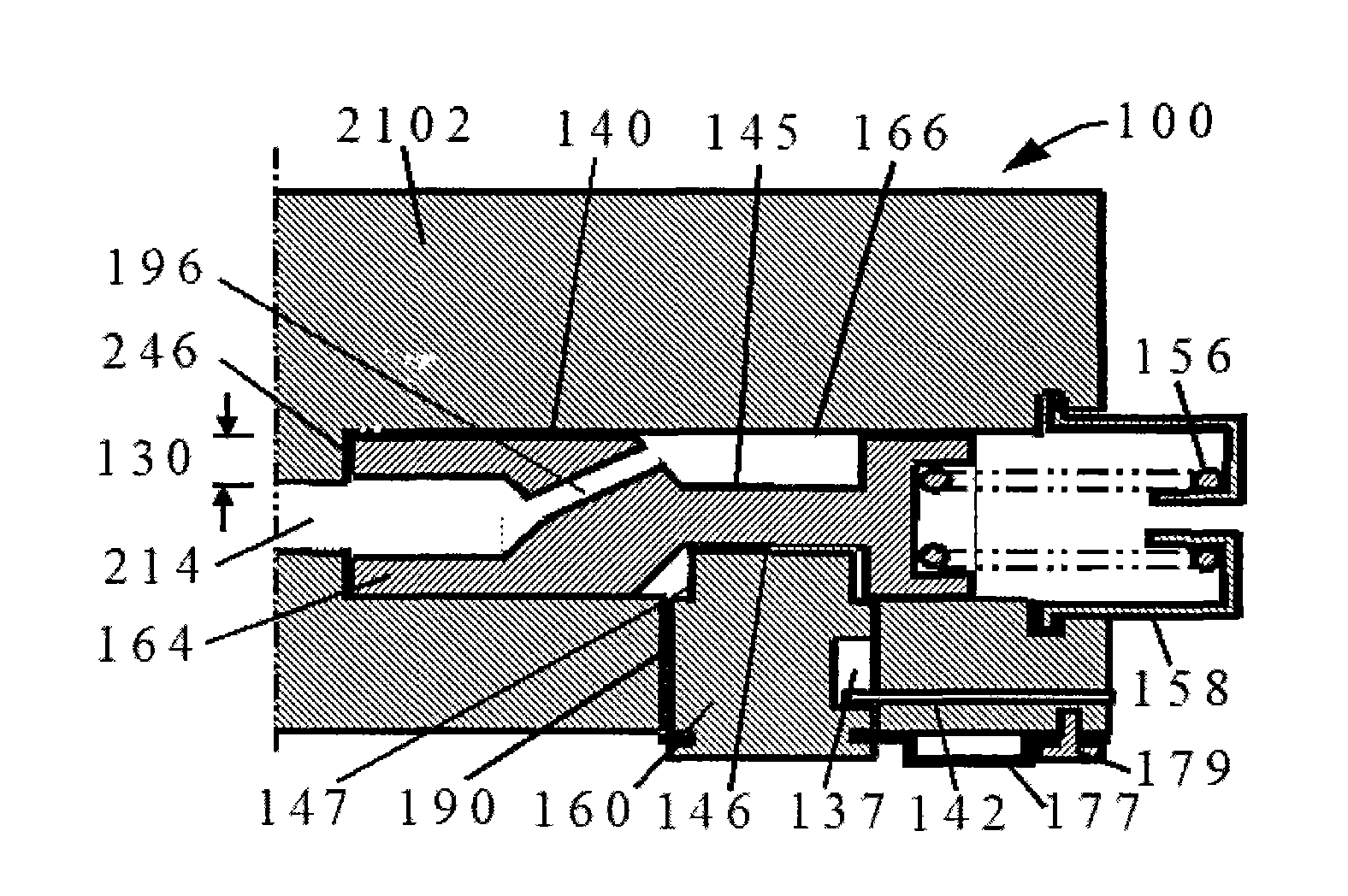

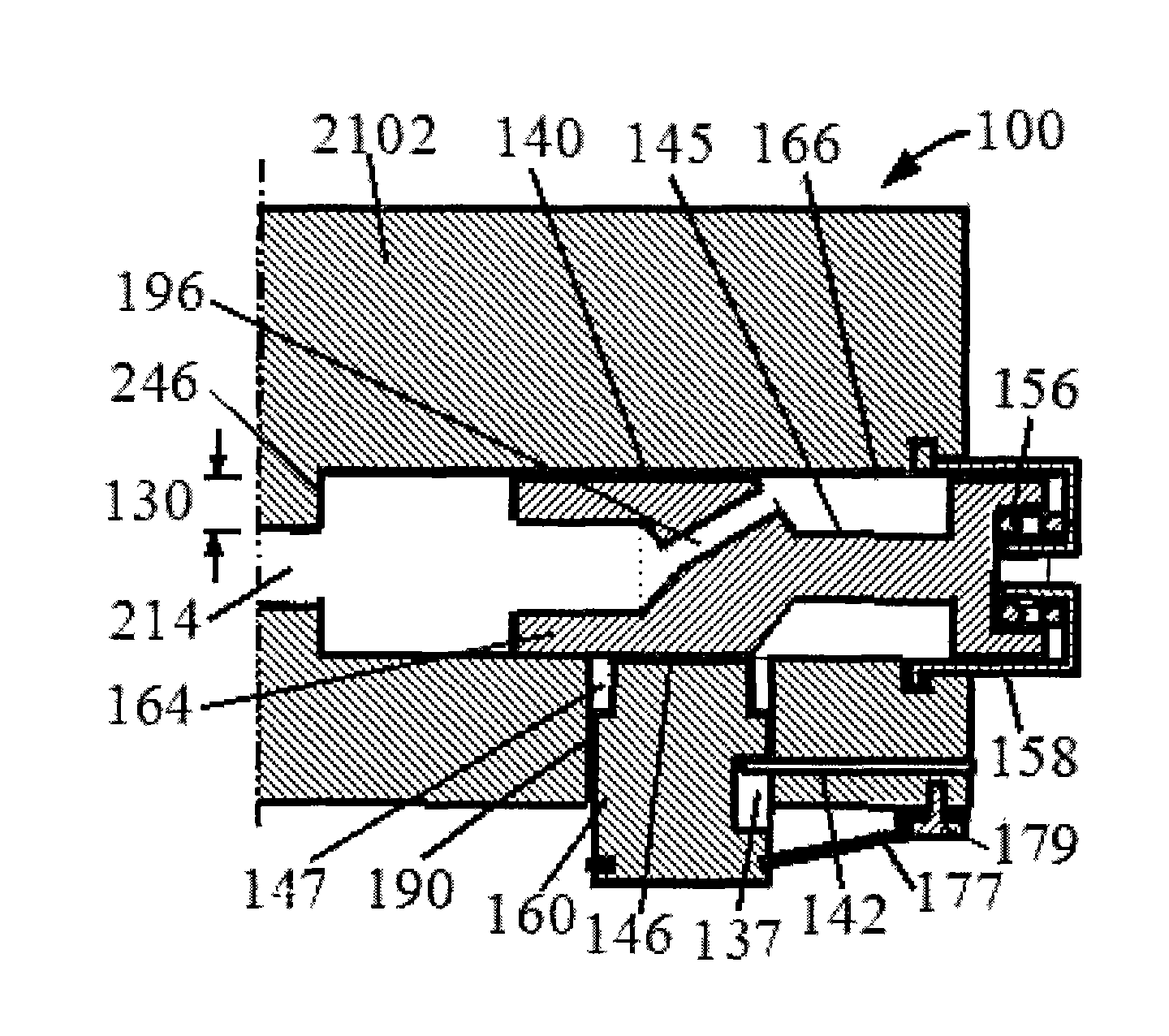

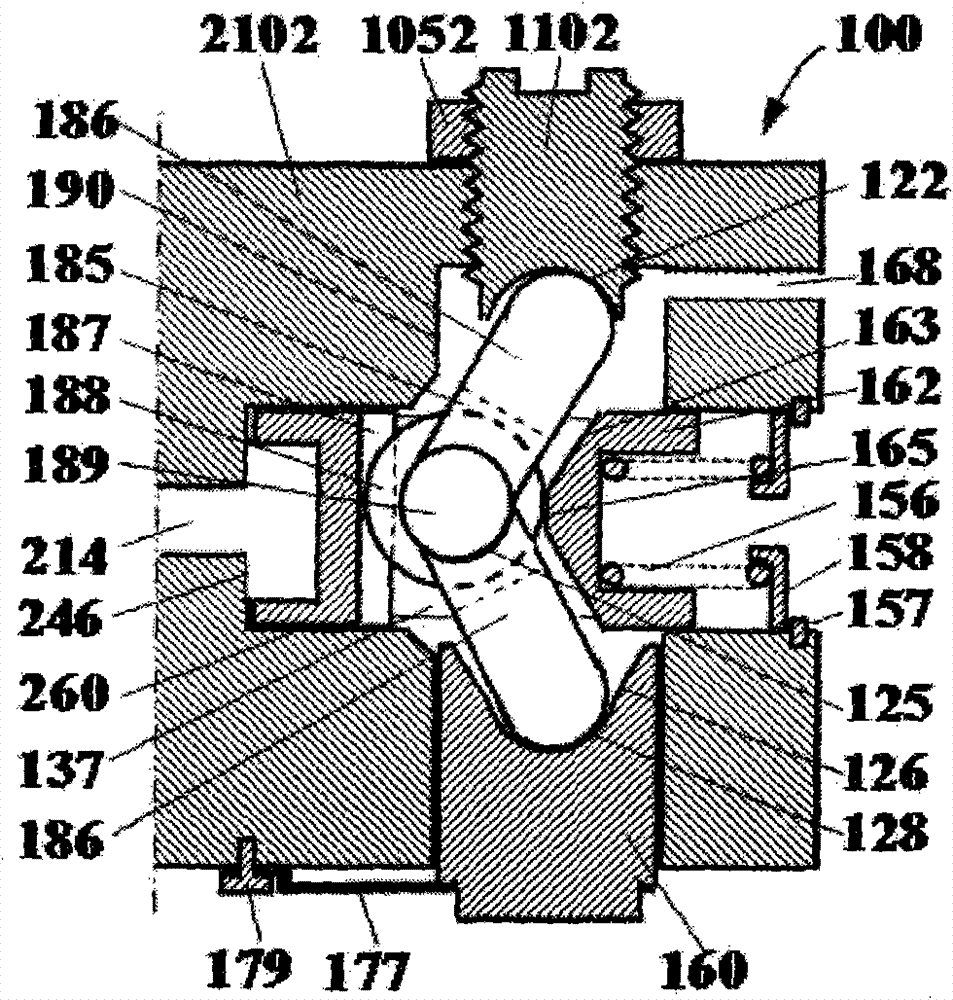

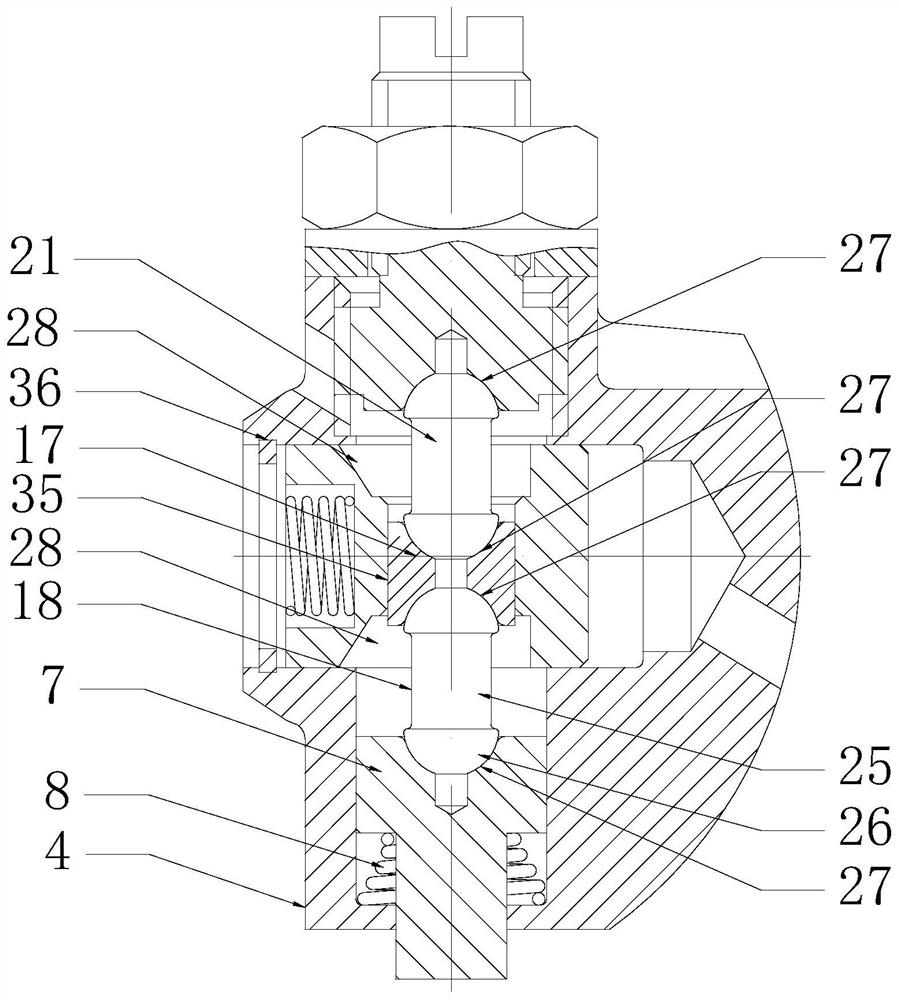

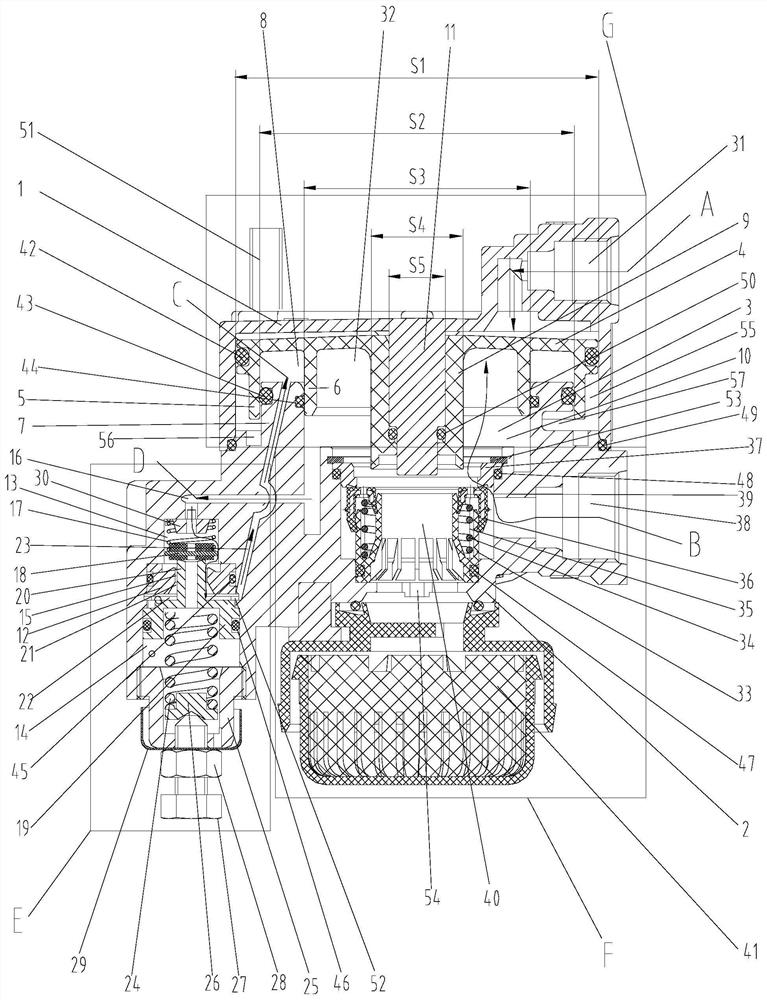

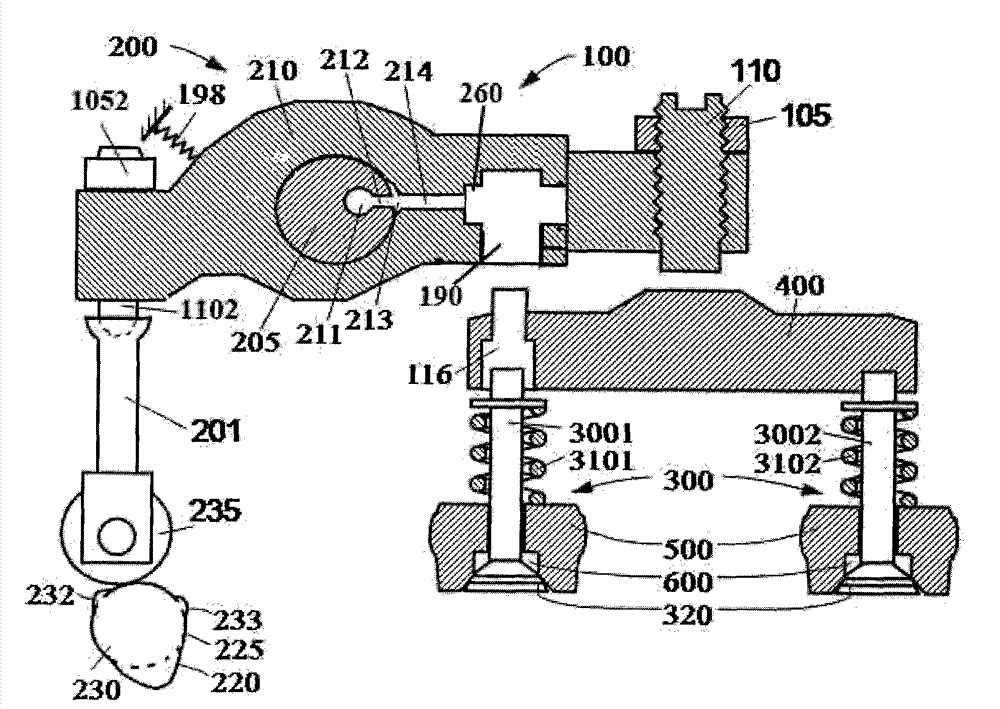

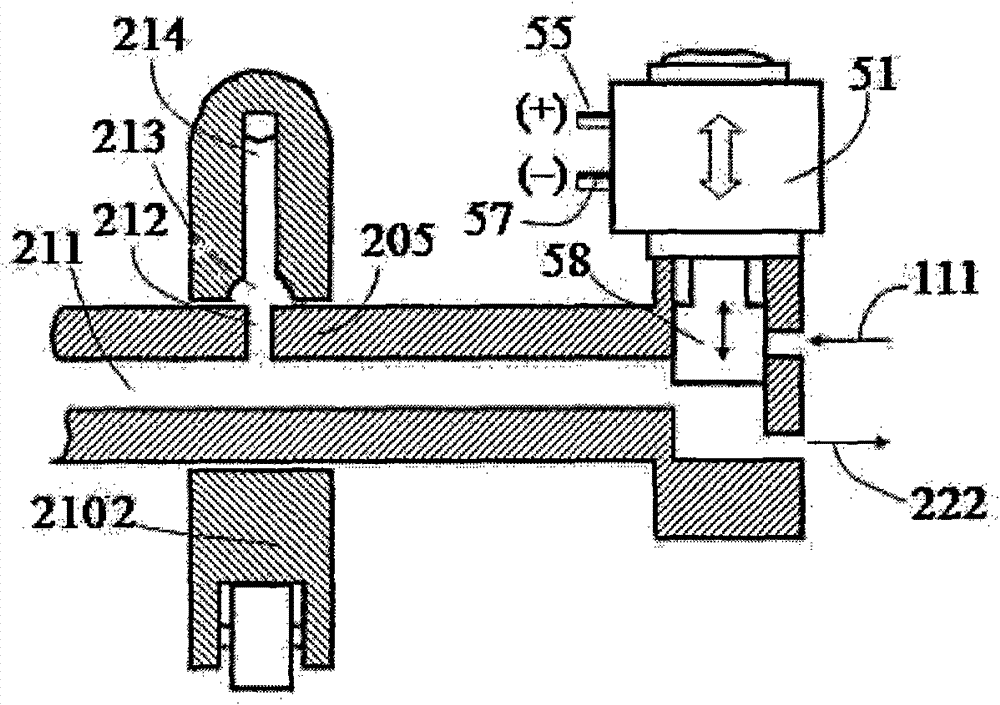

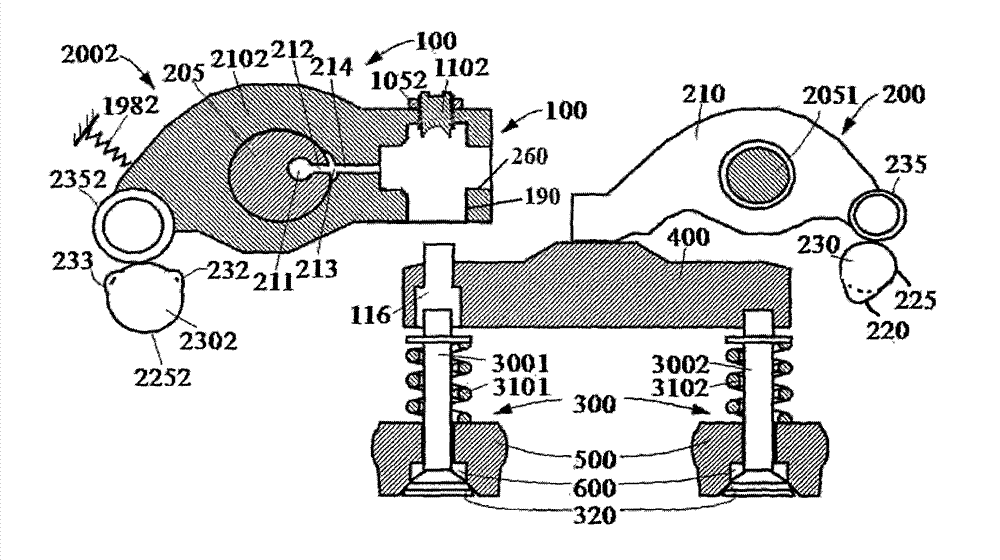

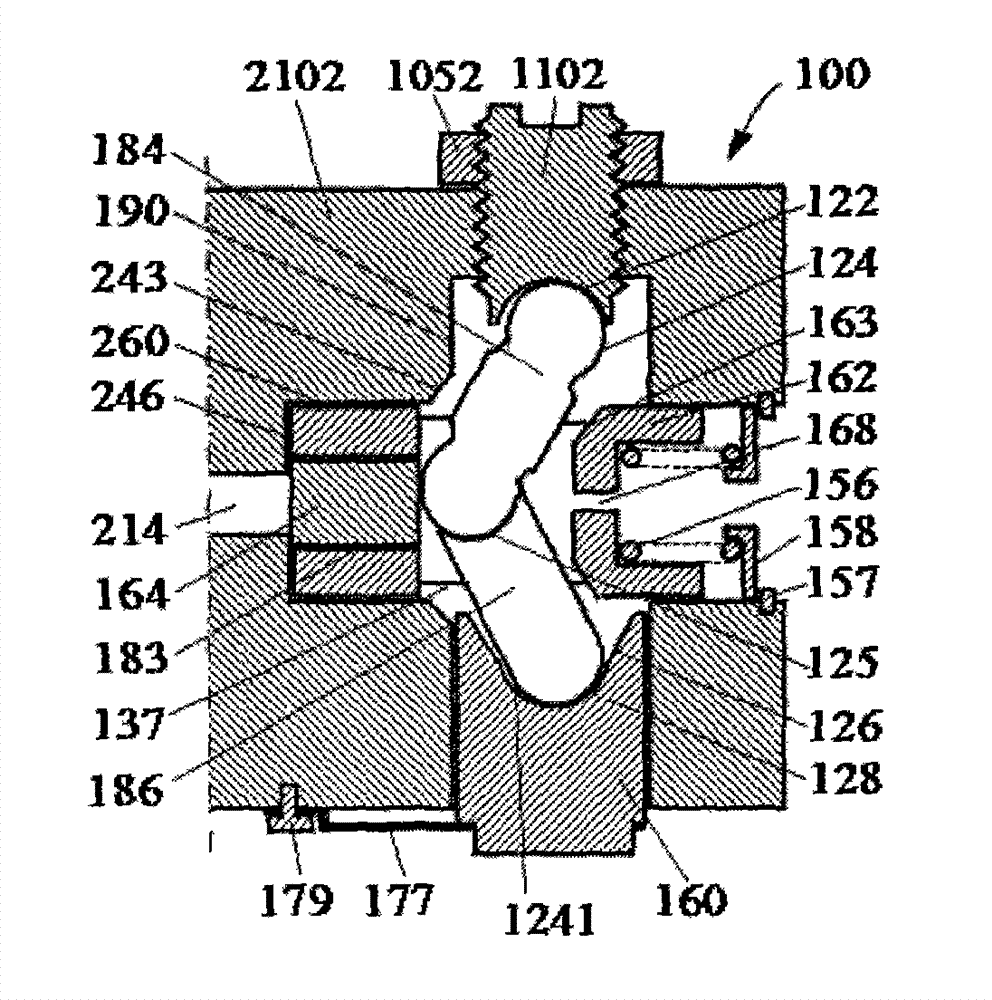

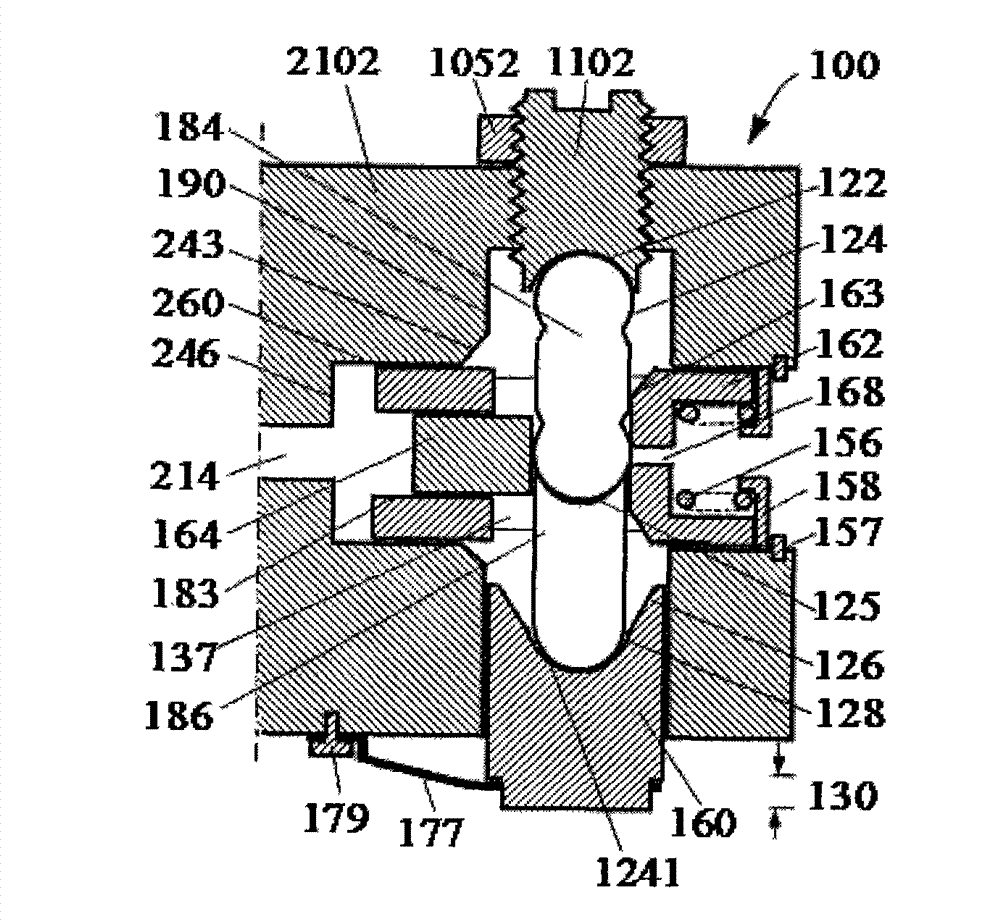

Driving device of engine brake

ActiveCN102191965AReduce the overall heightReduce volumeMachines/enginesNon-mechanical valveAir contentControl valves

The invention provides a driving device of an engine brake. The driving device comprises a braking box body, connecting rods, a driving piston and a braking plunger, wherein a vertical blind hole and a horizontal blind hole which intersect with each other are arranged in the braking box body; the driving piston is arranged in the horizontal blind hole; the braking plunger is arranged at lower part of the vertical blind hole; the connecting rods comprise an upper connecting rod and a lower connecting rod; a revolute pair is arranged between the upper connecting rod and the braking box body; another revolute pair is arranged between the lower connecting rod and the braking plunger; and a fluid channel is arranged in the braking box body to connect the horizontal blind hole with an engine oil fluid network. The driving device has the following beneficial effects: the driving device can be integrated with the engine, thus reducing the height, volume and weight of the engine brake; the hydraulic braking control valve is not needed, thus lowering the cost and reducing the brake response time; the brake load is not borne by liquid, thus enabling the driving device not to be subjected to leakage, deformation and load fluctuation caused by high oil pressure and high oil temperature; and the lift of the brake valve is not affected by the oil temperature and pressure and the air content,thus ensuring that the lift of the brake valve can be a small value, and reducing the requirements for the gap between the engine piston and the air valve.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

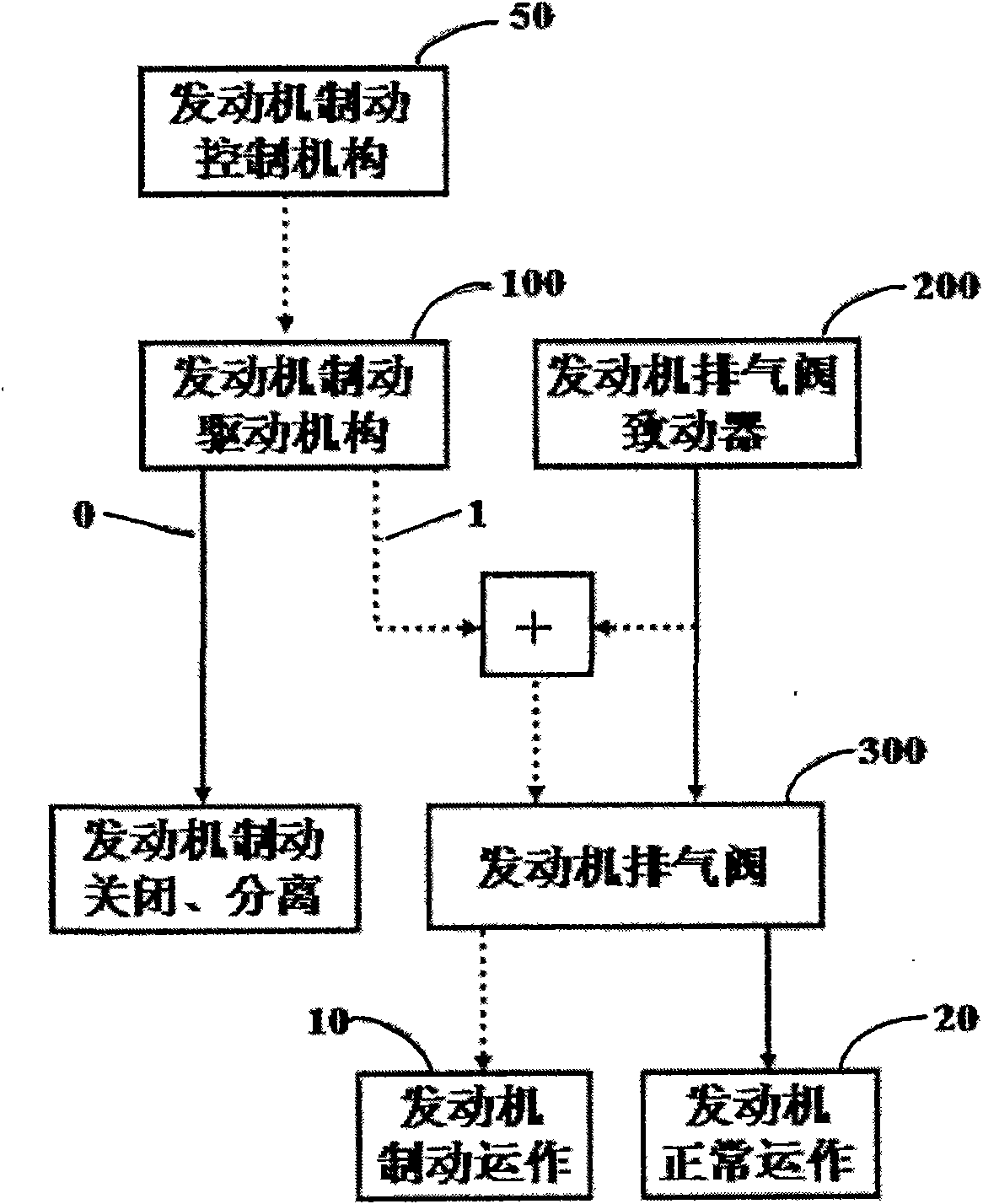

Driving mechanism for engine brake

InactiveCN101994538AReduce volumeReduce weightValve arrangementsMachines/enginesExhaust valveEngineering

