Patents

Literature

67results about How to "Prevent lock phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precursor electric automobile regenerative braking and ABS matching control method

InactiveCN104192107AAvoid jitterPrevent lock phenomenonElectrodynamic brake systemsBraking systemsAutomotive engineeringBrake force

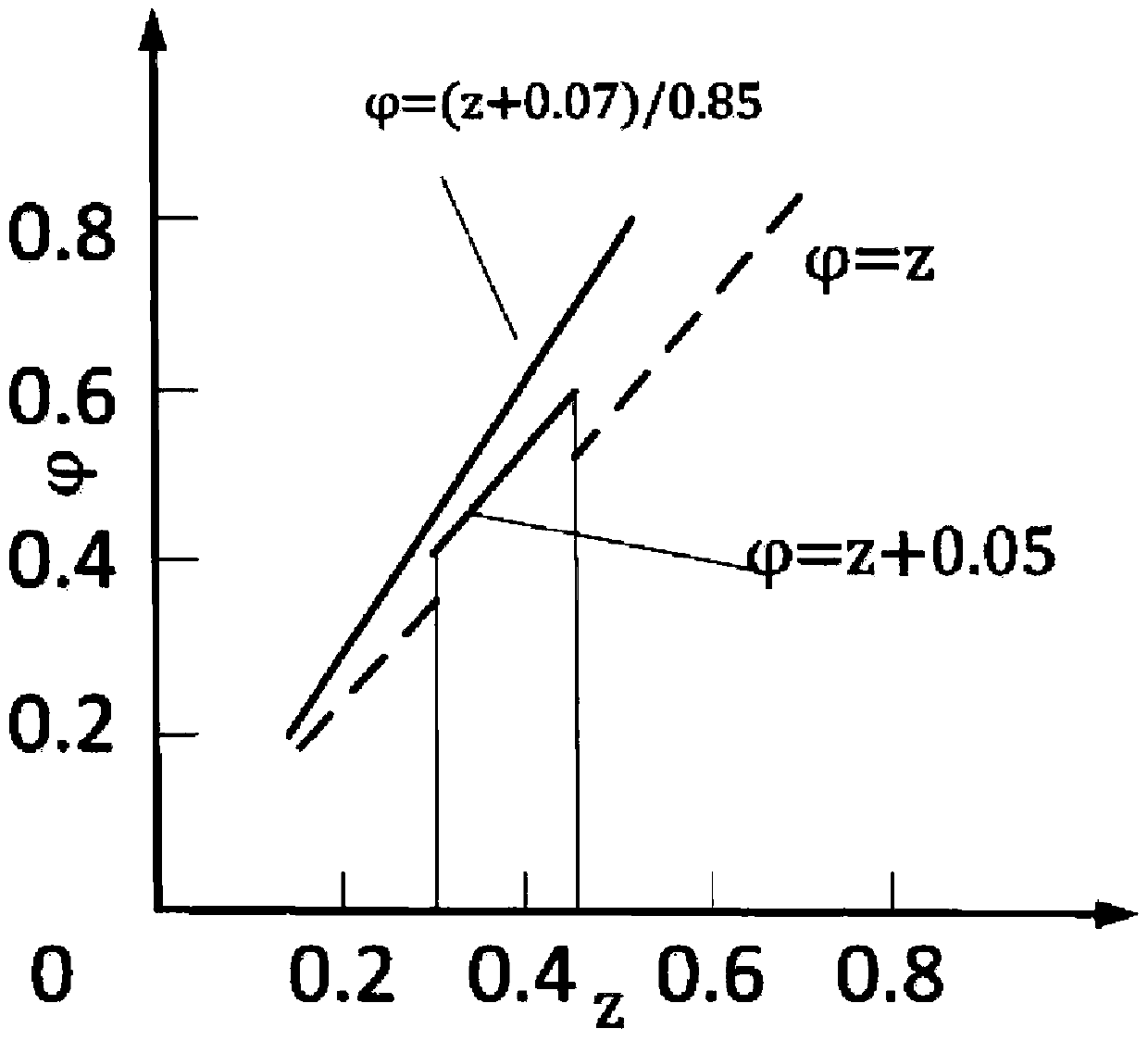

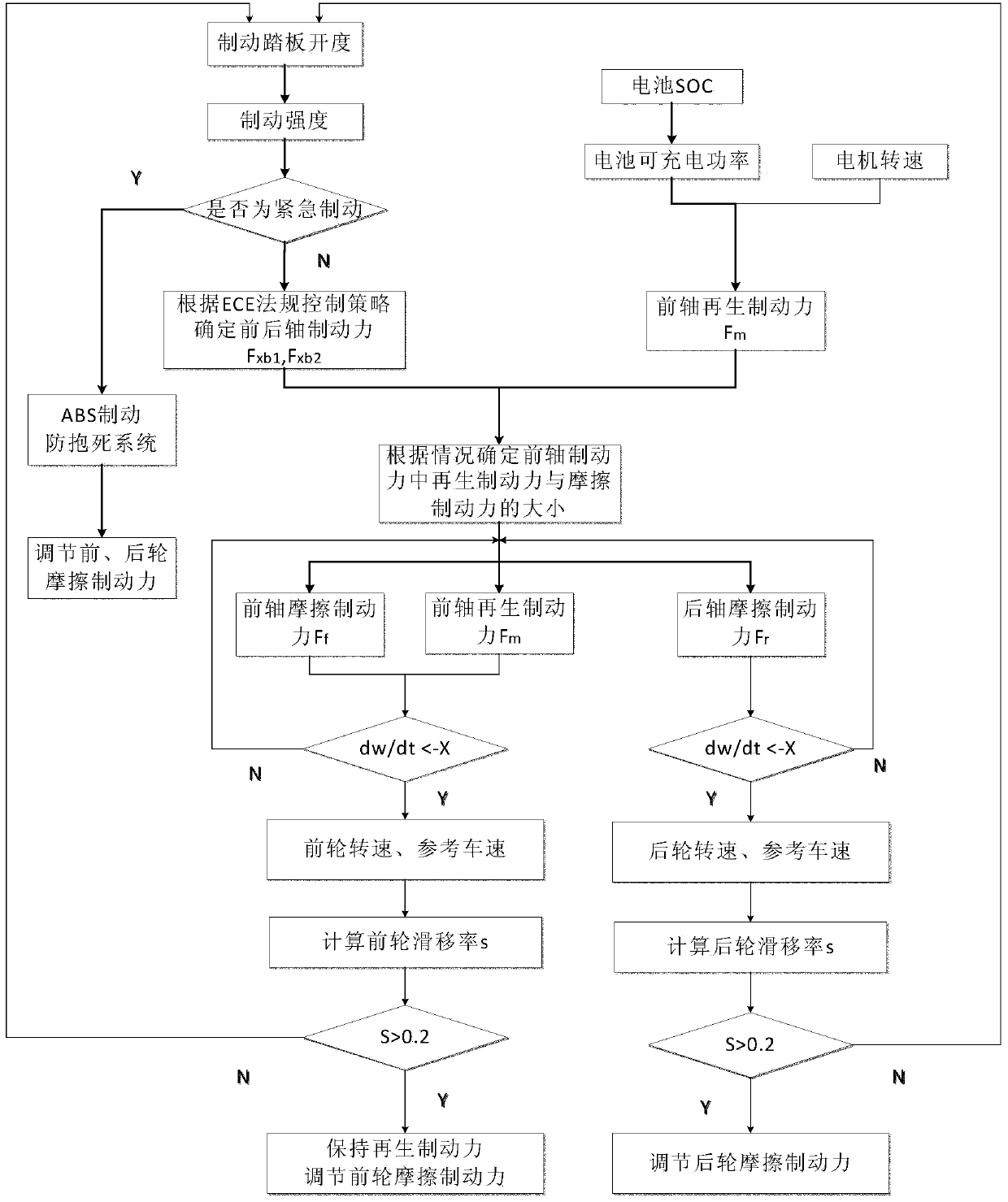

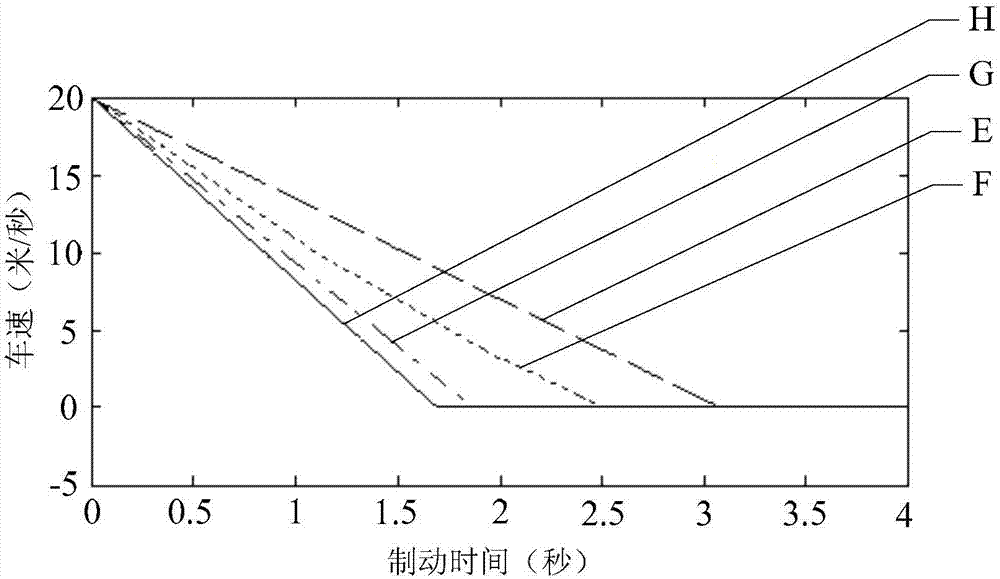

The invention relates to the technical field of electric automobiles, in particular to a precursor electric automobile regenerative braking and ABS matching control method. A controller determines the strength of braking, then whether the braking is emergency braking or not is judged according to the electric liquid composite braking strategy, and if the braking is the emergency braking, an ABS is started directly; if the braking is not the emergency braking, the braking force of a front axle of an automobile and the braking force of a rear axle of the automobile are determined, and the friction braking force of the front axle, the friction braking force of the rear axle and the regenerative braking force of the front axle are determined by combining the maximum regenerative braking force; when it is detected that front wheels arrive at the optimal slip rate, the ABS is started, the regenerative braking force is kept to be constant, the pressure of a wheel braking cylinder is adjusted, the wheel slip rate is controlled to be at the optimal value, and locking of the wheels is avoided; when it is detected that rear wheels are in a locking trend, and the rear wheel slip rate is controlled by using a traditional ABS. According to the method, a regenerative braking system and the ABS are combined to conduct comprehensive control, a part of braking energy can be recycled, the economical efficiency can be improved, and the automobile can obtain better braking performance.

