Quick-braking engine brake device

An engine braking and fast technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of large inertia, slow response, increased engine height and manufacturing costs of the braking system, and achieve cost reduction and reduction Requirements, effects of volume and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

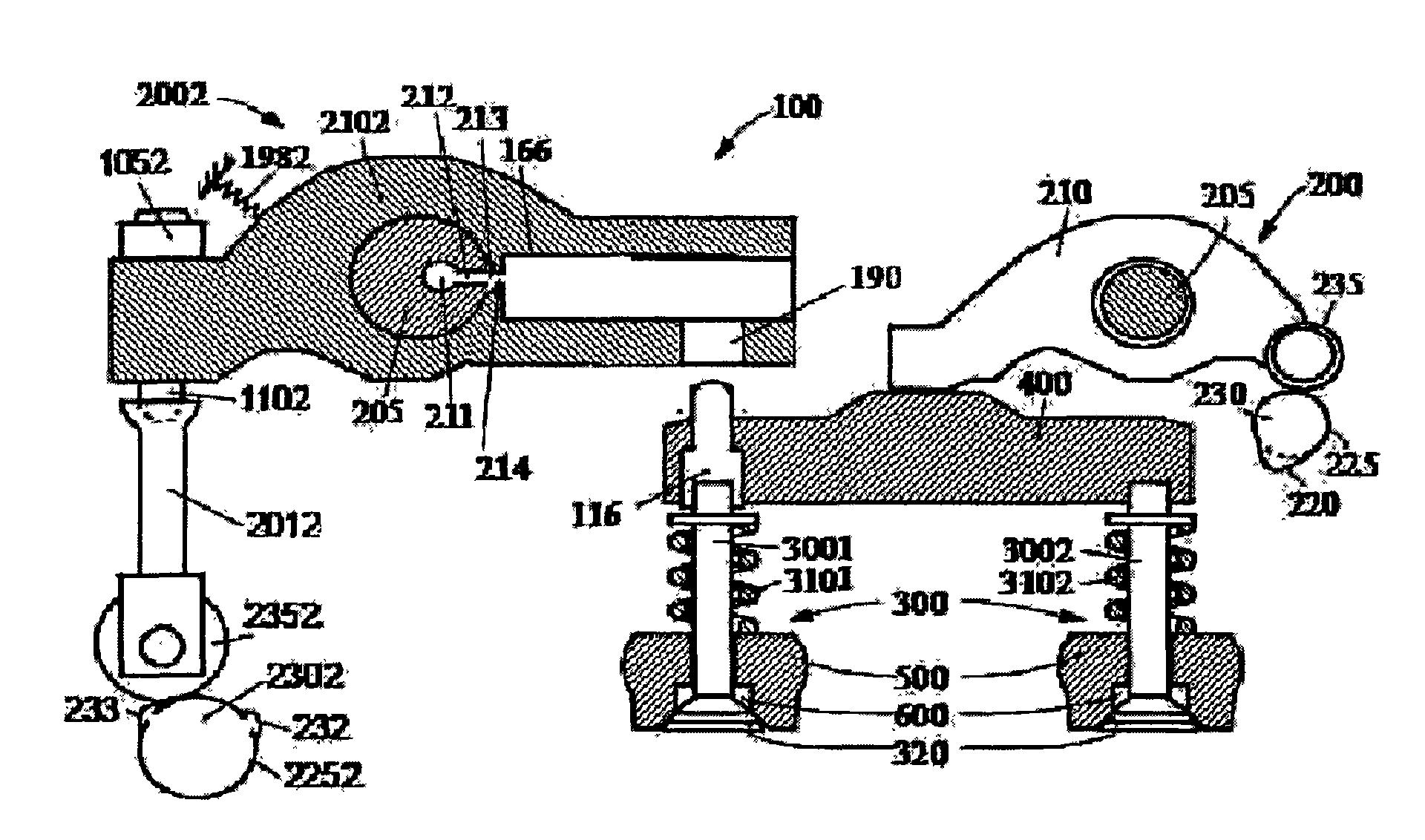

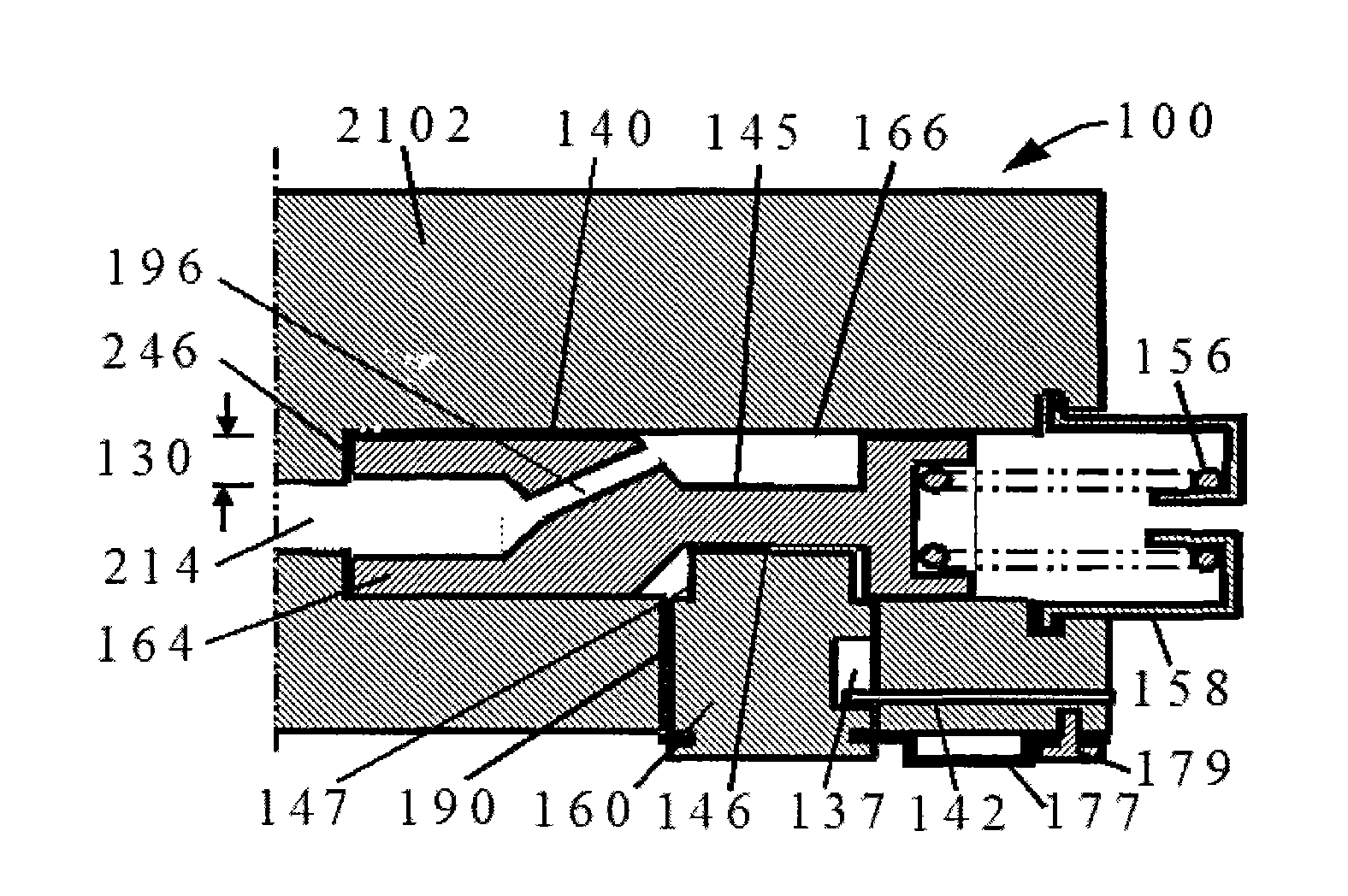

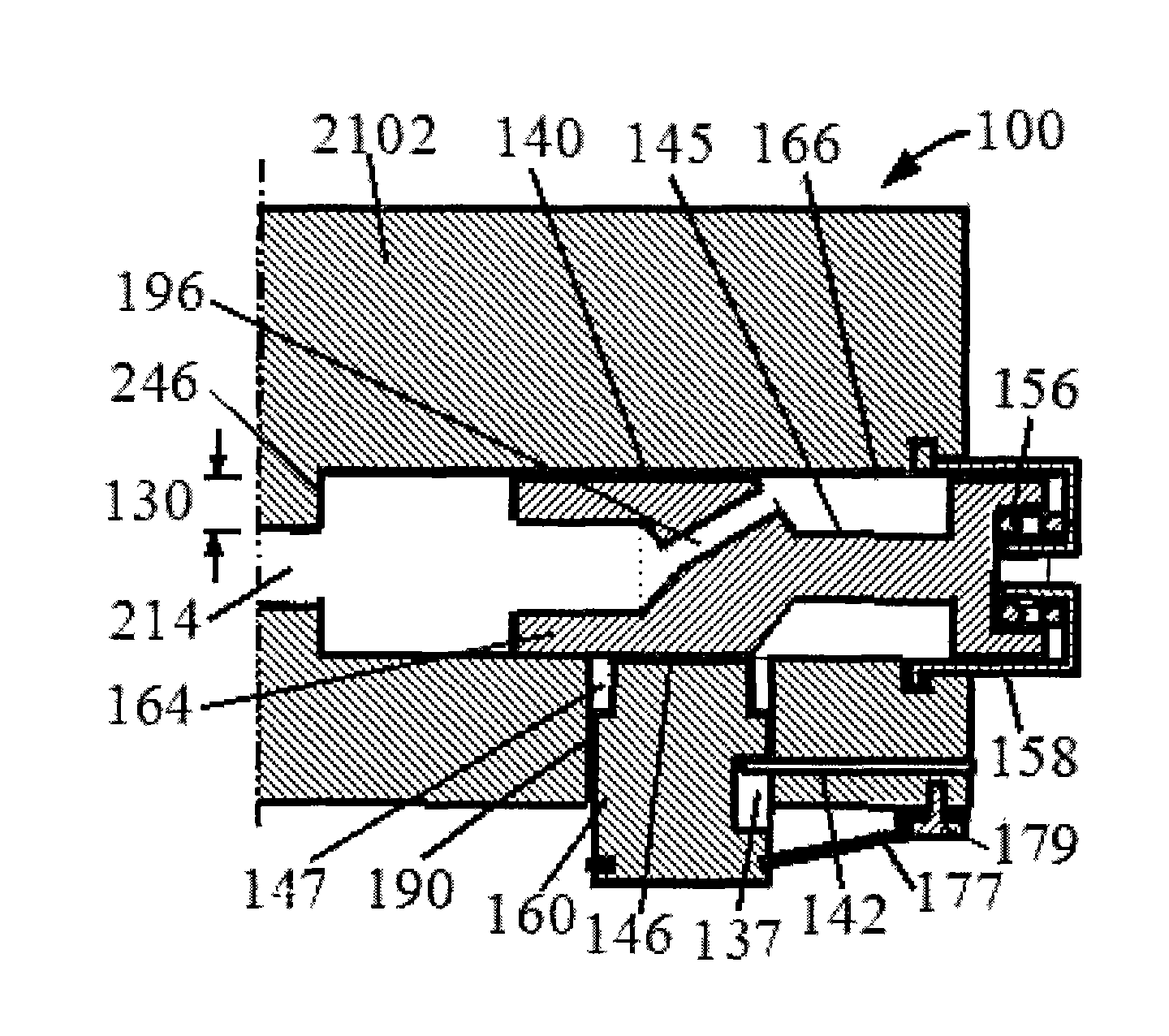

[0026] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, a fast braking engine braking device 100 of the present invention is composed of an exhaust valve control mechanism 2002, wherein the exhaust valve control mechanism 2002 is composed of a driving force input cam 2302, a cam follower 2352 , a push rod 2012, a rocker arm 2102 and a rocker shaft 205, the middle part of the rocker arm 2102 is set on the rocker shaft 205, one end of the push rod 2012 is connected with one end of the rocker arm 2102, and the Cam follower 2352 is arranged in the other end of push rod 2012, and described driving force input cam 2302 is arranged outside cam follower 2352, and the rotation circle of protruding part 232,233 in the driving force input cam 2302 and cam follower 2352 The outer circumference of the rocker arm 2102 is provided with a bias return spring 1982, the rocker arm 2102 is provided with a liquid channel 214, and the other end of the rocker arm 2102 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com