Turntable structure of injection molding machine

A technology of injection molding machine and turntable, which is applied in the field of injection molding machine turntable structure, can solve the problems of affecting the working efficiency of injection molding machine, the locking of the base and the rotating disk, and large contact area, so as to prevent locking, reduce friction, and small contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

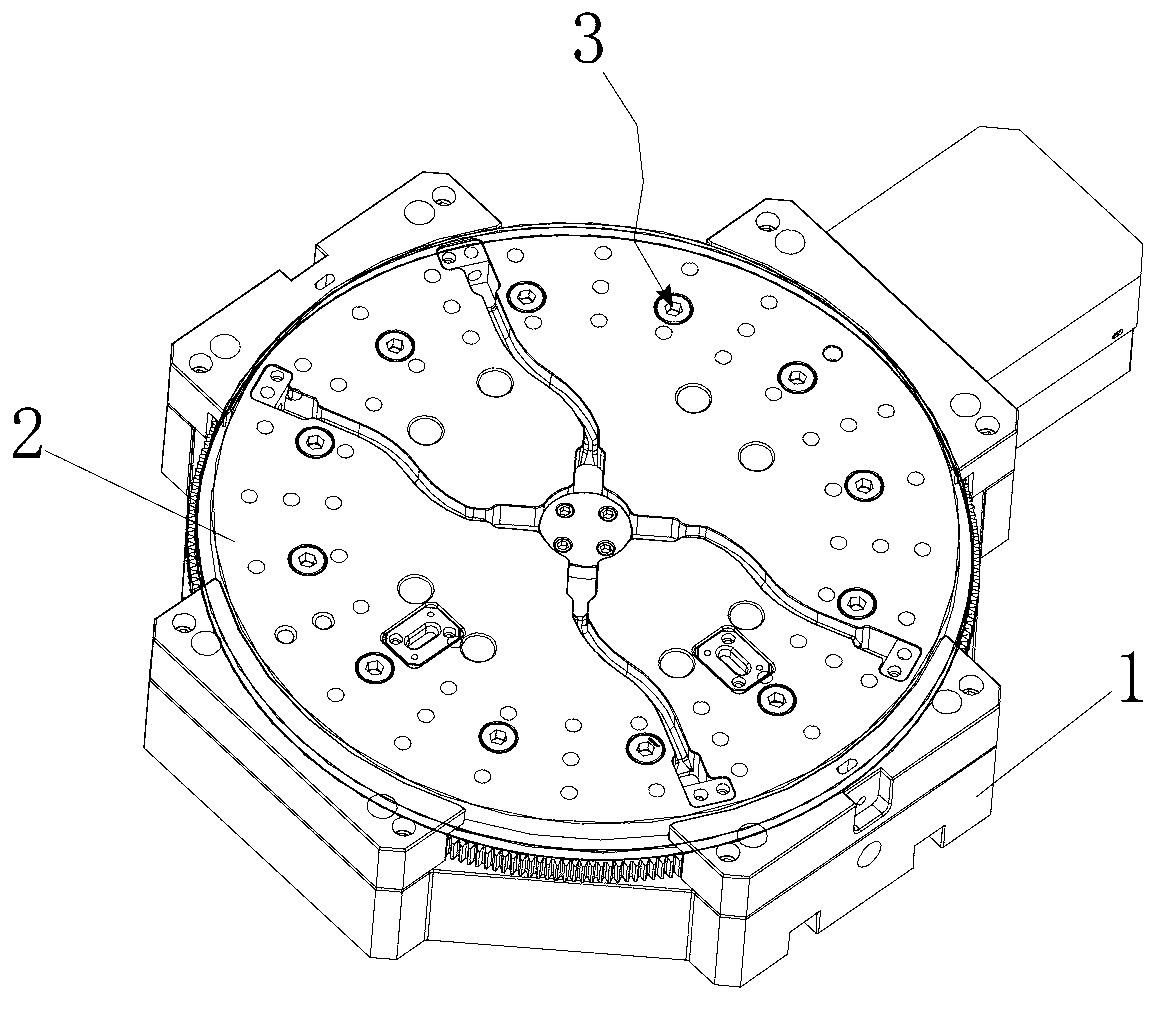

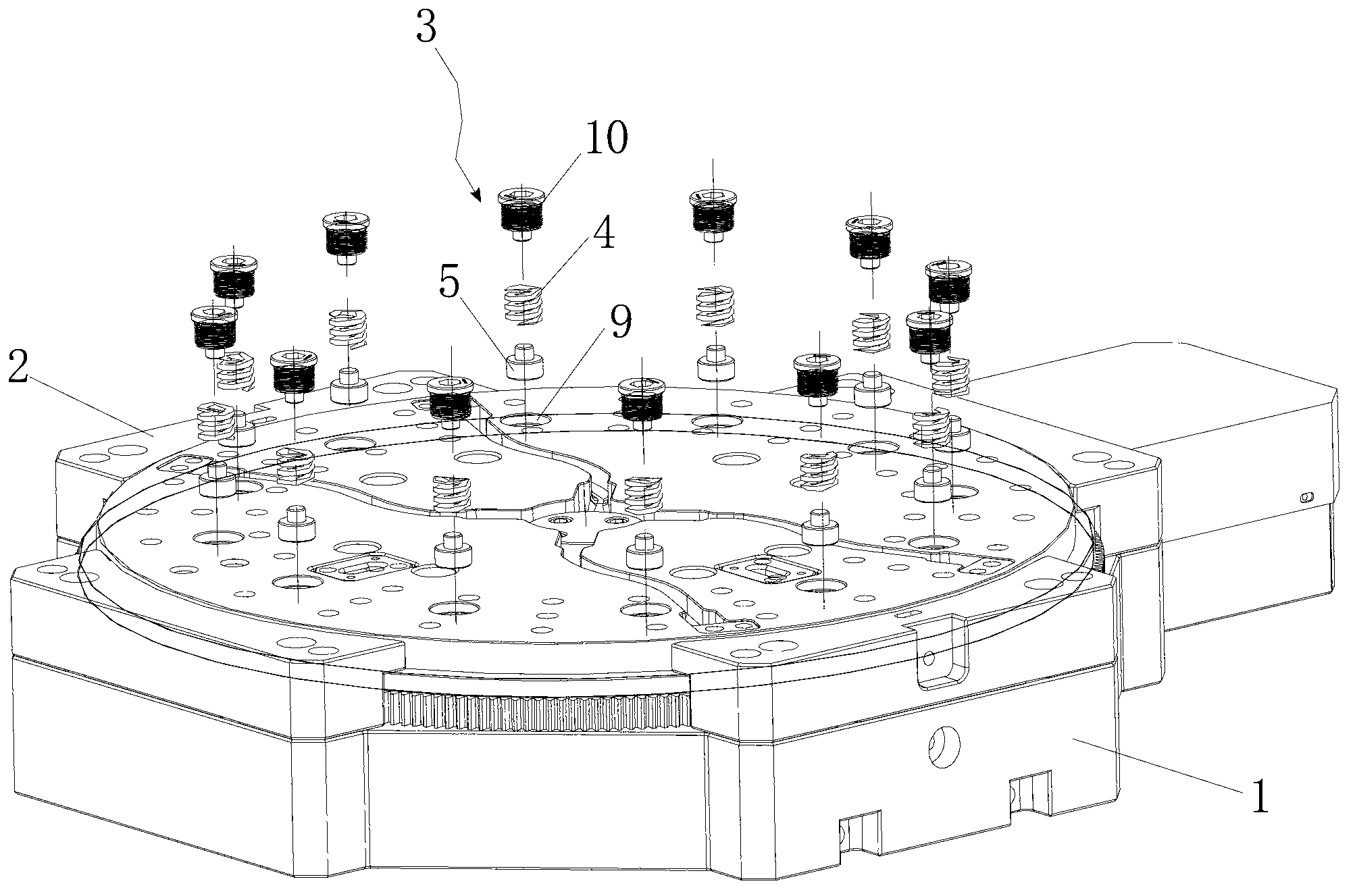

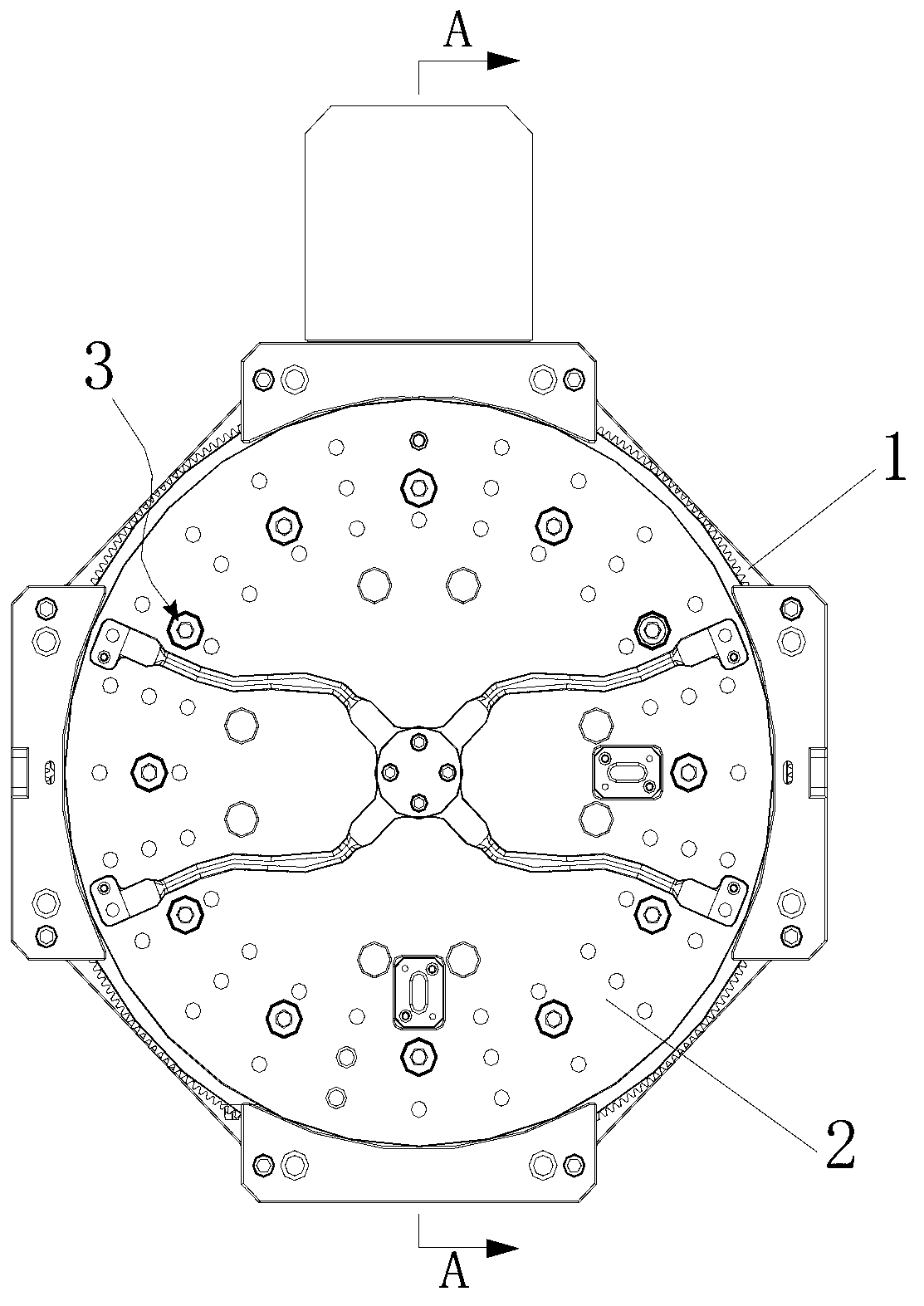

[0019] Embodiment one, with reference to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , to provide a turntable structure for injection molding machines, including a base 1, a turntable 2 installed on the base 1, a device is installed between the base 1 and the turntable 2 to lift