Owner:济宁中科智能科技有限公司

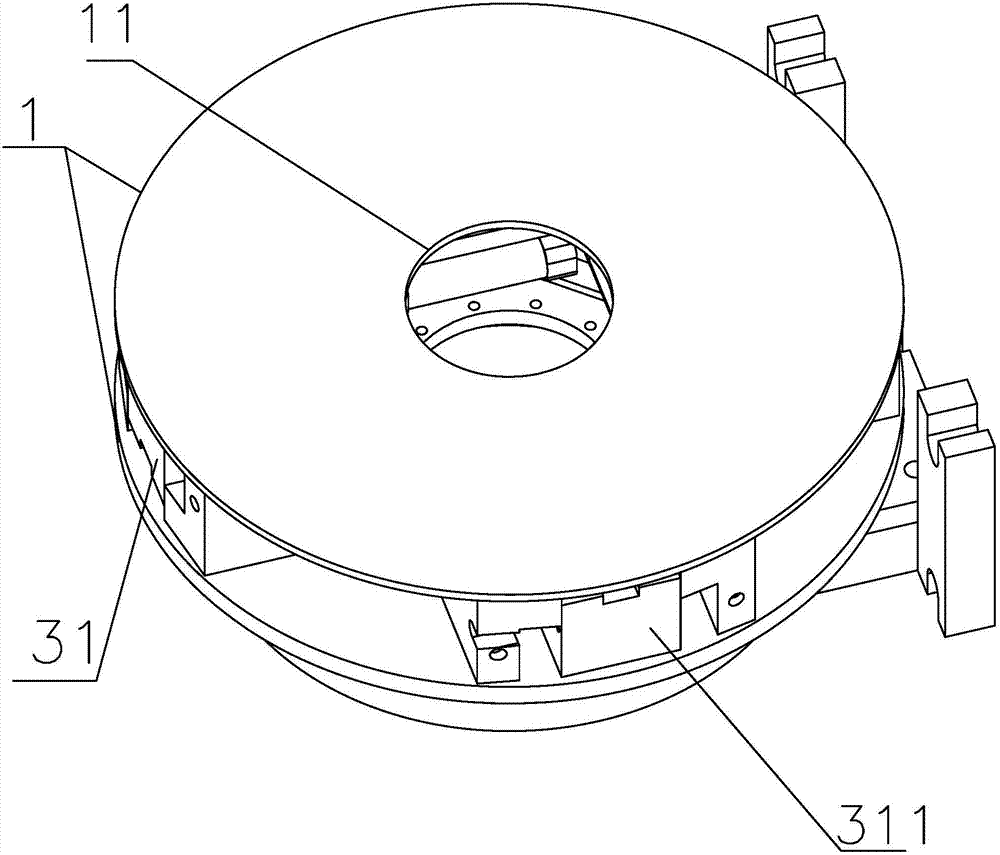

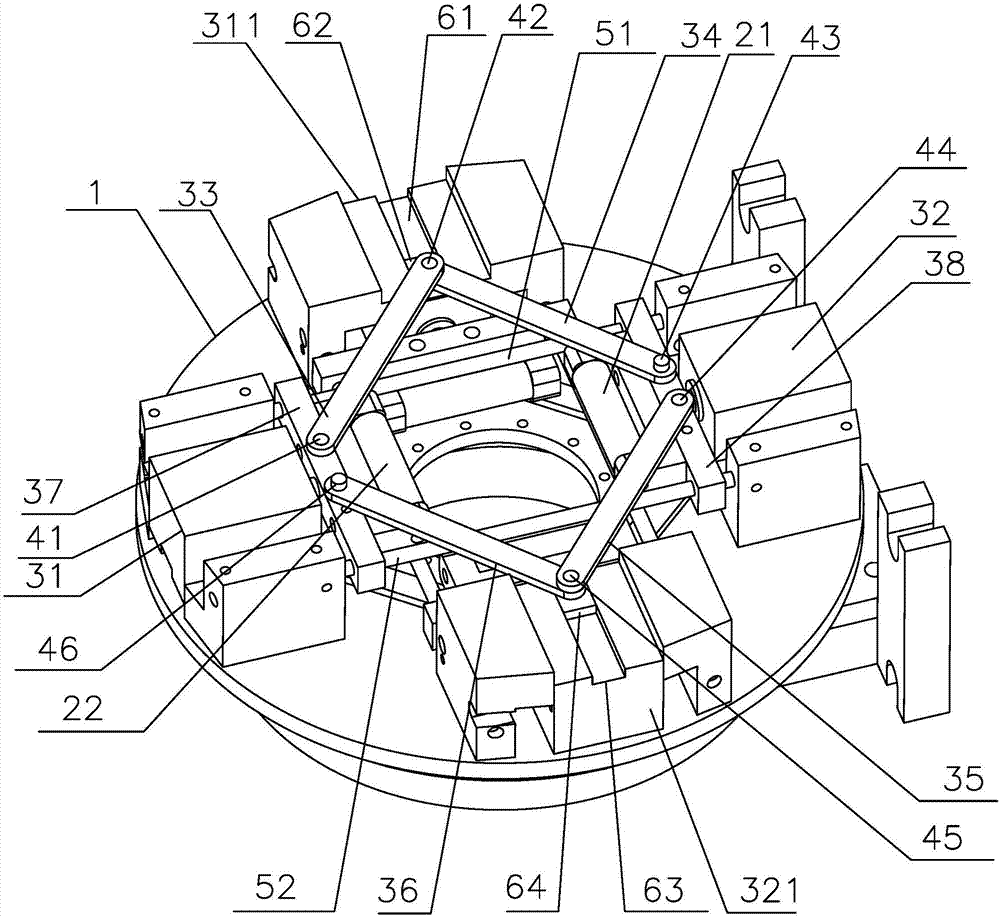

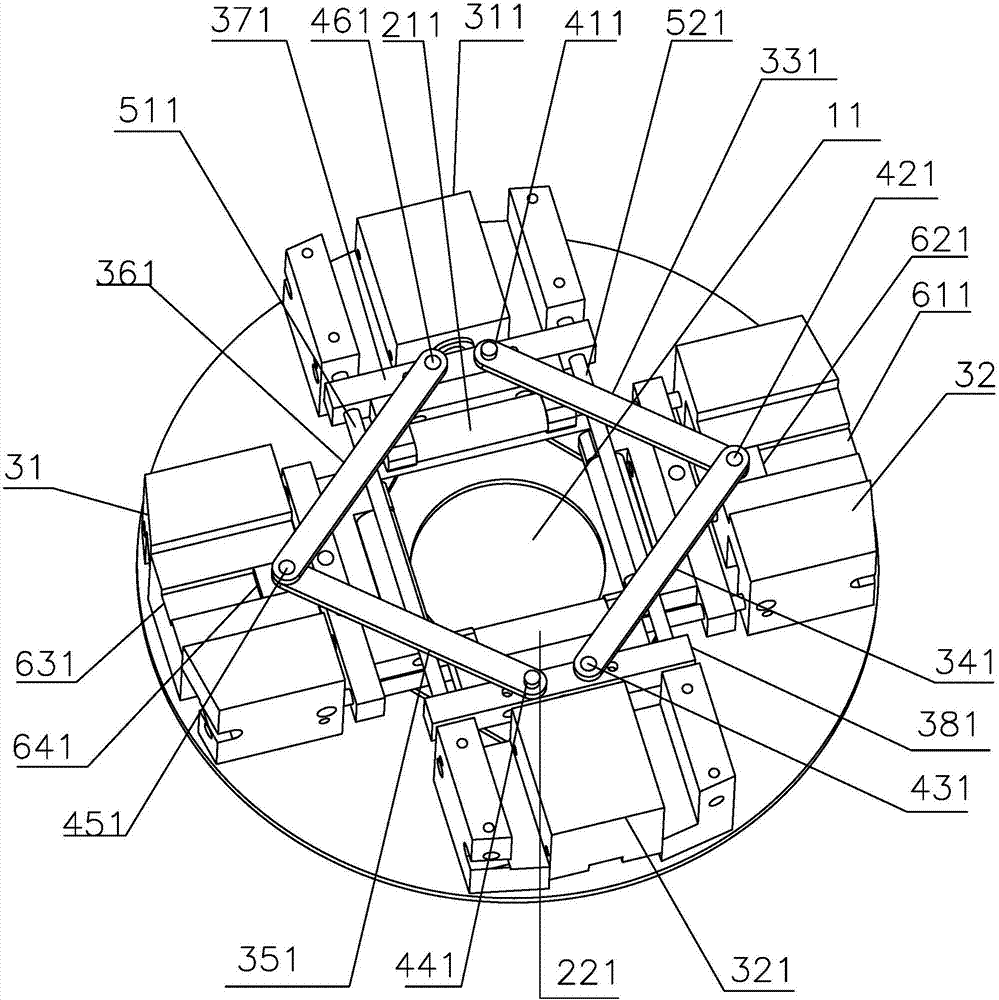

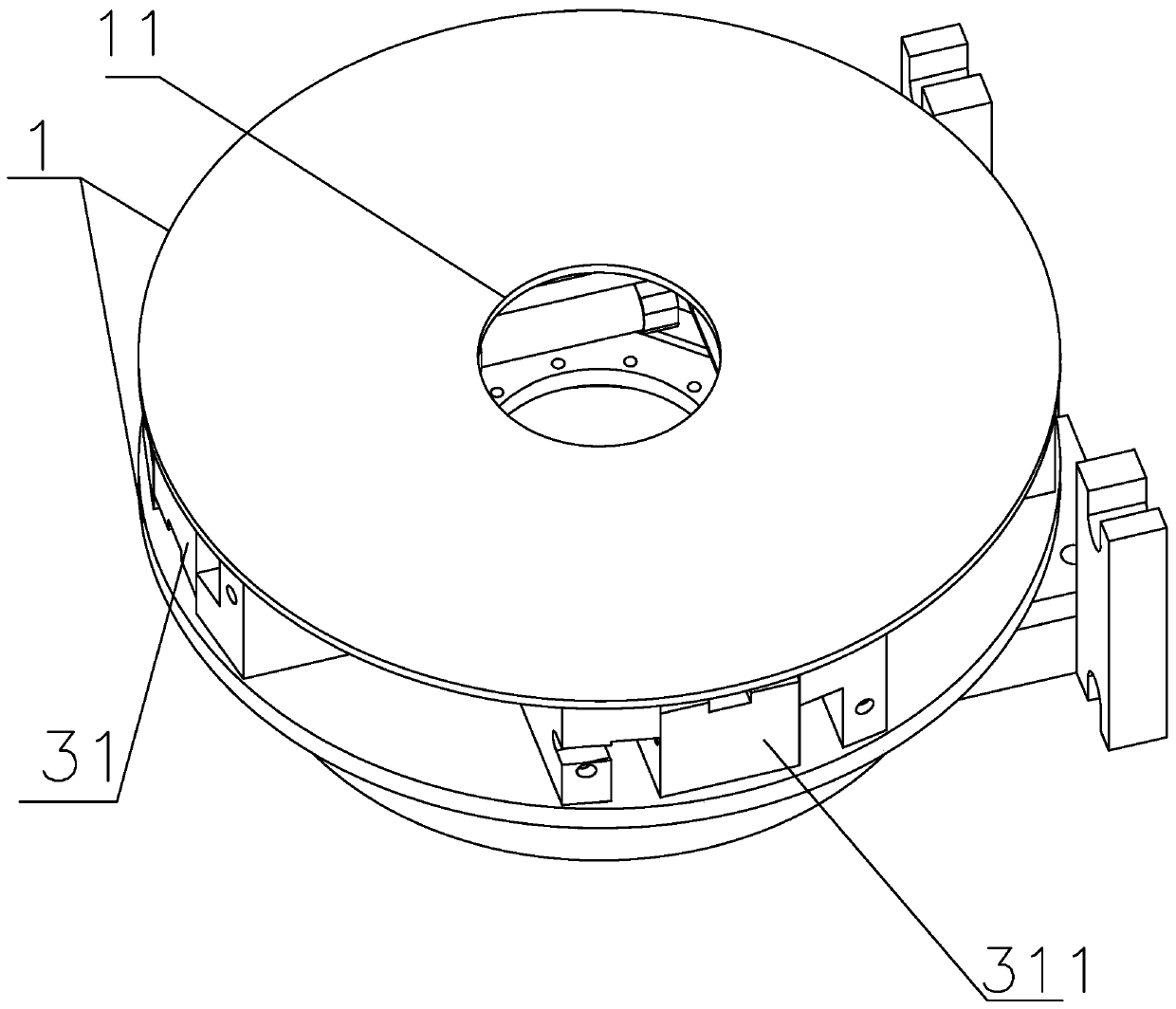

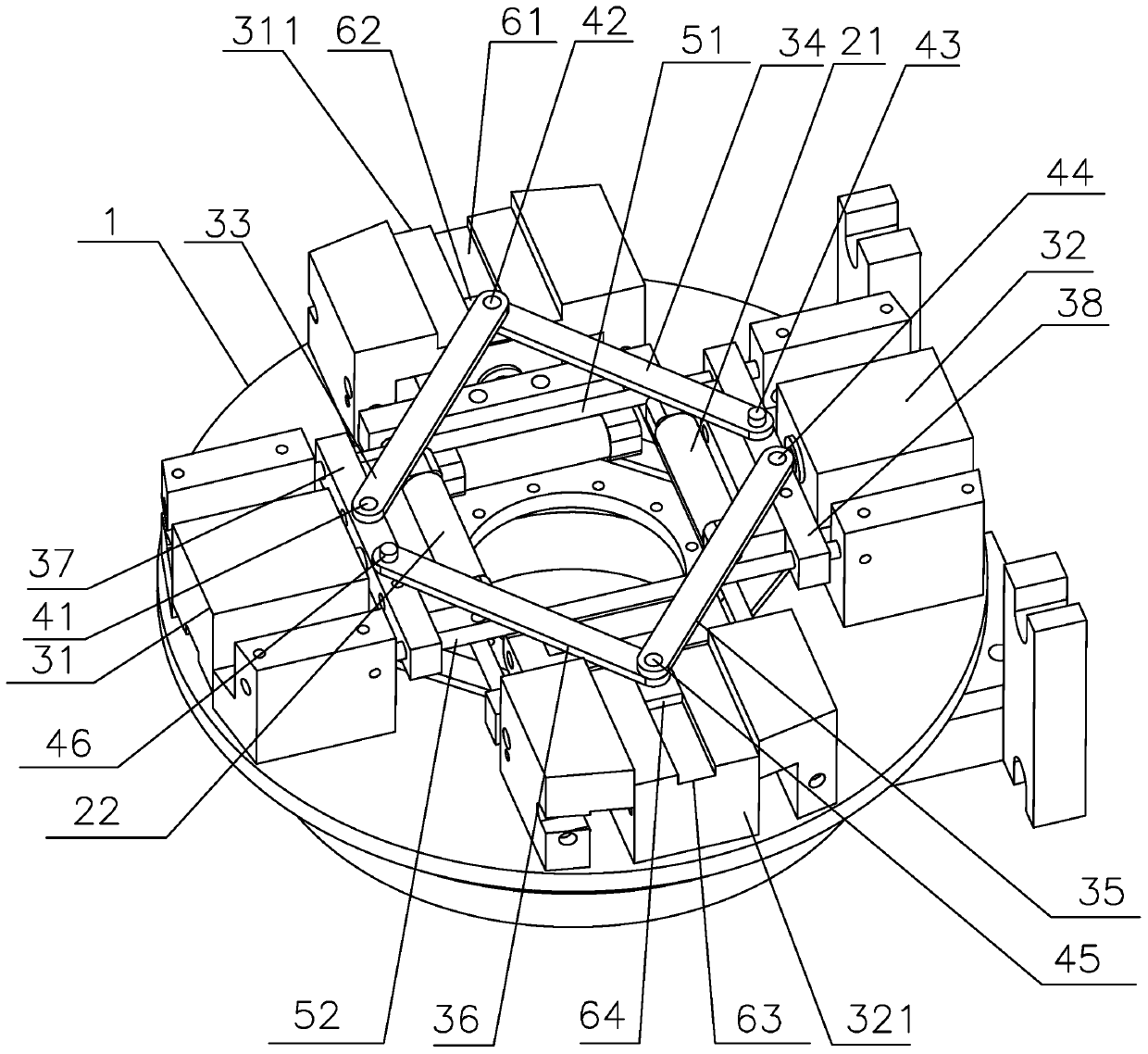

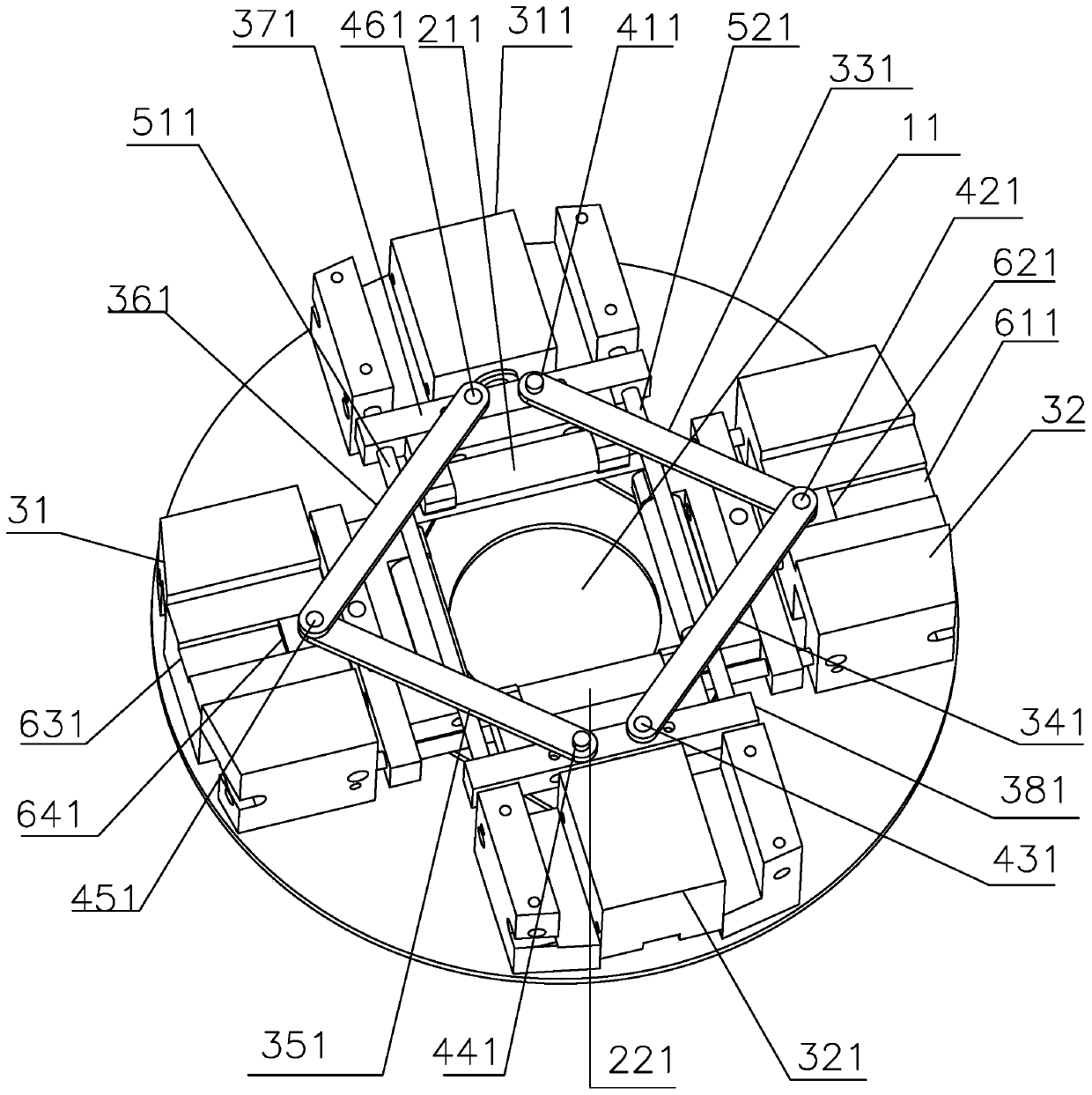

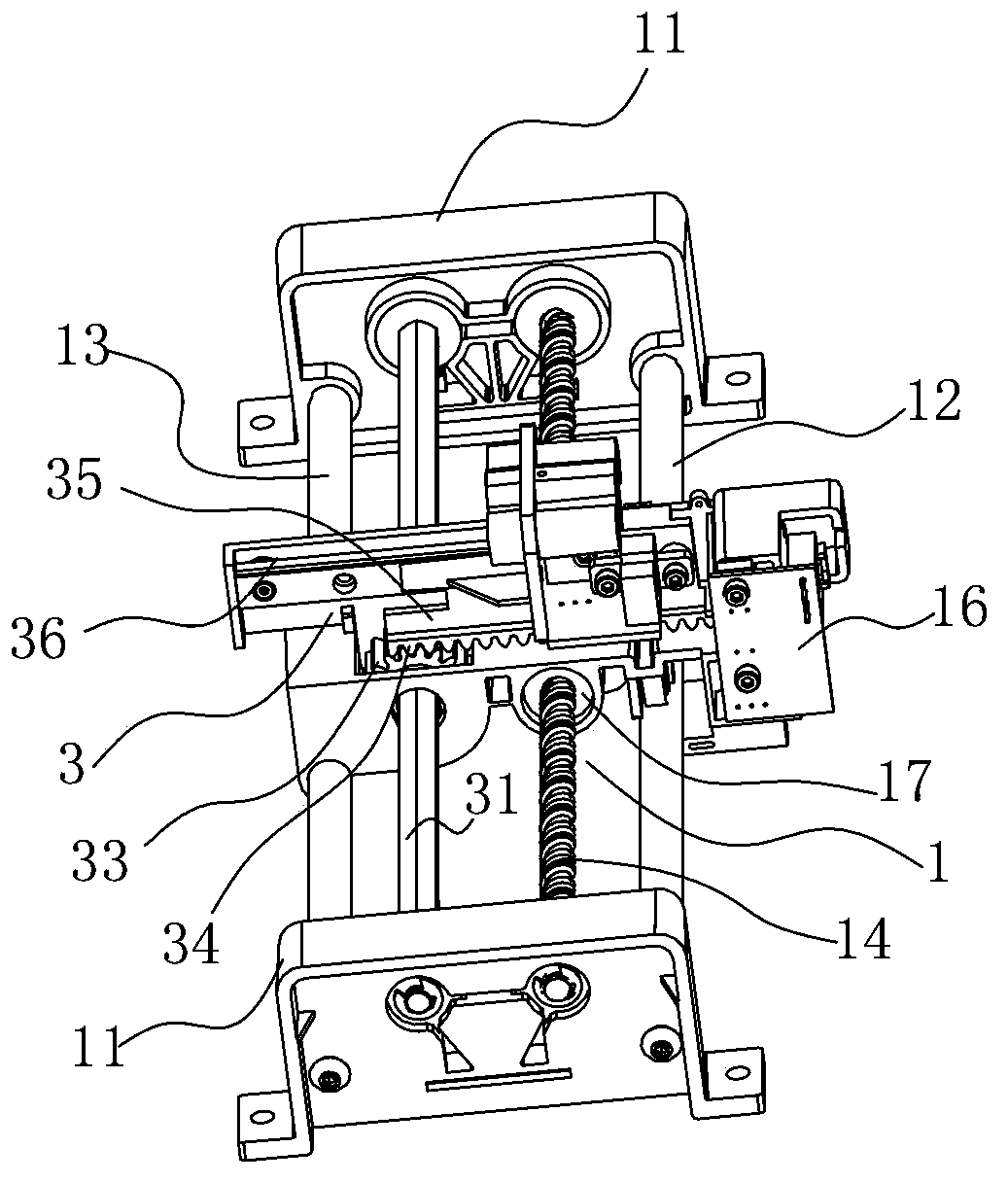

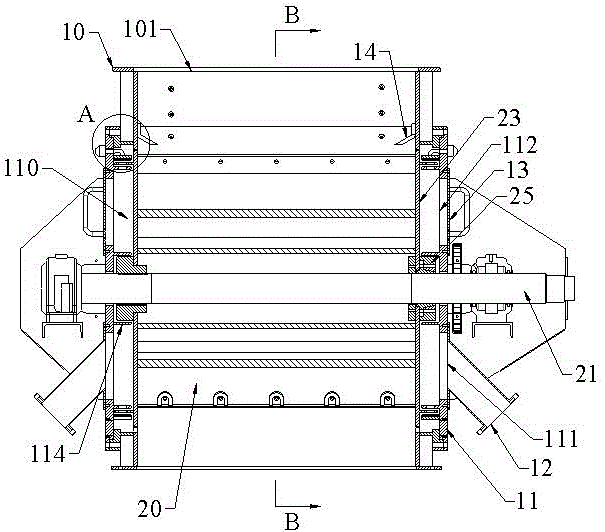

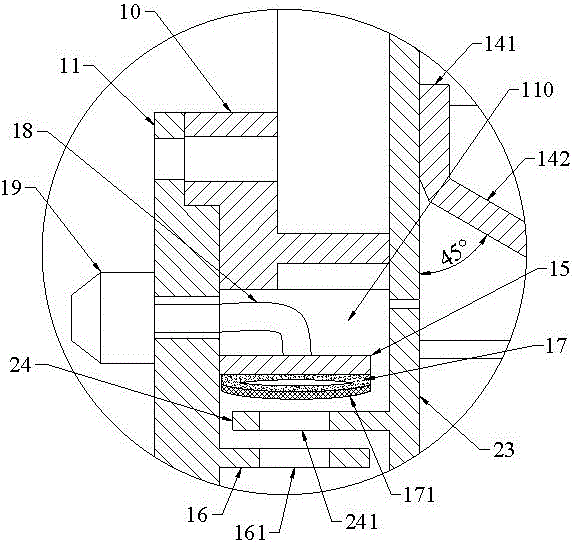

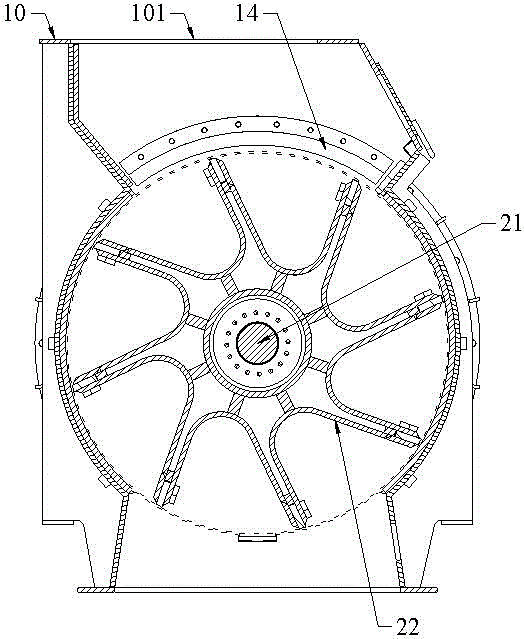

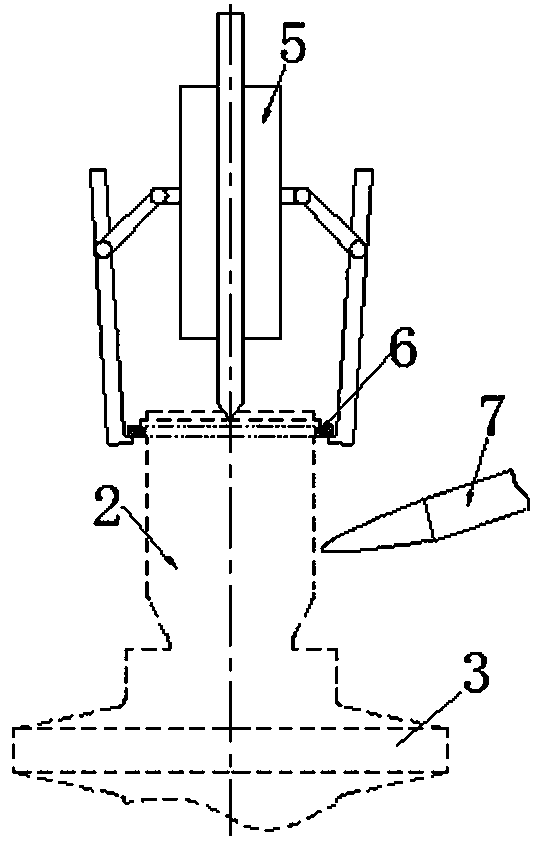

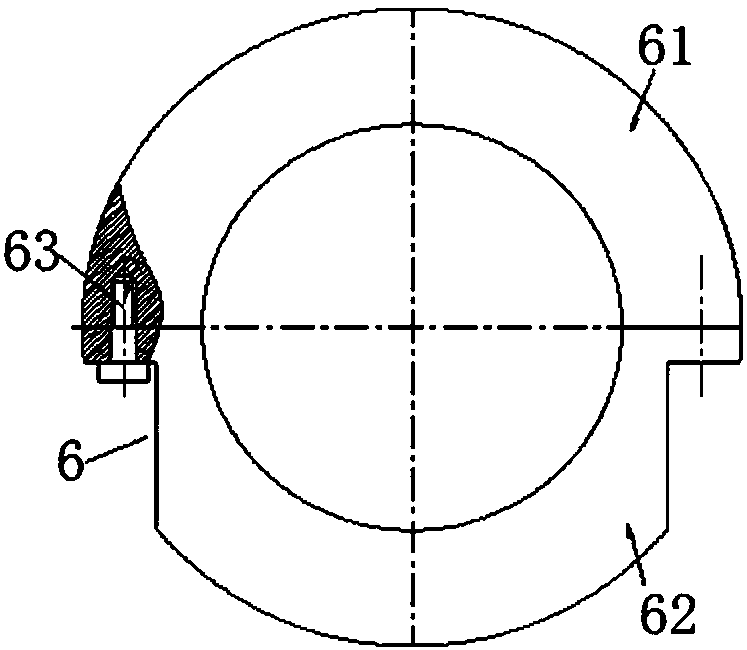

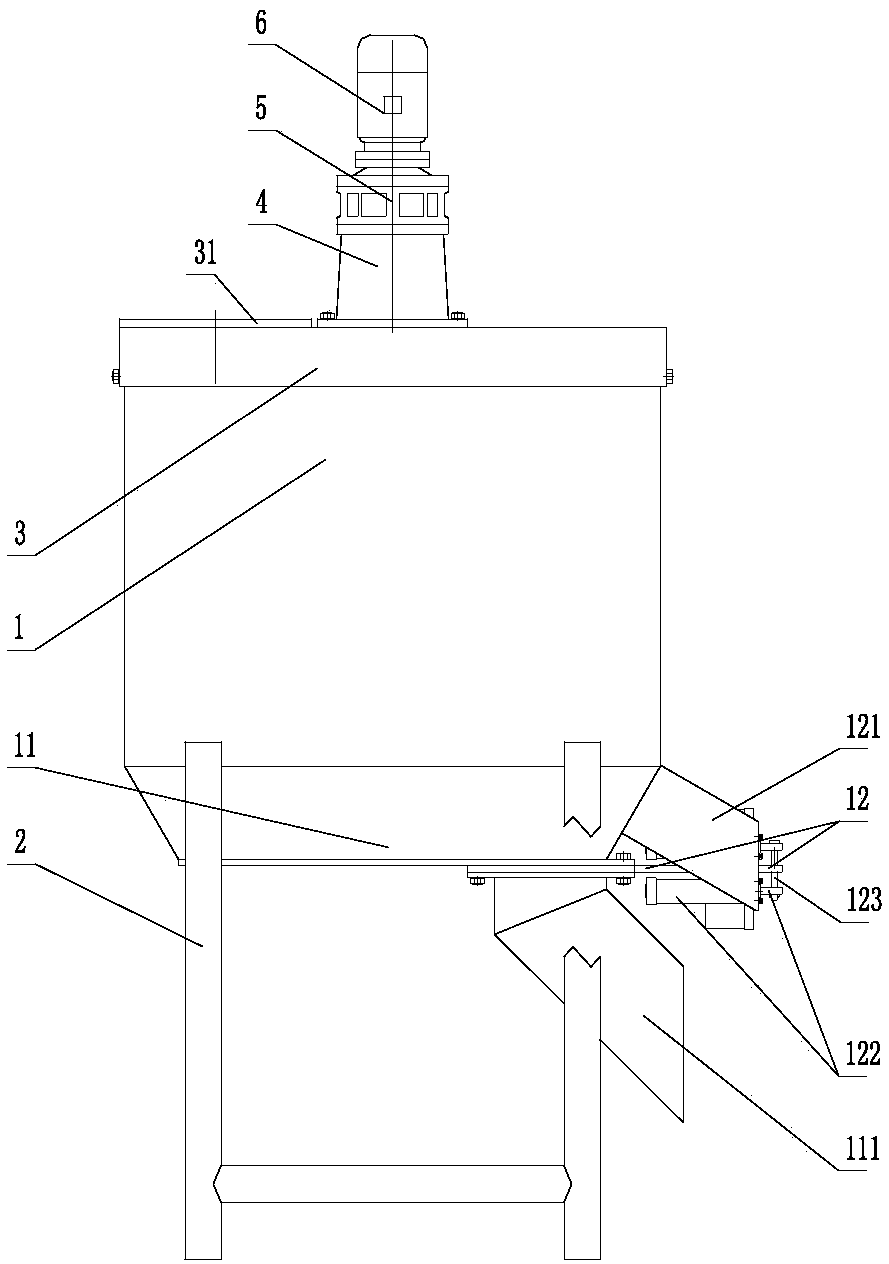

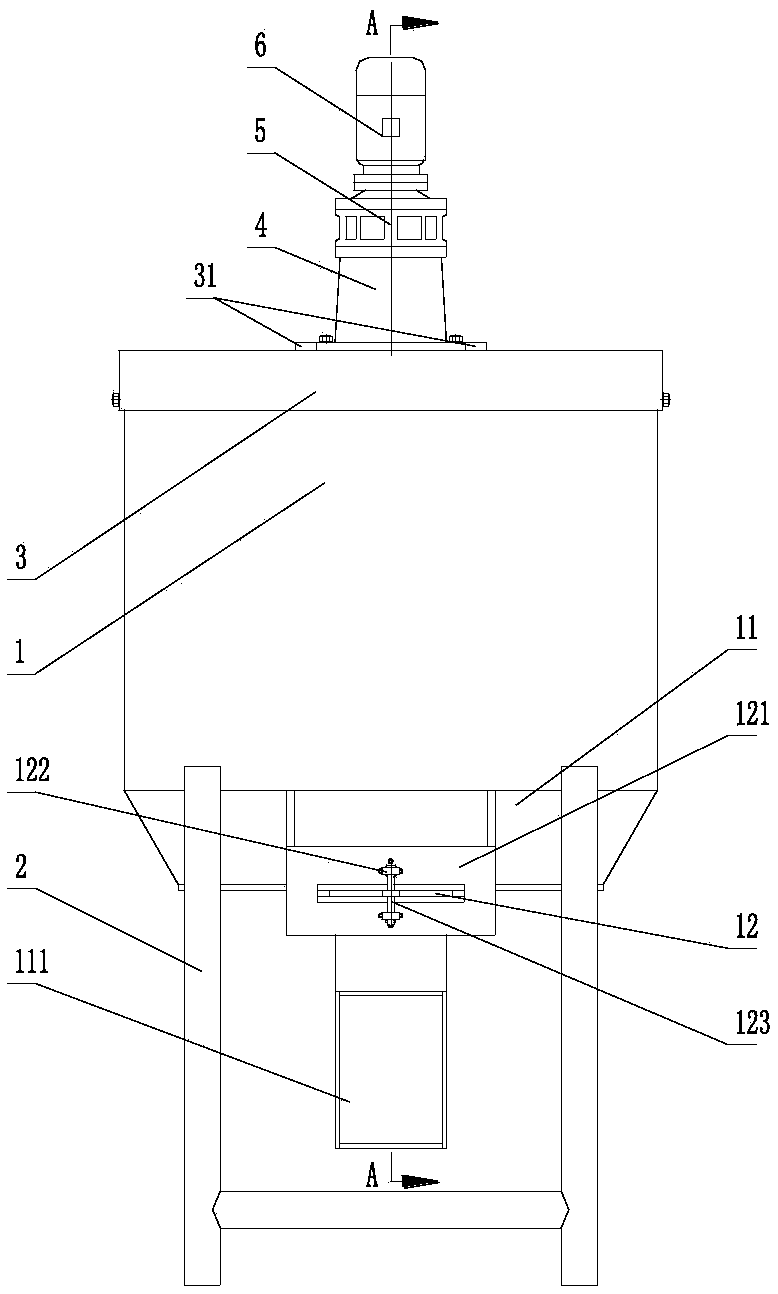

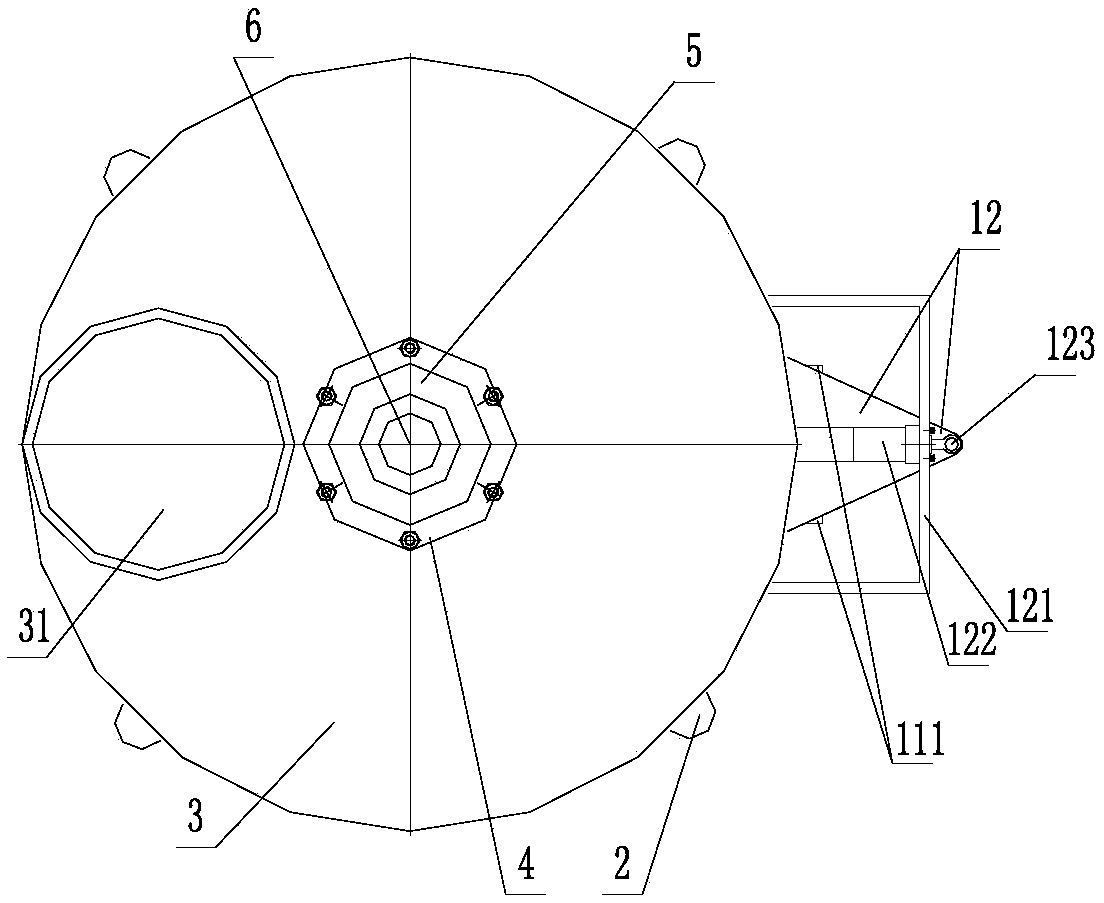

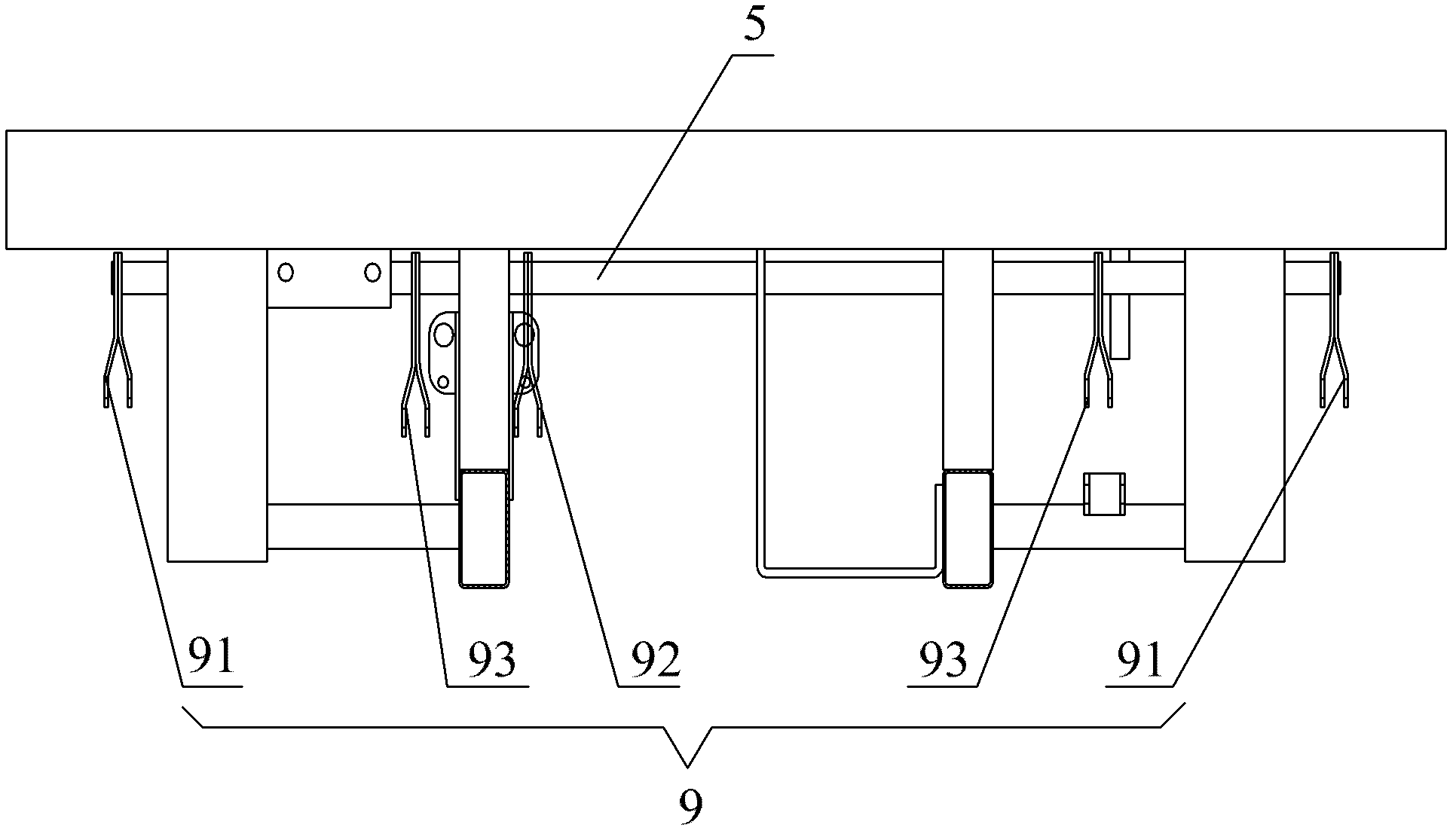

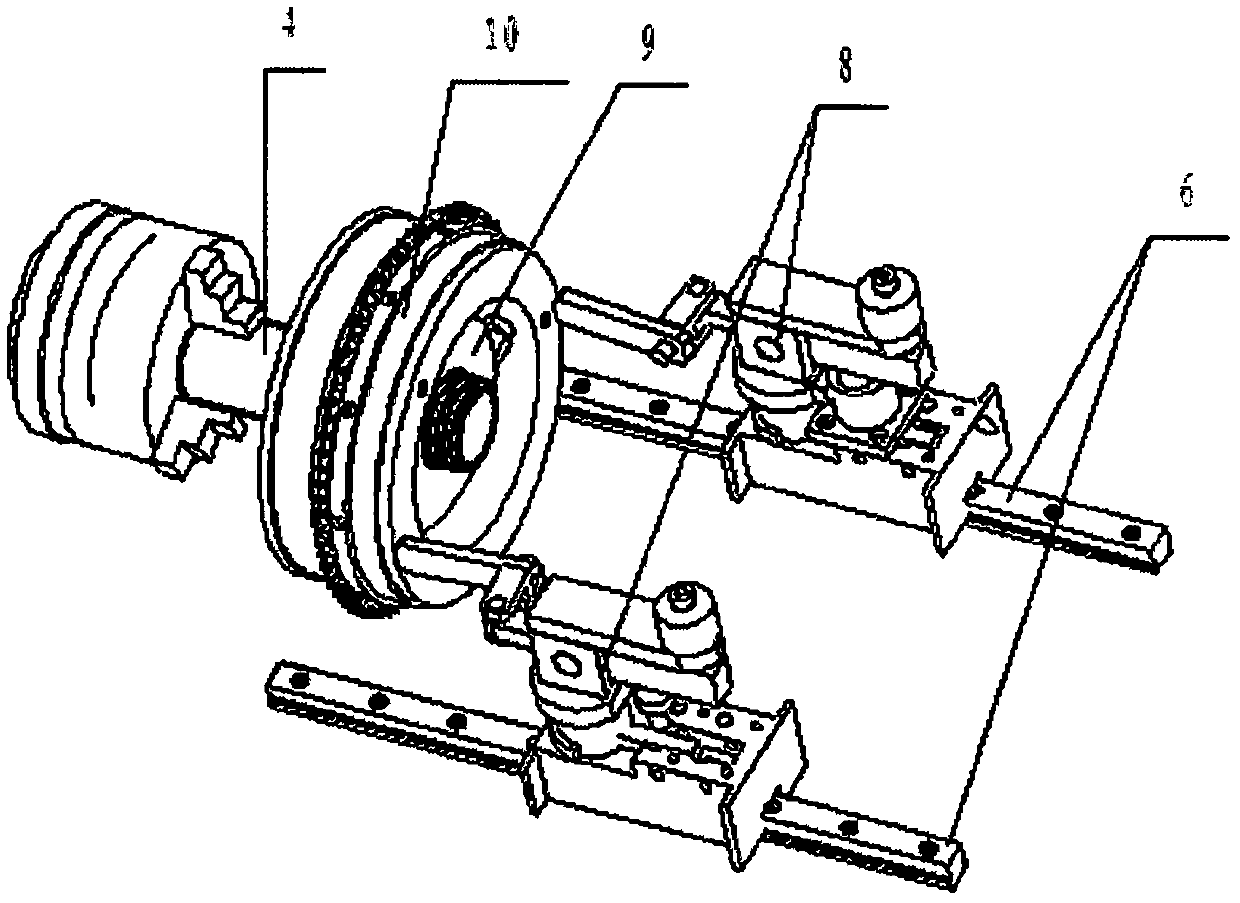

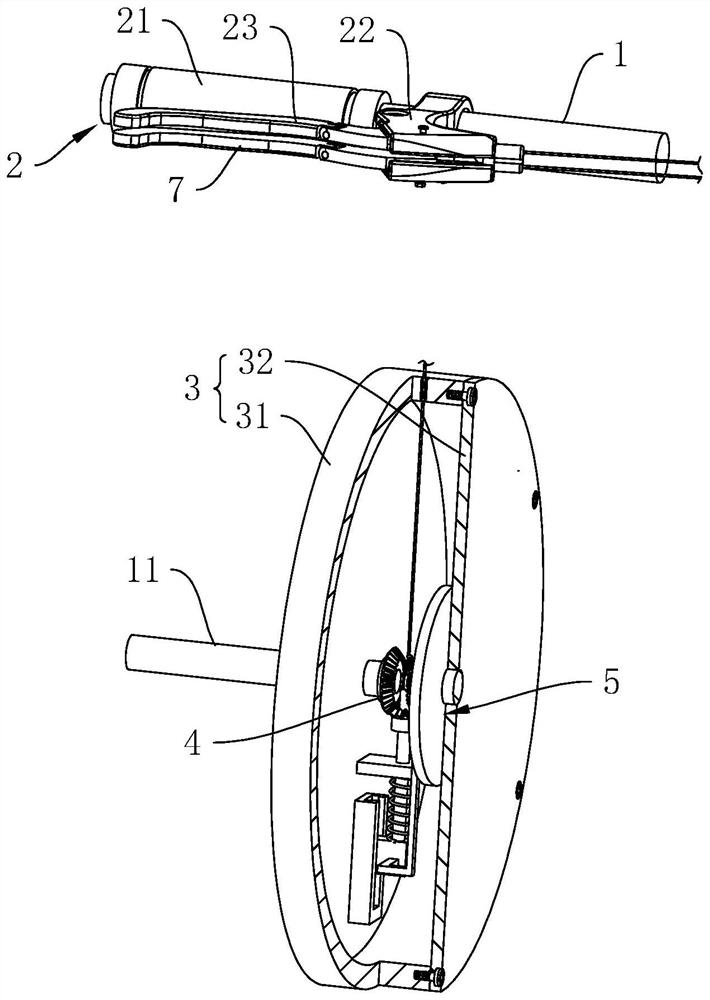

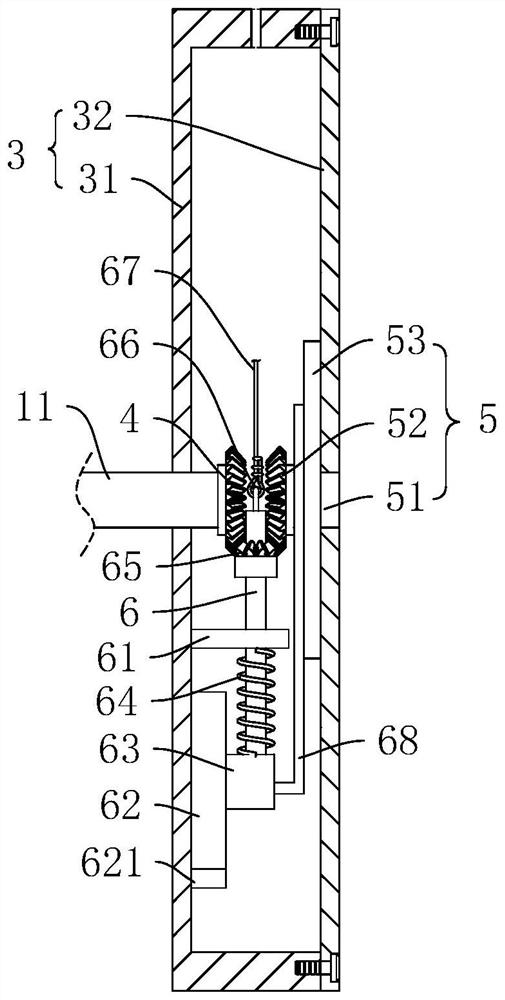

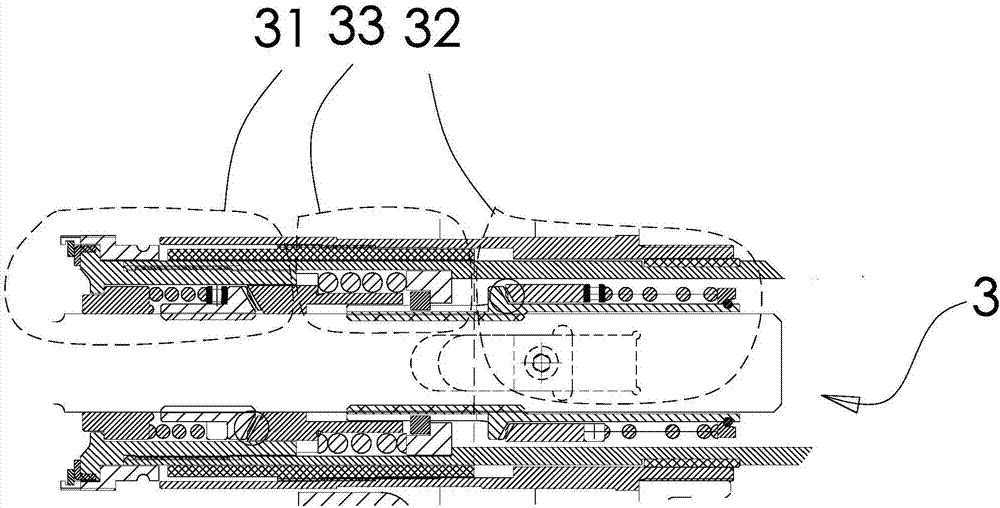

Light-typed pipe cutting chuck

ActiveCN106984842AGood synchronizationGuaranteed accuracyWork clamping meansChucksPipe fittingEngineering

The invention relates to the technical field of pipe fitting fixture, in particular to a light-typed pipe cutting chuck. The chuck comprises a master plate. The middle part of the master plate is provided with a through hole, wherein pipe fittings can penetrate through the through hole; a pneumatic clamp is arranged on the master plate, wherein the pneumatic clamp can hold the pipe fittings penetrating through the through hole. The pneumatic clamp comprises a plurality of pairs of clamp bars and a double hinged type clamping rod pneumatic drive mechanism which independently controls the same or opposite movement of each pair of the clamp bars. According to the light-typed pipe cutting chuck, through four connecting rods (double hinged type), the good synchronism of a first cylinder and a second cylinder can be ensured; the precision is greatly protected; most of materials of the light-typed pipe cutting chuck are aluminum materials, thus the weight is reduced at least 65% compared with the weight