Disassembly process of rotor parts

A rotor body and parts technology, which is applied in the dismantling process of steam turbine rotor parts, can solve the problems of convenience, safety and reliability, poor practicability and economy, high subjective experience and technical requirements of operators, and lack of dismantling technology for rotor parts. , to achieve the effect of improving reusability, good protection, and reliable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

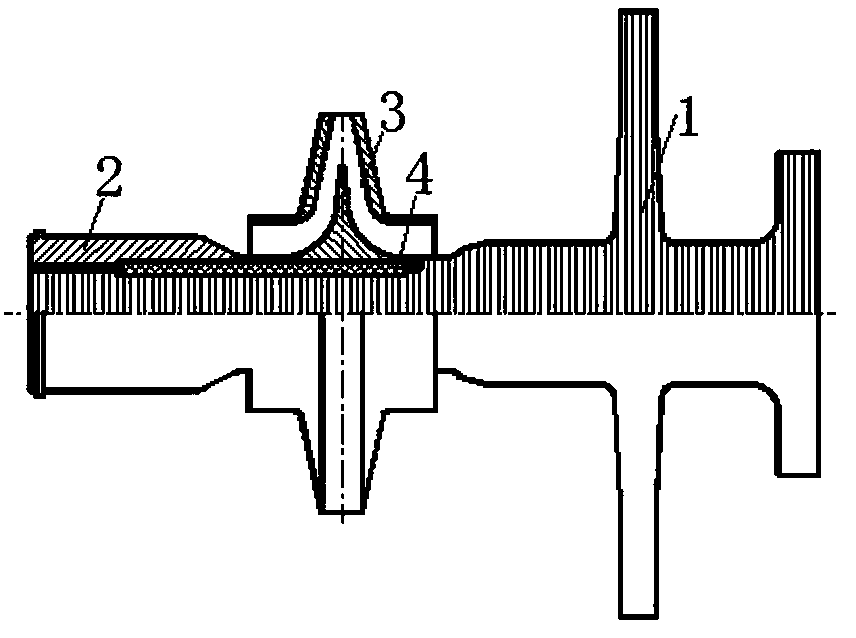

[0032] For the structure of the rotor part targeted by the present invention, see figure 1 As shown, it is mainly composed of a rotor body 1, a sleeve 2, an impeller 3 and a key 4, etc. The sleeve 2 and the impeller 3 are assembled on the rotor body 1 in an interference fit manner, and the interference is about 0.04 mm to 0.08 mm. The impeller 3 is located between the sleeve 2 and the disc on the rotor body 1 . The key 4 is fixed on the rotor body 1 with a screw tightening structure, and is located between the sleeve 2 , the impeller 3 and the rotor body 1 .

[0033] According to the structural particularity of the above-mentioned rotor parts, the present invention disassembles it in the order of first taking out the sleeve 2, then taking out the impeller 3, and then removing the key 4. Specifically, the present invention includes the following technical measures.

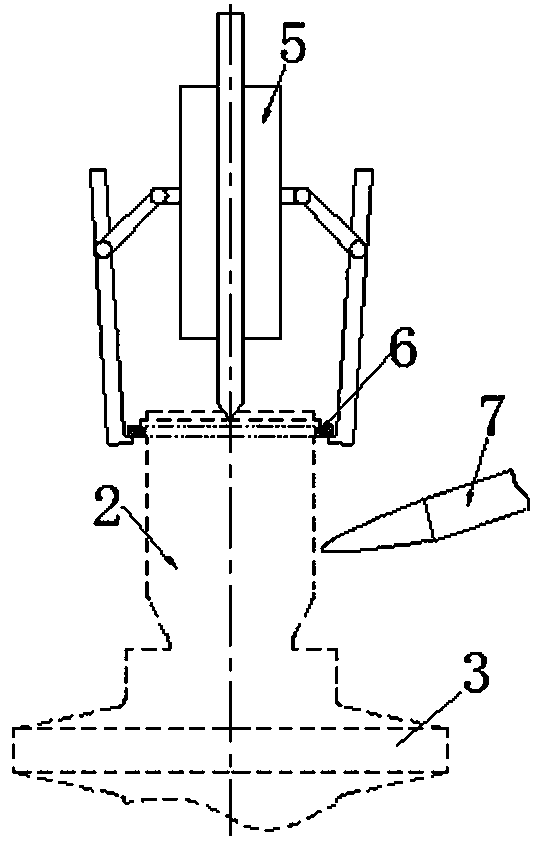

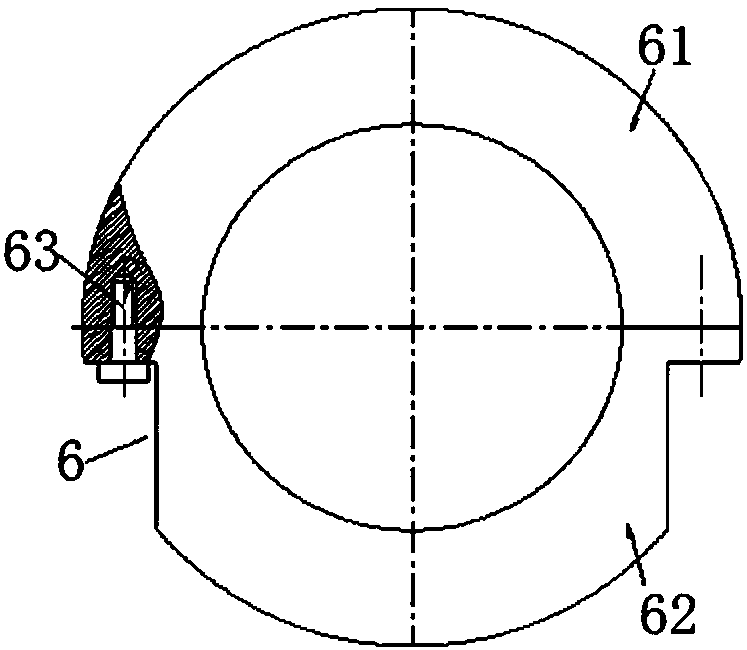

[0034] one. Regarding the disassembly and removal of the sleeve 2 on the rotor body 1 .

[0035] see figure...

Embodiment 2

[0054] The other contents of this embodiment are the same as those of Embodiment 1, the difference is that the heating of the sleeve and the impeller is carried out by electric heating plates respectively.

Embodiment 3

[0056] The other content of this embodiment is the same as that of Embodiment 1, the difference is that there is no transition ring structure on the sleeve, and the hook of the hydraulic puller is directly hooked on the convex ring on the outer circumference of the sleeve, which requires the convex ring to be in the radial direction. The raised height is high and the hook can be finally padded with pads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com