Vertical shaft type dry-mix mortar stirrer for building construction

A dry-mixed mortar and building construction technology, applied in cement mixing devices, liquid batching supply devices, clay preparation devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

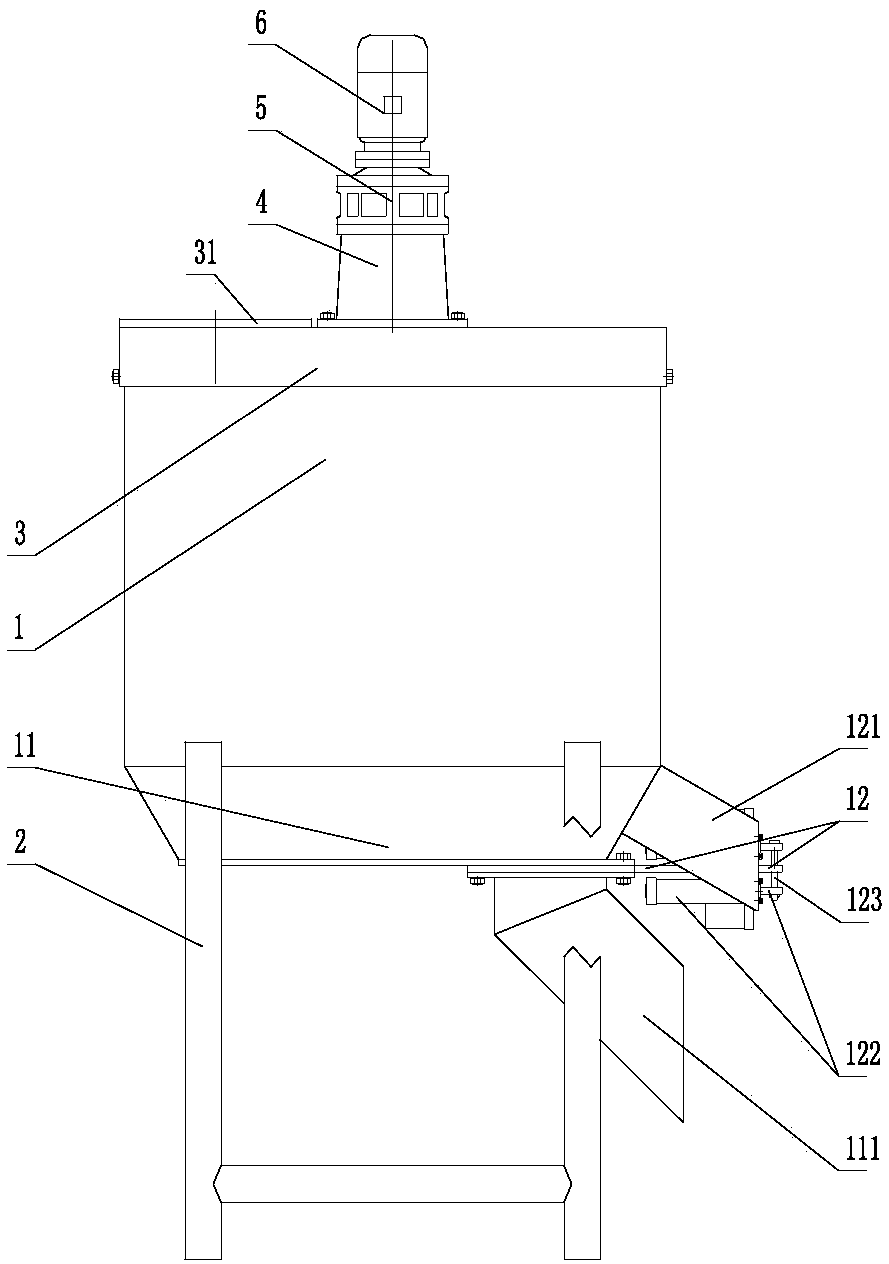

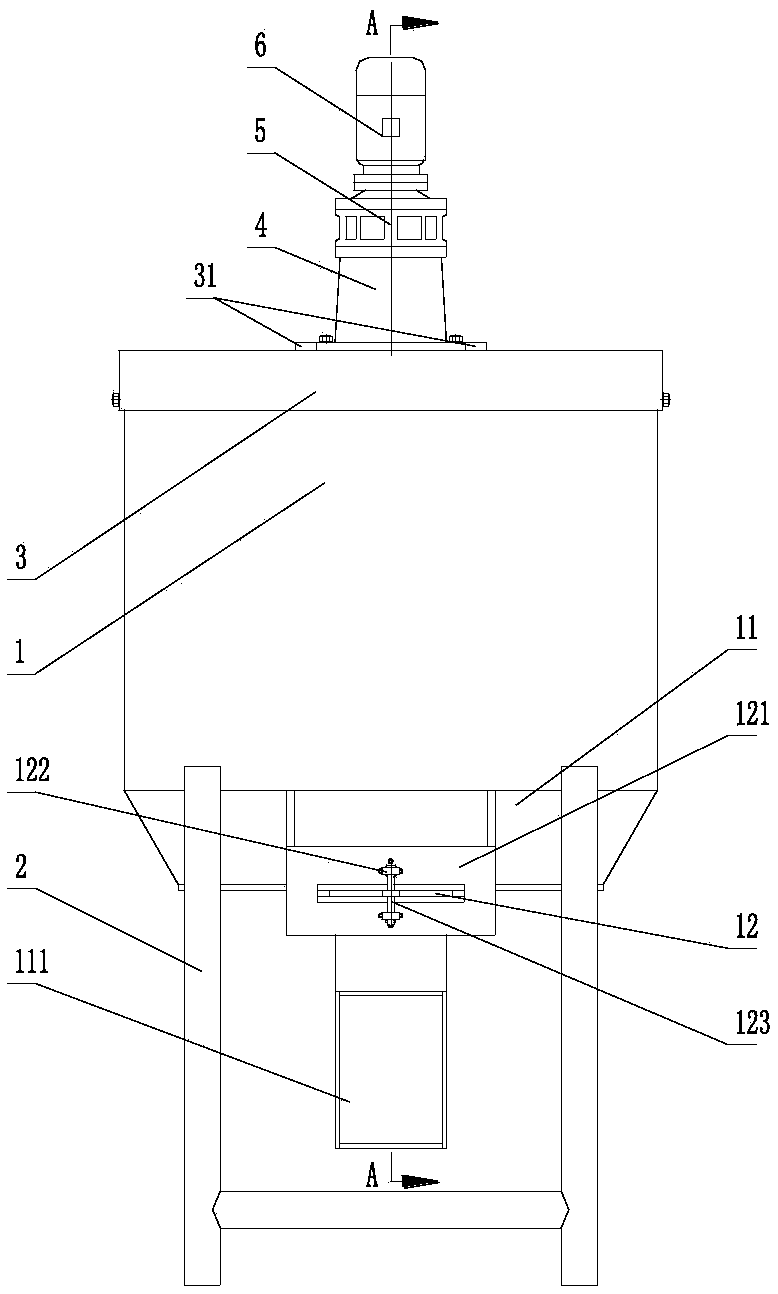

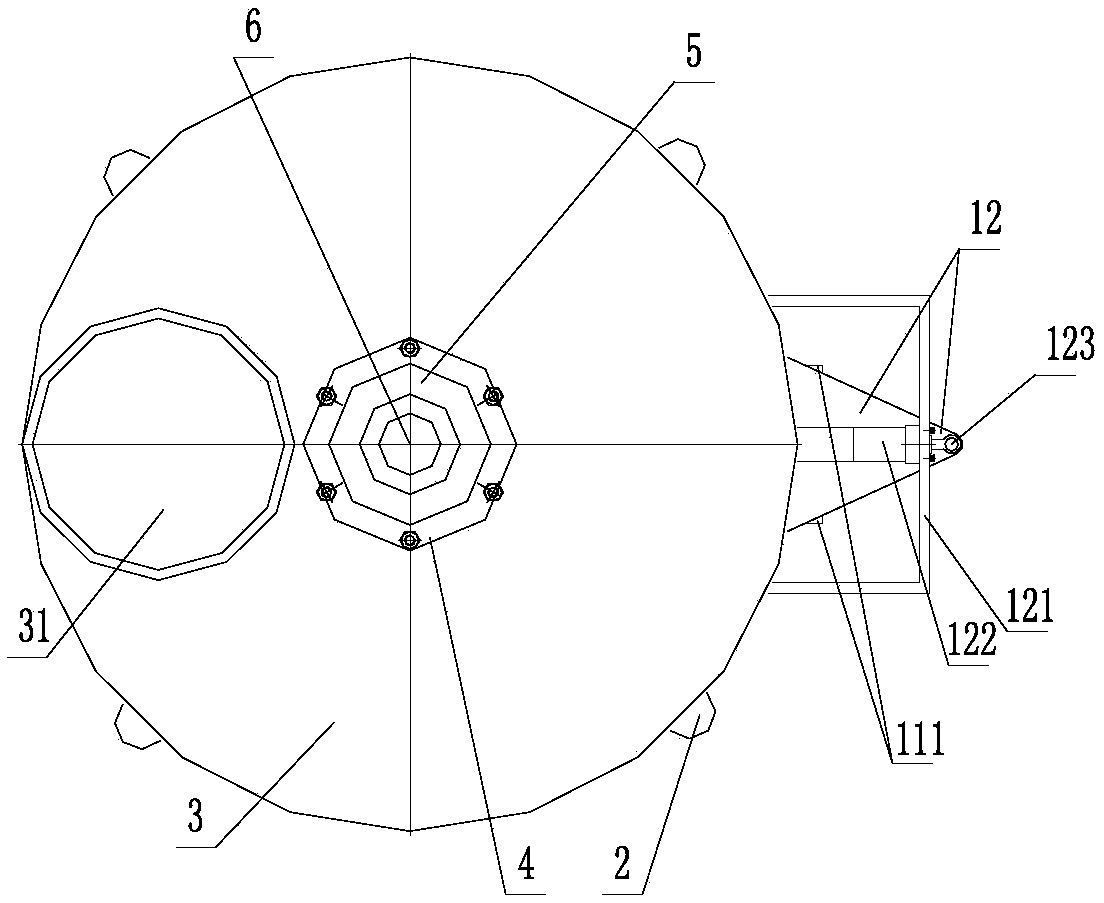

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

[0021] It should be noted that the "front", "rear", "left", "right", "upper" and "lower" here are only exemplary directions defined for the convenience of describing the present invention, as figure 1 As shown, the direction of the left side of the paper is "left", the direction of the right side of the paper is "right", the direction of the left and right sides of the paper is "vertical", the direction of the upper side of the paper is "top or top", and the direction of the lower side of the paper is "vertical". is "bottom or bottom", the direction of the front side of the paper is "front", the direction of the back side of the paper is "back", and the direction of the front and back side of the paper is "horizontal". Of course, those skilled in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com