of the conventional structure using steel materials; the existing T-typed slot is replaced by a guide rod, thereby avoiding the phenomenon of the claw locking because of the dust accumulation in the T-typed slot; movable structures are all placed outside; the fault is judged easily; the maintenance is more convenient.

Owner:俞雪清

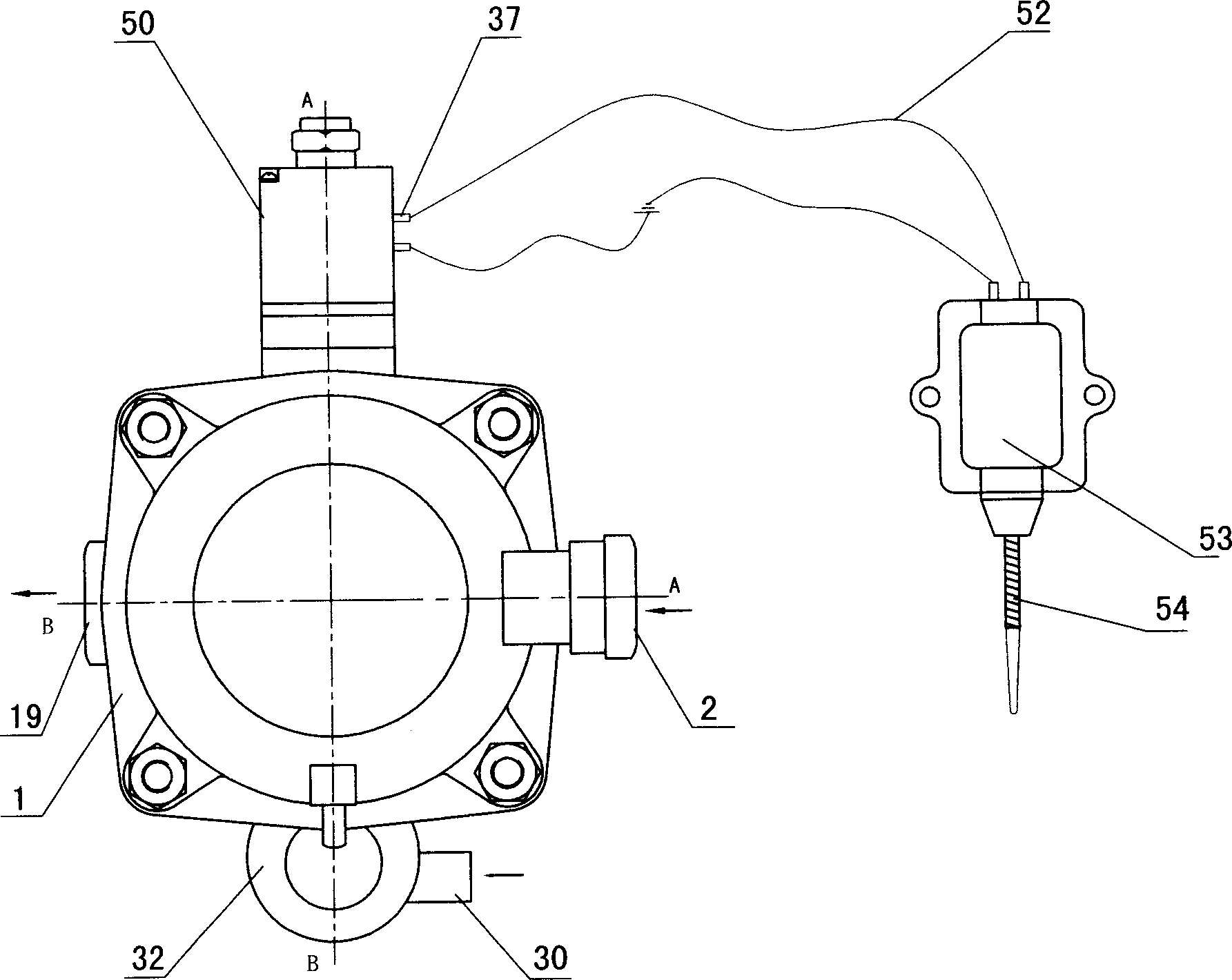

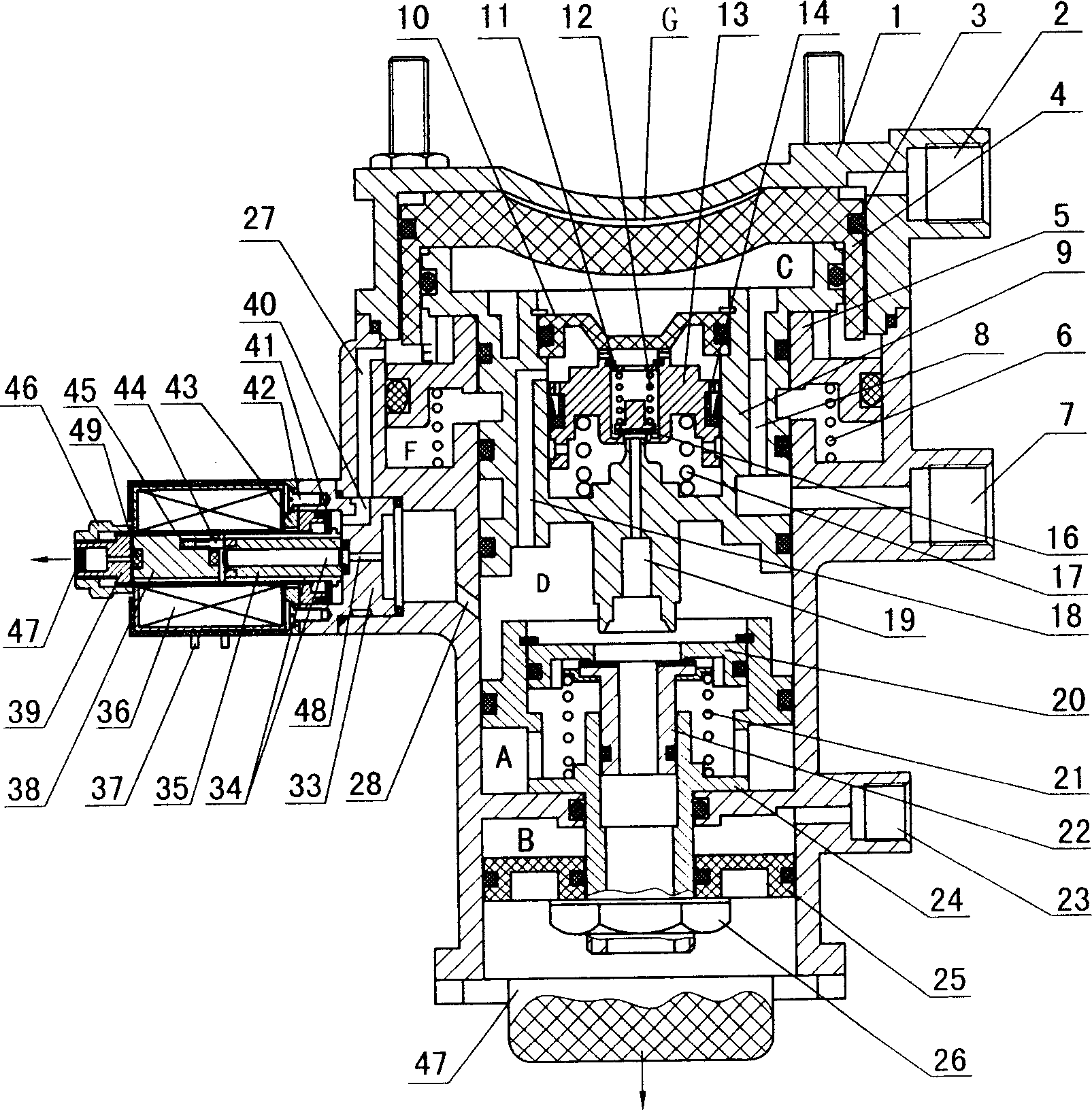

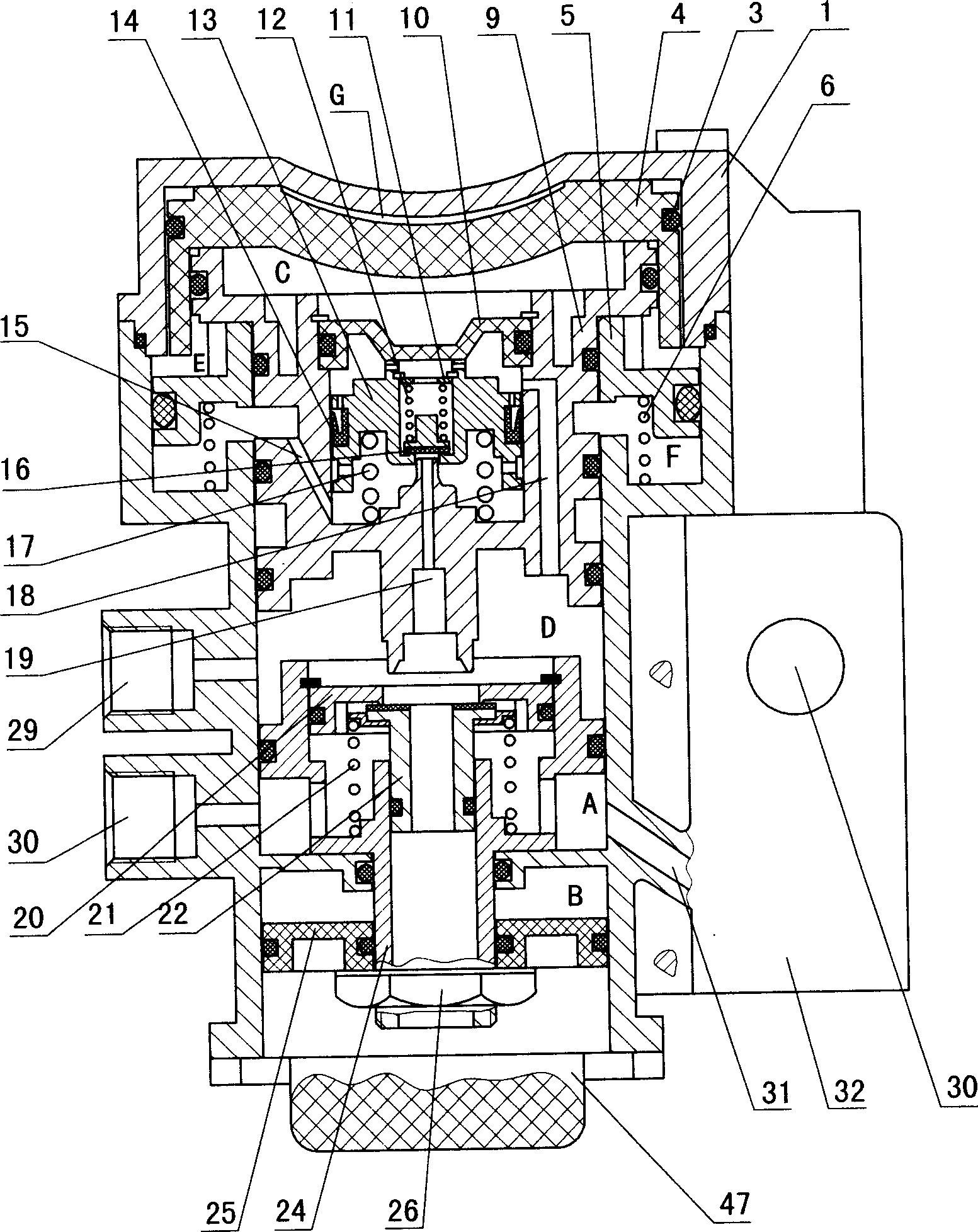

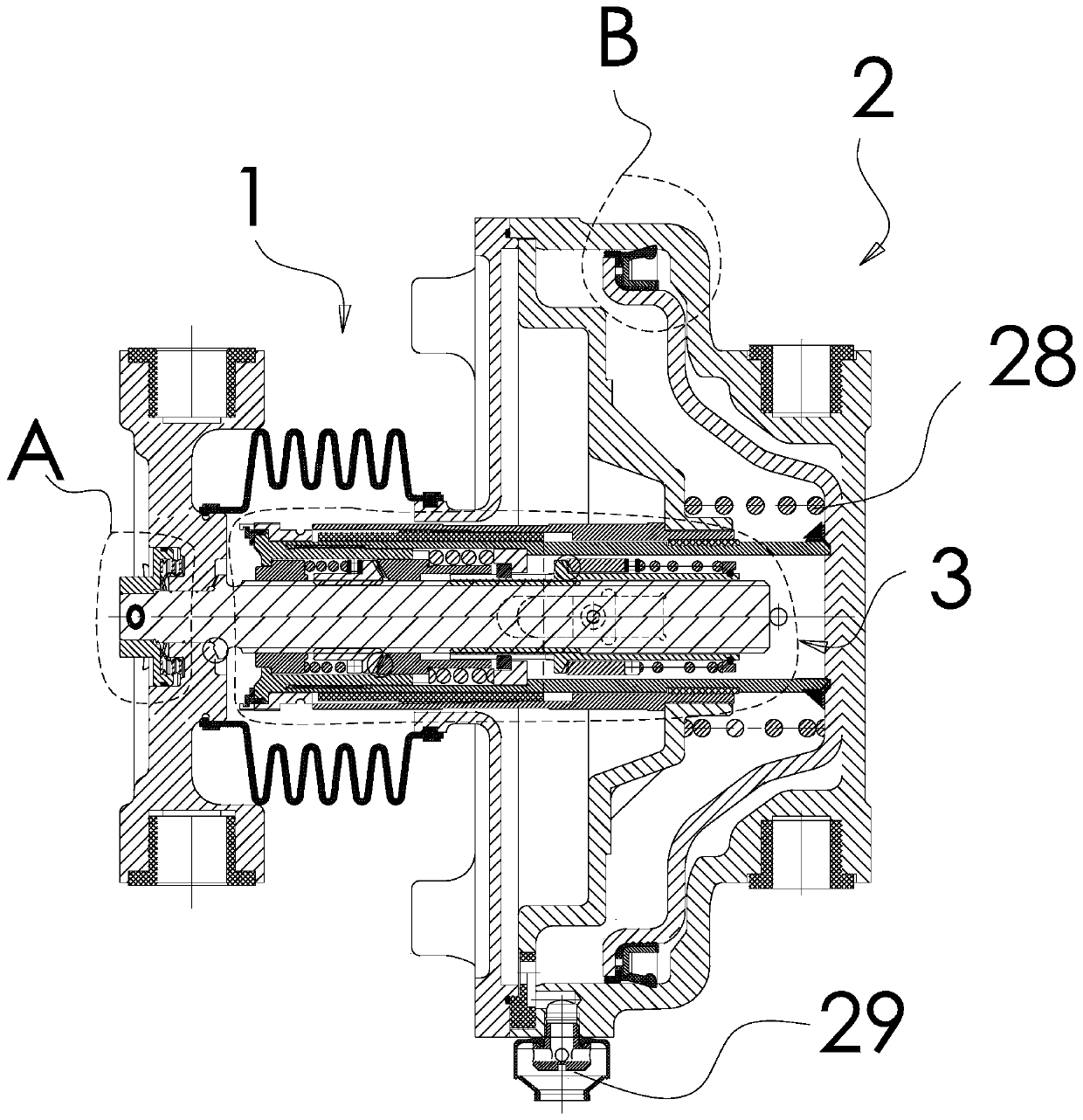

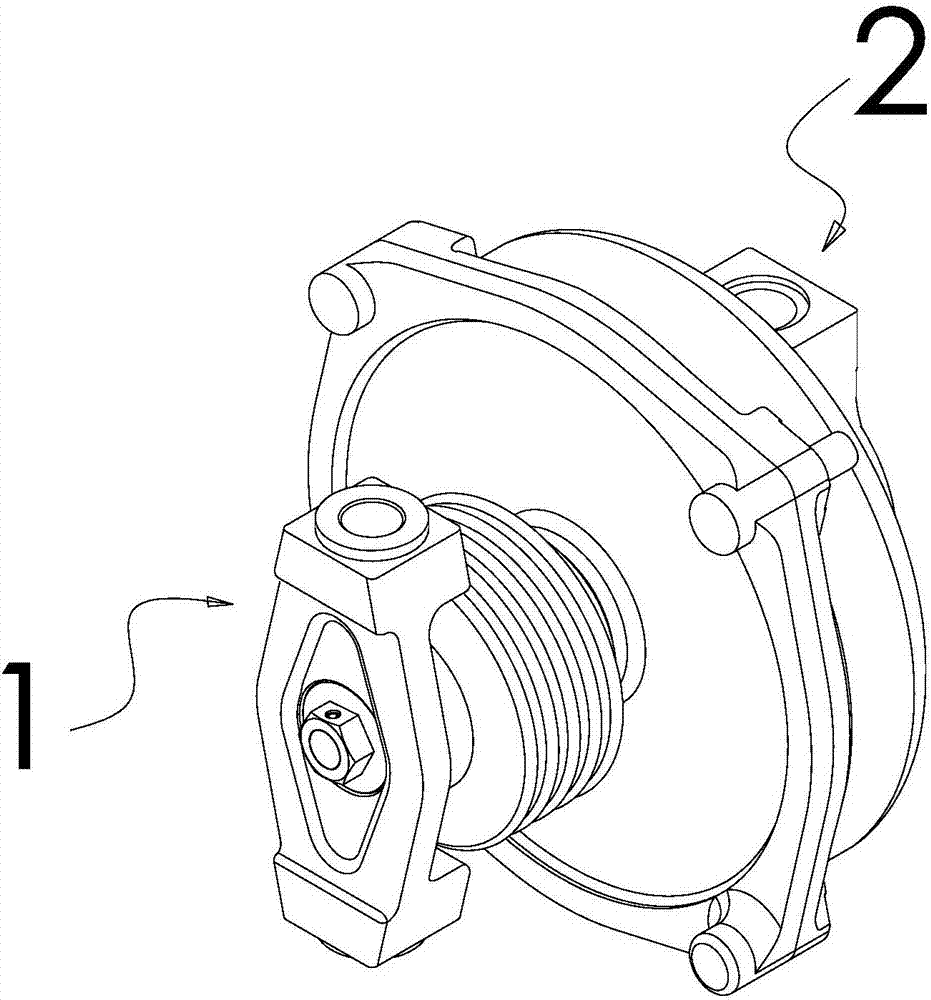

Double pipe electrically-controlled trailer brake valve

InactiveCN1876456ADetermining the amount of deformationLarge braking forceApplication and release valvesInlet channelElectric control

The invention relates to a dual-tube electric control trailer brake valve, wherein it adds an electromagnetic control valve and a load sensor, based on former valve, throttle valve, upper relay piston assembly, lower relay piston assembly and emergency piston assembly; the inner diameter lower relay piston is decreased stepped; the baffle disc sheathes the outer wall of lower relay piston to be sealed with the inner wall of valve to form vacuum chamber E and pressure adjustable chamber F; the pressure adjust piston is sealed inside the lower relay piston while a pressure adjust spring is mounted between its lower end and the lower relay piston; the side wall of lower relay piston has an air channel connecting the control chamber C and the air inlet, an air channel connecting the output chamber D and the upper end of pressure adjust piston, and an air channel connecting the lower end and the pressure adjust chamber F; the side wall of valve has an air channel connecting the vacuum chamber E and the outlet channel of electromagnetic control valve, and an air channel connecting the air inlet channel electromagnetic control valve. The invention can automatically adjust the brake pressure, with high sensitivity, better working property and high stability.

