Calibration-free bidirectional regulating sliding supporter

A two-way adjustment and supporter technology, which is applied in the field of tools, can solve the problems of large limitations and small use range of the supporter, and achieve the effects of reducing friction, increasing the practical range, and overcoming locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

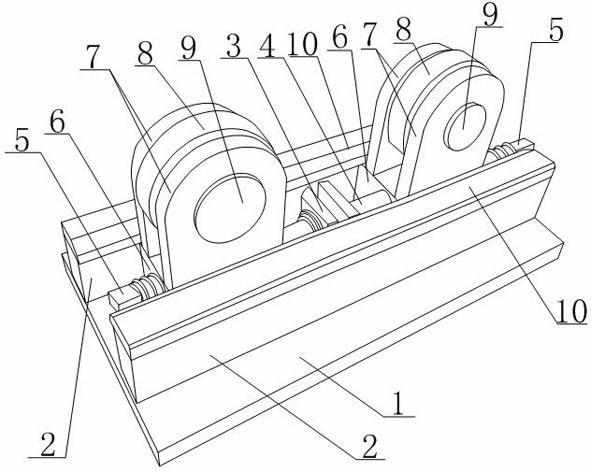

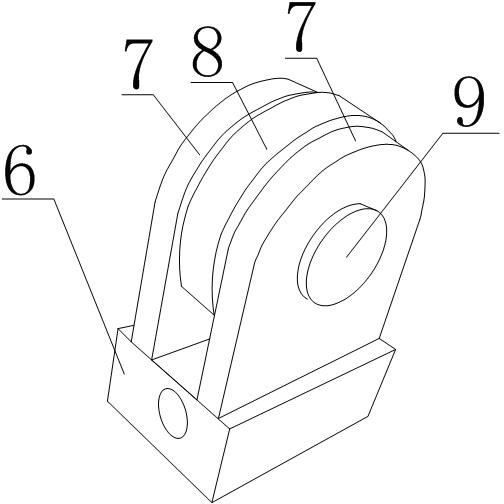

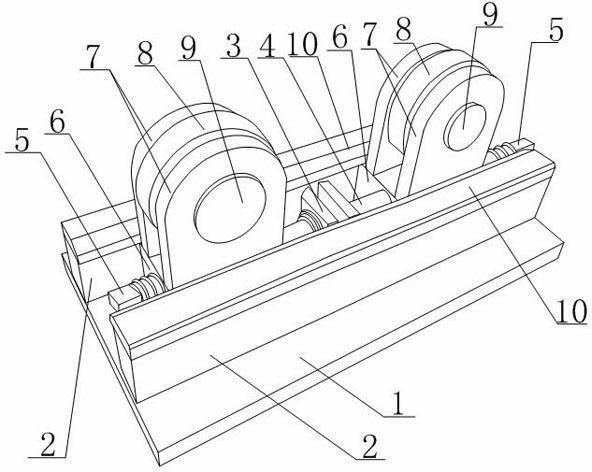

[0021] Such as figure 1 As shown, the proofreading-free two-way adjustable sliding supporter of the present invention includes a bottom plate 1, on which a set of slide rails are arranged, and the slide rails include two mutually parallel retaining bars 2, and a chute is formed between the retaining bars 2. Two supporters are arranged in the slide rail, the supporter includes a base 6, the width and height of the base 6 match the width of the chute and the height of the baffle plate 2, and two parallel bars 2 are arranged on the base 6. Support plate 7, roller 8 is installed between two support plates 7, and roller 8 is connected on the support plate 7 through bearing 9, is provided with screw hole on base 6, and support plate 7 is positioned at the part above the horizontal diameter of bearing 9 Be semicircle, and the radius of this semicircle is less than the diameter of roller 8; All be provided with clamping strip 10 on two retaining strips 2, the distance between two clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com