The invention relates to a driving mechanism for engine brake, which consists of an exhaust valve control mechanism, wherein the exhaust valve control mechanism consists of a driving force input mechanism and a driving force transmission mechanism, the driving force input mechanism is connected with the driving force transmission mechanism, an exhaust valve contact end is arranged in the driving force transmission mechanism, and is connected with a station control piston which is arranged in the driving force transmission mechanism, and the exhaust valve contact end is provided with a first station and a second station. The driving mechanism utilizes the engine power for driving a control valve rod of an exhaust valve, drives the control valve rod of the engine exhaust valve without usinga hydraulic device with high oil pressure, can be integrated with the engine, can reduce the size and the weight, reduces the brake reaction time, and eliminates high oil pressure and the leakage, deformation and load fluctuation caused by high oil pressure, and the brake valve rise is not influenced by the oil temperature, the oil pressure and the air content and can be designed to present a smaller size, so the requirement on an engine piston and the air valve gap can be reduced.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

Engine brake device with lower manufacture cost

InactiveCN102003236AReduce volumeReduce weightValve arrangementsMachines/enginesExhaust valveDrive wheel

The invention relates to an engine brake device with lower manufacture cost, comprising a vent valve control mechanism. The vent valve control mechanism comprises a driving force input cam, a cam driven wheel, a handspike, a rocker arm and a rocker arm shaft, wherein one end of the handspike is connected with one end of the rocker arm, the cam driven wheel is arranged at the other end of the handspike, the driving force input cam is arranged outside the cam driven wheel, a horizontal driving piston and a vertical brake plunger piston are arranged at the other end of the rocker arm, a circular groove is arranged in the middle of the driving piston, one side of the circular groove and one side of the driving piston at the left are used as a non-operation surface and an operation surface to compress and tightly contact with the upper end surface of the brake plunger piston, and a vent valve rod connecting piece is arranged below the brake plunger piston. Engine power is periodically transferred to the rocker arm by the driving force input cam, and a gap between the rocker arm and the vent valve rod connecting piece is controlled by utilizing an electromagnetic valve to switch two states of brake and normal operation, therefore, the size and the weight of the brake device are reduced without high oil pressure or the defects caused by the high oil pressure, such as leakage, deformation and load fluctuation.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