Owner:淄博龙达金山汽车部件有限公司

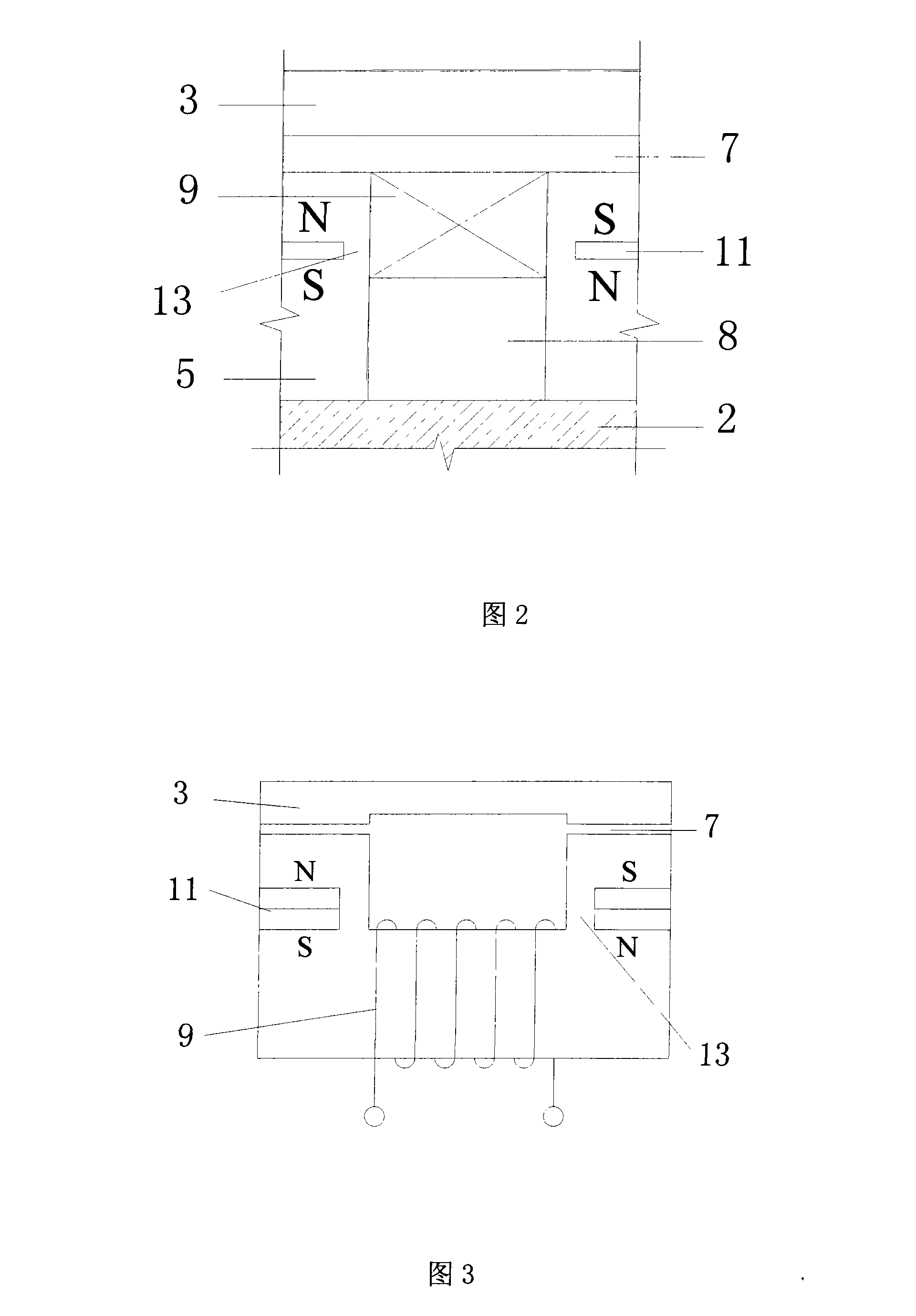

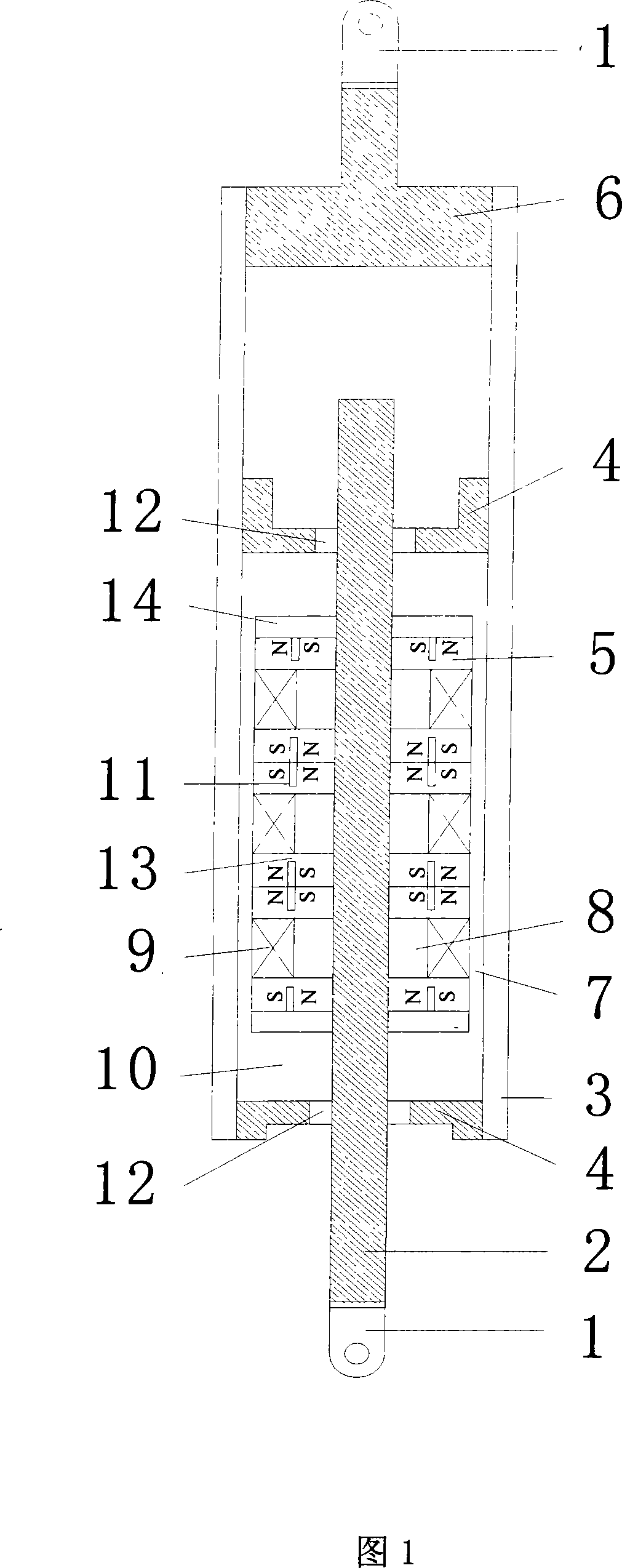

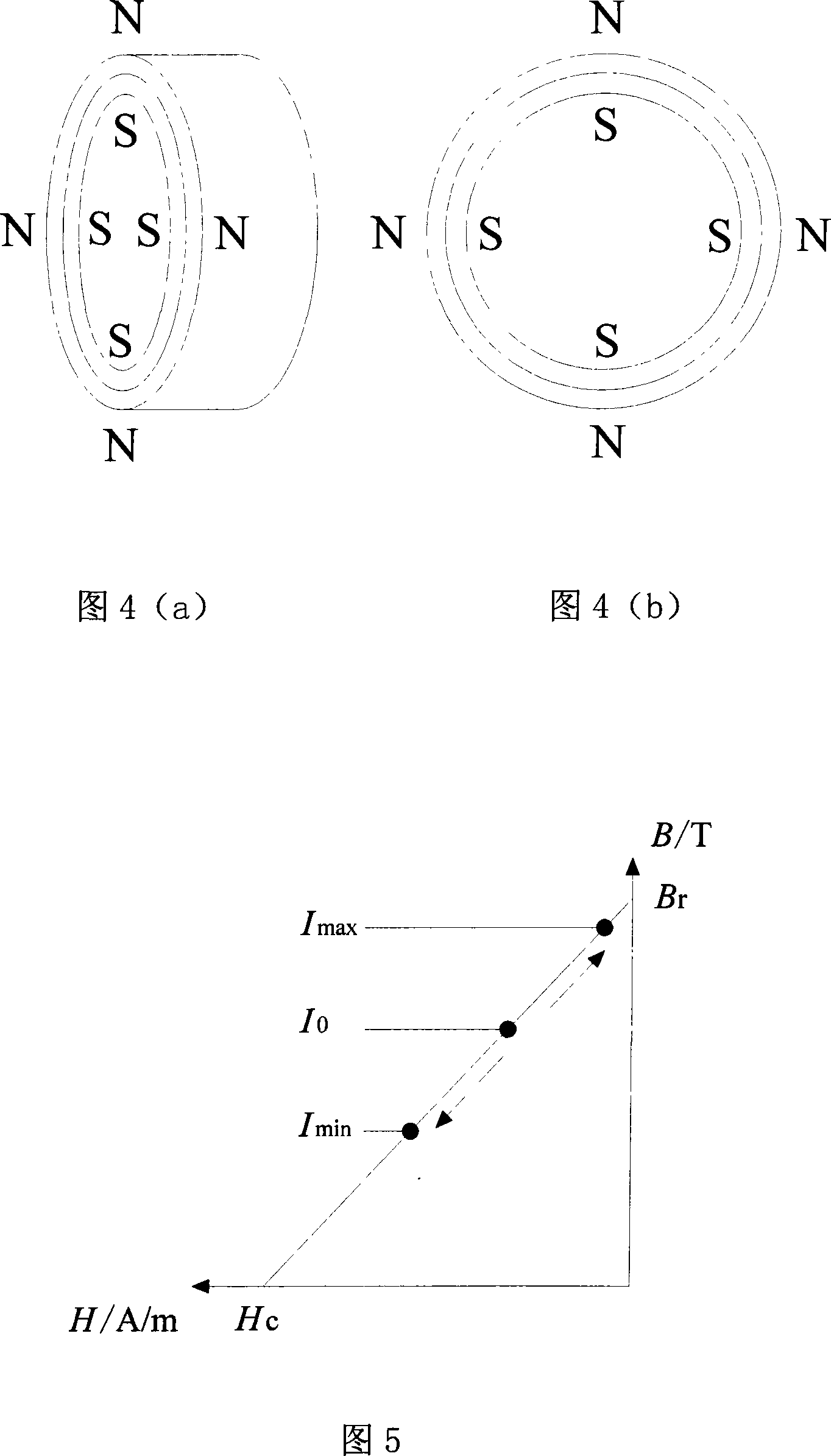

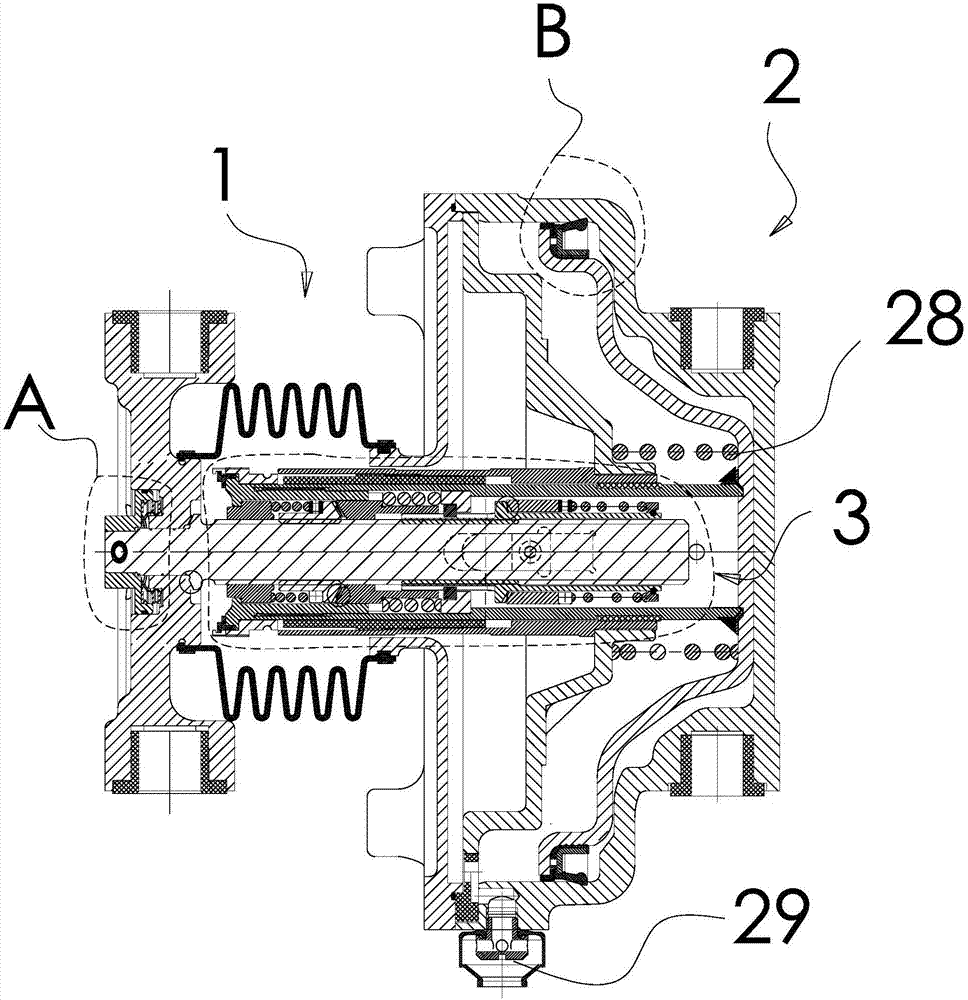

Damping force bidirectionally regulating MR damper

InactiveCN101215861APrevent lock phenomenonGuaranteed passive control effectShock proofingPower flowSnubber

The invention discloses a magneto-rheological damper which damping force can be adjusted in two ways, wherein a cylinder is connected with an upper and a lower end covers, a piston rod is inserted in the steel cylinder through a sealing ring which is arranged on the end cover, a non-corrosive steel damping magnetic slab is mounted on two ends of a piston slab, a plurality of the piston slabs are provided and alternately sleeved on the piston rod with a magnetic core sleeve barrel, the end surface of each piston slab is summarily opened with two grooves along the axial direction, a permanent magnetic ring is inserted in the groove, and the outer lateral of a magnetic core sleeve barrel is winded with an excitation coil. The damper respectively realizes the largest output and the smallest output through adding with the forward current and the inverse current, not only guarantees the fail-safe (fail-safe) performance of the damper, but also effectively prevents the occurrence of locking phenomenon, on the other hand, the invention provides a novel design of a composite magnetic circuit, greatly simplifies the composite magnetic circuit structure when the permanent magnet and the excitation coil coexist, which is beneficial to the practical manufacture and installation of the damper.

Owner:TIANJIN UNIV

Light Duty Cutting Chuck

The invention relates to the technical field of pipe fitting fixture, in particular to a light-typed pipe cutting chuck. The chuck comprises a master plate. The middle part of the master plate is provided with a through hole, wherein pipe fittings can penetrate through the through hole; a pneumatic clamp is arranged on the master plate, wherein the pneumatic clamp can hold the pipe fittings penetrating through the through hole. The pneumatic clamp comprises a plurality of pairs of clamp bars and a double hinged type clamping rod pneumatic drive mechanism which independently controls the same or opposite movement of each pair of the clamp bars. According to the light-typed pipe cutting chuck, through four connecting rods (double hinged type), the good synchronism of a first cylinder and a second cylinder can be ensured; the precision is greatly protected; most of materials of the light-typed pipe cutting chuck are aluminum materials, thus the weight is reduced at least 65% compared with the weight of the conventional structure using steel materials; the existing T-typed slot is replaced by a guide rod, thereby avoiding the phenomenon of the claw locking because of the dust accumulation in the T-typed slot; movable structures are all placed outside; the fault is judged easily; the maintenance is more convenient.

Owner:俞雪清

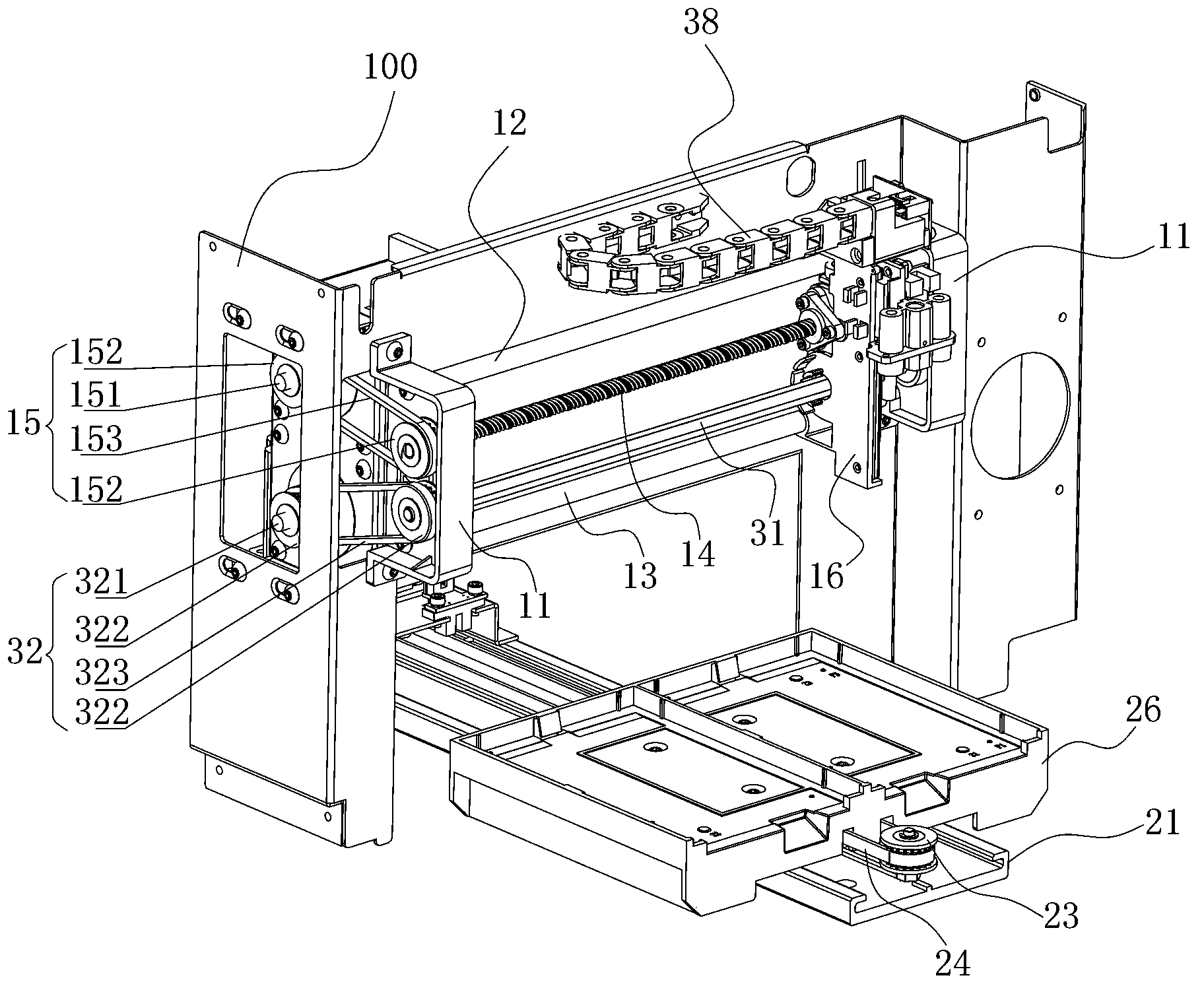

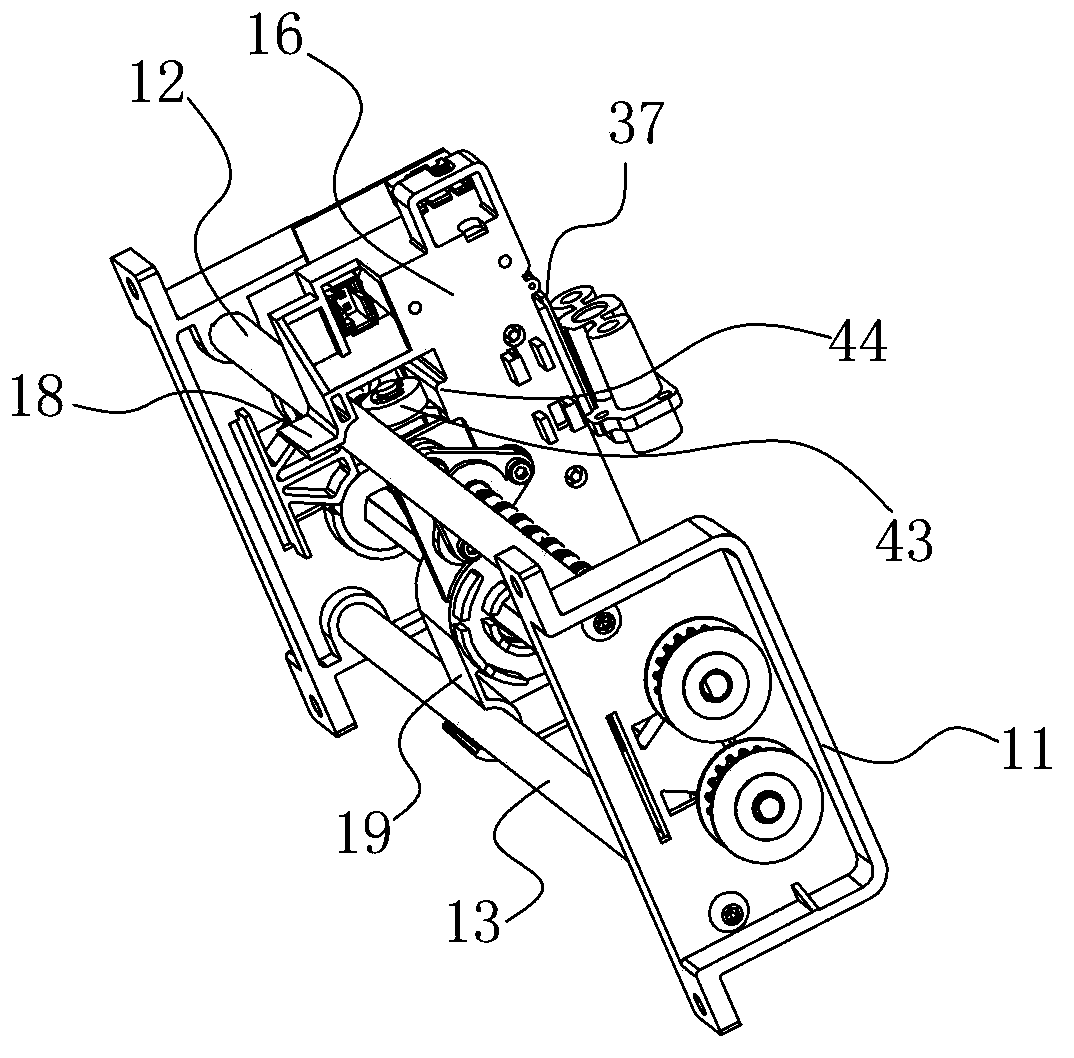

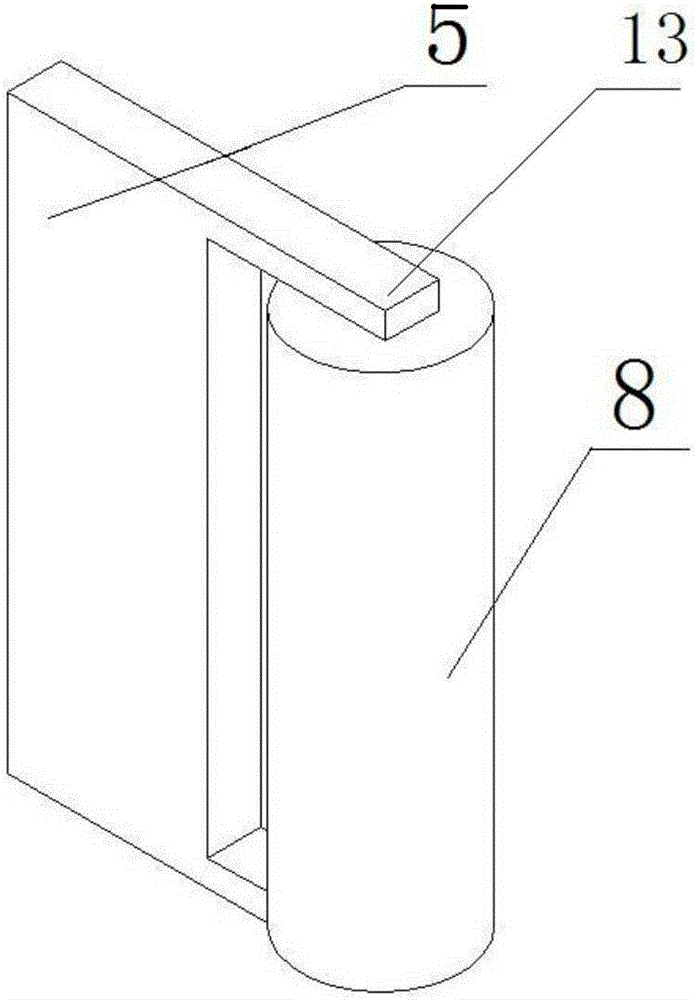

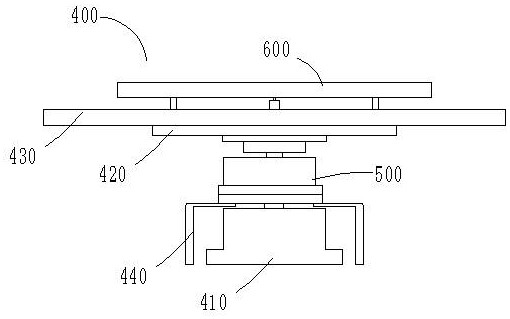

Autosampler

ActiveCN103472244APrevent lockGuaranteed stabilityMaterial analysisThree dimensional motionAutosampler

The invention discloses an autosampler at least including a three-dimensional motion system, the three-dimensional motion system includes an X axis motion mechanism, a Y axis motion mechanism and a Z axis motion mechanism, the X axis motion mechanism at least includes a fixing frame, a screw rod, a needle frame seat and an elastic adjusting structure, the fixing frame is formed by connecting in a surrounding mode two bases arranged along the vertical direction with two shafts arranged along the horizontal direction, the screw rod is arranged along the horizontal direction between the two shafts, both ends of the screw rod are respectively connected to the two bases; the needle frame seat cooperates with screw rod thread in a transmission mode through a nut arranged in the needle frame seat, two sides of the bottom of the needle frame seat extend outwards to form a protruding part, the protruding part is contacted with the two shafts, the elastic adjusting structure fixedly arranged on the inside wall of the needle frame seat protrudes and extends to one of the two shafts, and the protruding end of the elastic adjusting structure resists against the surface of one of the two shafts. The autosampler can avoid waggling of the needle frame seat and has the advantages of stable operation and high positioning accuracy.

