Compression release type engine cylinder internal braking device

A technology for engine cylinders and braking devices, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve problems such as delay in opening and closing, impact on vehicle braking performance, cracking of hydraulic oil chambers, etc., to achieve volume reduction and weight, fast response, and improved braking power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

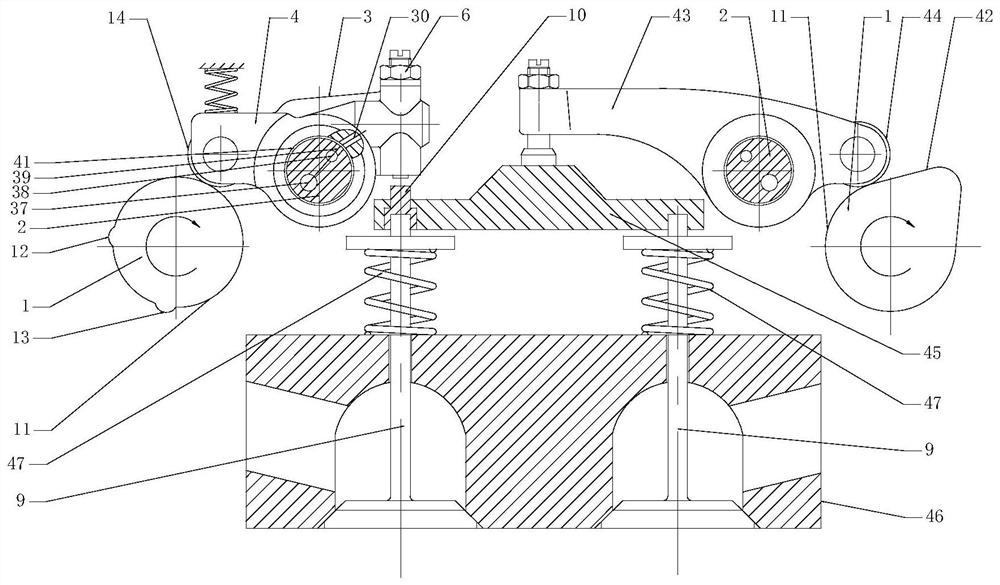

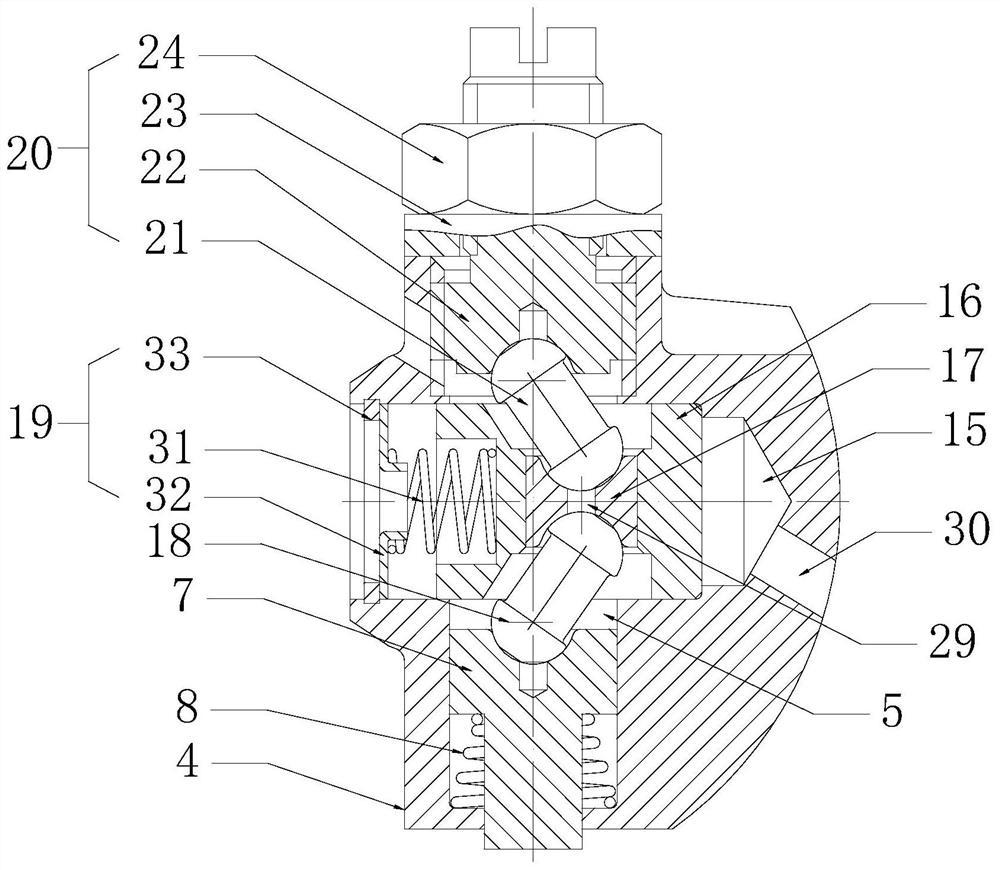

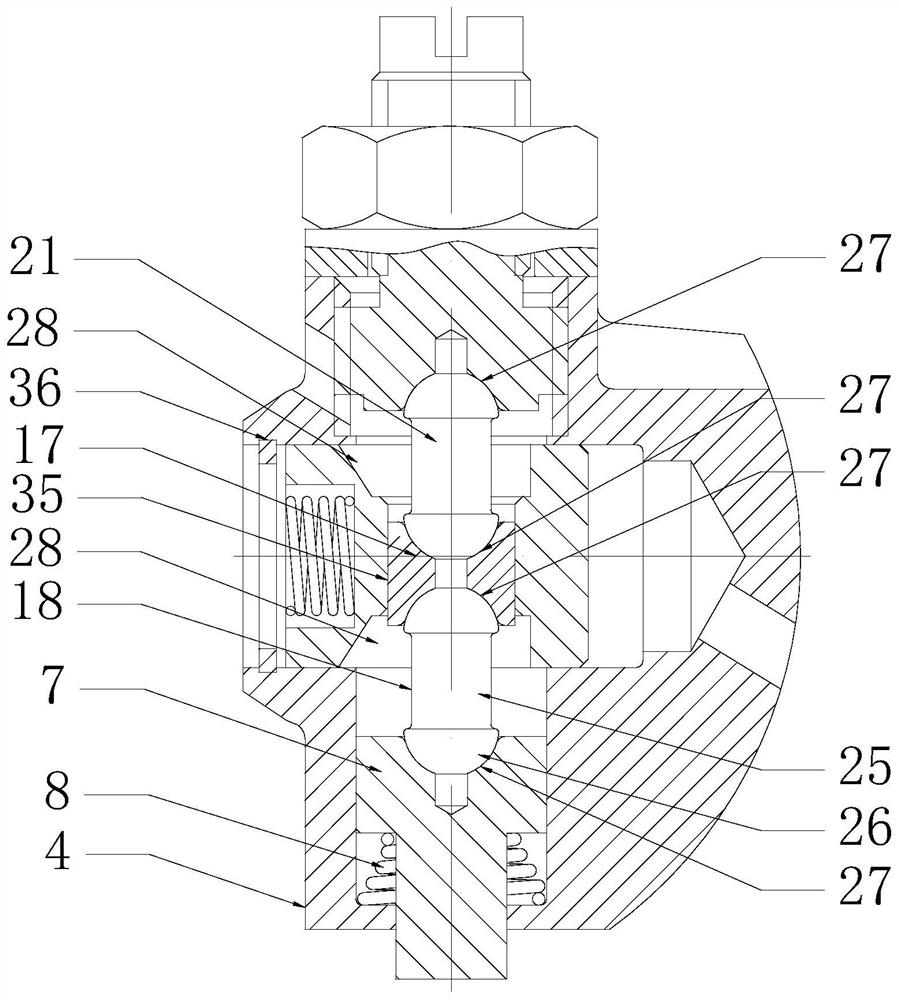

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

[0026] see Figure 1 to Figure 5 The present invention provides a compression-release type engine in-cylinder brake device, which includes a driving force input camshaft 1, and a brake rocker arm assembly 3 driven by the driving force input camshaft 1 to rotate and swing around a rocker arm shaft 2. The brake rocker arm assembly 3 includes a brake rocker arm 4 and a valve clearance control mechanism 6 arranged in the mounting hole 5 of the brake rocker arm 4. The valve clearance control mechanism 6 includes a brake plunger 7, a brake plunger 7 The return spring 8 with upward elastic force and the driving device with axial downward force on the brake plunger 7, the brake plunger 7 is facing the exhaust valve 9, when the brake plunger 7 is at the bottom dead center And when the distance between the brake plunger 7 and the valve cap 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com