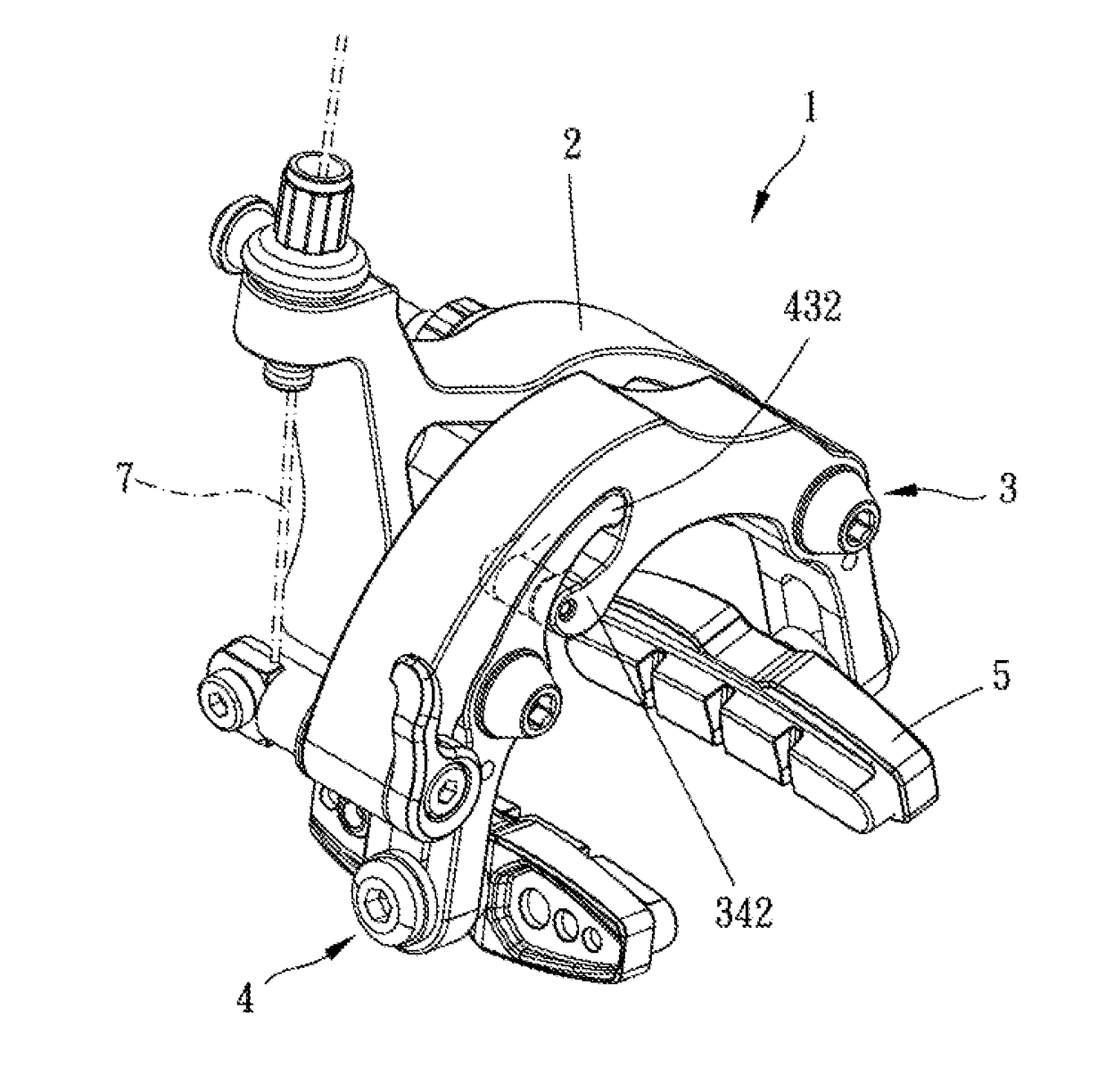

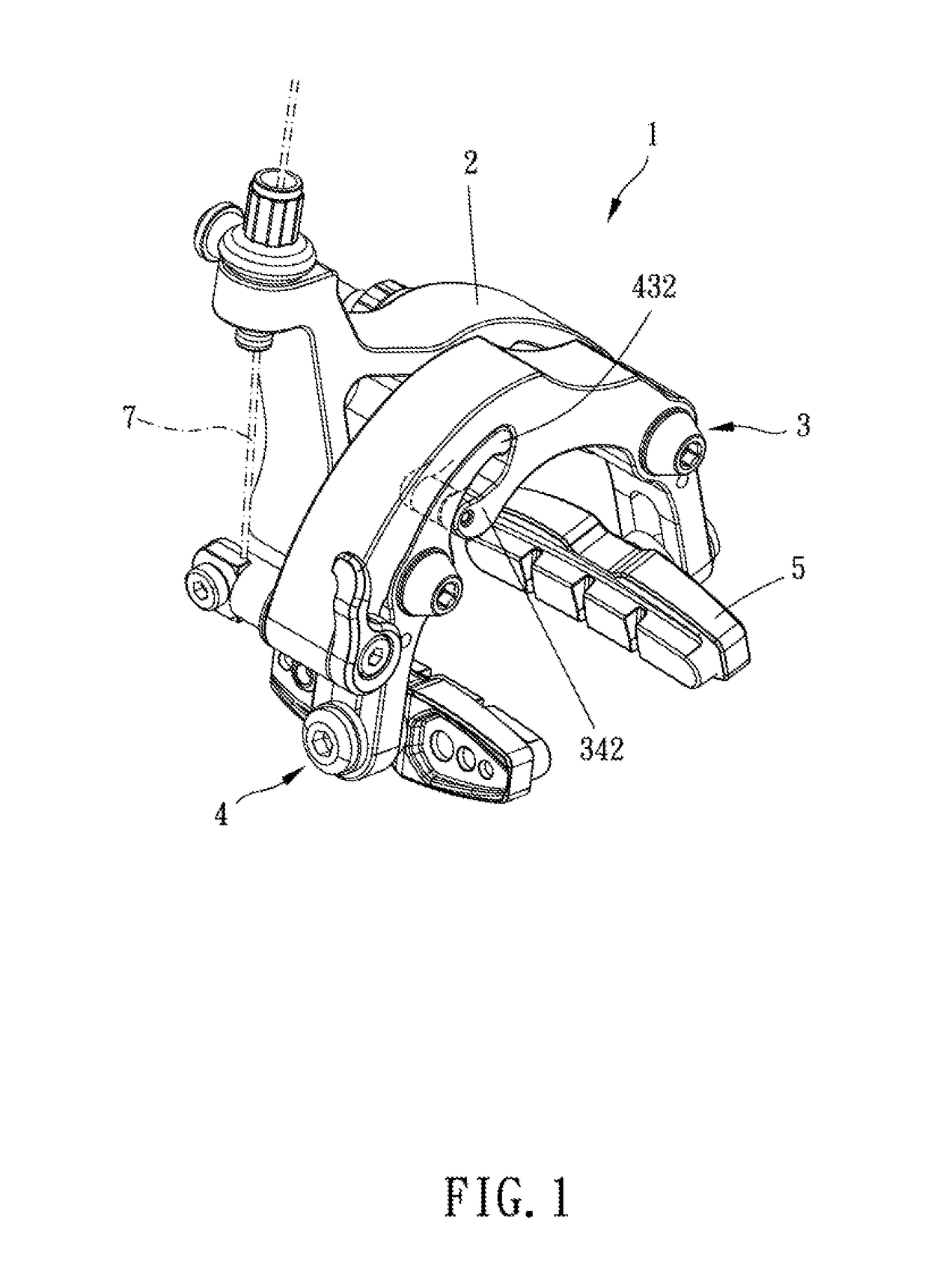

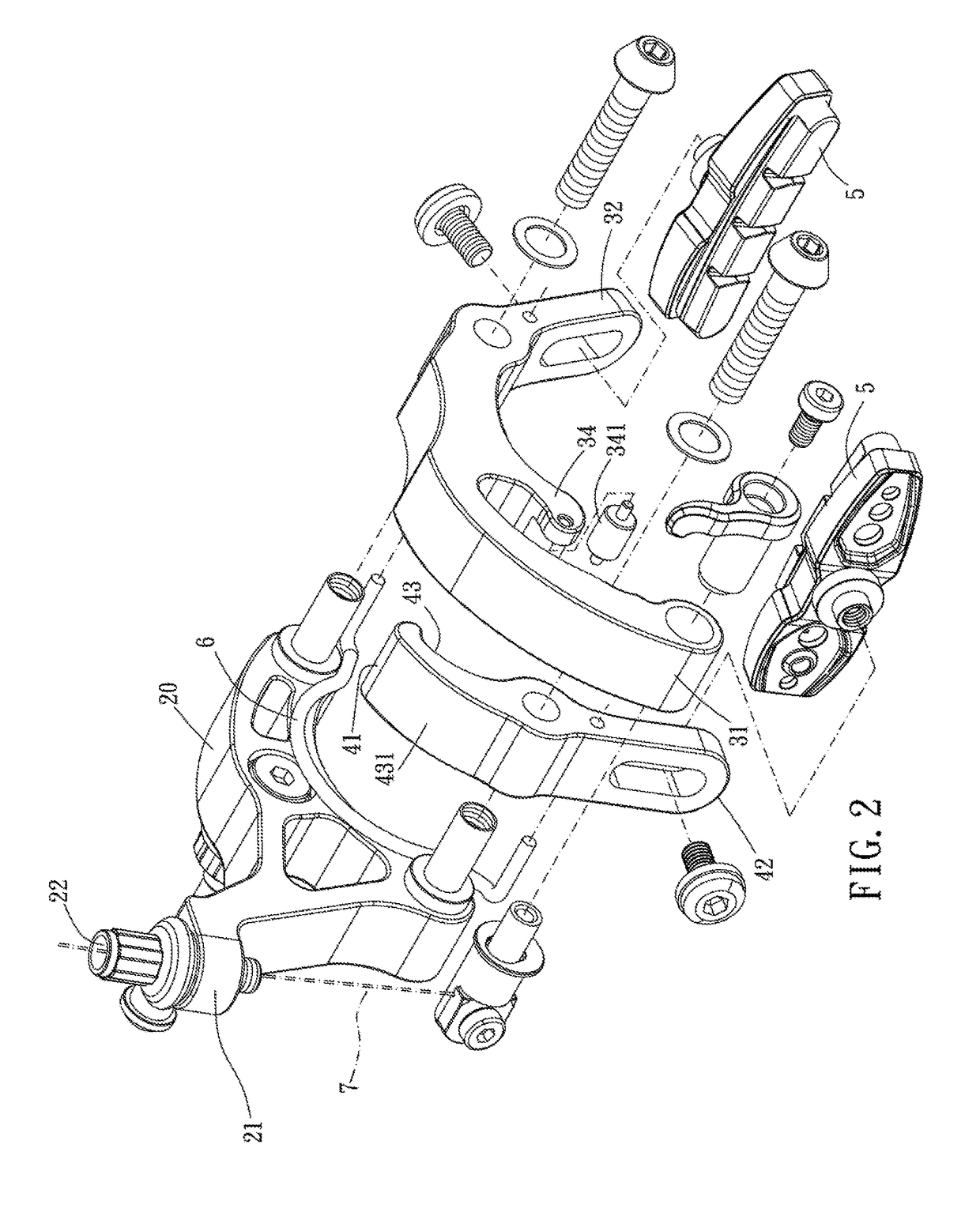

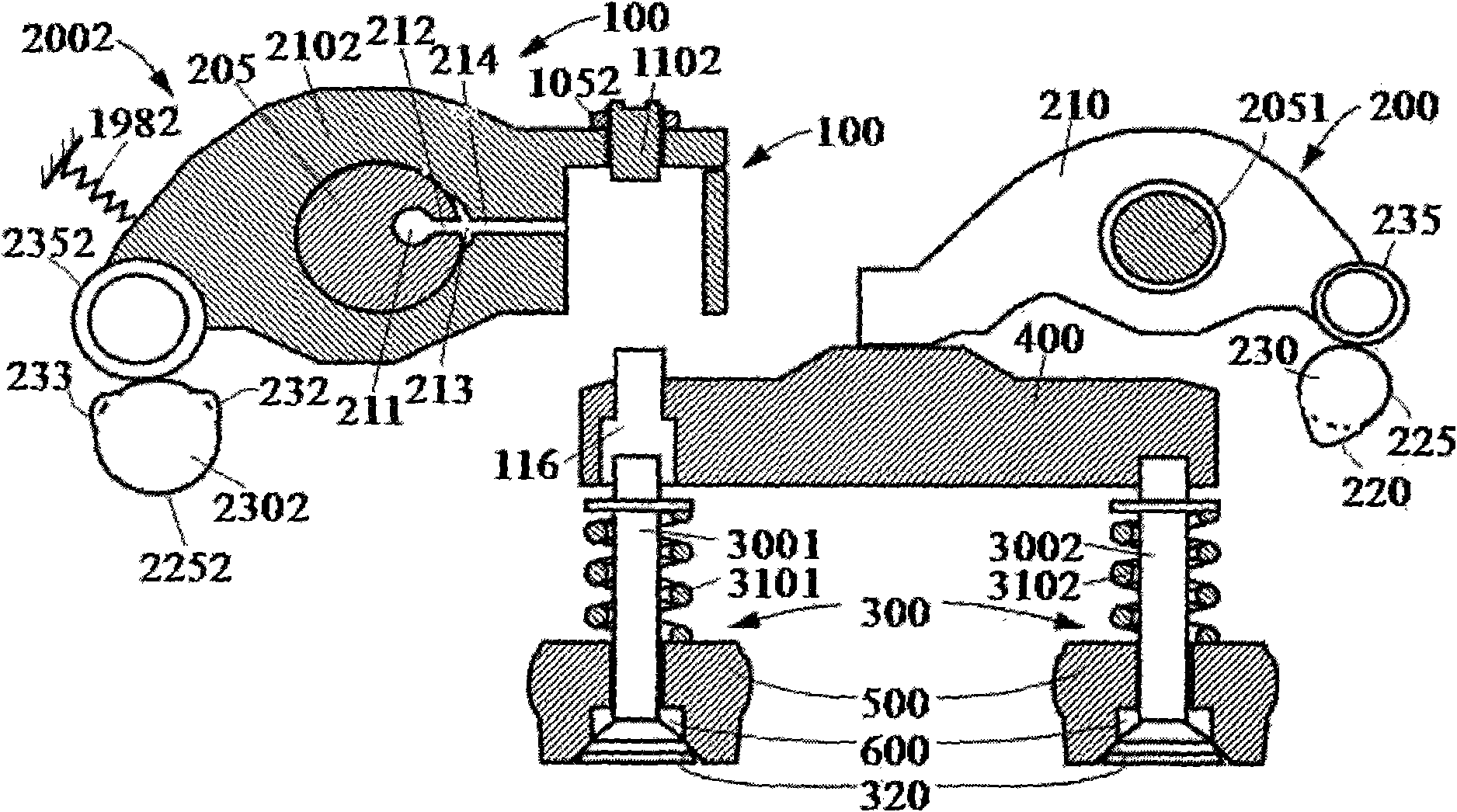

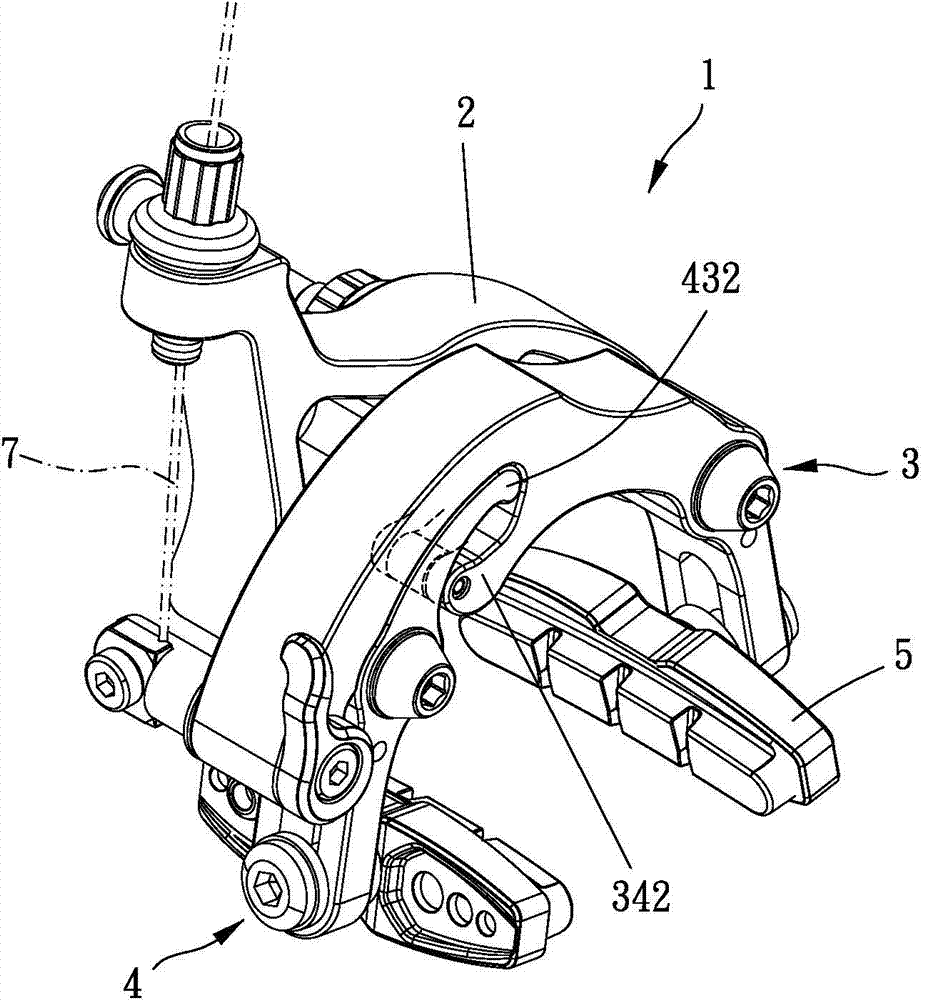

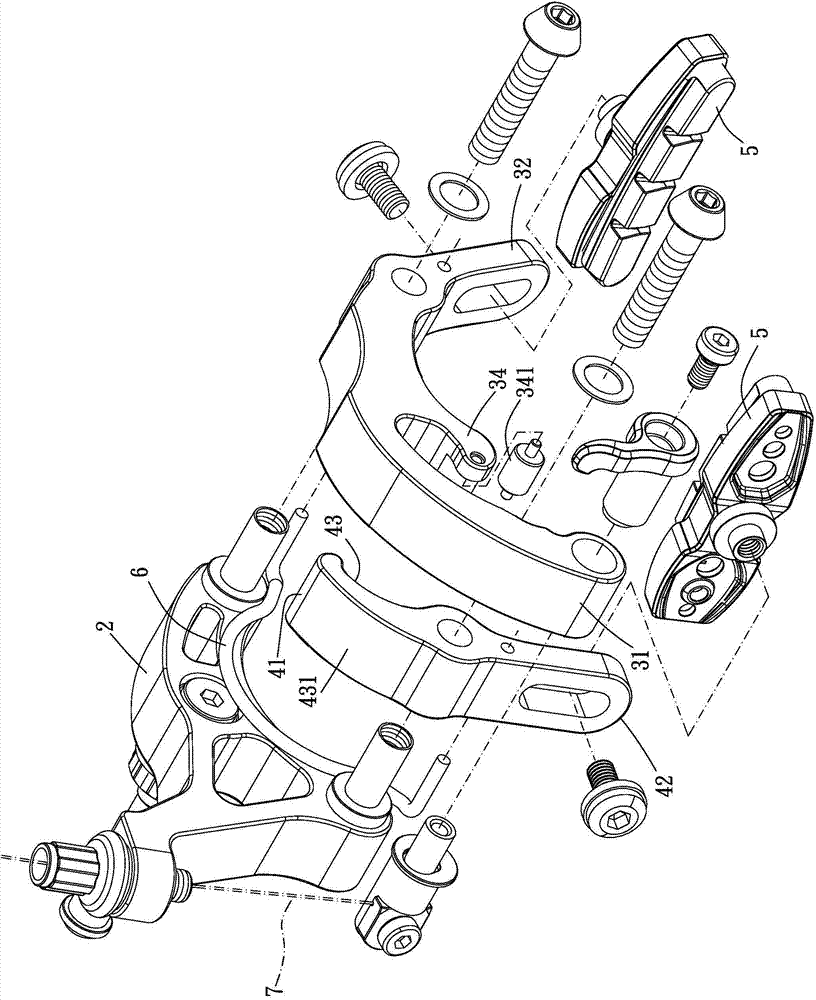

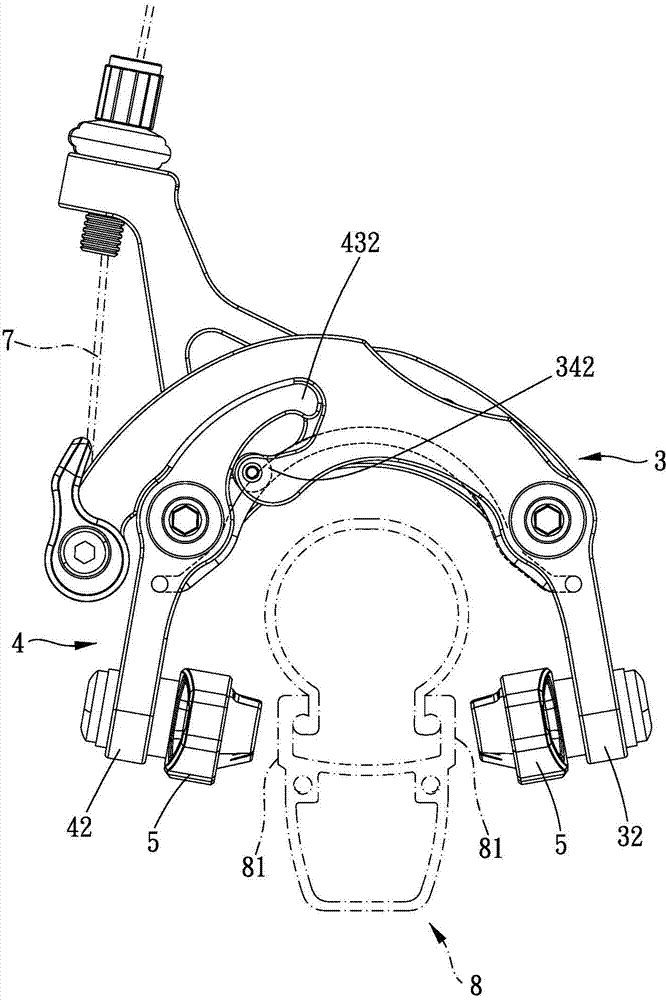

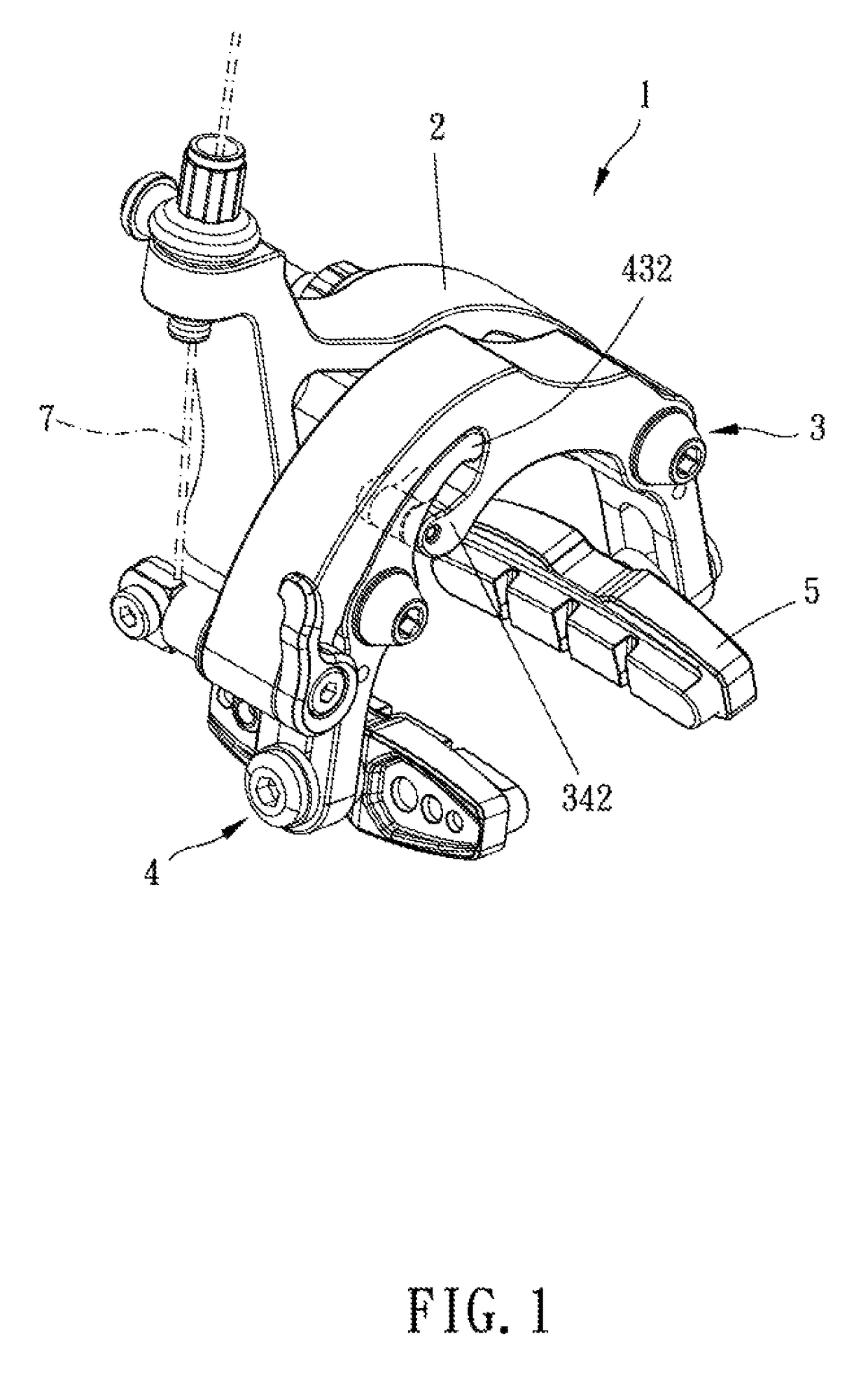

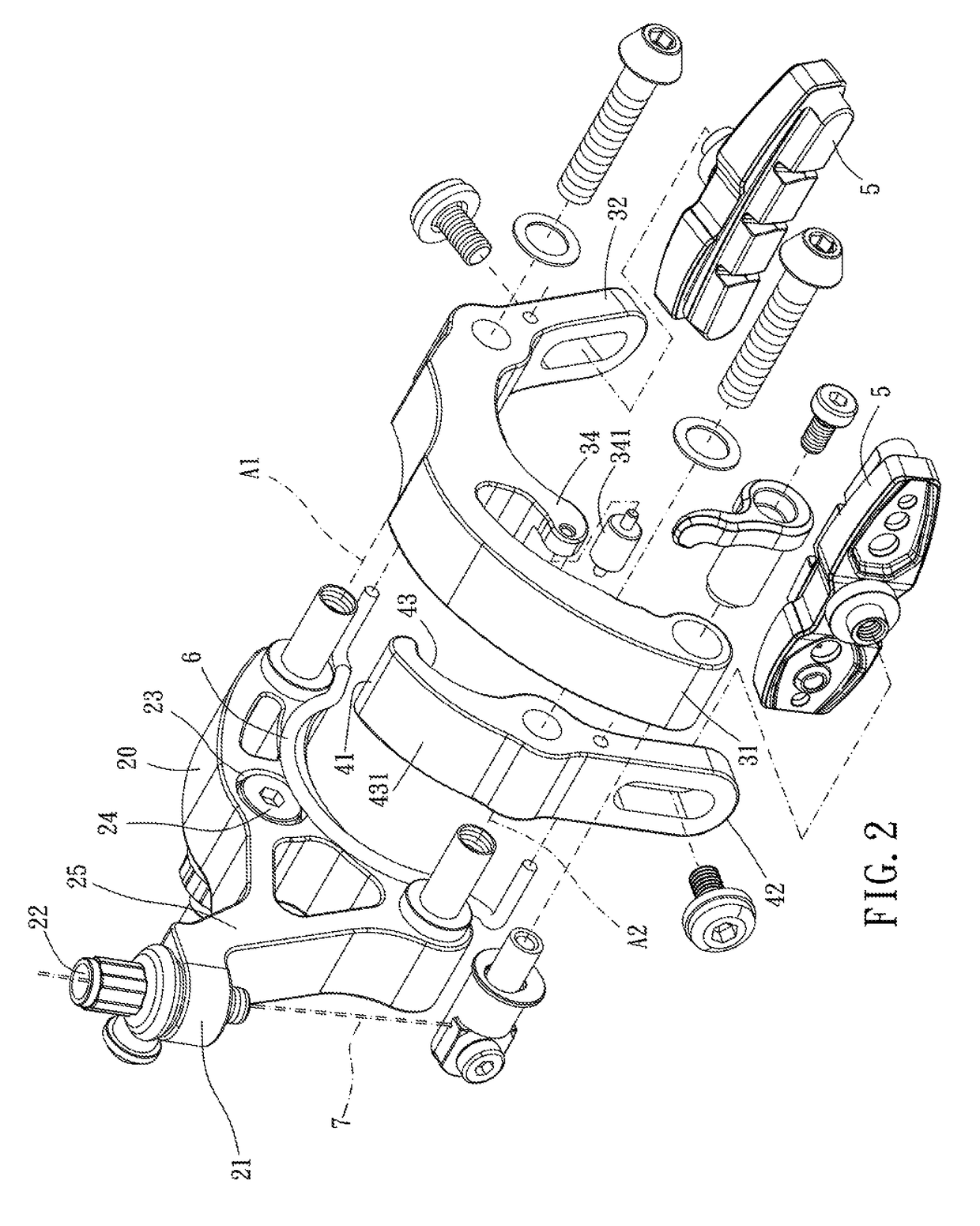

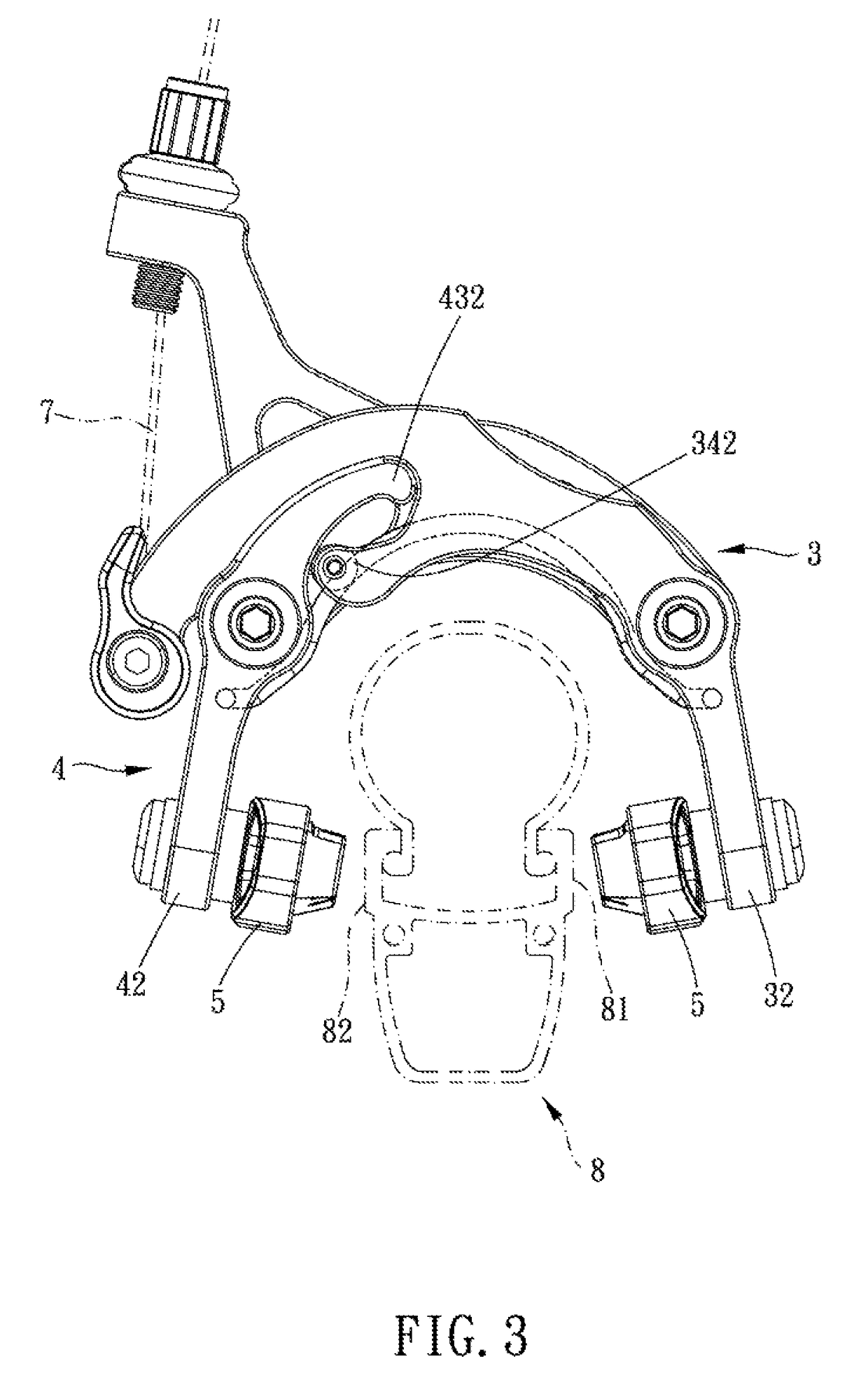

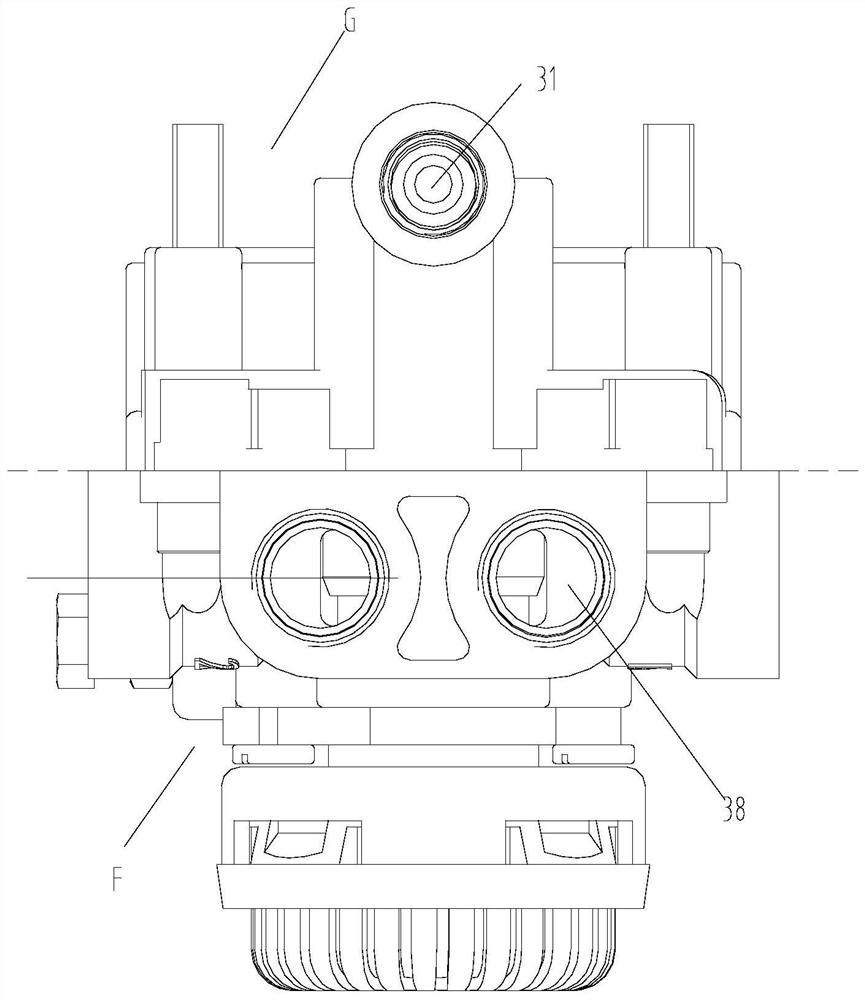

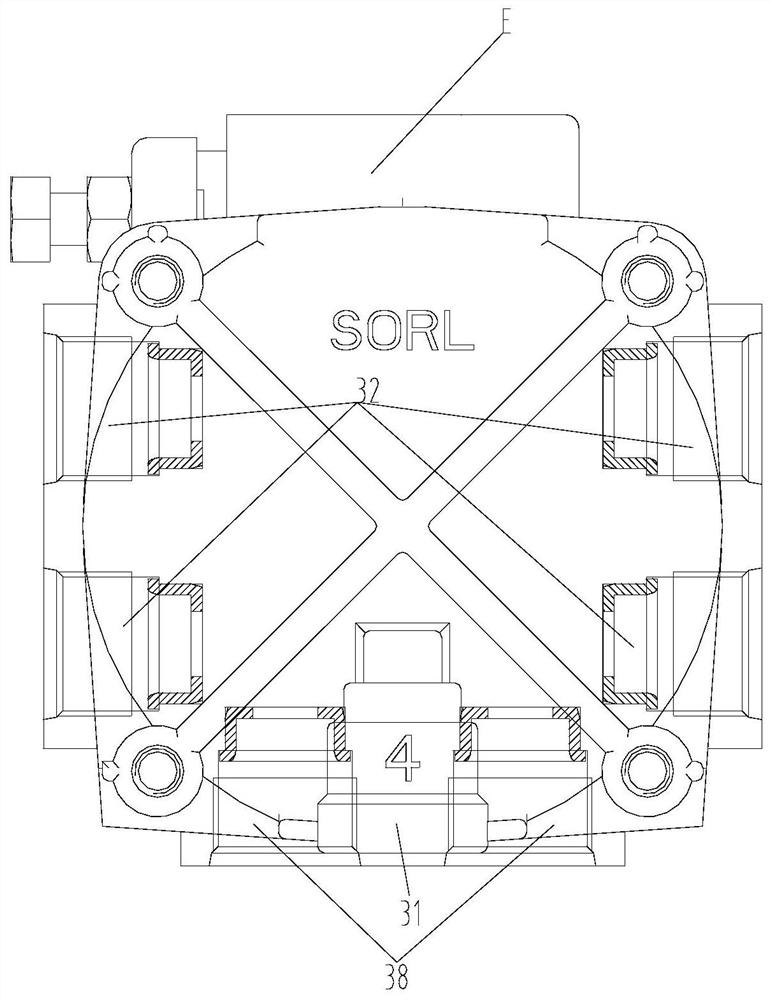

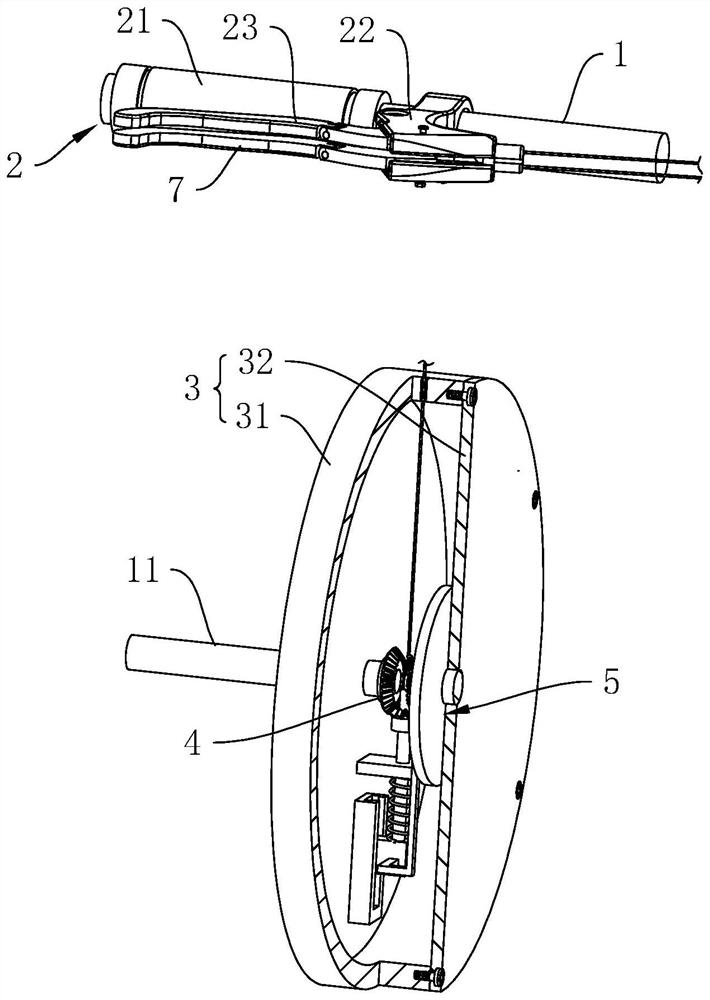

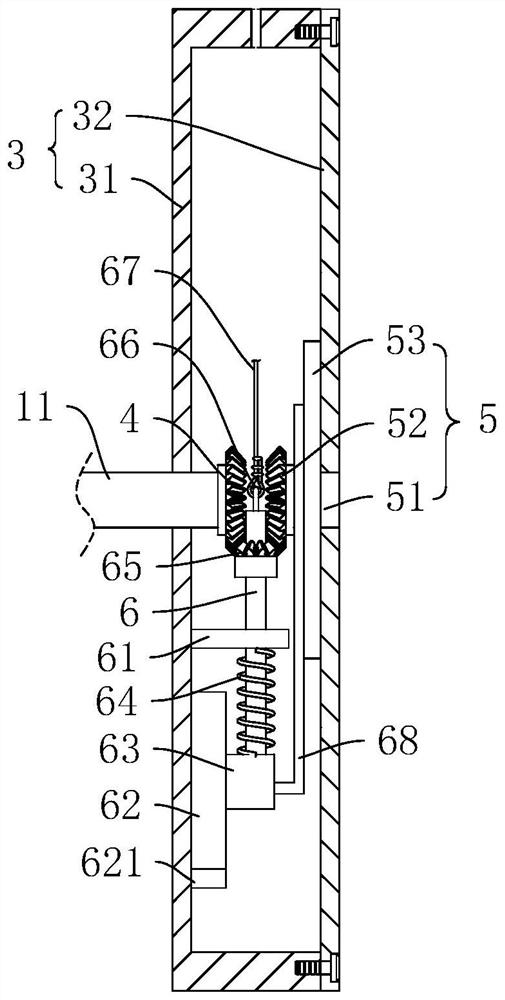

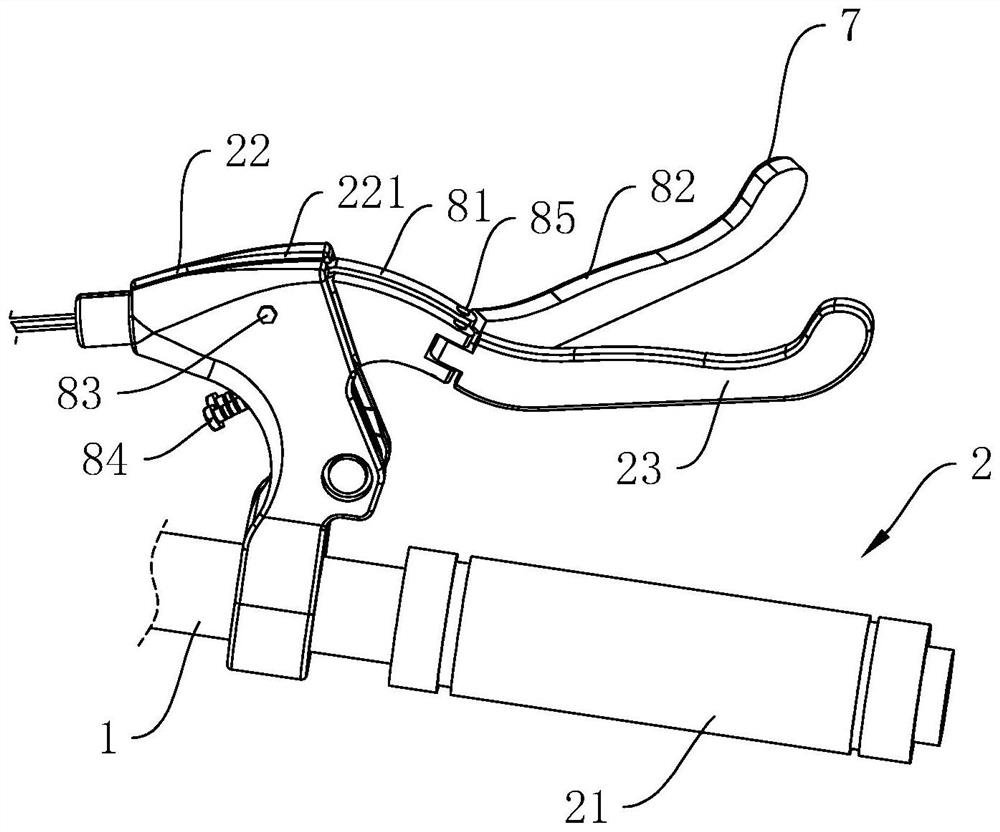

Brake for bicycle

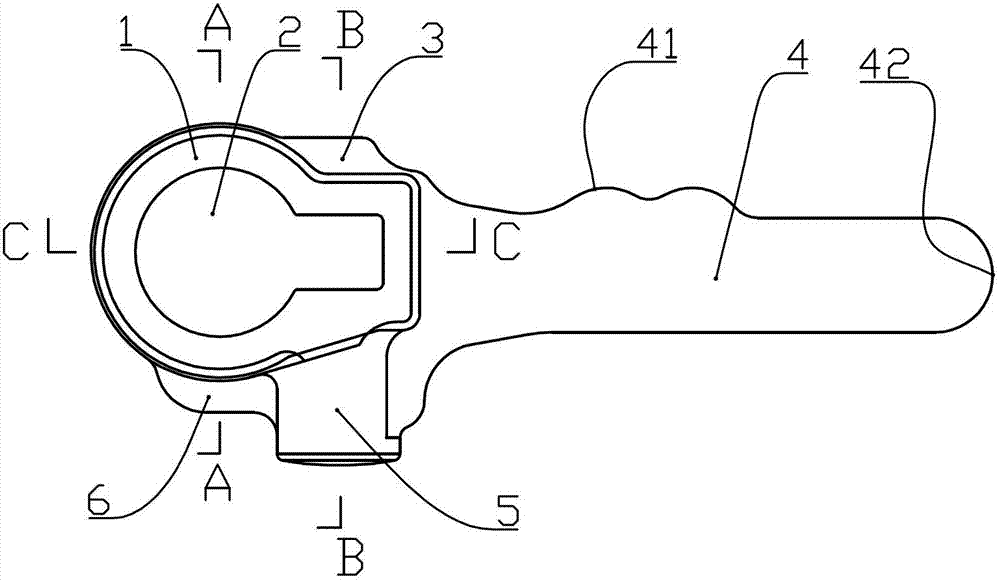

ActiveUS20180043964A1Reduced brake reaction timeEffective brakingCycle brakesMechanical engineeringEngineering

A brake for a bicycle includes a base, first and second arm assemblies. The first and second arm assemblies are pivoted to the base. The first arm assembly has a first end portion, for connection of a brake line a second end portion for frictionally contacting a brake side of a wheel rim. The second arm assembly is pivoted to the base and corresponds to the first arm assembly. The second aim assembly has a third end portion, a fourth end portion and a second abutting portion which is arranged on the third end portion. The second abutting portion is located correspondingly above the first abutting portion and interferable with the first abutting portion in a pivoting direction of the first abutting portion. The fourth end portion is swingable toward the brake side to clip the other brake side of the wheel rim.