Owner:苏州理瞳精密测量系统有限公司

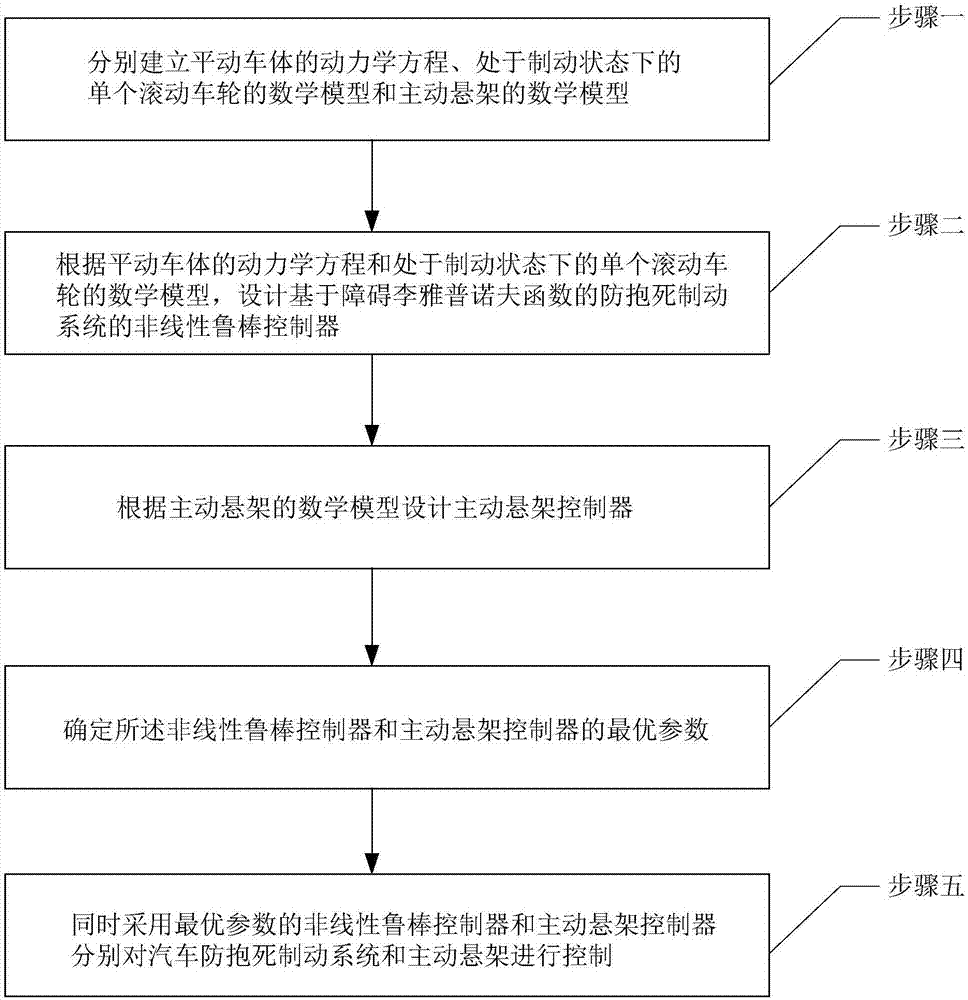

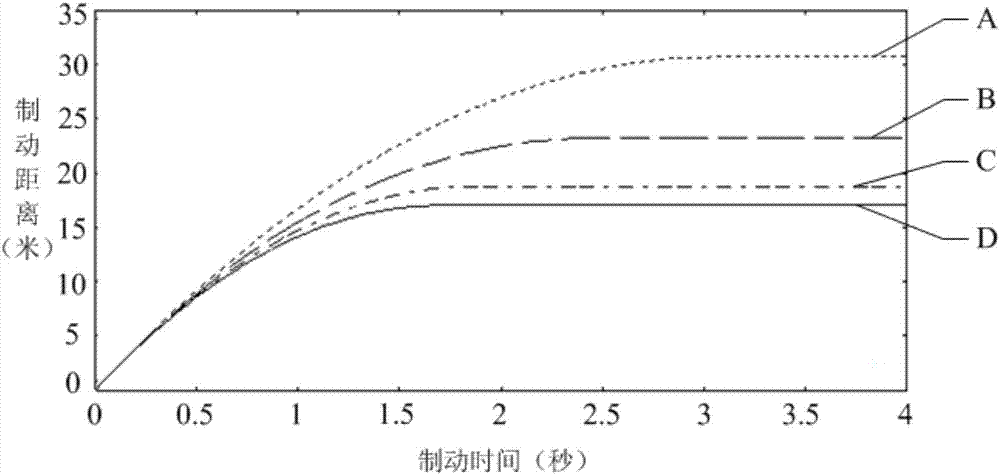

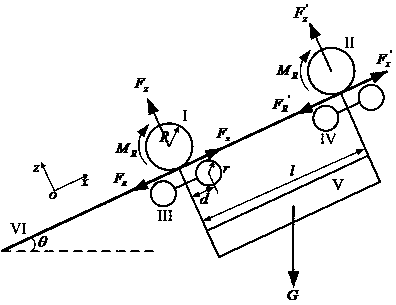

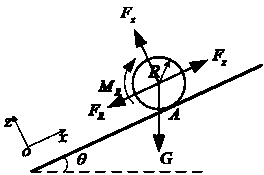

Non-linear robust control method of automobile anti-lock braking system based on active suspension assistance

ActiveCN106864438APrevent braking processPrevent lock phenomenonResilient suspensionsBraking systemsLinear controlAnti-lock braking system

The invention discloses a non-linear robust control method of an automobile anti-lock braking system based on active suspension assistance, and belongs to the field of non-linear control. The problem that existing automobile anti-lock braking systems based on a threshold value control method cannot optimally shorten the braking distance, and thus the wheel speed fluctuates is solved. The non-linear robust control method comprises the steps that a kinetic equation of a translation automobile body, a mathematical model of a single rolling automobile wheel in a braking state and a mathematical model of an active suspension are built; a non-linear robust controller of an anti-lock braking system based on an obstacle Lyapunov function is designed; an active suspension controller is designed; the optimal parameter of the non-linear robust controller and the optimal parameter of the active suspension controller are determined; and the automobile anti-lock braking system and the active suspension are controlled through the non-linear robust controller with the optimal parameter and the active suspension controller with the optimal parameter correspondingly. The non-linear robust control method is suitable for controlling the automobile anti-lock braking system.

Owner:HARBIN INST OF TECH

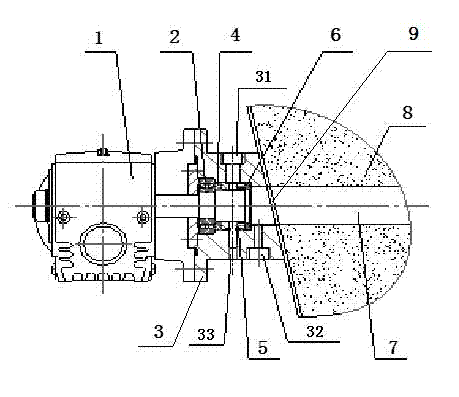

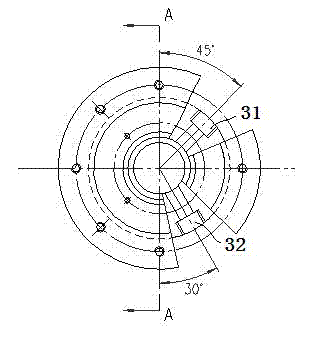

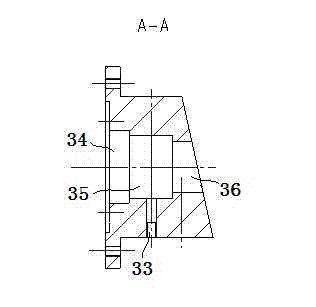

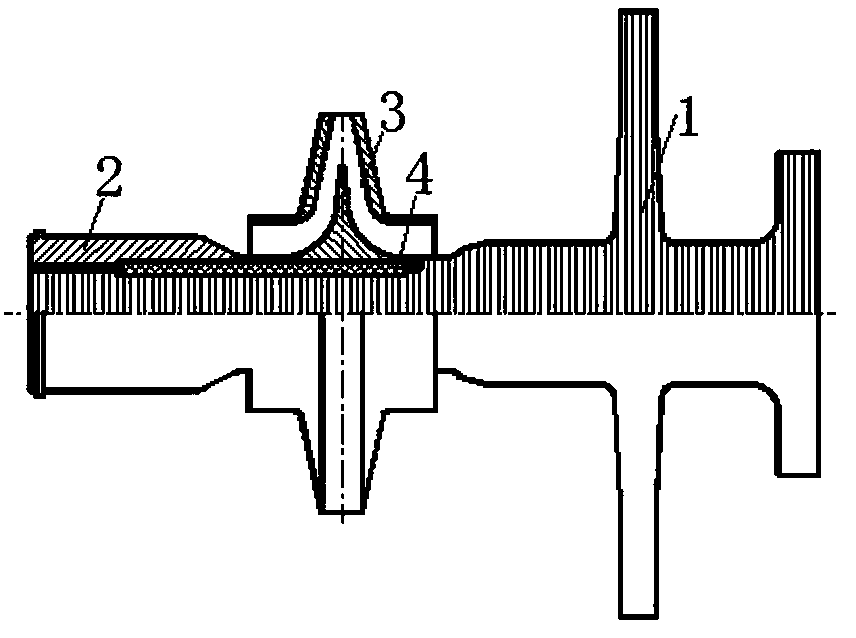

Sealing structure of rotating shaft of powder feeder

The invention relates to a sealing structure of a rotating shaft of a powder feeder, which comprises a supporting seat (3) and a plurality of seal gaskets. The left end of the supporting seat (3) is connected with a motor flange, the right end of the supporting seat (3) is connected with a powder cylinder (9), the rotating shaft (7) of the motor axially penetrates through the supporting seat (3) to the powder cylinder (9), a bearing (2) is mounted in a left-end cavity (34) of the supporting seat (3), and the seal gaskets are mounted on the rotating shaft (7) to seal the left end and the right end of a middle cavity (35). The sealing structure is characterized in that an air inlet and a discharge outlet (33) are arranged on the supporting seat (3), and a local high-pressure area is formed by compressed air entering the supporting seat (3) from the air inlet and then has a function of preventing powder entering while discharging a small quantity of powder from the discharge outlet (33). The sealing structure is an integration of mechanical seal and pneumatic seal, is simple and compact and has excellent sealing effect.

Owner:SHENYANG MECHANICAL DESIGN RES INST CHINA LIGHT IND GENERAL COUNCIL

Star-shaped discharging valve with protecting structure

ActiveCN105923356AReduce contentAvoid accumulationCleaningLoading/unloadingStructural engineeringEquipment use

The invention relates to a star-shaped discharging valve with a protecting structure. The star-shaped discharging valve with the protecting structure comprises a shell, a rotor and a flange cover, wherein the rotor comprises a rotating shaft; a plurality of blades with U-shaped cross sections are arranged on the periphery of the rotating shaft; circular side plates are arranged at the left side and right side of each blade; an expansion sleeve matched with the rotating shaft is arranged in the center of each side plate; a buffering cavity is arranged between each side plate and the flange cover; a cylindrical inner protecting sleeve is arranged in the buffering cavity; a cylindrical upper protecting sleeve is arranged at the outer side of the inner protecting sleeve; a cylindrical lower protecting sleeve is arranged at the inner side of the inner protecting sleeve; a mounting hole matched with the rotating shaft is arranged in the center of the flange cover; and a shaft sleeve matched with the expansion sleeve is arranged at the outer side of the mounting hole. The star-shaped discharging valve with the protecting structure has the beneficial effects that dust and powdery materials on the discharging valve are convenient and fast to clean through matching of an air bag and a hairbrush layer under the multiple protection effect of a material blocking plate, the upper protecting sleeve, the lower protecting sleeve, the inner protecting sleeve and the shaft sleeve, the cleaning efficiency is high, the implementation effect is good, the rotor is prevented from being locked up, and the service life of equipment is prolonged.

Owner:TONGLING NONFERROUS XINGTONG ELECTROMECHANICAL MFG CO LTD

Drill rod adopting pangolin scale biomimetic structure

The invention discloses a drill rod adopting a pangolin scale biomimetic structure. The drill rod comprises a rod body and hollow circular truncated cone units, wherein an inner cavity of each hollow circular truncated cone unit is cylindrical, bulged ridges and grooves are longitudinally formed in the outer circumference surface of each hollow circular truncated cone unit at intervals, the hollow circular truncated cone units are inlaid together end to end, tightly nested on the rod body and then fixed by glue. Compared with the prior art, the drill rod adopting the pangolin scale biomimetic structure can effectively prevent locking phenomenon of the drill rod during a drilling process of a soft coal seam, so that the drill rod is easy to retreat.

Owner:WUHAN UNIV

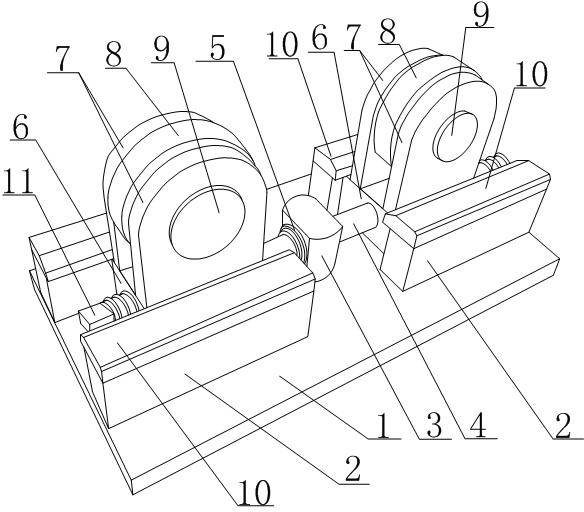

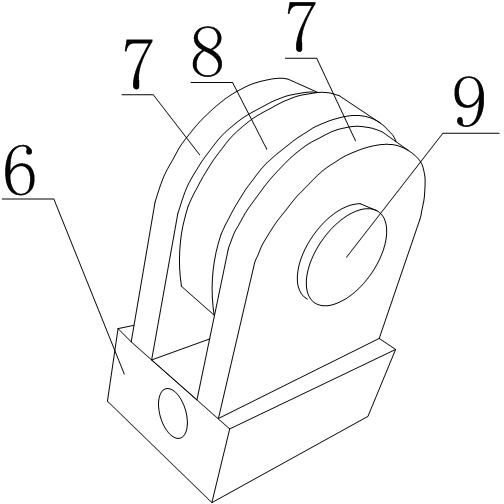

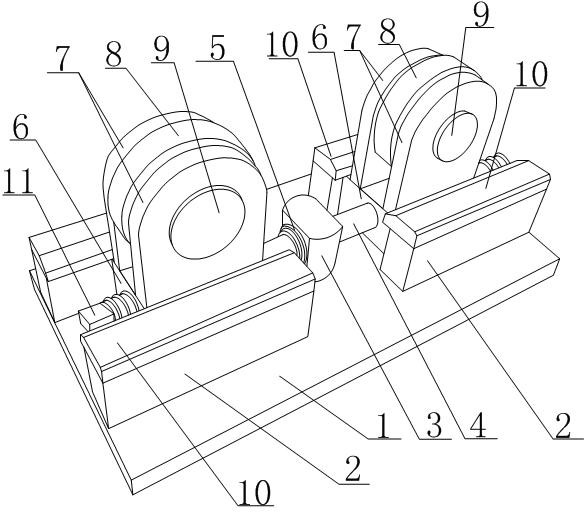

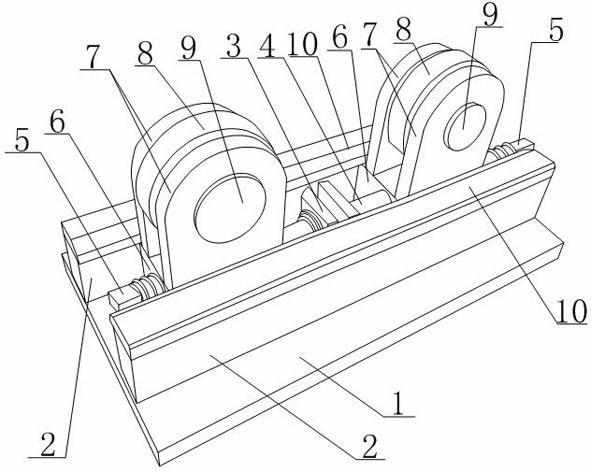

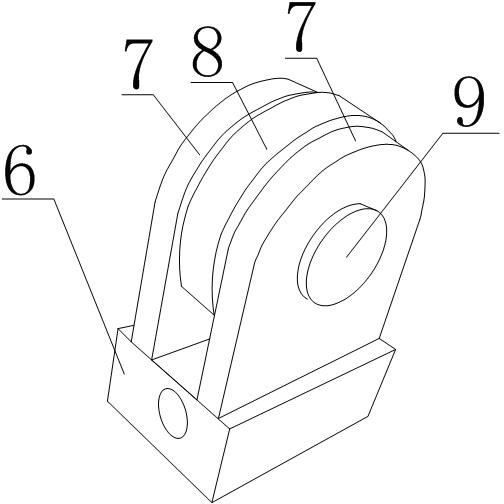

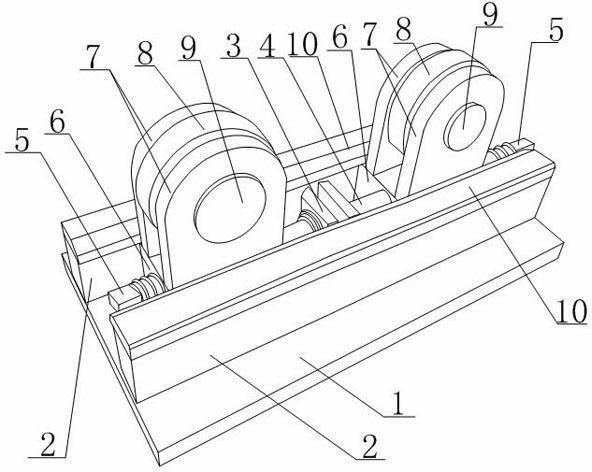

Unidirectional regulating sliding support device

InactiveCN102303251AAdjustable distanceAchieving Model Matching IssuesPositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:CHENGDU KESHENG PETROLEUM TECH +1

Calibration-free bidirectional regulating sliding supporter

InactiveCN102303252AIncrease practical rangeEasy to replacePositioning apparatusMetal-working holdersCalibration freeEngineering

Owner:CHENGDU KESHENG PETROLEUM TECH +1

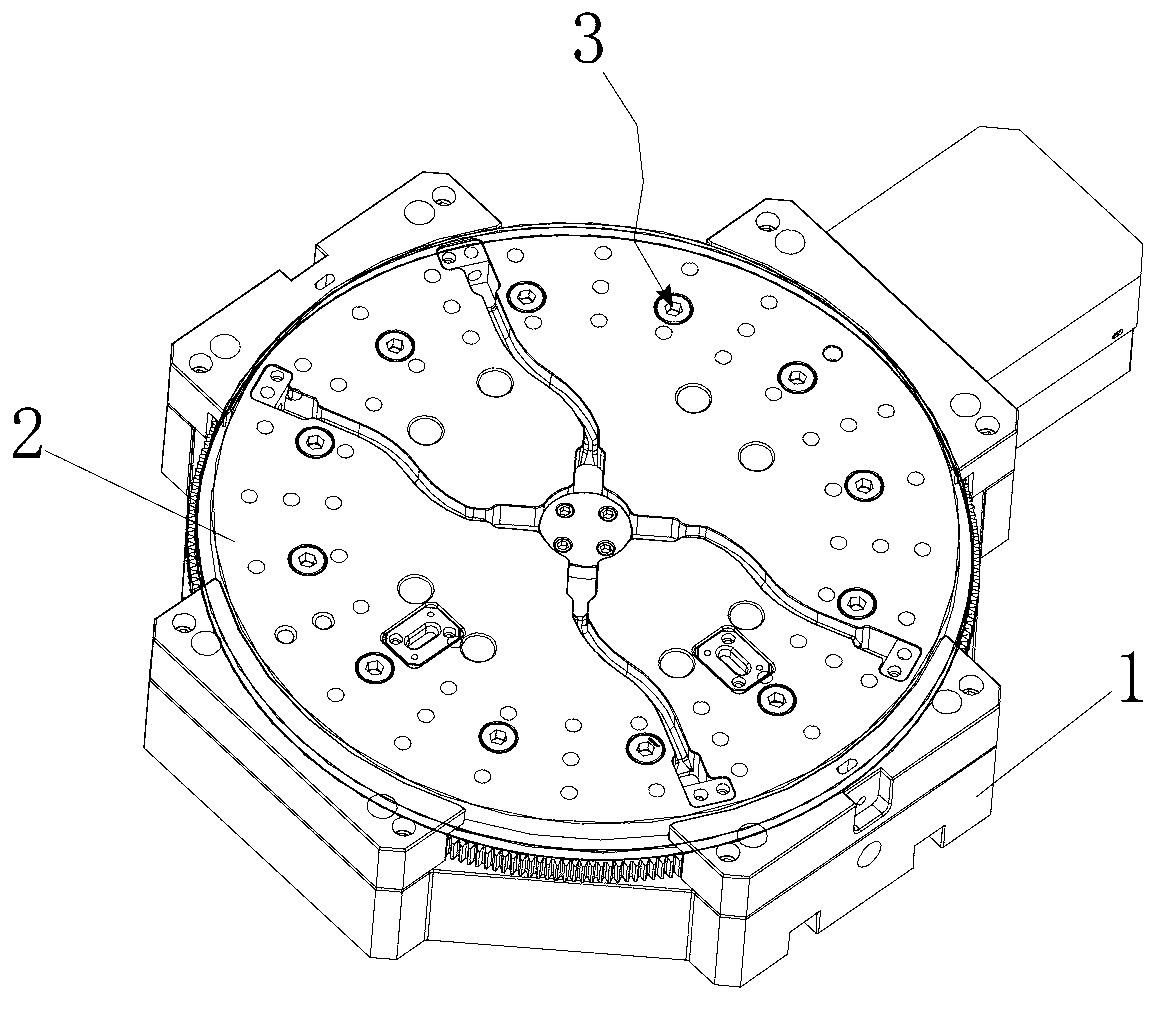

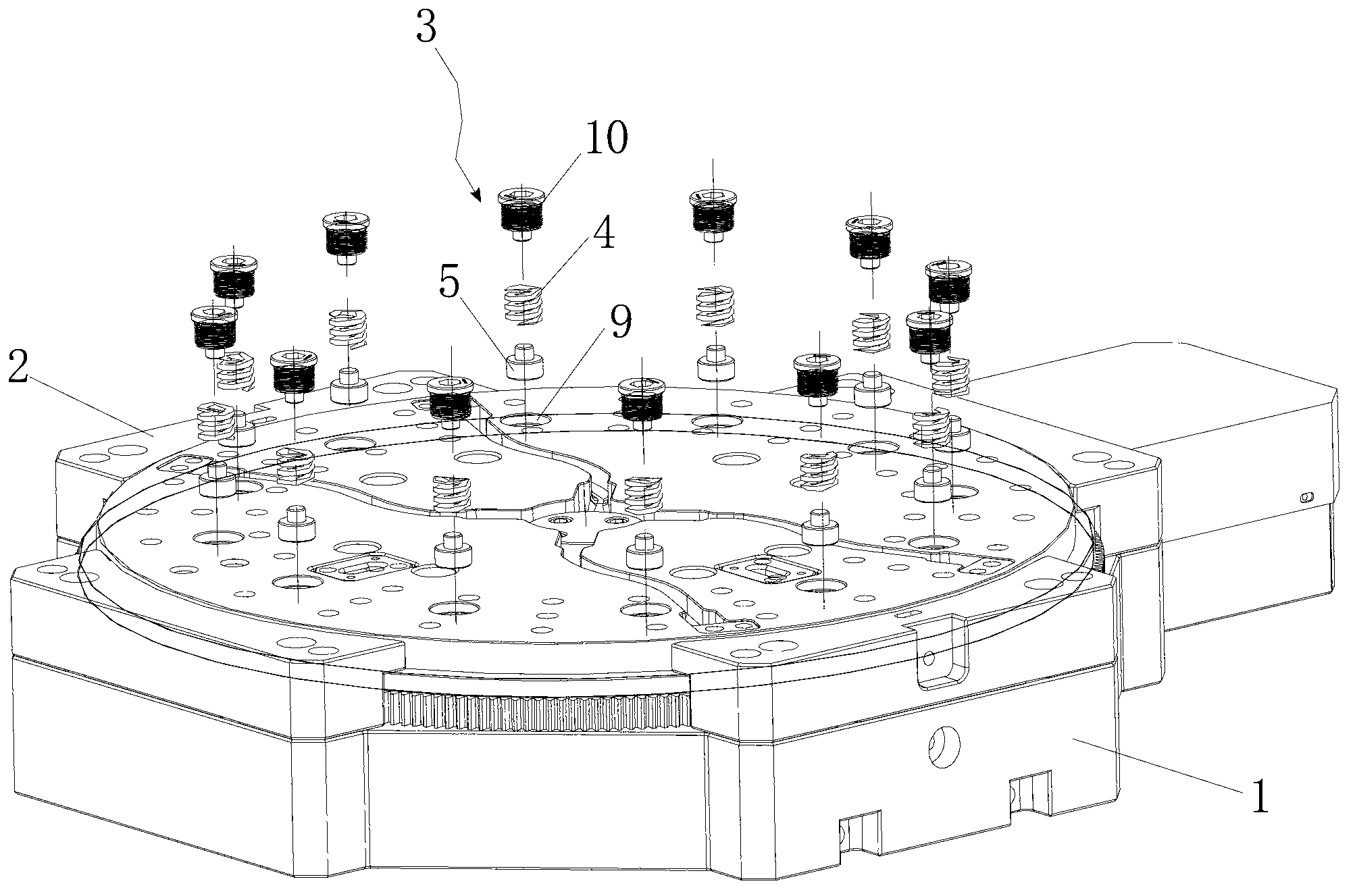

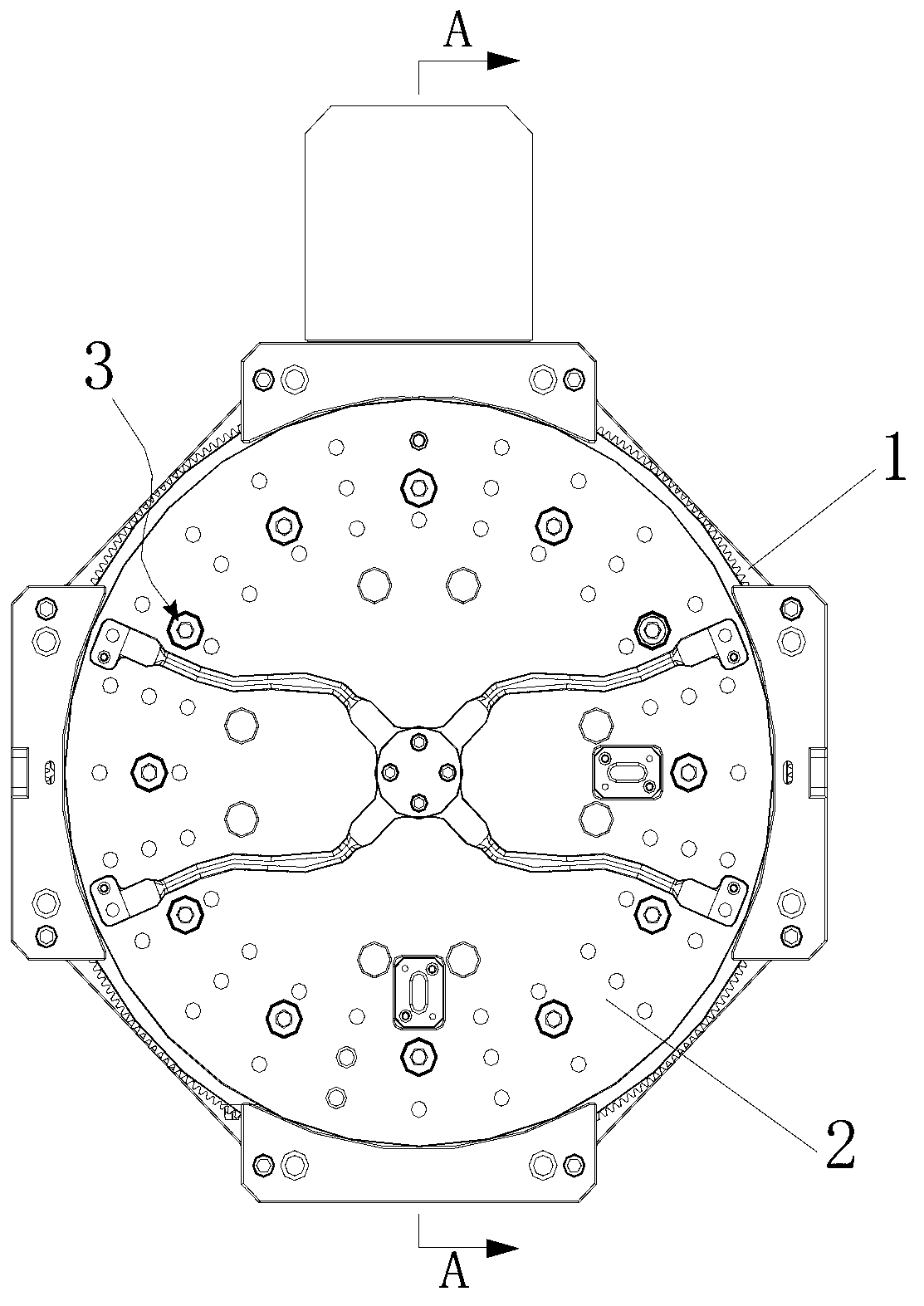

Turntable structure of injection molding machine

The invention discloses a turntable structure of an injection molding machine. The turntable structure comprises a base, and a rotating disk which is arranged on the base, wherein a plurality of elastic anti-abrasion devices for jacking the rotating disk to reserve a certain clearance between the base and the rotating disk are arranged between the base and the rotating disk; each elastic anti-abrasion device consists of a spring and an anti-abrasion piece connected with one end of the spring; and the springs are matched with the anti-abrasion pieces, so that the anti-abrasion pieces are in elastic contact with the base or the rotating disk. The certain clearance is reserved between the base and the rotating disk, so that surface contact directly formed between the base and the rotating disk is avoided; a contact area between the base and the rotating disk is small; in a process of rotating the rotating disk, the friction between the base and the rotating disk is greatly reduced, so that a phenomenon of locking of the base and the rotating disk can be effectively avoided; and therefore, the working efficiency of the injection molding machine is greatly improved.

