Driving device of engine brake

A driving device and brake technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of large inertia of the braking system, slow response, increased engine height and manufacturing cost, etc., to reduce costs and reduce requirements. , the effect of reducing the braking reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

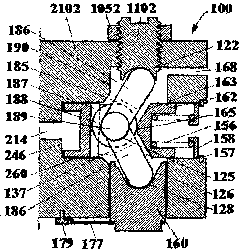

[0023] Such as figure 1 As shown, a driving device 100 for an engine brake of the present invention is composed of a brake box 2102, an upper connecting rod 186, a lower connecting rod 186 with the same structure, and a driving piston 162, and the driving piston 162 is located in the braking box. In the horizontal piston hole 260 of 2102, it is usually pushed to the left by the return spring 156, and rests on the end surface 246 of the piston hole 260. The other end of the return spring 156 is located on the spring seat 158 , and the spring seat 158 is positioned by the retaining ring 157 fixed on the brake case 2102 . In the middle of the driving piston 162, there is a cutout 137 as a guide groove. The width of the guide groove 137 is approximately the same as the diameter of the upper connecting rod and the lower connecting rod 186. At the left end of the horizontal hole 260, the inclinations of the upper link and the lower link 186 are approximately the same. There is...

Embodiment 2

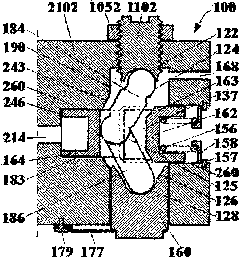

[0028] Such as figure 2As shown, the driving mechanism 100 of this embodiment is an evolution of the first embodiment. The drive pistons include a right drive piston 162 and a left drive piston 164 . In this embodiment, the upper connecting rod 184 and the lower connecting rod 186 are still connected by the spherical surface 125, but there is no spherical body and no guide ring is needed. Right drive piston 162 still has guide groove 137, and the width of guide groove 137 is approximately the same as the diameter of two connecting rods 184 and 186, and the right side of guide groove 137 has two chamfers 163, and left drive piston 164 is positioned at the left end of horizontal hole 183. The inclinations of the upper links 184 and 186 are approximately the same. The brake plunger 160 is located in the vertical piston hole 190 of the brake box 2102, and is connected to the third convex spherical surface at the bottom of the lower connecting rod 186 through the third concave s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com