Owner:WEN YUAN HUNG

Improved structure of engine brake device

InactiveCN102003240AReduce volumeReduce weightValve arrangementsMachines/enginesExhaust valveDrive wheel

The invention relates to an improved structure of an engine brake device, which comprises an exhaust valve control mechanism, wherein the exhaust valve control mechanism comprises a drive force input cam, a cam driven wheel, a rocking arm and a rocking arm shaft, the cam driven wheel is arranged at the other end of a push rod, the drive force input cam is arranged outside the cam driven wheel, the other end of the rocking arm is provided with a vertical valve gap regulating piston, a horizontal drive piston and a vertical brake plunger piston are arranged in the valve gap regulating piston, the middle of the drive piston is provided with a circular groove, the side surface of the circular groove and the side surface of the drive piston at the left side of the circular groove are used as anon working face and a working face which are in press and contact with the upper end face of the brake plunger piston, and an exhaust valve rod connecting member is arranged below the brake plunger piston. The drive force input cam is used for transferring driving force of the engine to the rocking arm periodically, the switching of two states of brake and normal work is realized by using an electromagnetic valve to control a gap between the rocking arm and the exhaust valve rod connecting member, the volume and the weight of a brake are reduced, and high oil pressure and leakage, deformation and load fluctuation caused by high oil pressure are avoided.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

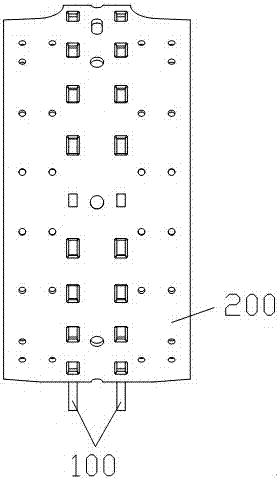

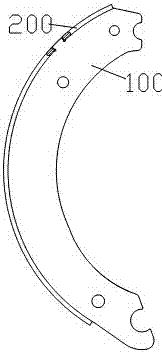

Bicycle brake

ActiveCN104773248AReduced brake reaction timeGood braking effectCycle brakesVehicle frameEngineering

The invention relates to a bicycle brake, which comprises a base, a first arm assembly and a second arm assembly, wherein the base is fixedly connected with a bicycle frame of a bicycle in a way without relative motion, the first arm assembly is pivoted on the base, and is provided with a first end part, a second end part and a first butting part, the first end part is connected with a braking line, and the second end part clamps and swings towards one braking edge of a wheel rim. The second arm assembly is pivoted at the base relative to the first arm assembly, and is provided with a third end part, a fourth end part and a second abutting part arranged at the third end part, the second butting part is arranged above the first butting part in a way with the interference in the pivoting direction, and the fourth end part clamps and swings towards to the other braking edge of the wheel rim.