Owner:DONGGUAN XIONGYOU MOLD PLASTIC

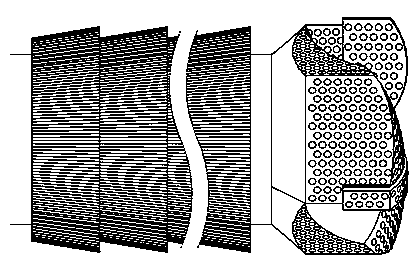

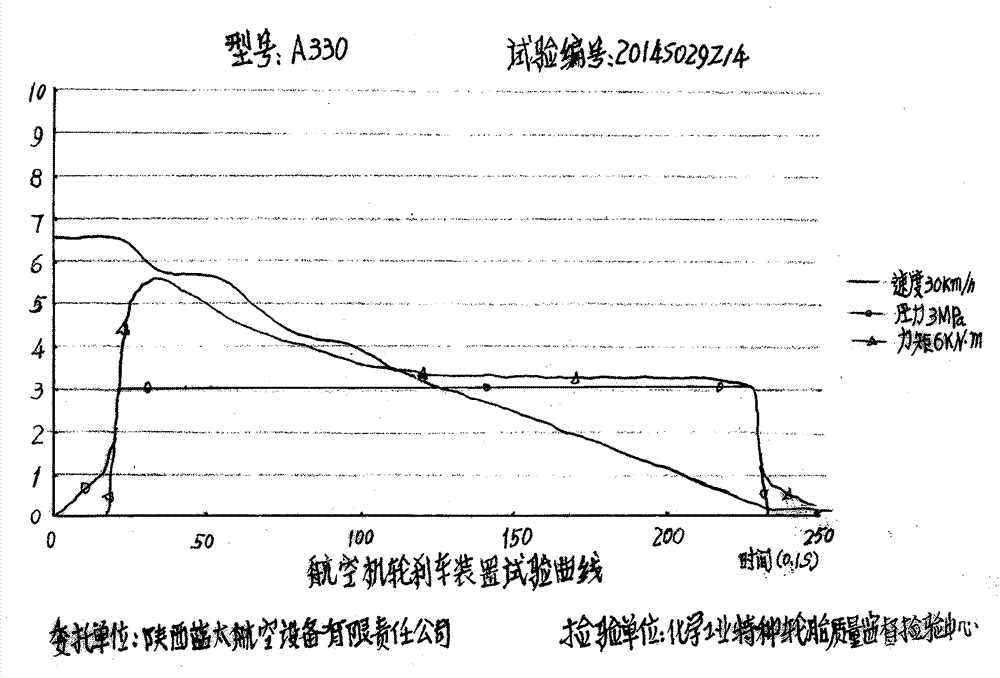

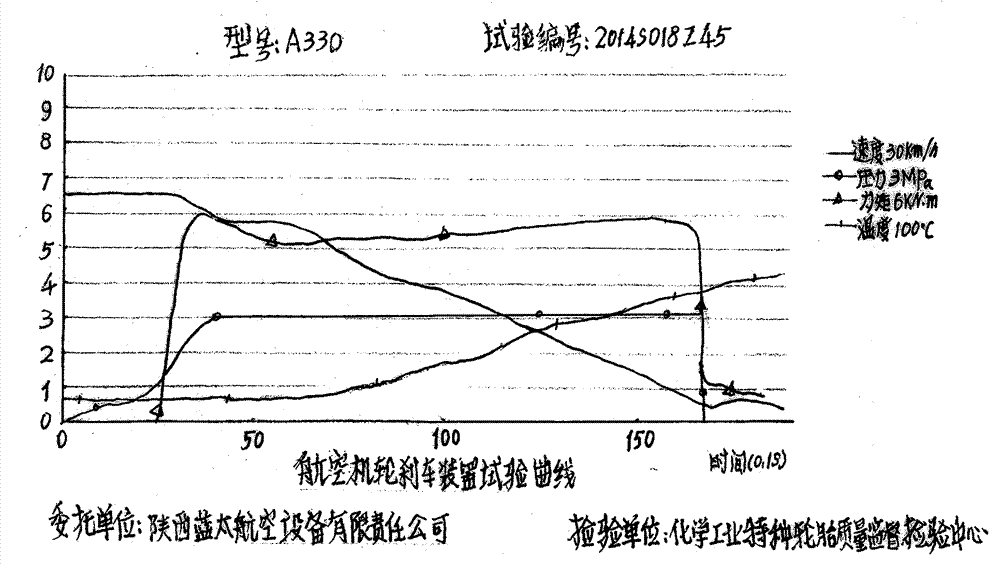

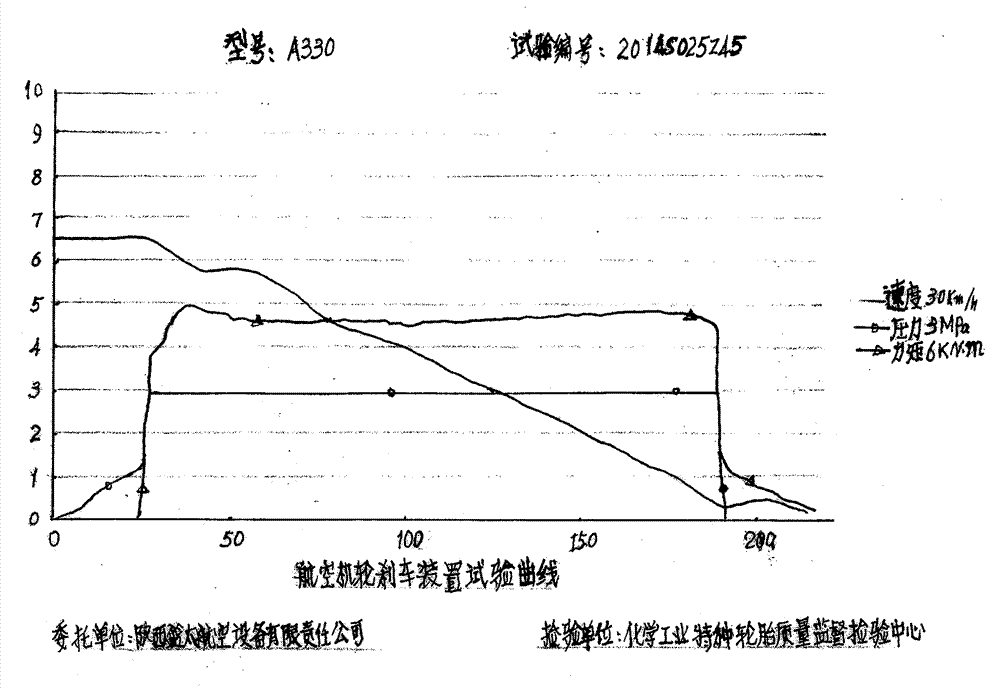

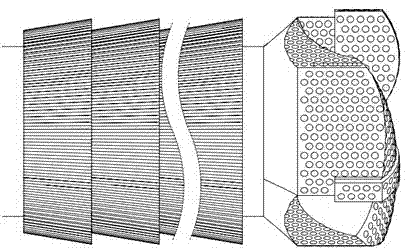

Brake power testing method of large kinetic energy brake device

ActiveCN104748902ALow kinetic energy requirementSuitable for comparative testApparatus for force/torque/work measurementAirplaneKinetic energy

The invention relates to a brake power testing method of a large kinetic energy brake device. At present, the once brake absorbing kinetic energy of a carbon brake device of a large aircraft can reach up to 85MJ, 105MJ and 125MJ, and the output energy of an existing inertia platform cannot completely meet the requirements of a testing schedule. The invention aims to provide the brake power testing method of the large kinetic energy brake device. According to the method provided by the invention, a carbon brake disk is arranged in the middle of the brake device in a national multi-disk type brake device, and a plurality of static discs (4) and moving discs (3) are arranged alternately, and the requirement that the kinetic energy of the AS inertia platform can be absorbed by a primary brake device of either a machine wheel or a main wheel can be reduced by reducing the method of a new technology of reasonably reducing the amount of friction surfaces under the condition of keeping the QF (Quality Factor) of the kinetic energy absorbed by a unit friction surface constant; furthermore, a method of testing the brake power of the brake device of a national airplane with large kinetic energy can be realized, and the phenomenon of locking either airplane wheels or a main wheel can be prevented in the test.

Owner:陕西蓝太航空设备有限责任公司

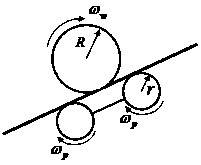

Inspection robot slip identification and intelligent self-adaptive control method

PendingCN111038509AEliminate Adaptive Control MethodsPrevent lock phenomenonAutonomous decision making processApparatus for overhead lines/cablesWire rodControl engineering

The invention discloses an inspection robot slip identification and intelligent self-adaptive control method. An inspection robot comprises a walking wheel and a pressing wheel, the walking wheel rolls on a patrolled wire rod, and the pressing wheel is located below the patrolled wire rod and used for pressing the patrolled wire rod on the walking wheel; the method comprises the following steps that (1) the inspection robot is used for detect whether slipping of the walking wheel is caused in real time by comparing the angular speed of the walking wheel and the angular speed of the pressing wheel in the patrol process, and in detecting of slipping, the pressing wheel is contacted with the patrolled wire rod; (2) if it is detected that slipping is not caused, inspection is continuously conducted, if slipping is found through detection, the slipping degree is judged according to a slipping model, and the slipping degree is determined through the ratio of the angular speed of the walkingwheel to the angular speed of the pressing wheel; and (3) self-adaptive slip control is carried out according to the slip degree. The control method disclosed by the invention has the characteristic of relatively accurate controlling on the slipping state.

Owner:GUANGDONG KEYSTAR INTELLIGENCE ROBOT CO LTD

Steel bottle necking machine

The invention provides a steel bottle necking machine. A guiding shaft is arranged on a base plate. A sliding plate is installed on the guiding shaft in a sliding mode. A limiting element is arranged on the base plate. A swing arm is rotationally installed on the sliding plate. The swing arm is provided with a rotating wheel base in the vertical direction in a restrained mode. A rotating wheel position adjusting mechanism is arranged between the swing arm and the rotating wheel base. A rotating wheel shaft is rotationally installed inside the rotating wheel base. A rotating wheel is installed at the stretching-out end of the rotating wheel shaft. A plurality of fine positioning sleeves are arranged at the upper portion of the base plate. A fine positioning shaft is installed at the bottom of the sliding plate. A rotating wheel shaft installation cavity is arranged inside the rotating wheel base. A cooling lubricating oil inlet and a cooling lubricating oil return opening are formed in the rotating wheel base. Circulating oil ways corresponding to the cooling lubricating oil inlet and the cooling lubricating oil return opening are formed in the rotating wheel shaft. The steel bottle necking machine is easy to use and convenient to operate, the cooling and lubricating purpose at the rotating wheel base is achieved, and the locking phenomenon in the production process does not appear in the using process; the steel bottle necking machine is suitable for automatic mass production, the labor cost and the production cost are lowered, and the product market competitiveness is improved.

Owner:潍坊神舟重工机械有限公司

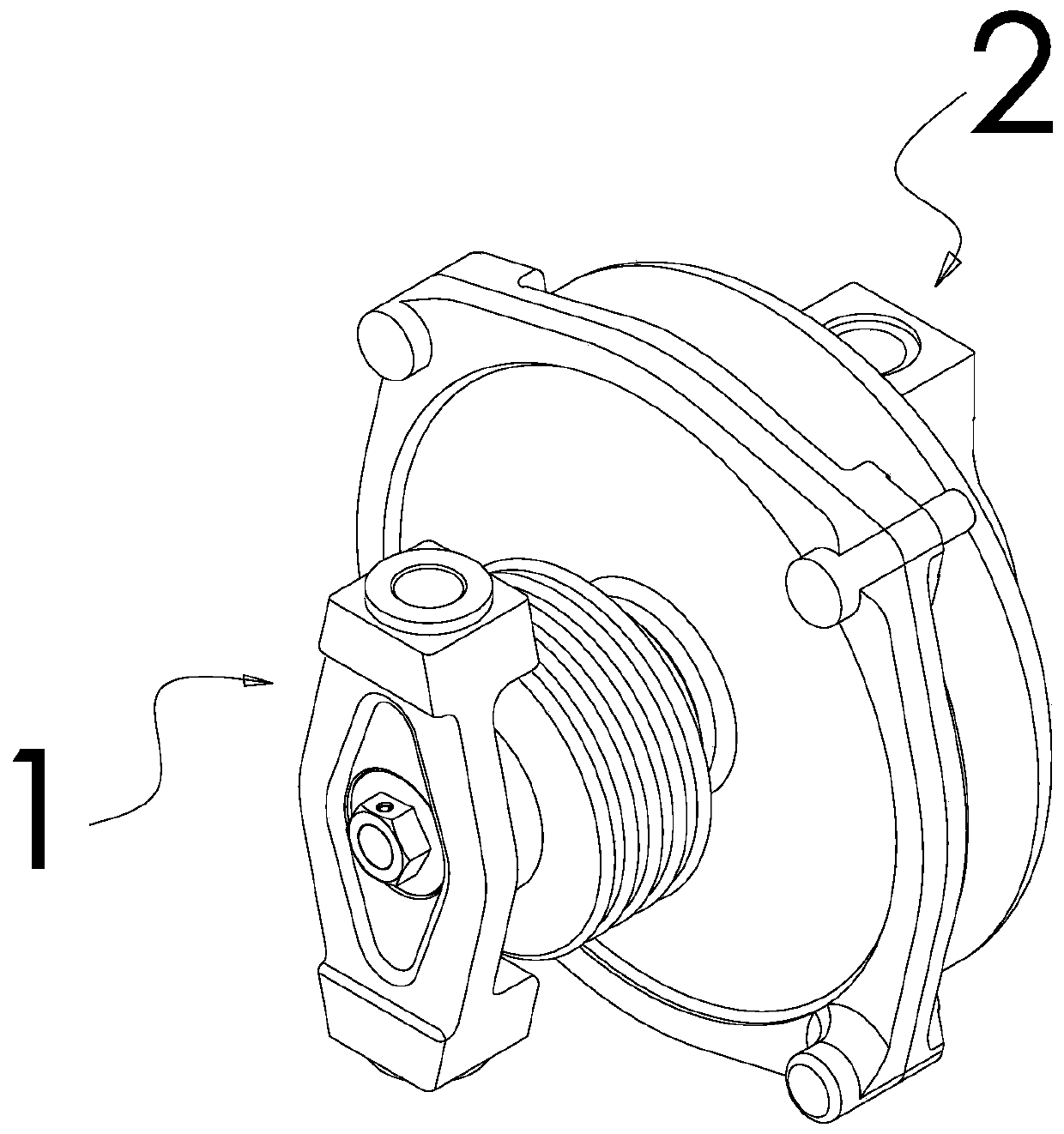

Disassembly process of rotor parts

ActiveCN107855728AHigh reusabilityReduce maintenance costsMetal working apparatusMetal-working hand toolsInterference fitImpeller

The invention discloses a disassembly process of rotor parts. The rotor parts are mainly composed of a rotor body, a sleeve and an impeller, wherein the sleeve and the impeller are assembled on the rotor body in an interference fit mode. The disassembly process comprises the following steps that 1, the sleeve on the rotor body is heated in a heating mode, and therefore the sleeve can generate thermal expansion on the rotor body, and the sleeve can keep the thermal expansion state; 2, the axial pulling is carried out on the sleeve on the rotor body at the shaft end of the rotor body by adoptinga hydraulic puller, and therefore the sleeve can be taken out from the rotor body; 3, the impeller on the rotor body is heated in a heating mode, and therefore the impeller can generate thermal expansion on the rotor body, and the impeller can keep the thermal expansion state; and 4, axial pushing is carried out on the impeller in the axial direction of the rotor body by adopting a synchronous jack, and therefore the impeller can be taken out from the rotor body. The disassembly process is capable of protecting all the parts well, and has the characteristics of being high in operability, easyand convenient, safe and efficient, good in economical efficiency, reliable, practical and the like.

Owner:DONGFANG TURBINE CO LTD

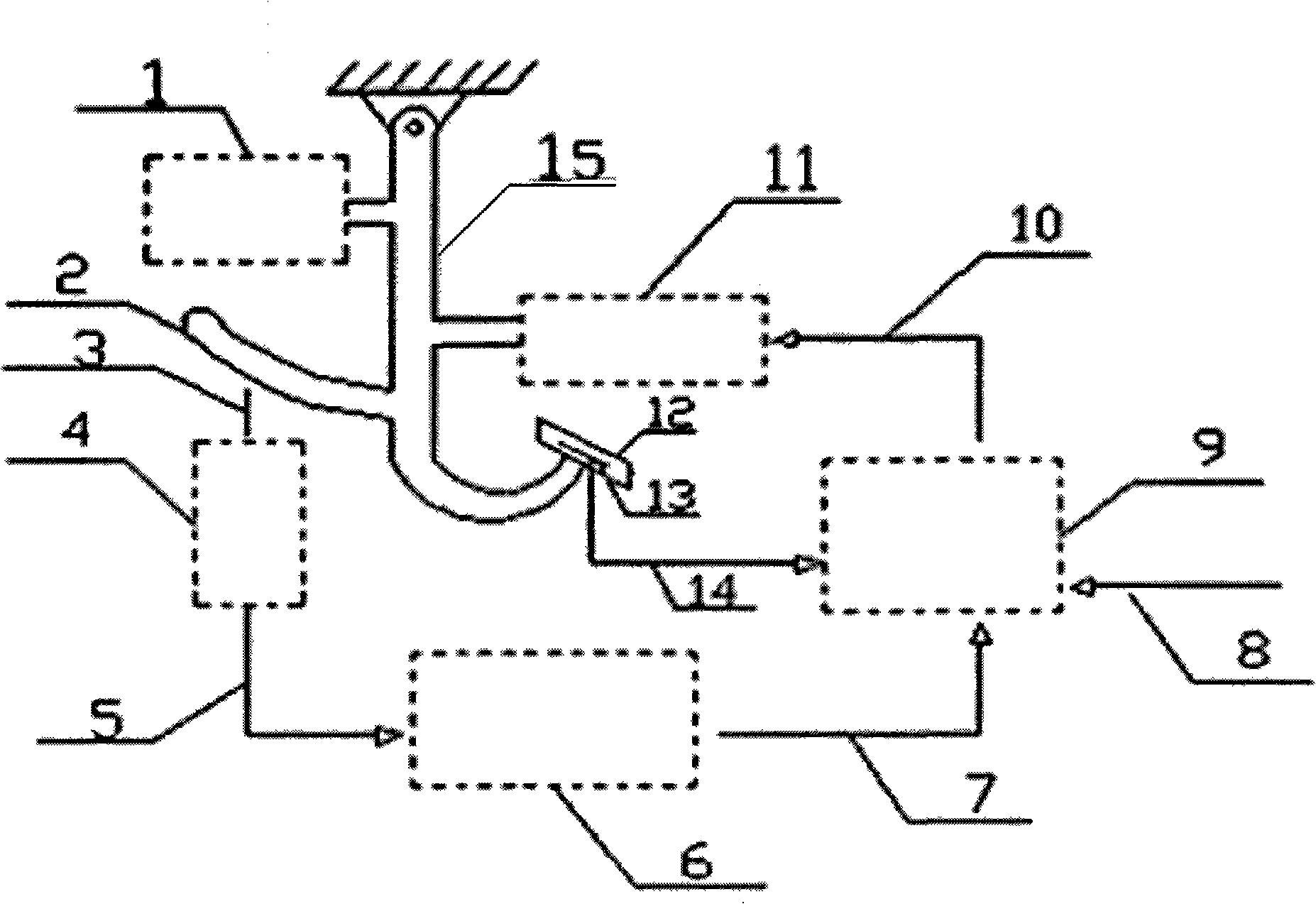

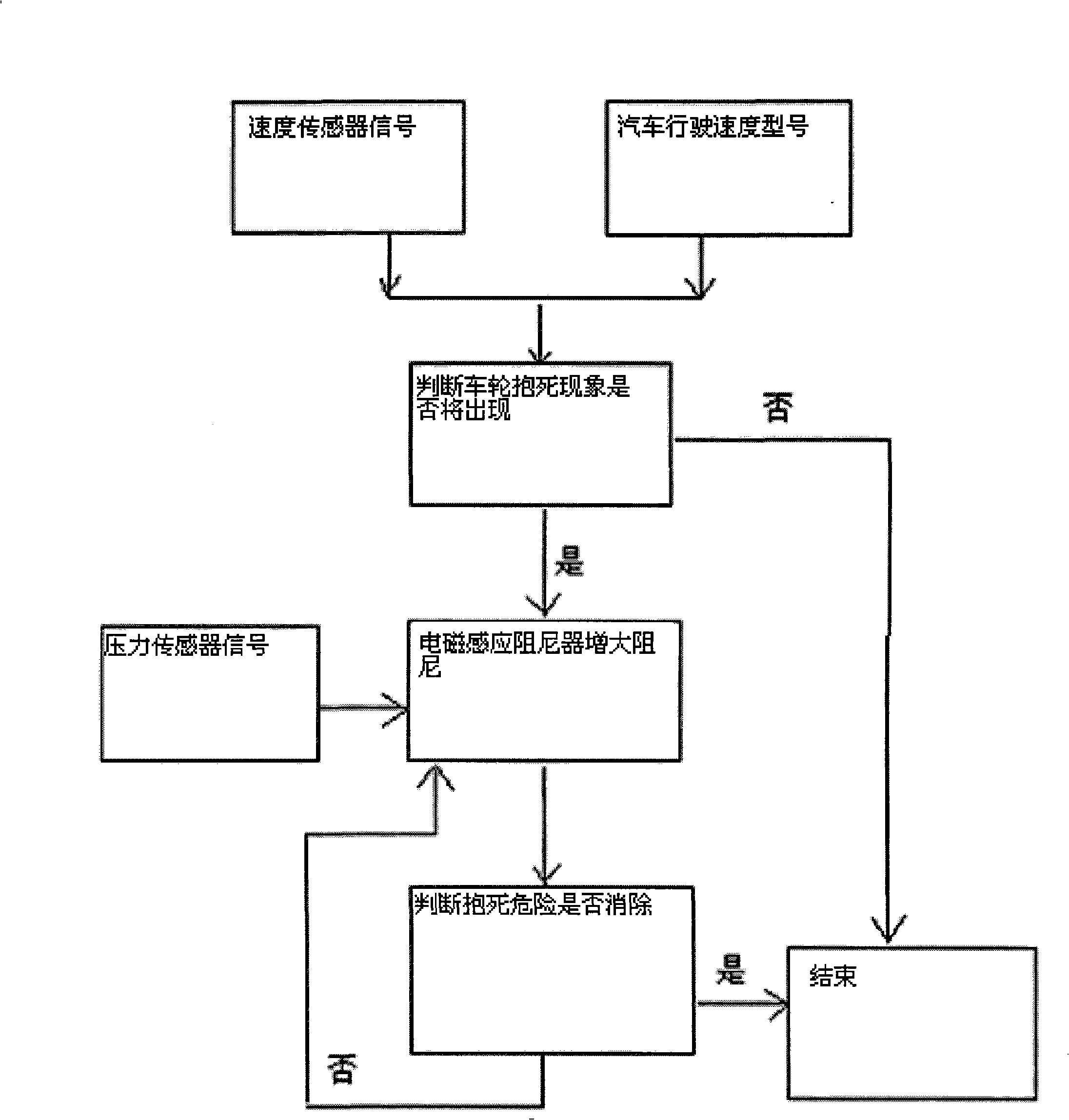

Intelligent damping locking-proof system for brake of automobile

The invention discloses an intelligent damping anti-lock braking system of a car brake. An electromagnetic induction damper and a bending rod are arranged in sequence at the lower part of a brake pedal linkage, wherein, the electromagnetic induction damper and the bending rod are both connected fixedly with the brake pedal linkage; the brake pedal is provided with a pressure sensor; the signal sending terminal of a speed sensor is adjacent to the bending rod and is aimed at the circle center of the bending rod; concave and convex parts with equal spacing are arranged on an end face of the bending rod adjacent to the speed sensor; the signal output terminal of the speed sensor is connected with an I / O interface of an ECU control unit via a D / A converter; the pressure sensor is connected with the second I / O interface of the ECU control unit; the third I / O interface of the ECU control unit is connected with an electromagnetic induction damper; the output terminal of the ECU control unit also inputs vehicle speed signals. The invention is capable of preventing wheel from locking, is capable of maintaining the direction of the car, and also has the greatest function of an ABS anti-lock braking system.

