A fine-pressed brake shoe and its preparation method

A technology of brake shoes and precision pressing, applied in the field of auto parts, can solve the problems of easy deformation of punched and welded brake shoes, large quality of cast brake shoes, unstable casting quality, etc., and achieves easy after-sale maintenance, The effect of high production efficiency and improved product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

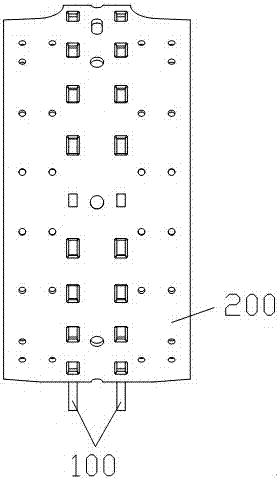

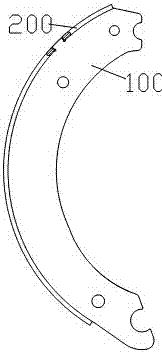

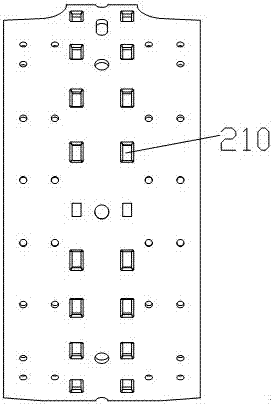

[0033] like Figure 1-4 As shown, the fine pressure type brake shoe includes a rib plate 100 and a panel 200, the rib plate 100 is arc-shaped, and the mounting surface of the panel 200 matches the shape of the mounting surface of the rib plate 100; the installation of the rib plate 100 A protruding positioning block 110 is provided on the surface, and a positioning hole 210 penetrating through the panel 200 is provided on the panel 200. The positioning block 110 passes through the positioning hole 210, and the rib plate 100 and the panel 200 are fixedly connected by coining and crimping.

[0034] In order to ensure the firmness of the installation, multiple positioning blocks 110 are provided, and multiple positioning holes 210 are provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com