Owner:温芫鋐

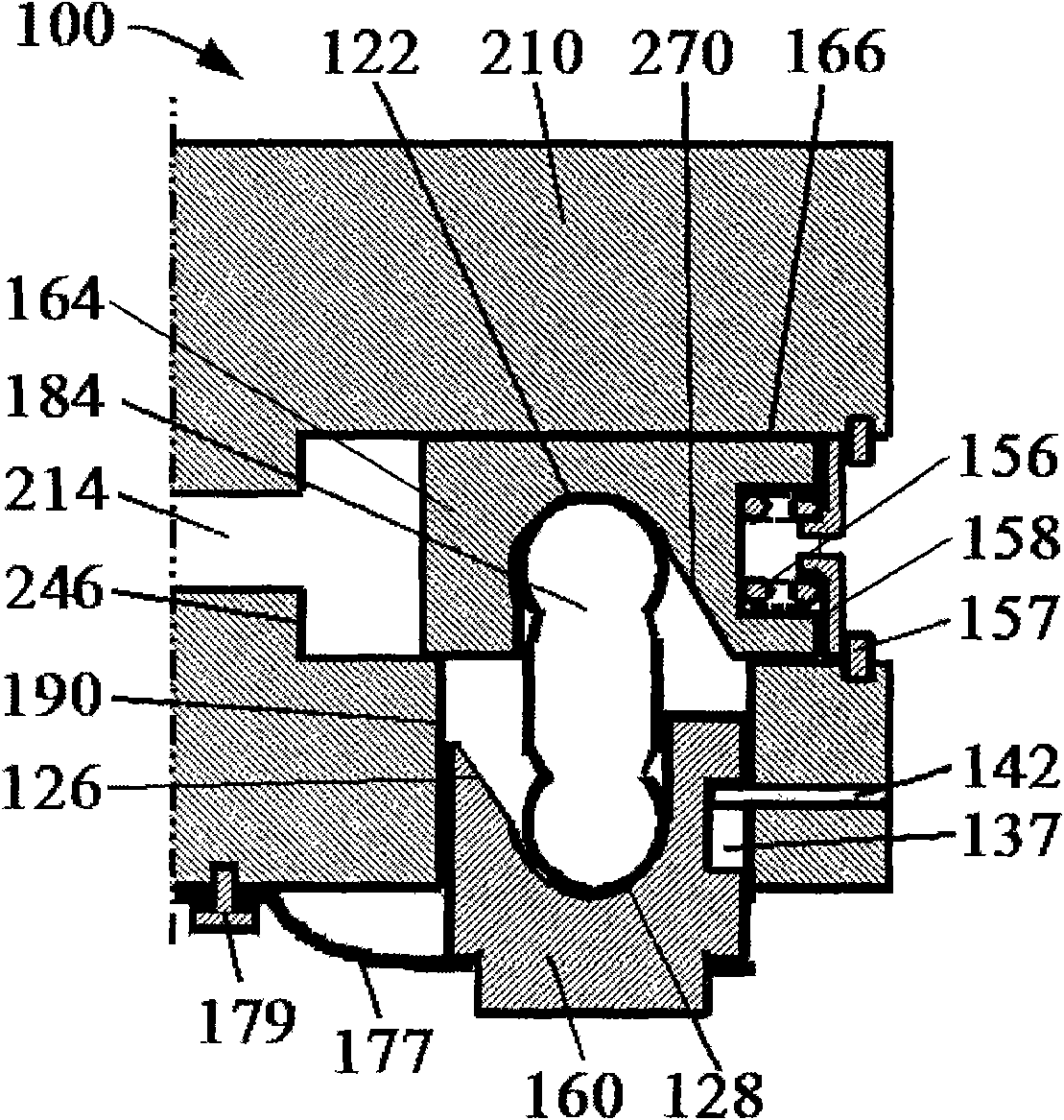

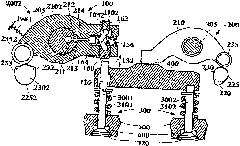

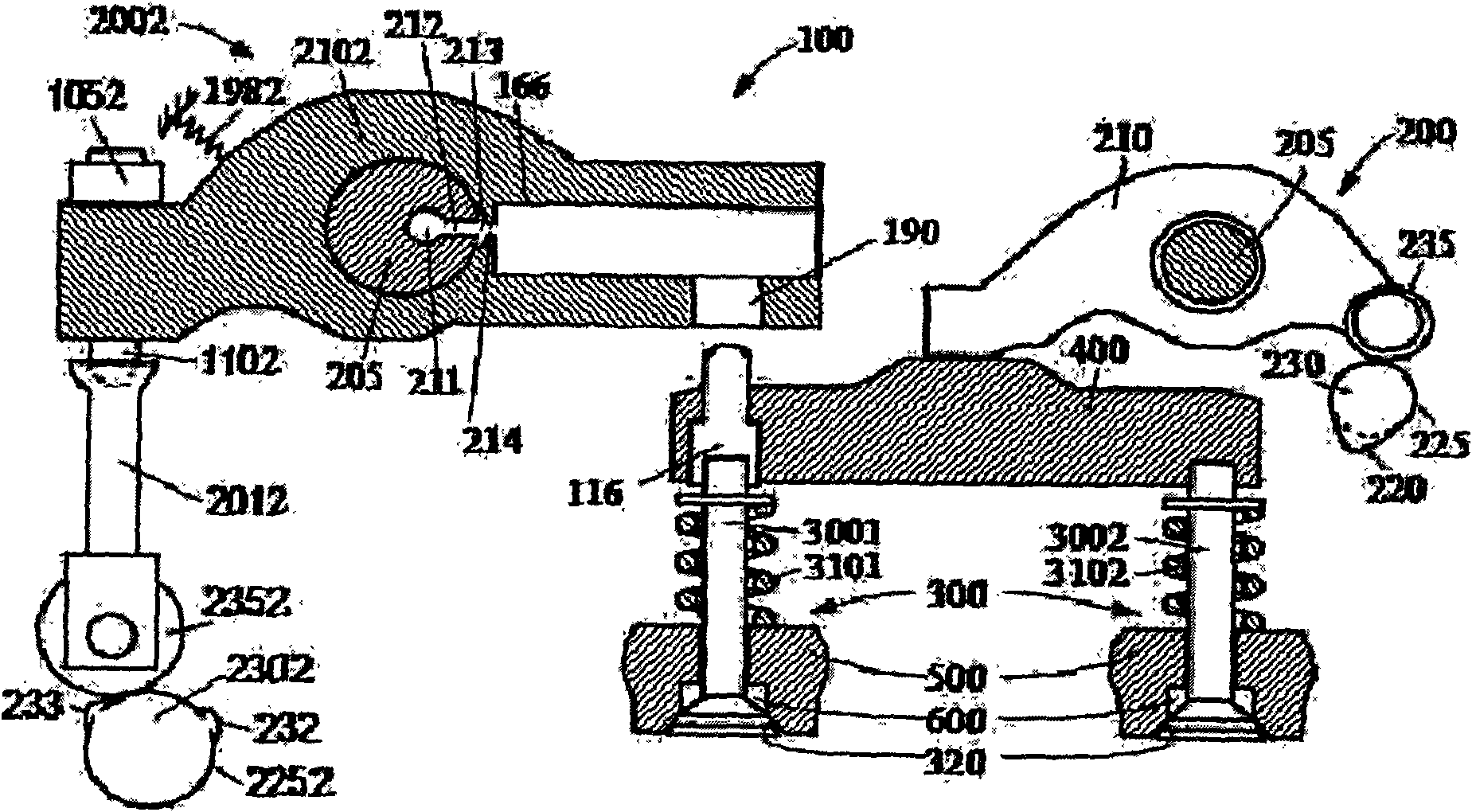

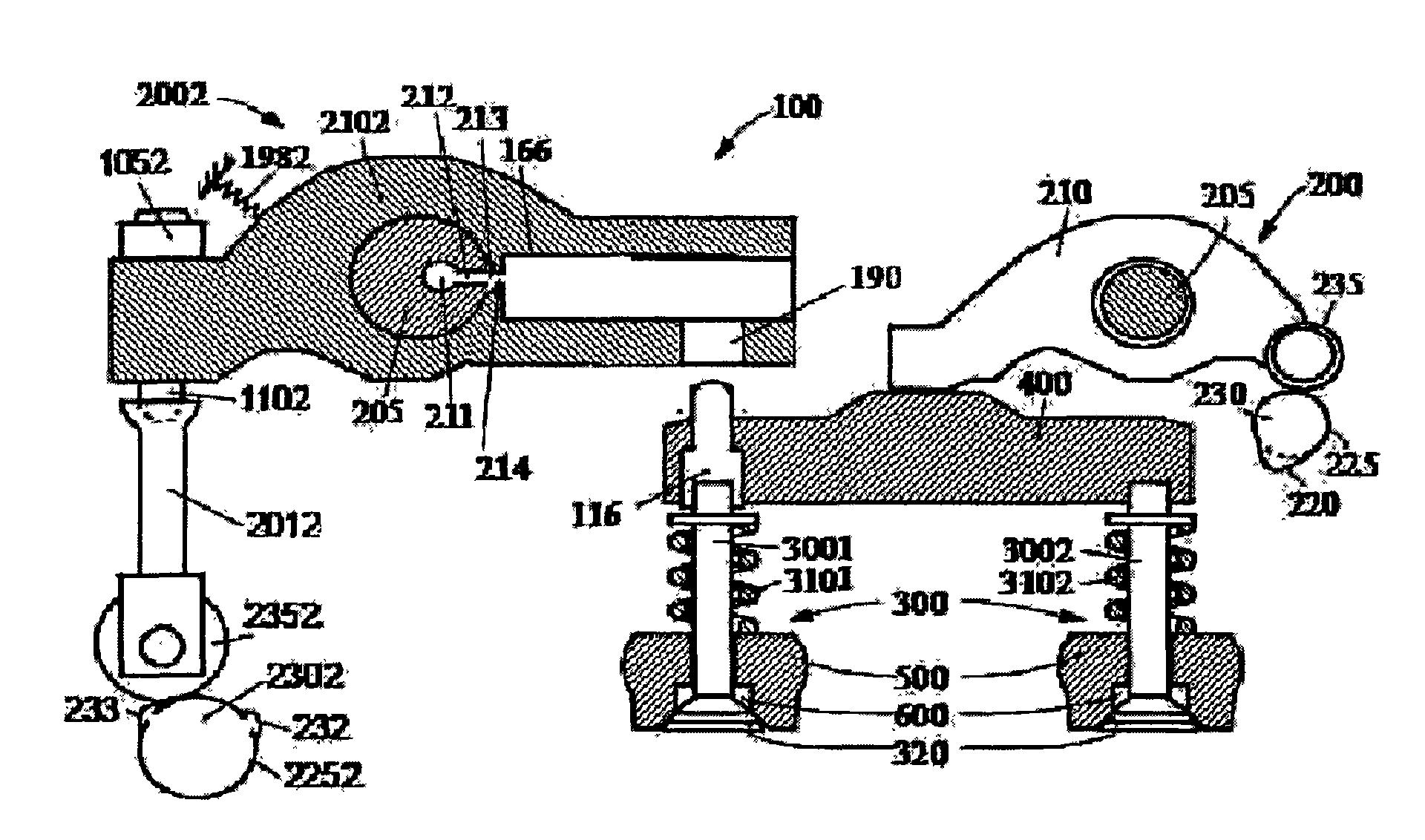

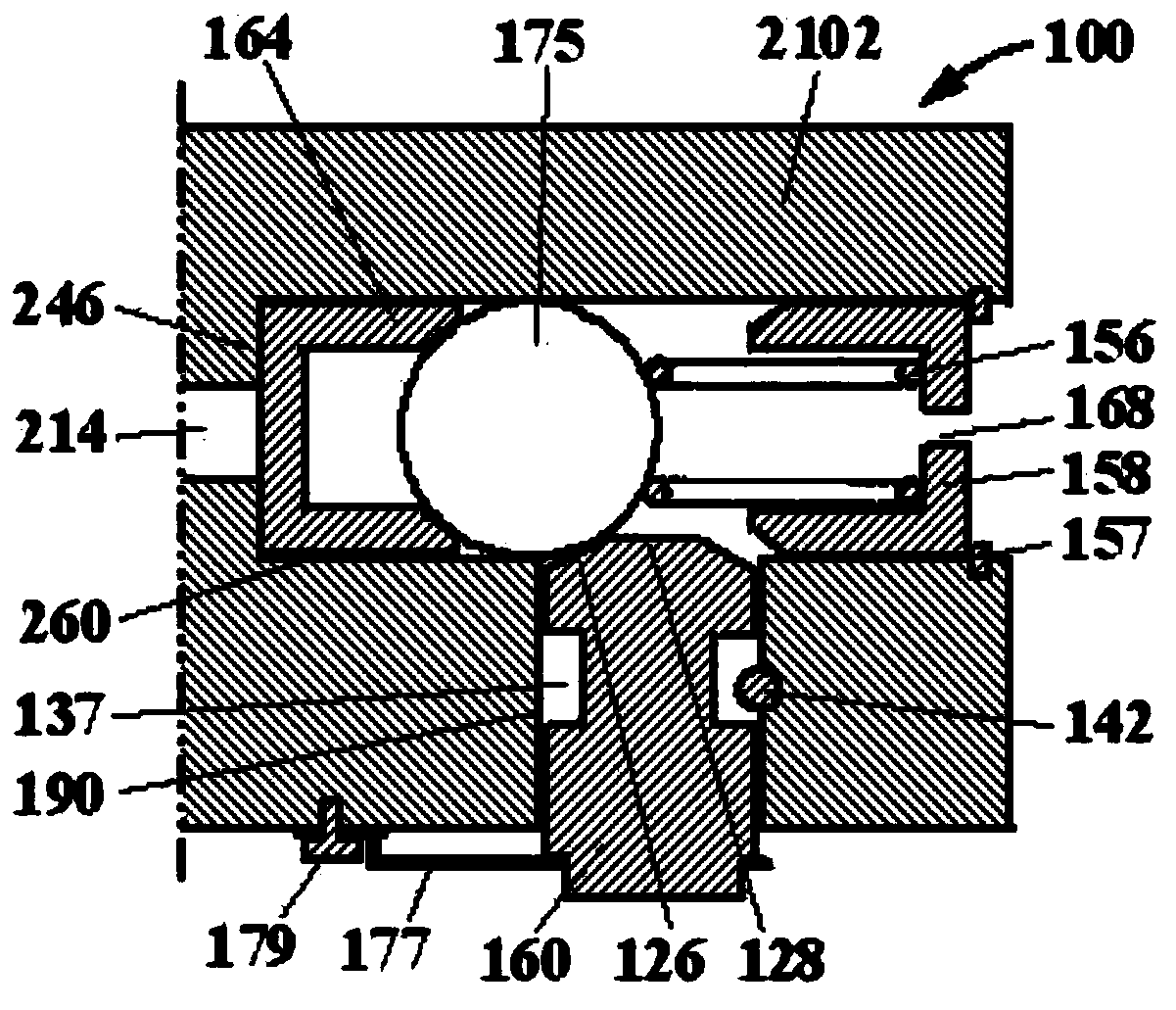

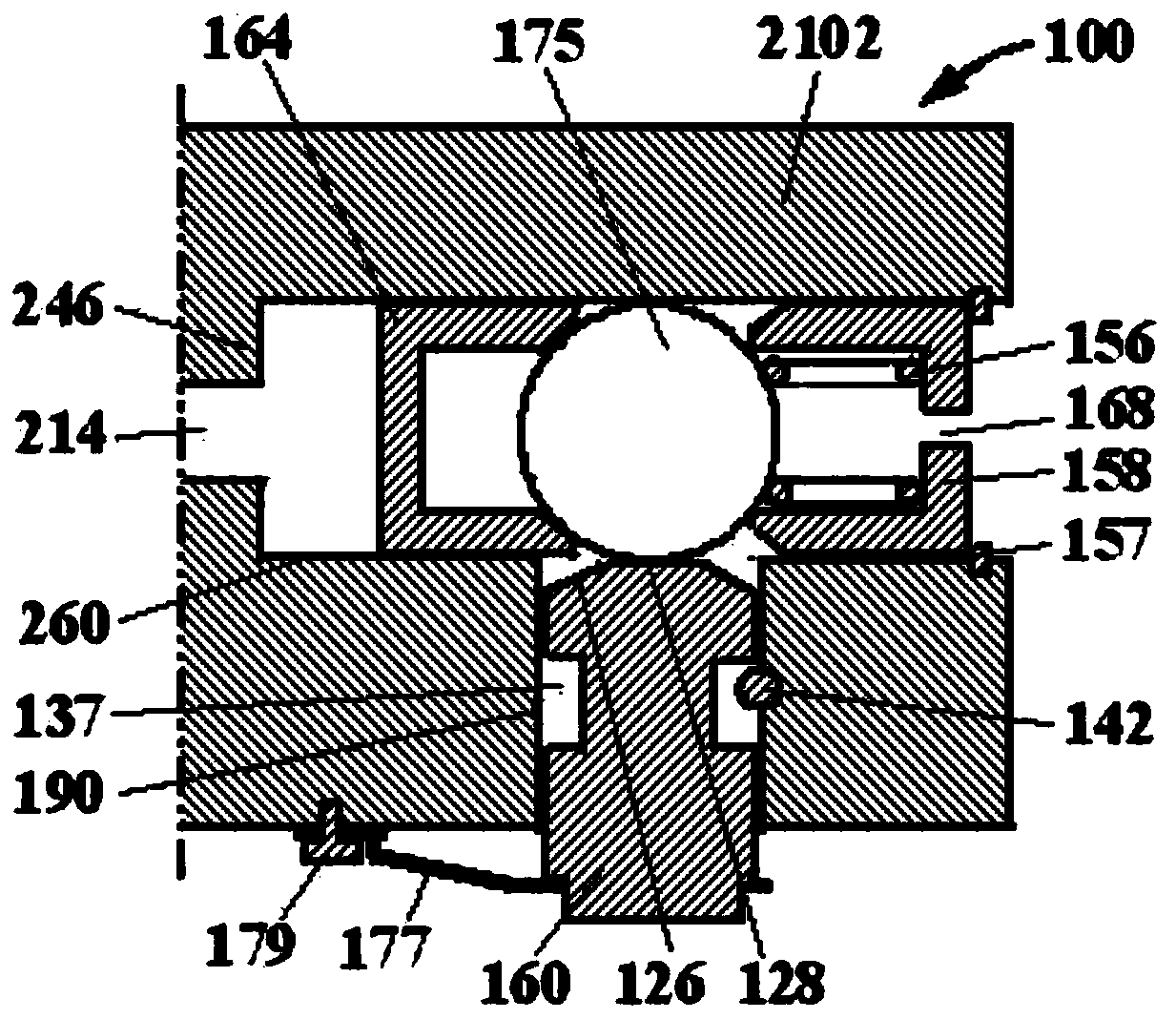

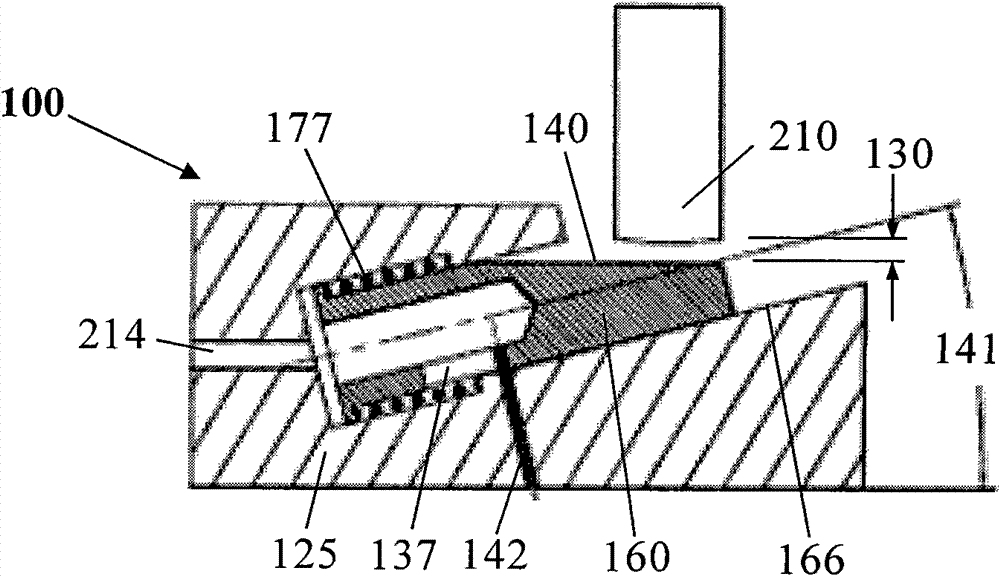

Valve actuating system of engine and method for generating engine auxiliary valve lift curve