Owner:ZHEJIANG UNIV

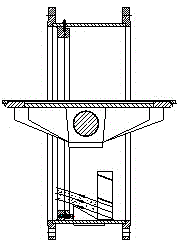

Vertical shaft type dry-mix mortar stirrer for building construction

InactiveCN108908718AImprove the mixing effectGood dispersionDischarging apparatusCement mixing apparatusMotor driveArchitectural engineering

The invention discloses a vertical shaft type dry-mix mortar stirrer for building construction. The vertical shaft type dry-mix mortar stirrer comprises a stirring box, wherein a box cover is arrangedon the top end of the stirring box in a sleeved manner, and is provided with a material inlet, the center of the box cover is provided with a cycloid pin gear speed reducer and a motor, the output end of the speed reducer is provided with a stirring shaft, the stirring shaft extends to the interior of the stirring box, and is respectively provided with upper stirring blades, lower stirring bladesand bottom stirring frame type paddles, the bottom of the stirring box is provided with a circular material discharge port, the lower side of the circular material discharge port is provided with anobliquely-arranged material discharge hopper, and a material discharge valve plate is arranged between the circular material discharge port and the material discharge hopper. According to the presentinvention, the motor drives the upper stirring blades, the lower stirring blades and the bottom stirring frame type paddles on the stirring shaft to rotate through the speed reducer until the mortar is uniformly stirred, the stirred material is scraped into the material discharge hopper by the material outlet scraping plate after the stirring so as to discharge the material, such that the dry-mixed mortar material has advantages of good mixing and stirring effect and good dispersibility so as to achieve the uniform mixing and stirring effect; and the sealing separation sleeve is arranged on the bottom portion of the stirring shaft in a sleeved manner so as to prevent the phenomenon of locking.

Owner:CHINA THIRD METALLURGICAL GRP

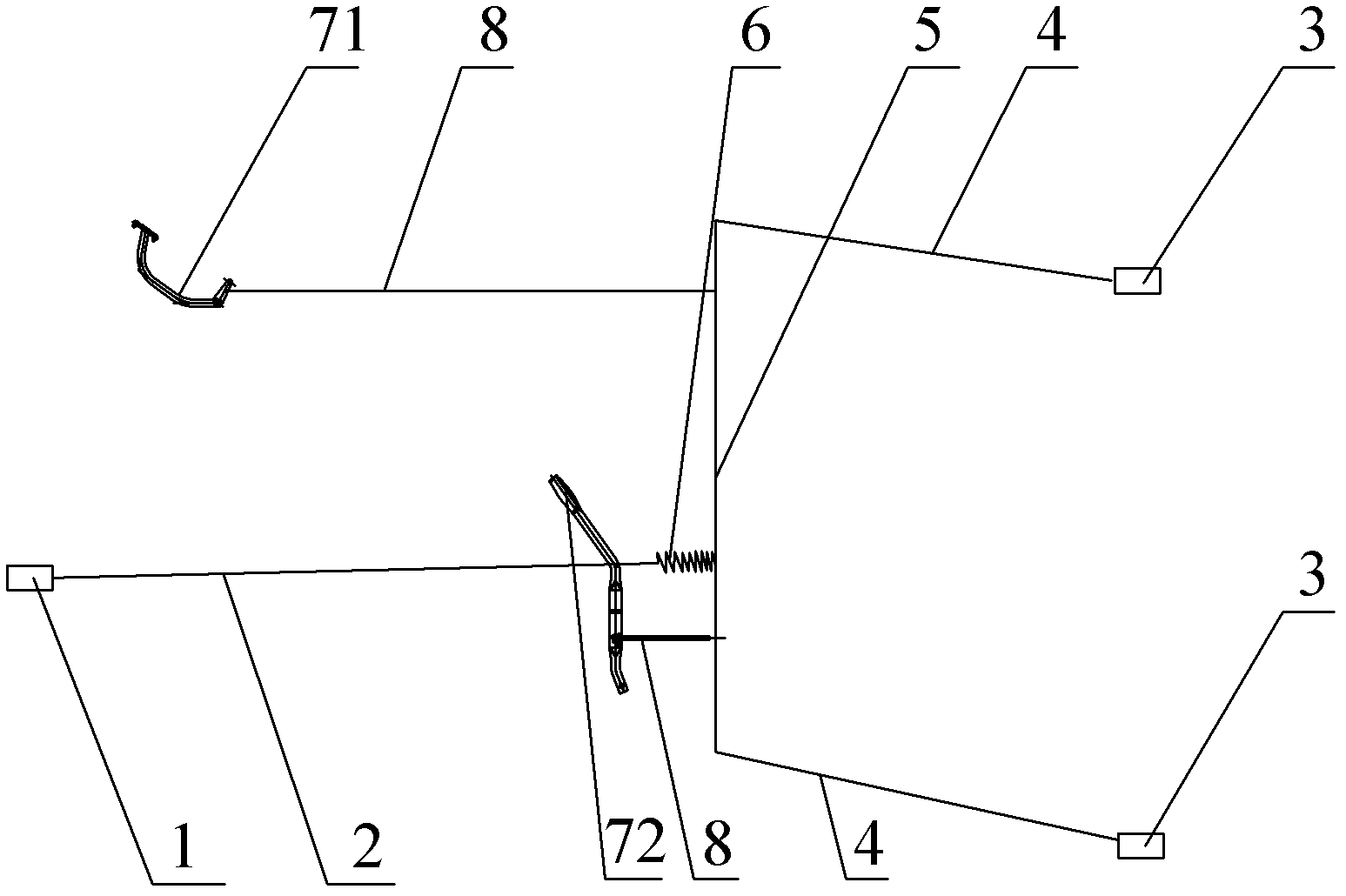

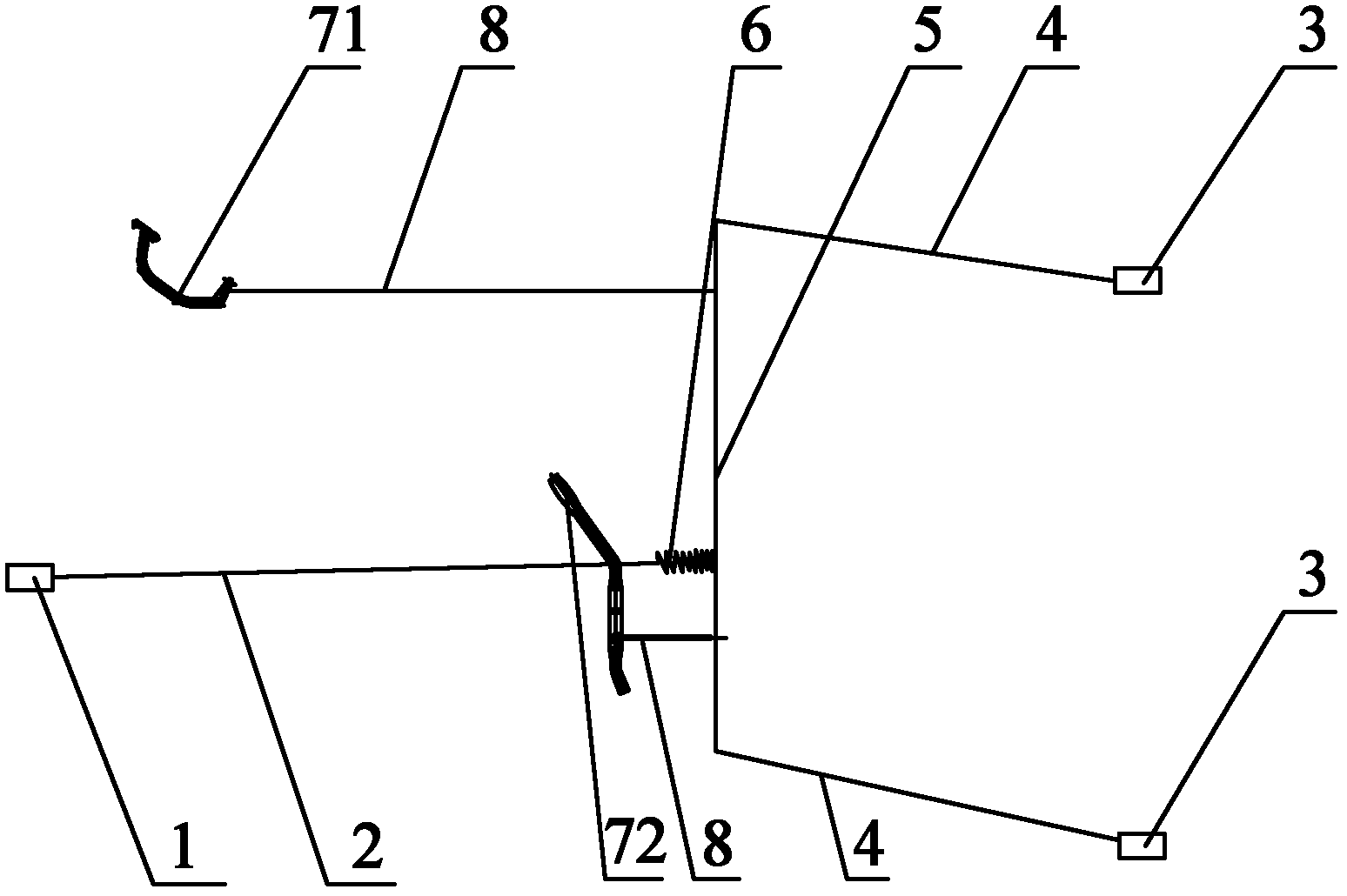

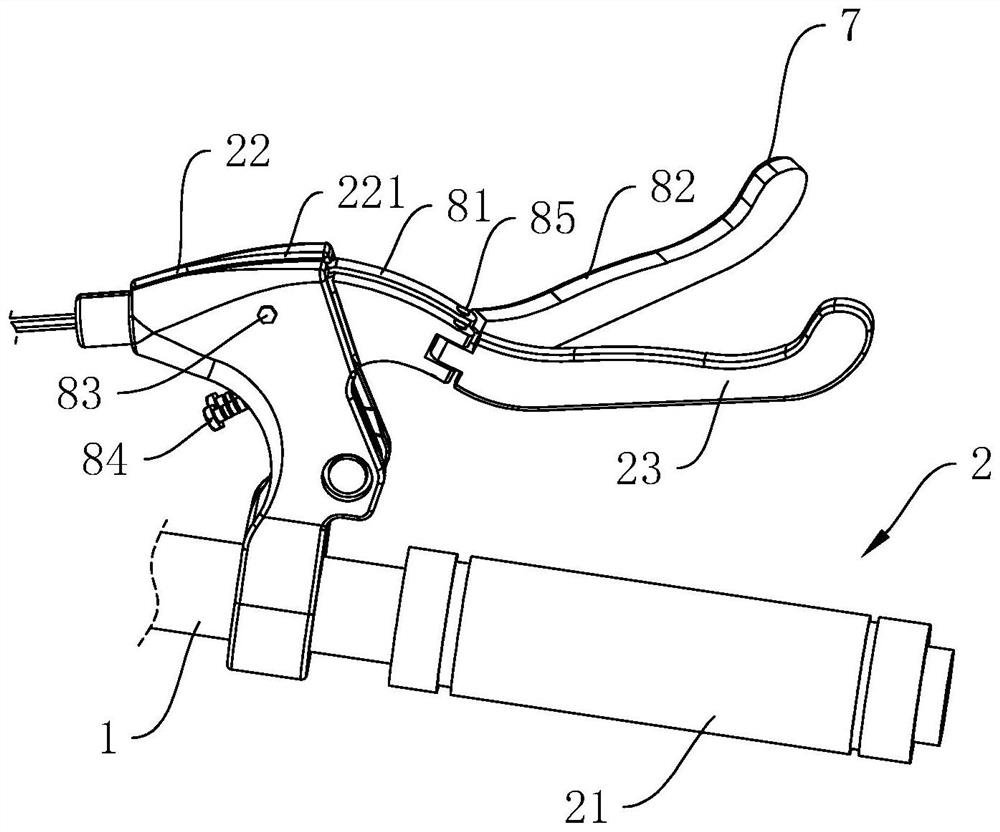

Motor tricycle and brake system thereof

The invention discloses a brake system of a motor tricycle, which comprises a front-wheel brake, rear-wheel brakes, a brake linkage rod and a brake operation part. The brake operation part is connected with the brake linkage rod, the rear-wheel brakes are connected with the brake linkage rod through rear-wheel brake pull rods, and the front-wheel brake is connected with the brake linkage rod through a front-wheel brake pull rod and a compensation spring connected with the front-wheel brake pull rod. The brake system of the motor tricycle is a front-wheel and rear-wheel combined brake system, and due to the structural design of the brake system, locking of the front wheel can be avoided on the basis of effective braking and safety potential hazards caused by locking are eliminated. The invention further discloses the motor tricycle comprising the brake system.

Owner:LONCIN MOTOR

Coating material used for preventing locking of engine crankshaft, and preparation method and usage method thereof

InactiveCN109423179AExtended service lifeImprove waterproof performanceFireproof paintsCrankshaftsEpoxyAntioxidant

The invention discloses a coating material used for preventing locking of an engine crankshaft, and a preparation method and a usage method thereof. Raw materials of the coating material are composedof, by weight, PAG polyether base oil, modified plant-based synthetic ester oxidation sunflower seed oil, epoxy resin, organic molybdenum, tungsten disulfide powder, tungsten diselenide powder, graphite fluoride powder, polyphenyl, a flame retardant, an anti-wear agent, and an antioxidant. The coating material is applied to a crankshaft journal surface or / and a bearing surface between a crankshaftjournal and a bearing bush (tile), and can provide adequate lubrication under the condition that effective lubrication cannot be provided due to inferior quality of engine oil or adequate lubricationcannot be provided between a crankshaft and a connecting rod when engine oil reduces; and the coating material can withstand a protective coating that is extremely high in temperature, not easy to wash off and burned out, has excellent waterproof, rust proof, anti-corrosion and anti-fretting wear characteristics on metal parts, can form solid dry film lubrication in the environment above 200 DEGC, can play the role of lubricating and preventing metal sintering from being stuck at a temperature of up to 1400 DEG C, and effectively avoids occurrence of the phenomenon that dry friction is generated between the tile and the crankshaft to eventually lead to the locking between the crankshaft and the connecting rod.

Owner:李保文

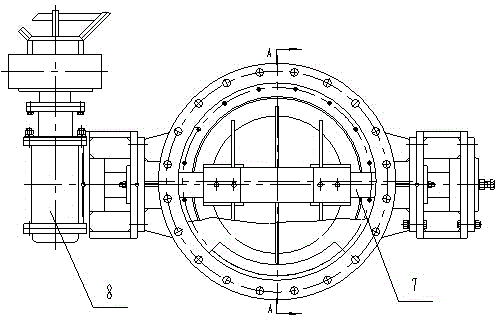

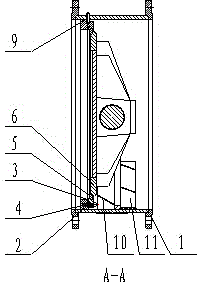

Anti-locking high-temperature seal butterfly valve

ActiveCN104964048AEliminate expansion and contraction restrictionsGuaranteed normal operation of the switchLift valveValve housingsEconomic benefitsButterfly valve

The invention provides an anti-locking high-temperature seal butterfly valve and belongs to the technical field of seal butterfly valves. The anti-locking high-temperature seal butterfly valve is used for preventing the occurrence of high-temperature locking fault of a seal valve. According to the technical scheme, a valve body seal ring of the seal butterfly valve is located on the inner side of a valve body supporting seat, a plurality of locking bolts are arranged on the periphery of the valve body seal ring in the horizontal direction and connected with the valve body supporting seat, the contacting face between the valve body supporting seat and the valve body seal ring is provided with a directional pin, the directional pin is arranged in the diameter direction of the valve body seal ring, and a gap of 2-3 mm is formed between the outer circumferential face of the valve body seal ring and the inner circumferential face of the valve body seal ring. By means of the anti-locking high-temperature seal butterfly valve, the limitation of the temperature changes of the valve body on the dilatation of the valve body seal ring is eliminated, the influence of temperature rise dilatation on the valve sealing pair junction surface is also eliminated, the locking phenomenon of the seal butterfly valve is avoided, and meanwhile the valve can be in a good sealing state all the time. The anti-locking high-temperature seal butterfly valve has the advantages that the structure is simple, the design is reasonable, the problem that the fault of locking occurrence of the high-temperature seal butterfly valve in high-temperature working conditions is not solved for a long time is solved, and the economic benefit of enterprises is remarkably improved.

Owner:HEBEI CHANGHONG VALVE CO LTD

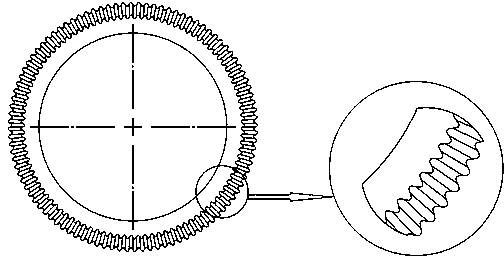

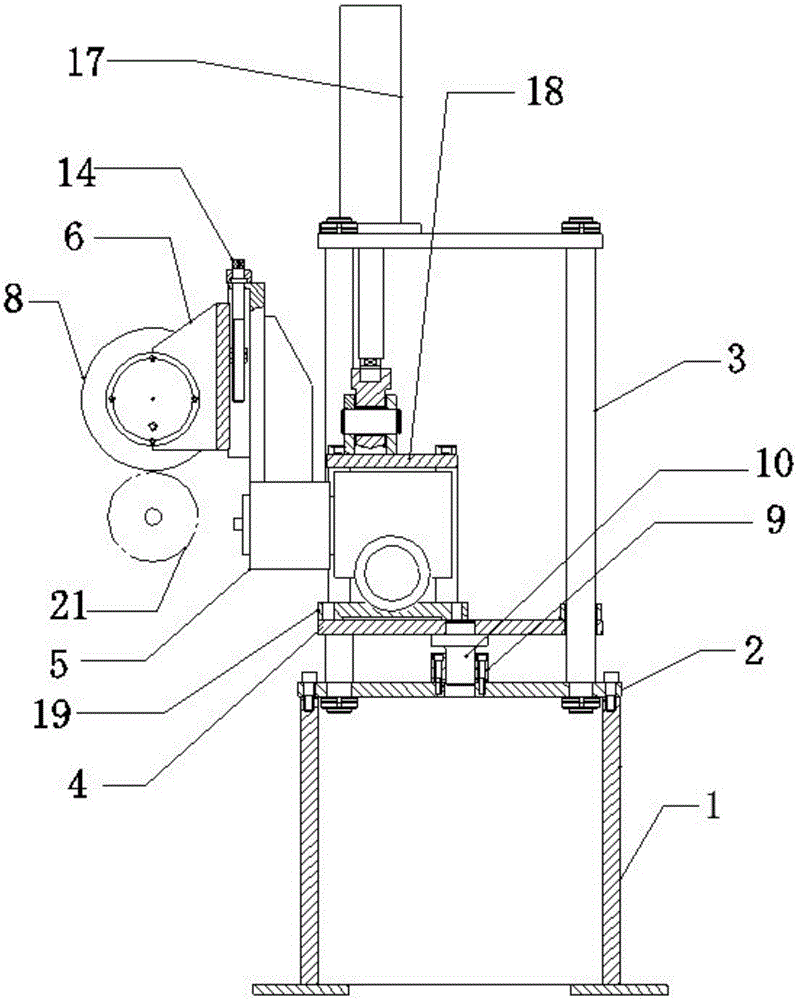

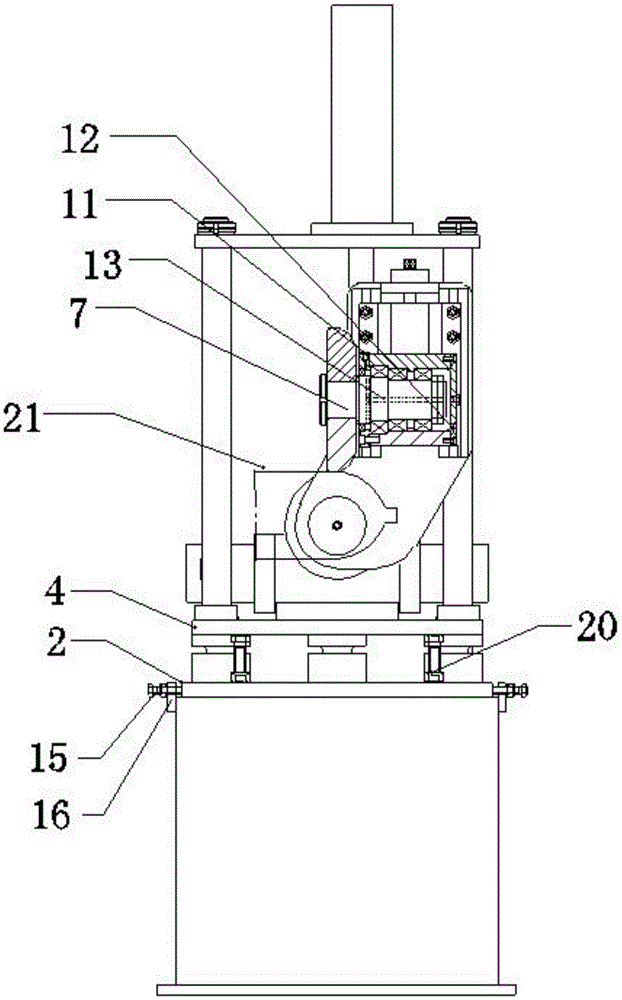

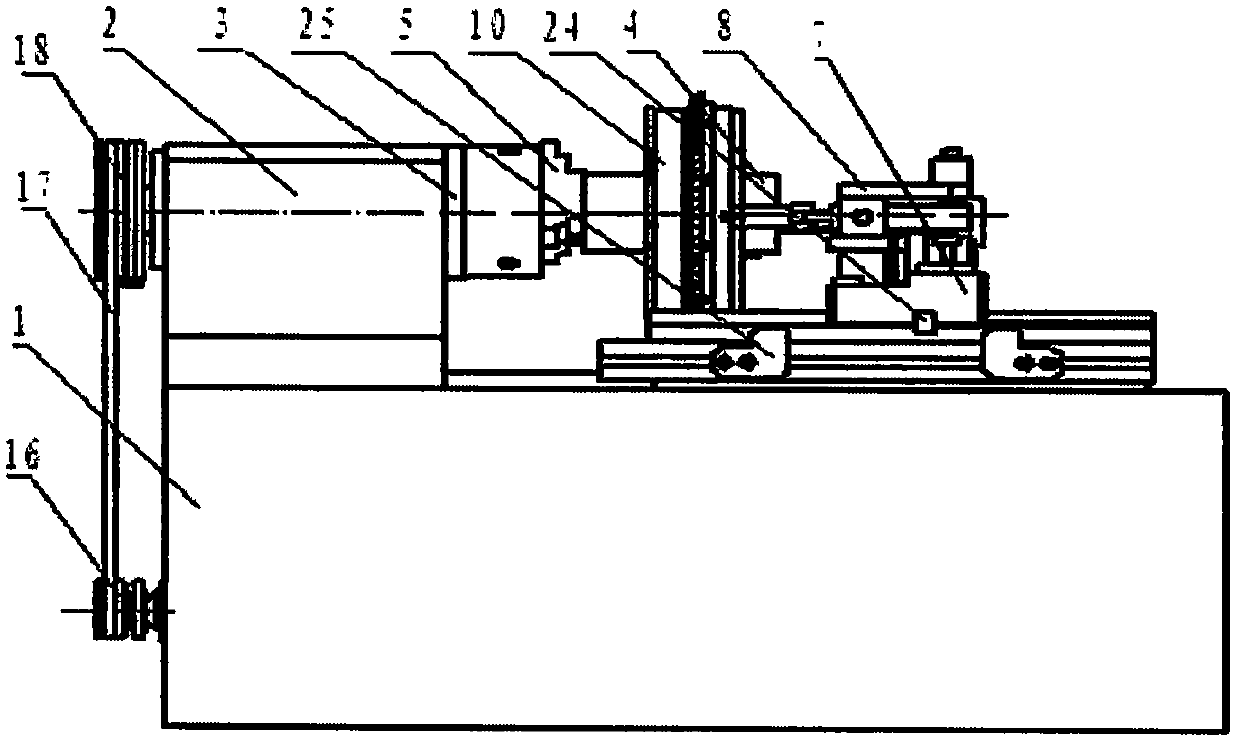

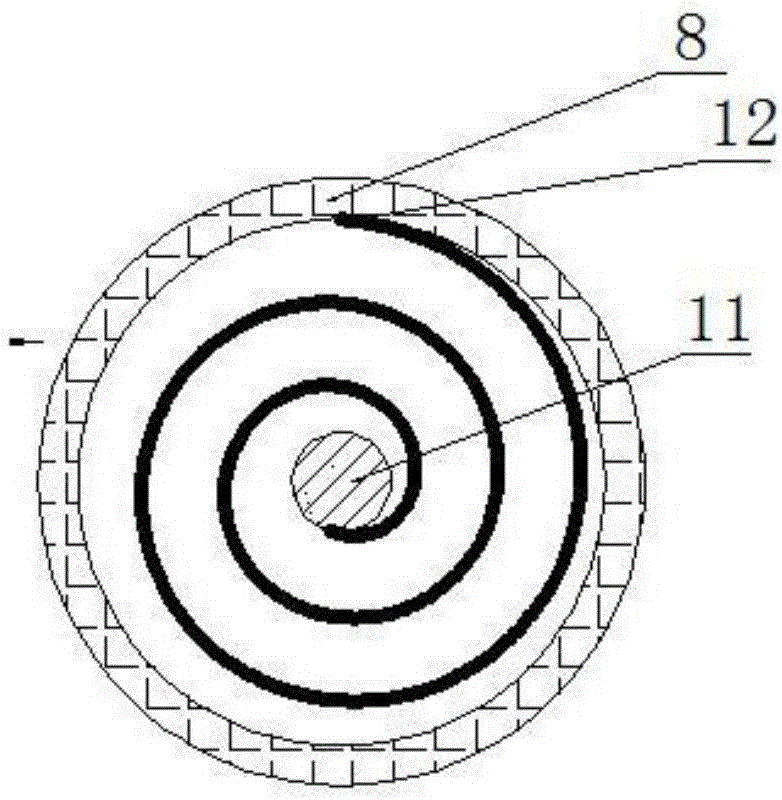

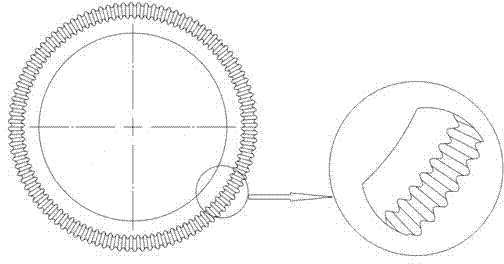

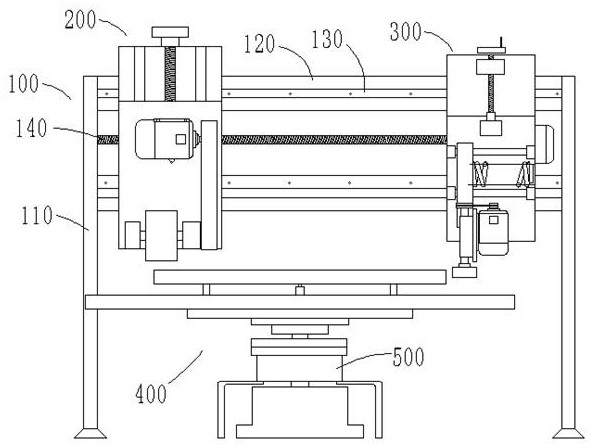

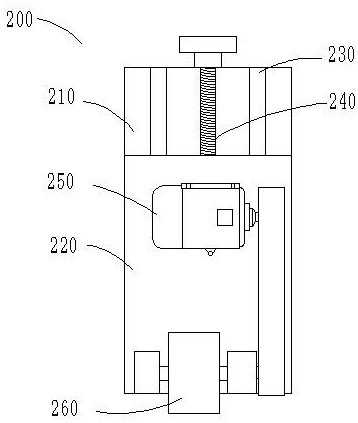

Thread ring gage automatic precise finishing machine tool

InactiveCN107866730APrevent lock phenomenonGrind evenlyLapping machinesFrequency changerRotation velocity

The invention relates to a thread ring gage automatic precise finishing machine tool. The thread ring gage automatic precise finishing machine tool comprises a machine body, a headstock, a headstock main shaft, a finishing tool clamping mechanism, a finishing tool, a linear guideway pair, a bracket, a pneumatic clamping mechanism, an electric appliance, a transmission component and the like. The rotation velocity of the main shaft is controlled by a frequency changer, stepless speed regulation is achieved, and the requirement for finishing of workpieces with different specifications is met. Acomposite floating mechanism designed on the bracket can ensure stable finishing and even overlapped finishing of each point of a workpiece, and meanwhile, the workpiece is prevented from being lockedwith the finishing tool, the pneumatic clamping mechanism for clamping the workpiece is fixed to the top face of the bracket, a large chain wheel mounted on an excircle of the pneumatic clamping mechanism is connected with a transmission mechanism, so that the workpiece and the finishing tool rotate in reverse directions, and thus the finishing efficiency is improved. According to the scheme, compared with a machine tool main shaft chuck clamping finishing tool currently and commonly used in China and a traditional finishing mode that a person uses the pair of hands to hold the workpiece, thethread ring gage automatic precise finishing machine tool is safer and more convenient, and the efficiency and the precision are improved greatly.

