Bicycle brake feedback mechanism

A bicycle and auxiliary brake technology, applied in the field of bicycle brake feedback mechanism, can solve the problems of slow braking speed of brake pads, easy wear and tear of brake pads, and failure to brake in time, so as to reduce the difficulty of starting, improve the utilization rate, increase the The effect of movable space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

The embodiment of the present application discloses a bicycle brake feedback mechanism.

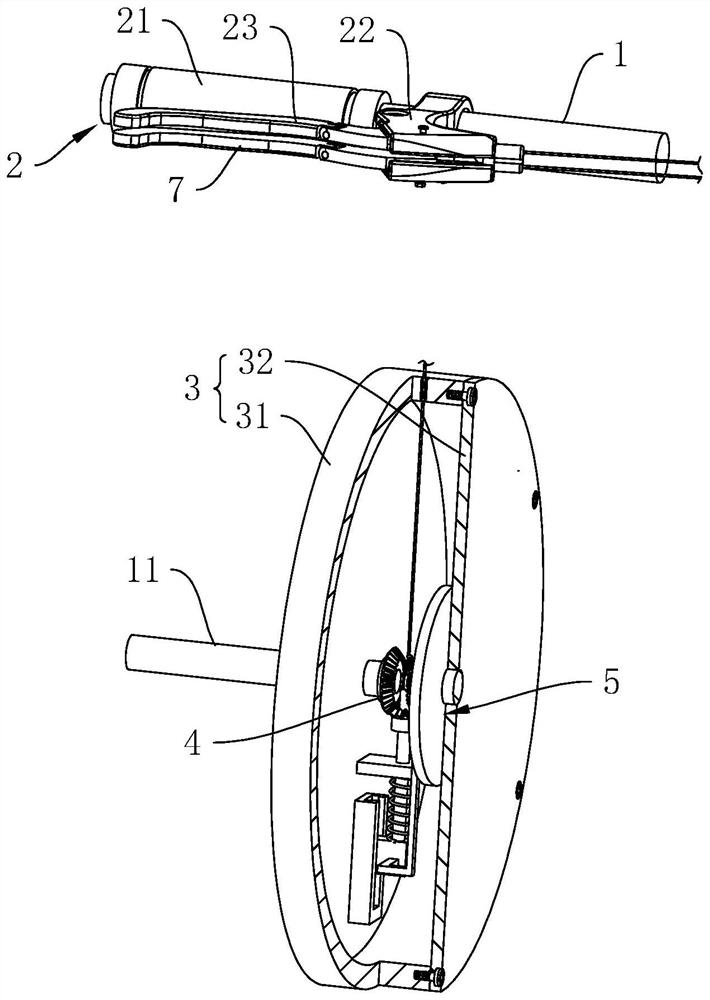

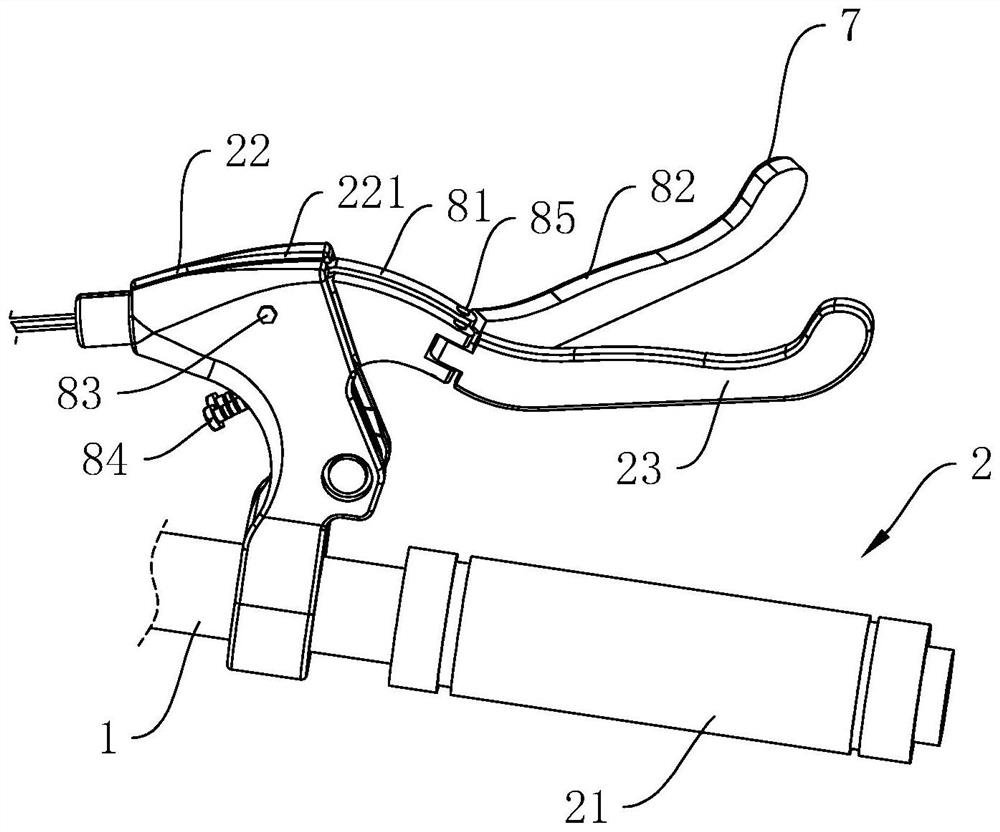

[0036] refer to figure 1 , including the main brake handle 2 installed on the frame 1 and the V-type brake assembly installed on the wheel frame, the main brake handle 2 is connected with the V-type brake assembly, and the main brake handle 2 is used to operate the V-type brake The brake assembly is used to decelerate the bicycle through the V-brake assembly.

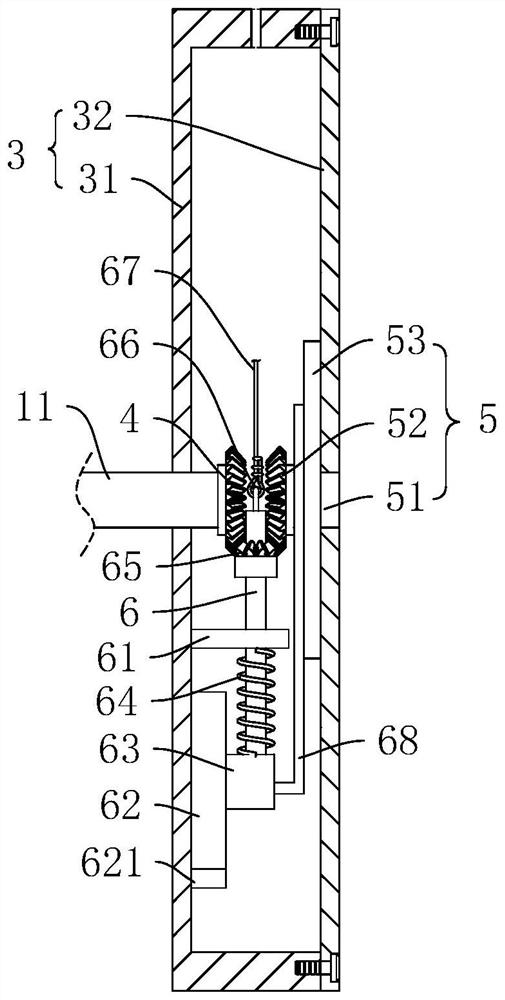

[0037] refer to figure 1 , the brake feedback mechanism also includes a wheel shaft 11 rotatably installed on the wheel frame and an installation box 3 installed on the side of the wheel frame, and the installation box 3 includes a box body 31 fixed on the wheel frame by fasteners and fixed on the wheel frame by fasteners. The box cover 32 on the side of the box body 31, the installation box 3 is set as a hollow cylinder as a whole, one end of the wheel shaft 11 penetrates the center of the box body 31 and is rotatably connected w...

Embodiment 2

refer to Figure 4 , the difference between this embodiment and Embodiment 1 is that the utilization of braking energy is different. In this embodiment, a connecting rod 68 is fixed on the side of the reset block 63 away from the sliding seat 62 , one end of the connecting rod 68 is dislocated and extends above the flywheel shaft 51 , and the end of the connecting rod 68 is fixed with a deceleration plate 69 , and the deceleration plate 69 Arranged in an arc, the center of the deceleration plate 69 is disposed toward the axis of the flywheel shaft 51 .

[0049] The implementation principle of the second embodiment of the present application is as follows: when the auxiliary brake handle 7 is not firmly grasped, the reset block 63 is in the original position under the action of the reset spring 64, and the speed reduction plate 69 is in contact with the outer wall of the flywheel shaft 51 at this time. 69 Lock the flywheel shaft 51 to keep the flywheel 53 stationary during the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com