the turntable 2 so that the base 1 and the turntable 2. Several elastic wear-resistant devices 3 with a certain gap are left, and the several elastic wear-resistant devices 3 are arranged in a ring on the same circumference of the rotating disk 2. The elastic wear-resistant device 3 is composed of a spring 4, which is connected with the spring 4 is composed of a wear-resistant part 5 connected at one end, and the wear-resistant part 5 is in elastic contact with the base 1 or the rotating disk 2 by using the spring 4 to cooperate with the wear-resistant part 5 .

[0020] The wear-resistant part 5 has a wear-resistant protrusion 8 , and the wear-resistant protrusion 8 is in contact with t...

Embodiment 2

[0023] Embodiment two, refer to Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , to provide a turntable structure for injection molding machines, including a base 1, a turntable 2 installed on the base 1, a device is installed between the base 1 and the turntable 2 to lift the turntable 2 so that the base 1 and the turntable 2. Several elastic wear-resistant devices 3 with a certain gap are left. The several elastic wear-resistant devices 3 are arranged in a ring on the same circumference of the base 1. The elastic wear-resistant devices 3 are composed of a spring 4 and the spring 4 It is composed of wear parts 5 connected at one end.

[0024] The wear-resistant member 5 has a wear-resistant protrusion 8 on it, and the wear-resistant protrusion 8 is in contact with the rotating disk 2 .

[0025] The elastic wear-resistant device 3 is installed in the base 1, and a blind hole 11 compatible with the elastic wear-resistant device 3 is provided in the base 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com