Owner:汉中汉江机械有限责任公司

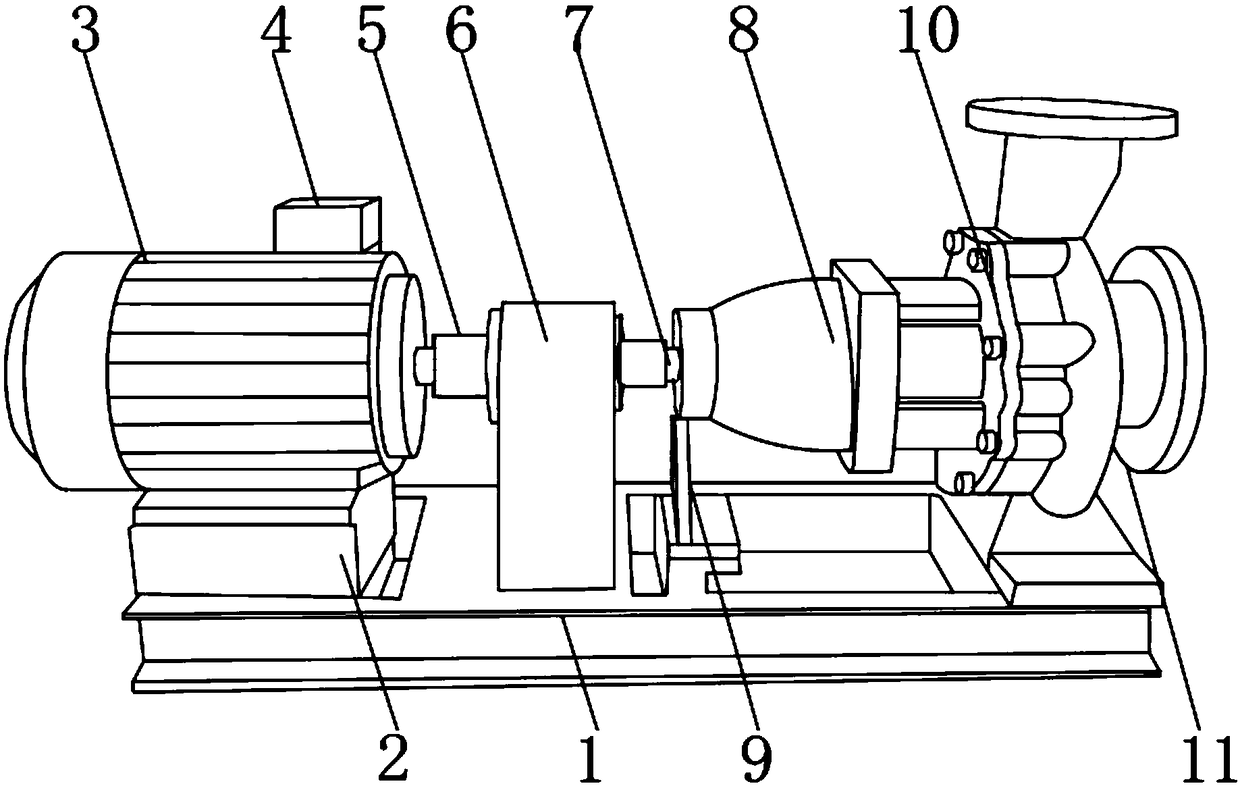

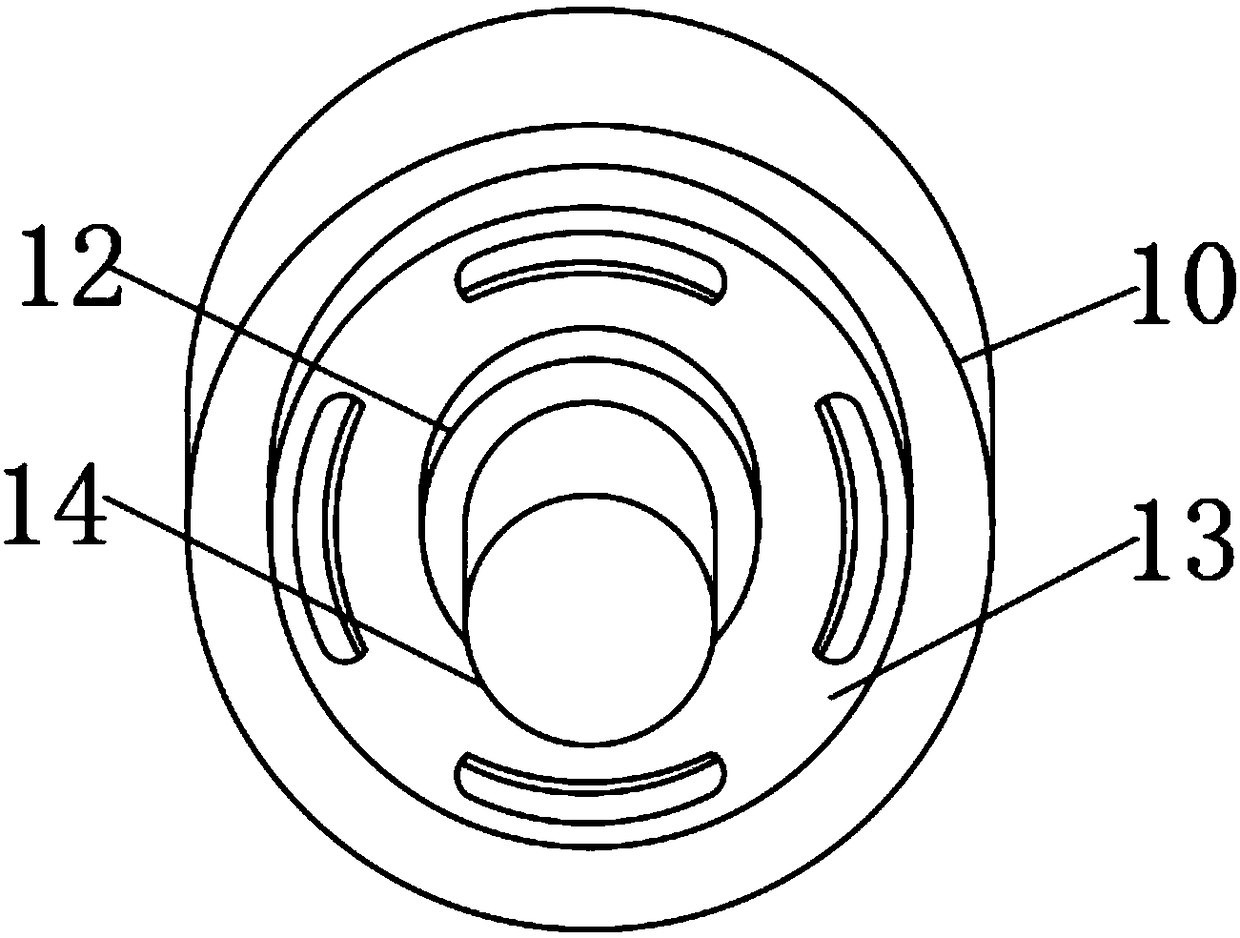

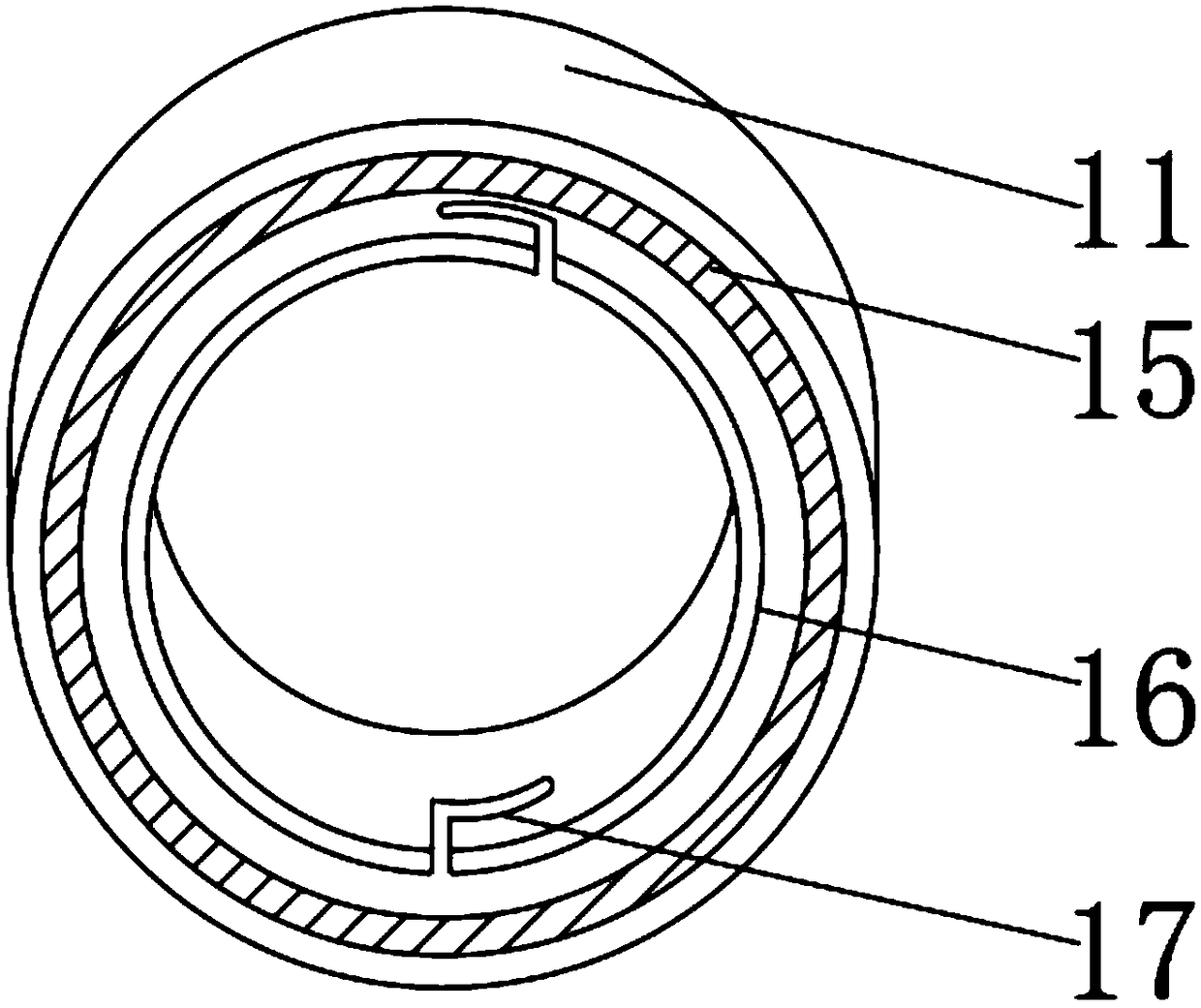

Anti-lock chemical centrifugal pump

InactiveCN108843583AProtect bearingsPrevent lock phenomenonPump componentsPump installationsCentrifugal pumpSlag

The invention discloses an anti-lock chemical centrifugal pump. The anti-lock chemical centrifugal pump comprises a bottom seat, a base is fixedly installed at the position, close to one side, of theouter surface of the upper end of the bottom seat, and a motor is fixedly installed on the outer surface of the upper end of the base. An outlet box is fixedly installed at the position, close to oneside, of the upper end of the motor, a pump shaft is arranged on one side of the motor, a middle support is arranged on the outer surface of the pump shaft, and a moving ring is arranged at one end ofthe pump shaft. A pump cover is arranged at one end of the pump shaft, a supporting plate is fixedly installed at the position, close to one side, of the bottom end of the pump cover, a pump body isfixedly installed on one side of the pump cover, and an installation ring is fixedly installed at the position, close to the middle, of one side of the pump body. The anti-lock chemical centrifugal pump is provided with a slag prevention cover, clamping grooves and a buffer plate, can prevent residues from falling into a bearing, is convenient for people to connect water pipes, can reduce the vibration caused by the chemical centrifugal pump, and brings better application prospects.

Owner:南京中溧知识产权代理有限公司

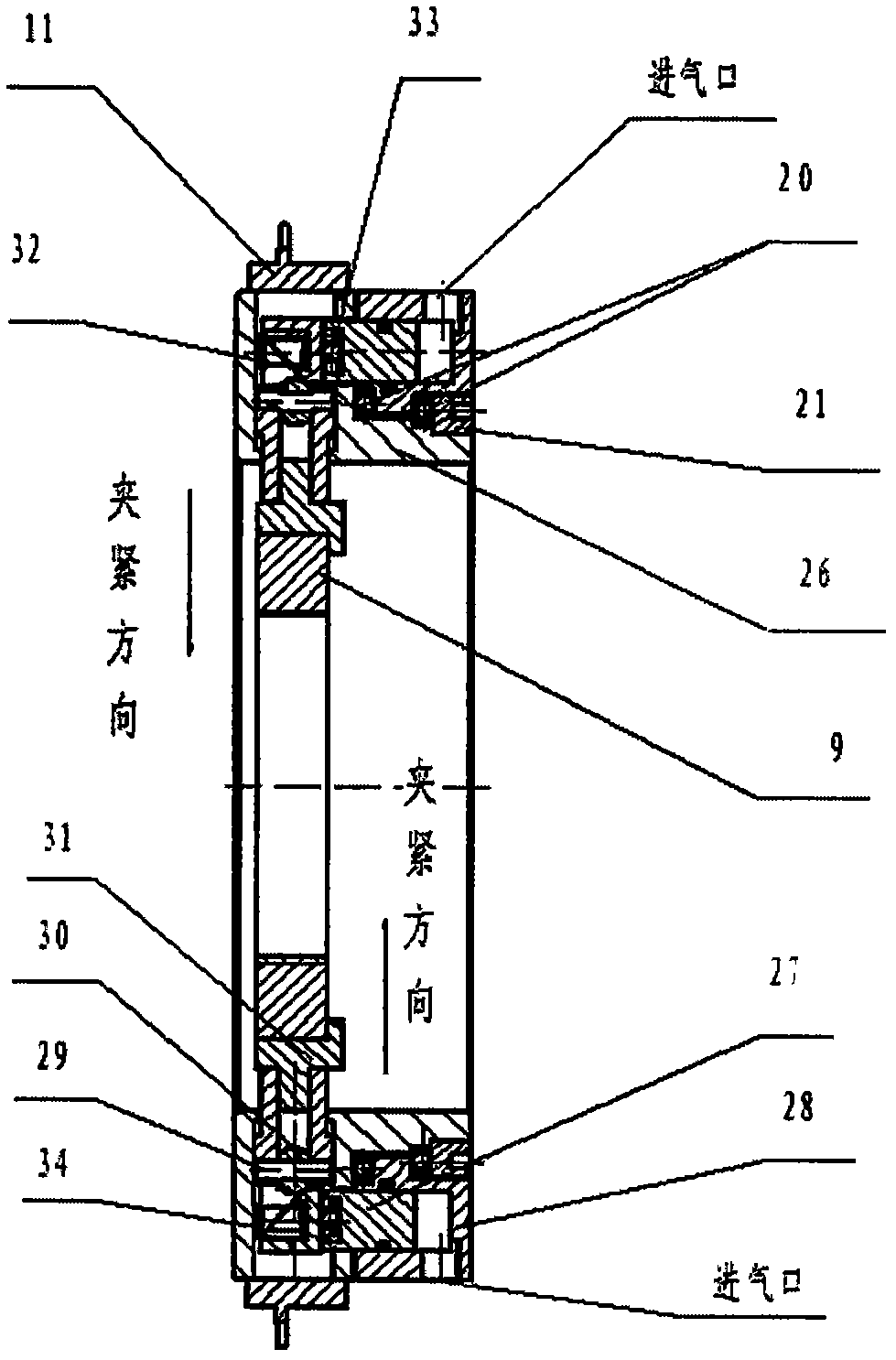

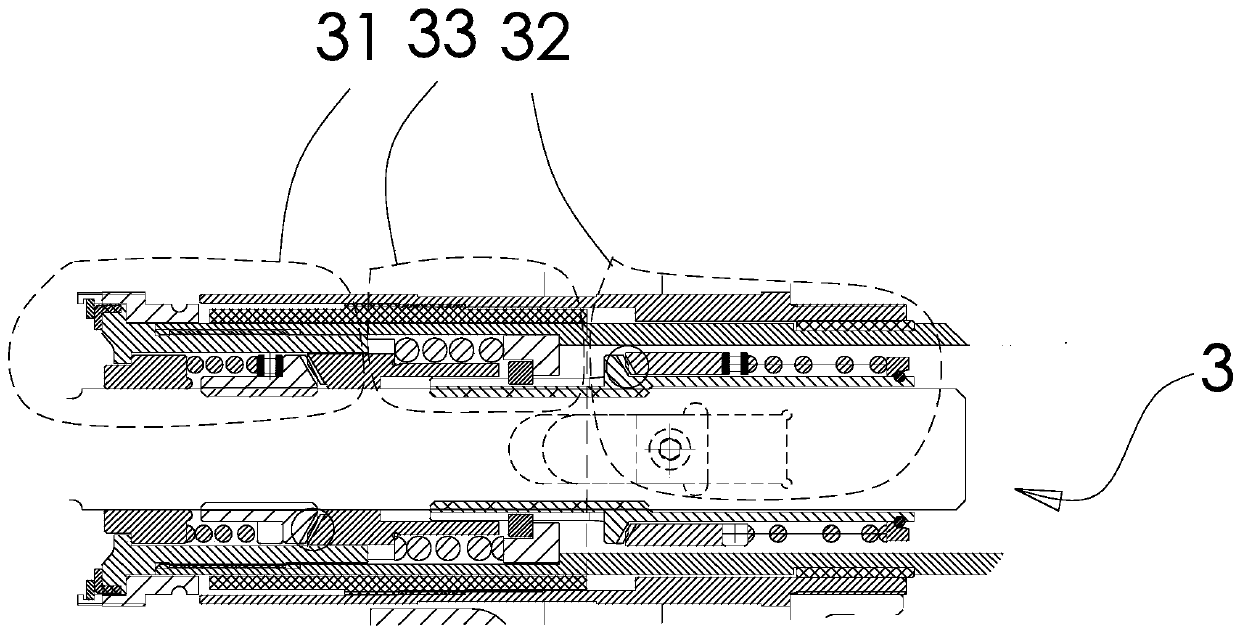

Pneumatic Brake Cylinder, Air Brake Device and Adjustment Clearance Identification Method

ActiveCN107327523BPrevent lock phenomenonImprove driving safetyBrake actuating mechanismsSlack adjustersPulp and paper industry

The invention relates to a pneumatic brake cylinder, an air brake device and a gap adjustment recognizing method. The pneumatic brake cylinder comprises a reset unit and a brake unit connected with the reset unit and is characterized in that a gap adjustment unit used for adjusting the brake gap is arranged between the reset unit and the brake unit and comprises a first adjustment module, a second adjustment module and an adjustment limiting module; the adjustment limiting module is arranged between the first adjustment module and the second adjustment module and comprises a limit spring and a limit base; and the limit spring is fixedly connected with the limit base and the first adjustment module so as to ensure that the size of the brake gap can be controlled within a certain range, the function of recognizing the gap adjustment size in the gap adjustment process is achieved, the locking phenomenon caused by extra adjustment is prevented, and the travelling safety is improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

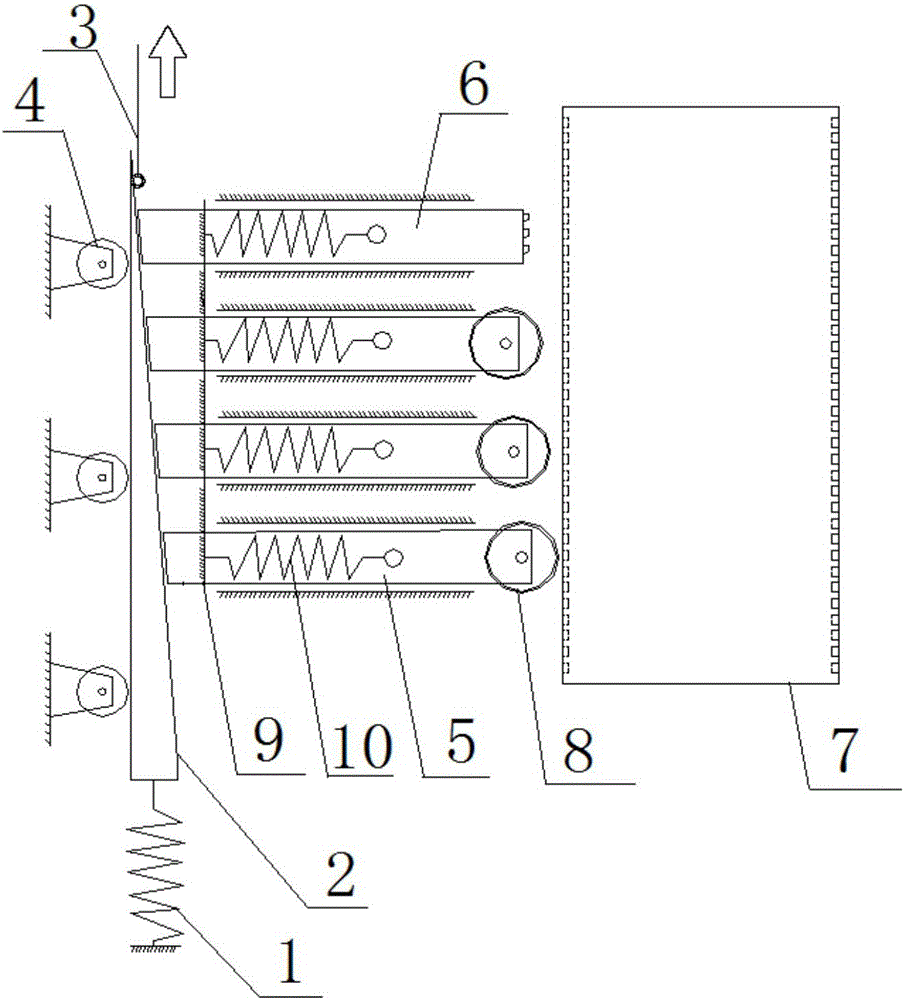

Clockwork energy storage assisting braking device

The invention discloses a clockwork energy storage assisting braking device. The clockwork energy storage assisting braking device comprises at least two telescopic braking devices and a braking bar, wherein a clockwork energy storage friction wheel is arranged at the end part of each of the telescopic braking devices, and comprises a friction wheel body; and a fixing shaft is arranged in each of the friction wheel bodies and is connected with the corresponding friction wheel body through a corresponding energy storage clockwork.

Owner:徐州乐泰机电科技有限公司

Drill rod adopting pangolin scale biomimetic structure

The invention discloses a drill rod adopting a pangolin scale biomimetic structure. The drill rod comprises a rod body and hollow circular truncated cone units, wherein an inner cavity of each hollow circular truncated cone unit is cylindrical, bulged ridges and grooves are longitudinally formed in the outer circumference surface of each hollow circular truncated cone unit at intervals, the hollow circular truncated cone units are inlaid together end to end, tightly nested on the rod body and then fixed by glue. Compared with the prior art, the drill rod adopting the pangolin scale biomimetic structure can effectively prevent locking phenomenon of the drill rod during a drilling process of a soft coal seam, so that the drill rod is easy to retreat.

Owner:WUHAN UNIV

Bicycle brake feedback mechanism

PendingCN114572333ADoes not affect stopReduce rotation speedCycle brakesRider propulsionVehicle frameGear wheel

The invention discloses a bicycle brake feedback mechanism, and belongs to the technical field of bicycle braking. The main brake handle is mounted on a frame, the V-shaped brake assembly is mounted on a wheel carrier, the wheel shaft and the mounting box are mounted on the wheel carrier, one end of the wheel shaft is rotatably connected with the mounting box, a driving gear is fixed to the end, located in the mounting box, of the wheel shaft, and a flywheel assembly is arranged on the inner wall of the mounting box. An auxiliary brake shaft is slidably connected to the inner wall of the mounting box in the vertical direction, a transmission gear is rotatably connected to the periphery of the auxiliary brake shaft, a reset assembly is arranged in the mounting box, one end of the auxiliary brake shaft is connected with a brake rope capable of driving the driving gear to be meshed with the transmission gear, and the end, away from the auxiliary brake shaft, of the brake rope is connected with an auxiliary brake handle. The flywheel assembly is used for decelerating the wheels, meanwhile, the energy of the flywheel assembly can be applied to bicycle starting, the starting difficulty of a rider is relieved, and the energy utilization rate is increased.

Owner:深圳中华自行车(集团)股份有限公司

Metal desktop grinding device and method of use thereof

ActiveCN111673570BReduce waiting timeImprove work efficiencyEdge grinding machinesGrinding carriagesDrive motorSlow speed

The invention relates to a grinding device for a metal desktop and a method for using it, comprising a bracket, a surface grinding device and a side grinding device are slidably arranged on the support, and a Desktop fixing device, the desktop fixing device includes a driving motor, the driving motor is connected with a reducer, the output shaft of the reducer is connected with a slowing device, the output shaft of the slowing device is connected with a turntable, the desktop to be polished Place it on the turntable, use the surface grinding device and the side grinding device to grind the tabletop and the side of the tabletop respectively, when the grinding is completed and the turntable needs to stop rotating, turn on the slowing device on the tabletop fixing device to stop the turntable quickly, reducing Waiting time, improve work efficiency.

Owner:招远东威金属工艺家具有限公司

Pneumatic brake cylinder, air brake device and gap adjustment recognizing method

ActiveCN107327523APrevent lock phenomenonImprove driving safetyBrake actuating mechanismsSlack adjustersPulp and paper industry

The invention relates to a pneumatic brake cylinder, an air brake device and a gap adjustment recognizing method. The pneumatic brake cylinder comprises a reset unit and a brake unit connected with the reset unit and is characterized in that a gap adjustment unit used for adjusting the brake gap is arranged between the reset unit and the brake unit and comprises a first adjustment module, a second adjustment module and an adjustment limiting module; the adjustment limiting module is arranged between the first adjustment module and the second adjustment module and comprises a limit spring and a limit base; and the limit spring is fixedly connected with the limit base and the first adjustment module so as to ensure that the size of the brake gap can be controlled within a certain range, the function of recognizing the gap adjustment size in the gap adjustment process is achieved, the locking phenomenon caused by extra adjustment is prevented, and the travelling safety is improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com