Anti-locking high-temperature seal butterfly valve

A high-temperature sealing and anti-locking technology, applied in the field of sealing butterfly valves, can solve the problems of disrupting the rhythm and continuity of production, not being effectively solved, and economic losses, to ensure rhythm and continuity, simple structure, high The effect of promoting value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

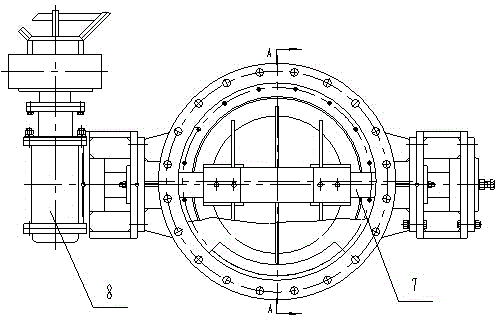

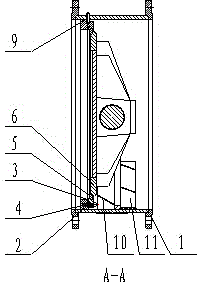

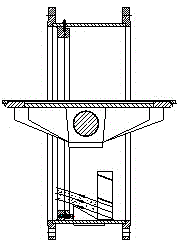

[0019] The present invention comprises a valve body 1, a valve body support seat 2, a valve body seal ring 3, a valve plate seal ring 5, a valve plate 6, a valve stem 7, and a transmission device 8, the valve body support seat 2 is connected with the valve body 1, and the transmission Device 8 is connected with valve stem 7, and valve stem 7 is connected with valve plate 6, and these structures are all prior art.

[0020] figure 1 , 2 , 3 shows that the present invention changes the rigid connection structure between the valve body sealing ring 3 and the valve body 1, and places the valve body sealing ring 3 on the windward side of the valve body support seat 2, and connects it with the locking bolt 4, When the sealing ring 3 of the valve body expands due to the influence of temperature rise, the long bolt hole of the sealing ring makes the sealing ring expand and contract freely without restriction, eliminating the influence of valve temperature changes on the expansion and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com