InactiveCN103470330AReduce the overall heightReduce volumeValve arrangementsOutput powerValve actuatorChain type

The invention discloses a valve actuating system of an engine and a method for generating an engine auxiliary valve lift curve. A main valve lift curve of the engine is generated in the first working state of the system, and an auxiliary valve lift curve is generated in the second working state of the system. The system comprises a mechanical loading solid chain type auxiliary valve actuator. The solid chain type auxiliary valve actuator comprises a rolling ball or a drive piston or the combination of a rolling ball and a drive piston, a spring and a fluid flow channel, wherein the rolling ball or the drive piston or the combination of the rolling ball and the drive piston can move between a first working station and a second working station, the valve actuating system is in the working state and generates the main valve lift curve when in the first working station, the valve actuating system is in the second working state and generates the auxiliary valve lift curve when in the second working station, the fluid flow channel is used for providing pressurized fluid, and the spring and the pressurized fluid play roles on the two sides of the rolling ball or the drive piston or the combination of the rolling ball and the drive piston respectively to control the rolling ball or the drive piston or the combination of the rolling ball and the drive piston to switch between the first working station and the second working station.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

Fixed chain type mechanism and method for producing auxiliary valve rise curve of engine

InactiveCN103470328AReduce the overall heightReduce volumeValve arrangementsMachines/enginesValve actuatorEngineering

The invention discloses a fixed chain type mechanism for producing an auxiliary valve rise curve of an engine and a method for producing the auxiliary valve rise curve of the engine. The engine comprises a valve actuator for producing a main valve rise curve of the engine. The fixed chain type mechanism comprises a rolling ball or a driving piston or a combination of the rolling ball and the driving piston, a spring and a fluid passageway, wherein the rolling ball or the driving piston or the combination of the rolling ball and the driving piston can move between a first working position and a second working position; when the rolling ball or the driving piston or the combination of the rolling ball and the driving piston is located at the first working position, the fixed chain mechanism is in mechanical connection with a valve of the engine, and the auxiliary valve rise curve of the engine is produced; when the rolling ball or the driving piston or the combination of the rolling ball and the driving piston is located at the second working position, the fixed chain mechanism has no effect on the valve of the engine, and the auxiliary valve rise curve is switched to the main valve rise curve; the fluid passageway is used for supplying pressurized fluid, the spring and the pressurized fluid act on two sides of the rolling ball or the driving piston or the combination of the rolling ball and the driving piston respectively, and the rolling ball or the driving piston or the combination of the rolling ball and the driving piston is switched between the first working position and the second working position under the control of the spring and the pressurized fluid.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

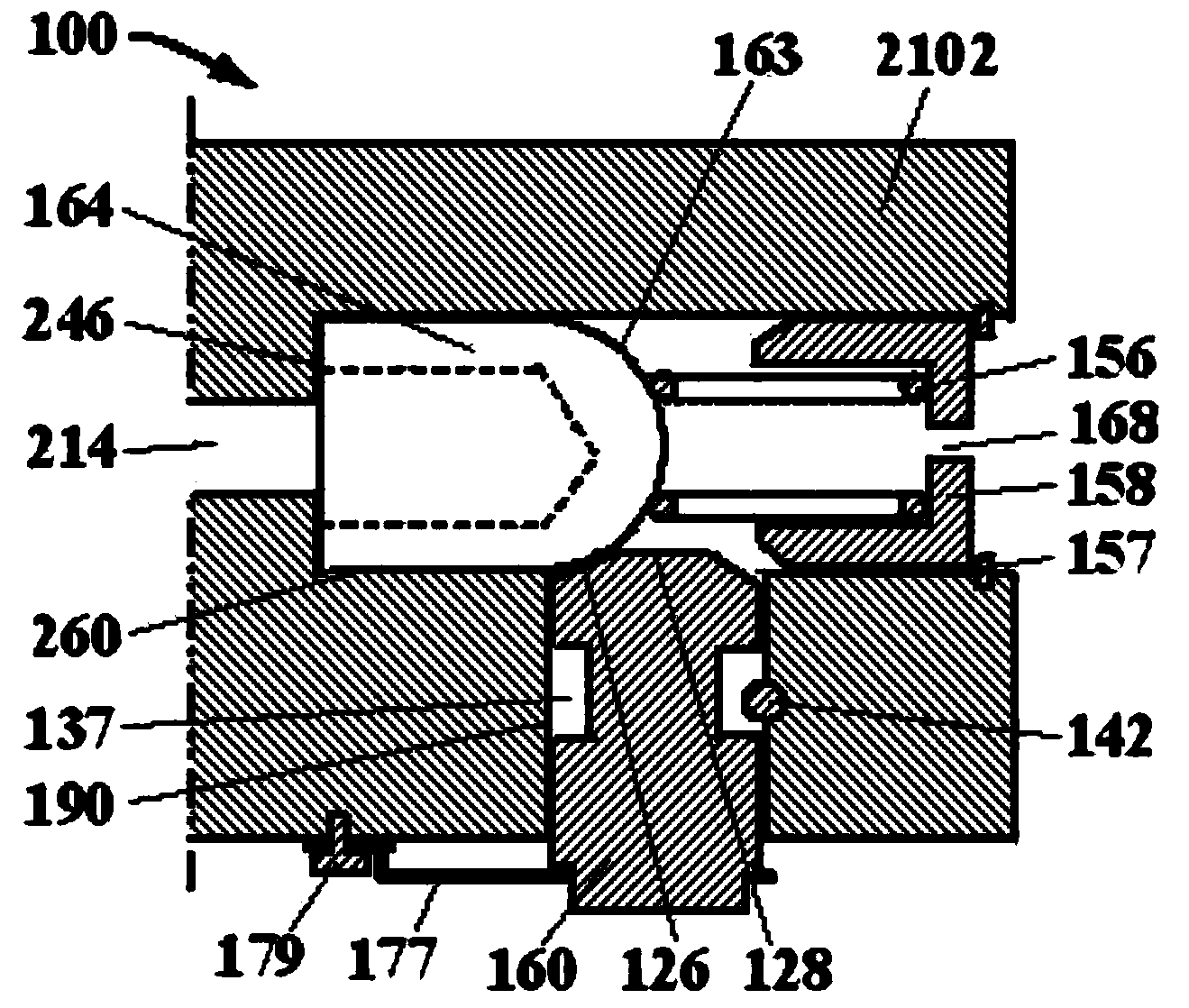

Parallel-central-valve type automobile brake master cylinder

InactiveCN103241230BShorten the vertical distanceSmall space requirementFluid braking transmissionEngineeringWheel cylinder

The invention discloses a parallel-central-valve type automobile brake master cylinder. The cylinder comprises a cylinder body upper portion, a cylinder body lower portion, a left master cylinder, a right master cylinder and a force transmitting mechanism, the force transmitting mechanism is arranged inside the cylinder body upper portion and transfers thrust coming from a push rod and a vacuum booster to the left master cylinder and the right master cylinder which are parallel to each other in a left-and-right mode by the push rod, the left master cylinder and the right master cylinder are basically identical in structure, are symmetrically arranged inside the cylinder body lower portion, convert and amplify the mechanical thrust transferred by the push rod into a hydraulic force and then transmit the hydraulic force through an oil outlet by a brake pipeline to all wheel cylinders and wheel brakes, and the cylinder body upper portion is fixedly connected with the cylinder body lower portion. According to the automobile brake master cylinder, the dual parallel cylinder structure is adopted, two brake hydraulic loops work independently, the fact that oil pressure of one cylinder can not be established has little influence on the other cylinder, the longitudinal distance of the brake master cylinder can be greatly shortened, the requirement for the engine compartment space is reduced, classes of parts are reduced, the machining cost is reduced, and the brake master cylinder is good in generality and broad in application prospect.

Owner:JILIN UNIV

Quick-braking engine brake device

InactiveCN102003239AReduce volumeReduce weightValve arrangementsMachines/enginesExhaust valveDrive wheel

The invention discloses a quick-braking engine brake device, which consists of an exhaust valve control mechanism, wherein the exhaust valve control mechanism consists of a driving force input cam, a cam driven wheel, a push rod, a rocker arm and a rocker arm shaft; one end of the push rod is connected with one end of the rocker arm; the cam driven wheel is arranged on the other end of the push rod; the driving force input cam is arranged outside the cam driven wheel; the other end of the rocker arm is provided with a horizontal driving piston and a vertical braking piston cylinder; a circular groove is formed on the middle part of the driving piston; a lateral side of the circular groove and the lateral surface, on the left of the circular groove, of the driving piston serve as a non-working face and a working face to contact the upper end face of the braking piston cylinder in a pressed way respectively; and a valve rod connector of an air exhaust valve is arranged below the braking piston cylinder. The driving force input cam transmits the power of an engine to the rocker arm periodically, the gap between the rocker arm and the valve rod connector of the air exhaust valve is controlled by an electromagnetic valve to realize switching between braking and normal working two states, so that the volume and weight of the brake are reduced, and high oil pressure and leakage, deformation and load fluctuation caused by the high oil pressure are avoided.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

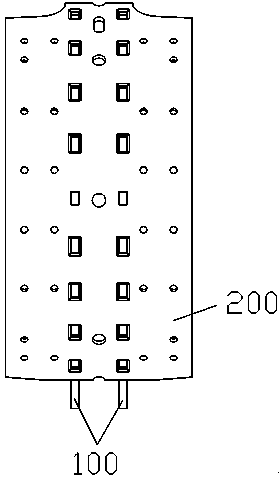

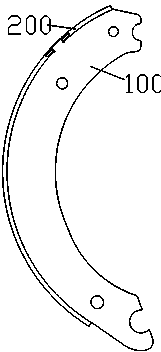

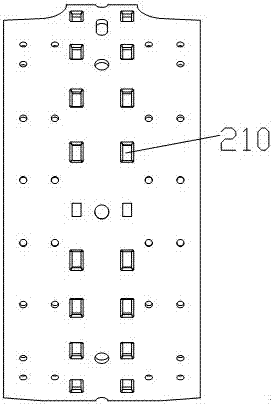

Coining type brake shoe and manufacturing method thereof

The invention discloses a coining type brake shoe and a manufacturing method thereof. The coining type brake shoe comprises rib plates and a face plate. Each rib plate is in an arc shape, and the mounting surface of the face plate is matched with the mounting surface of each rib plate in shape. Raised locating blocks are arranged on the mounting surface of each rib plate, locating holes for penetrating through the face plate are formed in the face plate, and the locating blocks penetrate through the locating holes. The rib plates and the face plate are fixedly connected in coining and pressure welding modes. The coining type brake shoe is simple in manufacturing process, simple in technology, short in production cycle, saving in time and labor, and small in production equipment layout requirement; the time-consuming and equipment-consuming working process such as welding and boring does not exist, the face plate and the rib plates are fixedly connected in a coining mode, the precision and strength of the entire brake shoe are guaranteed, and the appearance quality of the entire brake shoe is also greatly improved.

Owner:广东方盈汽车部件实业有限公司

Brake for bicycle

ActiveUS10189537B2Reduced brake reaction timeEffective brakingCycle brakesEngineeringMechanical engineering

A brake for a bicycle includes a base, first and second arm assemblies. The first and second arm assemblies are pivoted to the base. The first arm assembly has a first end portion, for connection of a brake line a second end portion for frictionally contacting a brake side of a wheel rim. The second arm assembly is pivoted to the base and corresponds to the first arm assembly. The second arm assembly has a third end portion, a fourth end portion and a second abutting portion which is arranged on the third end portion. The second abutting portion is located correspondingly above the first abutting portion and interferable with the first abutting portion in a pivoting direction of the first abutting portion. The fourth end portion is swingable toward the brake side to clip the other brake side of the wheel rim.

Owner:WEN YUAN HUNG

Driving device of engine brake

ActiveCN102191965BReduce the overall heightReduce volumeMachines/enginesNon-mechanical valveControl valvesOil temperature

The invention provides a driving device of an engine brake. The driving device comprises a braking box body, connecting rods, a driving piston and a braking plunger, wherein a vertical blind hole and a horizontal blind hole which intersect with each other are arranged in the braking box body; the driving piston is arranged in the horizontal blind hole; the braking plunger is arranged at lower part of the vertical blind hole; the connecting rods comprise an upper connecting rod and a lower connecting rod; a revolute pair is arranged between the upper connecting rod and the braking box body; another revolute pair is arranged between the lower connecting rod and the braking plunger; and a fluid channel is arranged in the braking box body to connect the horizontal blind hole with an engine oil fluid network. The driving device has the following beneficial effects: the driving device can be integrated with the engine, thus reducing the height, volume and weight of the engine brake; the hydraulic braking control valve is not needed, thus lowering the cost and reducing the brake response time; the brake load is not borne by liquid, thus enabling the driving device not to be subjected to leakage, deformation and load fluctuation caused by high oil pressure and high oil temperature; and the lift of the brake valve is not affected by the oil temperature and pressure and the air content,thus ensuring that the lift of the brake valve can be a small value, and reducing the requirements for the gap between the engine piston and the air valve.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

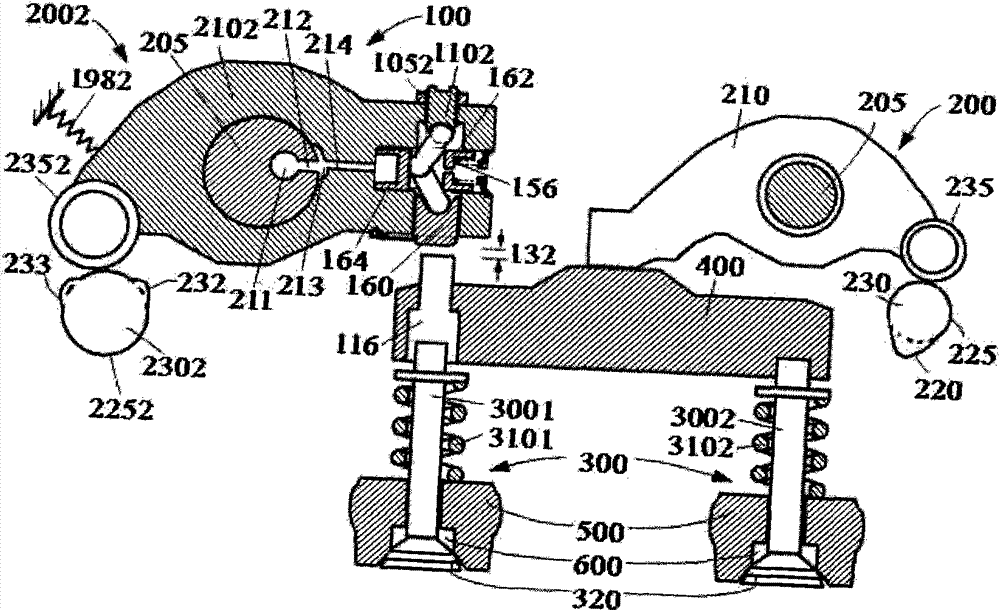

Compression release type engine cylinder internal braking device

PendingCN112267924AMove down to achieveQuick responseValve arrangementsMachines/enginesEngineeringCam

The invention discloses a compression release type engine cylinder internal braking device. The compression release type engine cylinder internal braking device comprises a driving force input cam shaft and a braking rocker arm assembly which is driven by the driving force input cam shaft and can rotate and swing around a rocker arm shaft; the braking rocker arm assembly comprises a braking rockerarm and a valve clearance control mechanism arranged in an installation hole of the braking rocker arm; the valve clearance control mechanism comprises a braking plunger, a reset spring and a drivingdevice, wherein the reset spring has upward elastic force on the braking plunger, and the driving device has downward acting force in the axial direction on the braking plunger; and the braking plunger right faces an exhaust valve. A driving piston of the compression release type engine cylinder internal braking device synchronously drives an upper connecting rod and a lower connecting rod to swing, due to the fact that spherical heads of the upper connecting rod and the lower connecting rod conduct twisting actions in corresponding spherical grooves, the upper connecting rod downwards extrudes a middle sliding block in the swinging and twisting process, then the middle sliding block extrudes the lower connecting rod, the lower connecting rod downwards extrudes the braking plunger, accordingly, the braking plunger moves downwards, a valve cap is triggered, and accordingly engine cylinder internal braking work is achieved.

Owner:ZHEJIANG QIANGNENG MOTIVITY

Method and mechanical load bearing fixed chain type mechanism for generating auxiliary valve lifting curve of engine

InactiveCN103527329AReduce the overall heightReduce volumeValve arrangementsOutput powerChain typeEngineering

The invention discloses a mechanical load bearing fixed chain type mechanism used for generating an auxiliary valve lifting curve of an engine and a method for generating the auxiliary valve lifting curve of the engine. A main valve lifting curve of the engine is generated through a first working state of the engine, and the auxiliary valve lifting curve of the engine is generated through a second working state of the engine. The fixed chain type mechanism comprises a rolling ball or a driving piston or a combination of the rolling ball and the driving piston, a spring and a fluid flow passage for providing pressurized fluid, and the rolling ball or the driving piston or the combination of the rolling ball and the driving piston can move between a first station and a second station. In the first station, a valve actuating system is in the first working state, and the main valve lifting curve is generated. In the second station, the valve actuating system of the engine is in the second working state, and the auxiliary valve lifting curve is generated. The spring and the pressurized fluid act on the two sides of the rolling ball or the driving piston or the combination of the rolling ball and the driving piston respectively and control the rolling ball or the driving piston or the combination of the rolling ball and the driving piston to be switched between the first station and the second station.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

Large-flow adjustable double-ahead proportional relay valve

PendingCN114274936ASmall reverse force areaFast brakingApplication and release valvesRelay valveEngineering

According to the high-flow adjustable double-ahead proportional relay valve, a piston structure is redesigned, so that a front cavity structure is reformed, and particularly, the reverse force application area of gas in a front cavity to a piston, especially a piston pressure plate, is reduced; the starting edge of the front cavity is changed from the inner cavity wall of the piston to the first annular structure moving towards the axis in the radial direction, so that the front output proportion is increased, braking is correspondingly faster, the braking response time is shortened, and the braking speed is increased on the basis of light treading and light braking.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

Bicycle brake feedback mechanism

PendingCN114572333ADoes not affect stopReduce rotation speedCycle brakesRider propulsionVehicle frameGear wheel

The invention discloses a bicycle brake feedback mechanism, and belongs to the technical field of bicycle braking. The main brake handle is mounted on a frame, the V-shaped brake assembly is mounted on a wheel carrier, the wheel shaft and the mounting box are mounted on the wheel carrier, one end of the wheel shaft is rotatably connected with the mounting box, a driving gear is fixed to the end, located in the mounting box, of the wheel shaft, and a flywheel assembly is arranged on the inner wall of the mounting box. An auxiliary brake shaft is slidably connected to the inner wall of the mounting box in the vertical direction, a transmission gear is rotatably connected to the periphery of the auxiliary brake shaft, a reset assembly is arranged in the mounting box, one end of the auxiliary brake shaft is connected with a brake rope capable of driving the driving gear to be meshed with the transmission gear, and the end, away from the auxiliary brake shaft, of the brake rope is connected with an auxiliary brake handle. The flywheel assembly is used for decelerating the wheels, meanwhile, the energy of the flywheel assembly can be applied to bicycle starting, the starting difficulty of a rider is relieved, and the energy utilization rate is increased.

Owner:深圳中华自行车(集团)股份有限公司

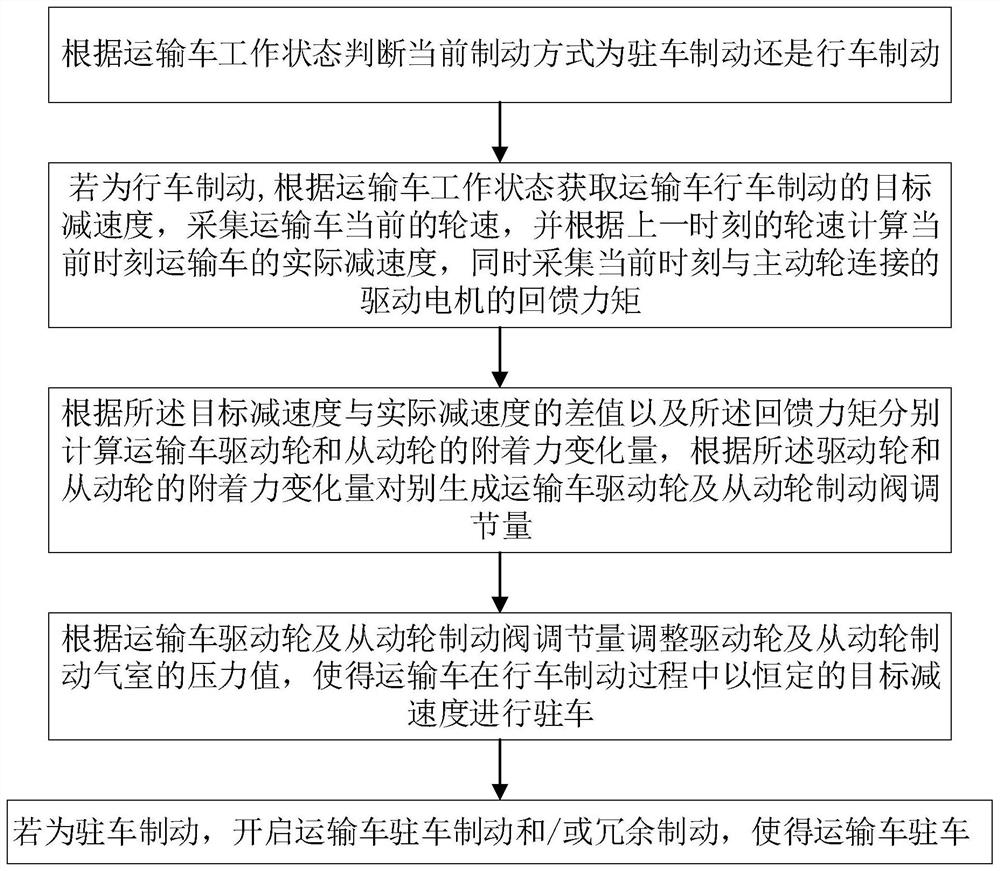

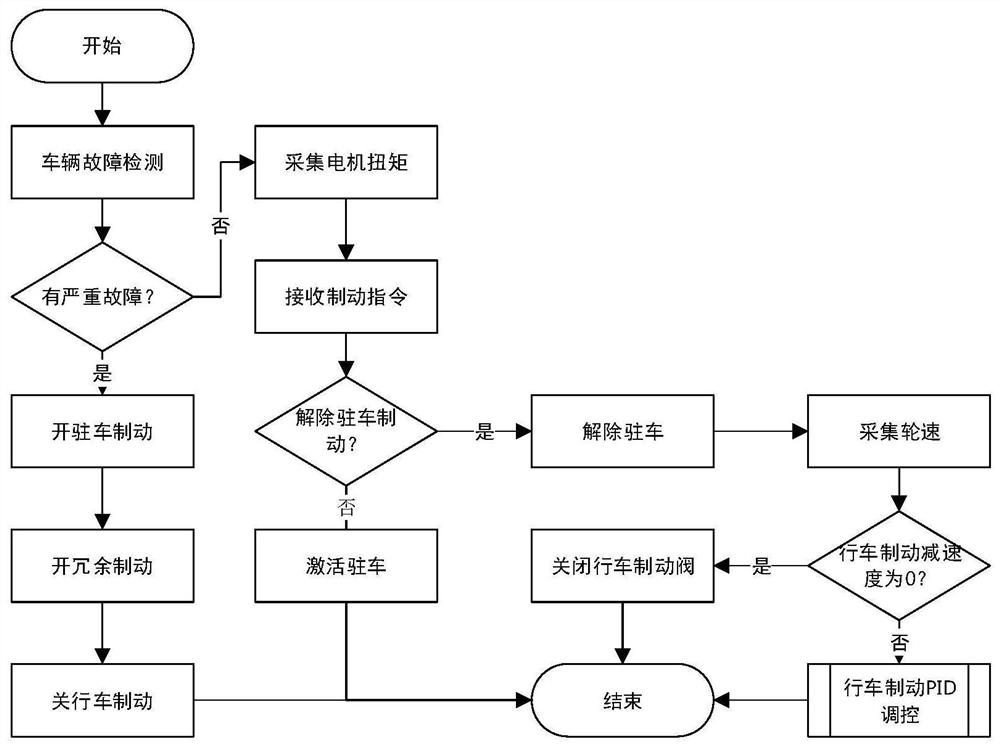

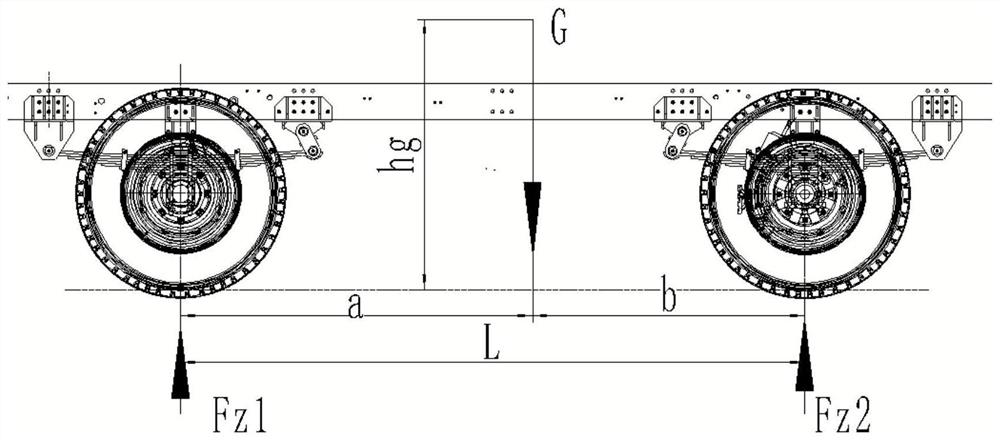

An intelligent braking method and system for a heavy-duty intelligent transport vehicle

ActiveCN112519736BReasonable brake distributionWith energy feedback functionApplication and release valvesDrive wheelElectric machinery

The invention belongs to the field of vehicle braking control, and specifically discloses an intelligent braking method and system for a heavy-duty intelligent transport vehicle. The method includes: judging the current braking mode according to the working state of the transport vehicle, and calculating the variation of the adhesion force of the driving wheel and the driven wheel of the transport vehicle respectively according to the difference between the target deceleration and the actual deceleration and the feedback torque, so as to generate a transport vehicle. The adjustment amount of the brake valve of the driving wheel and the driven wheel of the vehicle, so that the adjustment value can adjust the pressure value of the brake chamber of the driving wheel and the driven wheel, so that the transport vehicle can be parked at a constant target deceleration during the braking process of the vehicle. The system includes a main control module, a vehicle controller VCU, a vehicle speed sensor, an EBS brake controller, a parking brake module, a redundant brake module, a drive motor connected to a driving wheel, and a drive motor feedback torque collector. The invention ensures reasonable brake distribution of the brakes, and also enables the transport vehicle to park at a constant target deceleration during the service braking process.

Owner:湖北三环智能科技有限公司

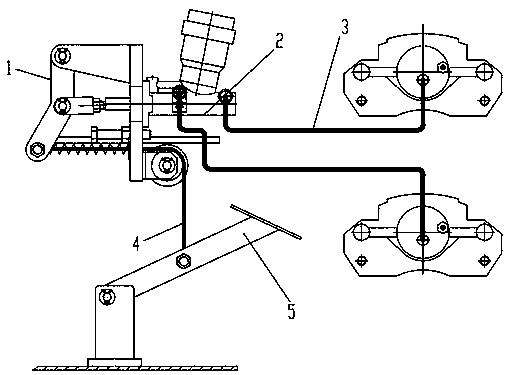

Electric locomotive brake device

InactiveCN111252044AReduced brake reaction timeShorter braking distanceHand actuated initiationsBrake arrangement with braking memberMaster cylinderControl theory

An electric locomotive brake device mainly solves the technical problems that a hand wheel mechanical brake device adopted by an existing locomotive is cumbersome, low in response speed, inconvenientfor a driver and an operator to operate and the like. The device is characterized by comprising a hand wheel rotating threaded lead screw, a cross arm, a brake connecting rod, a brake shoe, a foot valve, a steel wire rope, a hydraulic master cylinder and a hydraulic connecting rod, the hand wheel rotating threaded lead screw is connected with the cross arm, the cross arm is connected with the brake shoe through the brake connecting rod, and the foot valve is connected with the hydraulic connecting rod through the steel wire rope. The brake device is mainly applied to industrial and mining electric locomotives.

Owner:XIANGTAN ELECTRIC LOCOMOTIVE FACTORY

Improved engine brake device

ActiveCN102003242BReduce volumeReduce weightValve arrangementsMachines/enginesDrive wheelExhaust valve

The invention relates to an engine brake device which comprises an exhaust valve control mechanism. The exhaust valve control mechanism comprises a driving force input cam, a cam driven wheel, a push rod, a rocker arm and a rocker arm shaft, wherein one end of the push rod is connected with one end of the rocker arm, the cam driven wheel is arranged on the other end of the push rod, and the driving force input cam is arranged outside the cam driven wheel; the other end of the rocker arm is provided with a horizontal guide piston, a driving piston and a vertical brake plunger piston, two connecting rods are arranged in the guide piston, the convex spherical surface of the upper end of the upper connecting rod is matched with the concave spherical surface of the rocker arm, the convex spherical surface of the lower end of the lower connecting rod is matched with the convex spherical surface of the brake plunger piston, and an exhaust valve rod connecting piece is arranged below the brake plunger piston. The driving force input cam periodically transmits engine power to the rocker arm, the gap between the rocker arm and the exhaust valve rod connecting piece is controlled by using a solenoid valve, the switching between the brake working state and the normal working state is realized, the size and the weight of the brake are reduced, and high oil pressure and leakage, deformationand load fluctuation caused by high oil pressure do not occur.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

Multifunctional automobile high-order tail lamp

InactiveCN106335423ASimple structureReasonable designOptical signallingCar drivingBrake response time

The invention discloses a multifunctional automobile high-order tail lamp which comprises an accelerator linkage limit switch, a brake limit switch, an accelerator pedal refueling indication lamp, an accelerator pedal loosening indication lamp and a braking indication lamp, wherein a middle contact of the accelerator linkage limit switch is connected with a positive electrode of a power supply; a normally open contact of the accelerator linkage limit switch is connected with the accelerator pedal refueling indication lamp, a normally closed contact of the accelerator pedal refueling indication lamp is connected with the accelerator pedal loosening indication lamp, and a normally open contact of the brake limit switch is respectively connected with the positive electrode of the power supply and the braking indication lamp. The multifunctional automobile high-order tail lamp is capable of not only displaying the brake state, but also displaying the states of the accelerator pedal with different colors; and high-order tail lamps with corresponding colors are turned on by virtue of corresponding control switches through various operations during a running process of an automobile, thereby effectively assisting follow-up automobile drivers in mastering the running states of front automobiles in time, so that accurate operation is adopted in time, the braking response time is shortened, and occurrence of rear-end collision is effectively avoided.

Owner:葛向东

Improved engine brake driving device

InactiveCN102011622BOvercome preloadReduce volumeValve arrangementsMachines/enginesExhaust valveNetwork control

The invention relates to an improved engine brake driving device, comprising a vent valve control mechanism. The vent valve control mechanism comprises a brake cabinet, a brake plunger and a brake connector, wherein a plunger hole is formed in the brake cabinet, the brake plunger is arranged in the plunger hole in a sliding mode and provided with a working surface, an included angle is formed between the working surface and a central axis of the brake plunger, and the brake cabinet is internally provided with a fluid channel communicated with the plunger hole. The improved engine brake driving device is internally provided with the brake plunger and a spring, engine oil and the spring of an engine brake fluid network control the brake plunger to move so as to switch and maintain the two engine states, i.e. brake and normal work. The improved engine brake driving device can be integrated with an engine so as to reduce the size and the weight of an engine brake without adopting a hydraulic brake control valve, thereby decreasing the cost, shortening the brake reaction time, avoiding high oil pressure or leakage, deformation and load fluctuation caused by the high oil pressure, preventing the brake valve from being influenced by oil temperature, oil pressure and air contents and acquiring smaller brake valve lift.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

displacement compensator

ActiveCN104015718BReduce displacementReduced brake reaction timeBraking componentsMachine buildingCheck valve

The invention discloses a displacement compensator, which relates to the technical field of engineering machinery manufacturing; it includes a first oil cylinder, a second oil cylinder, a first check valve and a second check valve; the spring chamber of the first oil cylinder, the The spring chamber of the second oil cylinder and the first one-way valve imported oil and the second check valve's imported oil All communicate with the oil outlet of the brake valve; the non-spring chamber of the first oil cylinder, the non-spring chamber of the second oil cylinder and the non-spring chamber of the first one-way valve Oil outlet and the second check valve's Oil outlet Both are connected with the brake oil cylinder port of the wet brake. The invention can solve the problems of slow response and poor braking sensitivity of the construction machinery braking system.

Owner:柳工(常州)矿山机械有限公司

Automobile brake system automatic adjustment arm

ActiveCN103174778BConstant and consistent brake clearanceSensitive brakesSlack adjustersEngineeringBrake response time

The invention discloses an automatic adjusting arm of an automobile braking system. The automatic adjusting arm of the automobile braking system comprises a swing arm, one end of the swing arm is connected with a control wheel connecting part, a connecting hole is formed in the control wheel connecting part and is composed of a round hole and a rectangular hole which is located in one side, close to the swing arm, of the round hole, an adjusting wheel connecting part is arranged on the outer side of a connection position of the control wheel connecting part and the swing arm, the axis of the adjusting wheel connecting part is perpendicular to both the axis of the swing arm and the axis of the connecting hole, a connecting plate is connected with one side, away from the adjusting wheel connecting part, between the control wheel connecting part and the swing arm, and a connecting wall is arranged between the control wheel connecting part and the adjusting wheel connecting part. Through the automatic adjusting arm, the fact that all wheel braking appliances have constant and consistent braking clearances can be ensured, braking of a finished automobile is enabled to be more flexible, more balanced and more effective, the braking distance is shortened, even though all wheel braking shoes are inconsistent in thickness and different in abrasive degree, the optimal effectiveness of the braking can also be ensured, braking response time is shortened, and consumption of compressed air is reduced.

Owner:ZHEJIANG LONGHU FORGING

Engine braking device

ActiveCN102003238BReduce volumeReduce weightValve arrangementsMachines/enginesExhaust valveDrive wheel

The invention relates to a novel engine braking device which comprises an exhaust valve control mechanism, wherein the exhaust valve control mechanism comprises a driving force input cam, a cam driven wheel, a rocker arm and a rocker arm shaft; the driving force input cam is arranged outside the cam driven wheel; the other end of the rocker arm is provided with a vertical guide piston, a horizontal drive piston and a vertical braking plunger; two connecting rods are arranged in the guide piston; the convex spherical surface at the upper end of the upper connecting rod is matched with the concave spherical surface of a valve clearance adjusting screw; the convex spherical surface at the lower end of the lower connecting rod is matched with the concave spherical surface of the braking plunger; and a valve rod connecting element of an exhaust valve is arranged below the braking plunger. The driving force input cam periodically transfers the power of an engine to the rocker arm and controls a clearance between the rocker arm and the valve rod connecting element of the exhaust valve by utilizing an electromagnetic valve, thereby realizing the switch of two states of brake and normal work, reducing the size and the weight of a brake and having no high oil pressure and leakage, deformation and load fluctuation caused by the high oil pressure.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

A fine-pressed brake shoe and its preparation method

Owner:广东方盈汽车部件实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com