Thread ring gage automatic precise finishing machine tool

A thread ring gauge, precision technology, applied in the direction of grinding machine tools, grinding devices, metal processing equipment, etc., can solve the problems of poor grinding accuracy, high labor intensity, low grinding efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

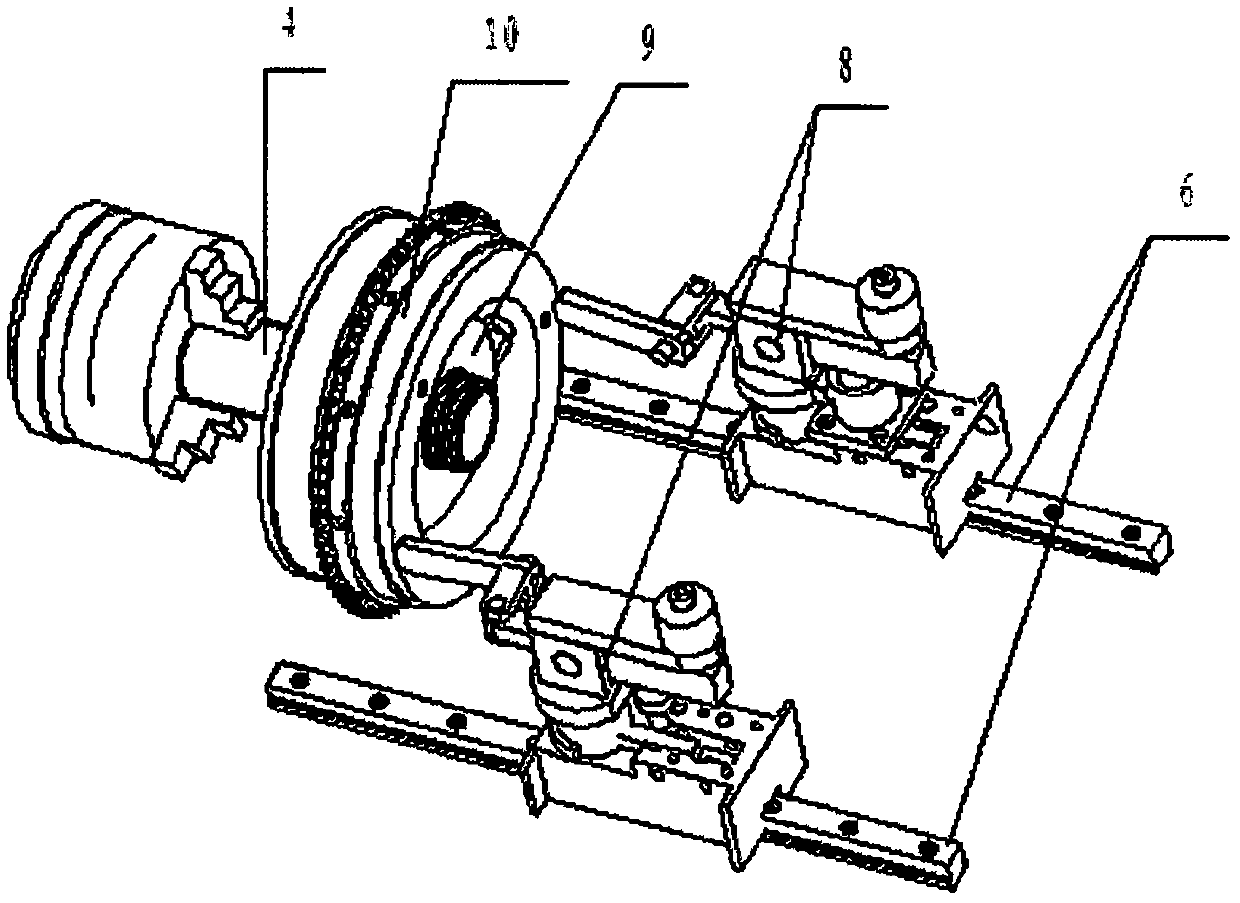

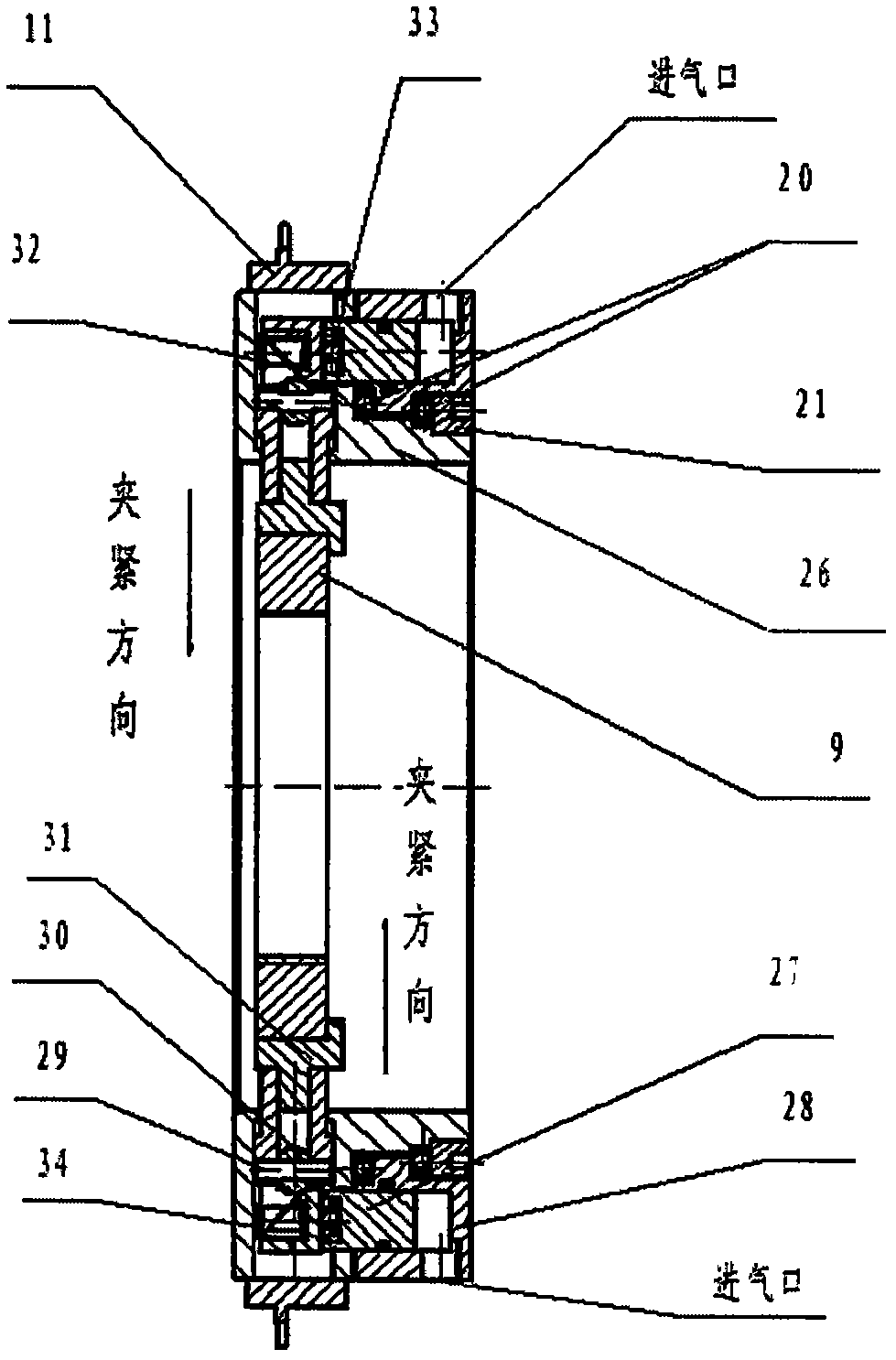

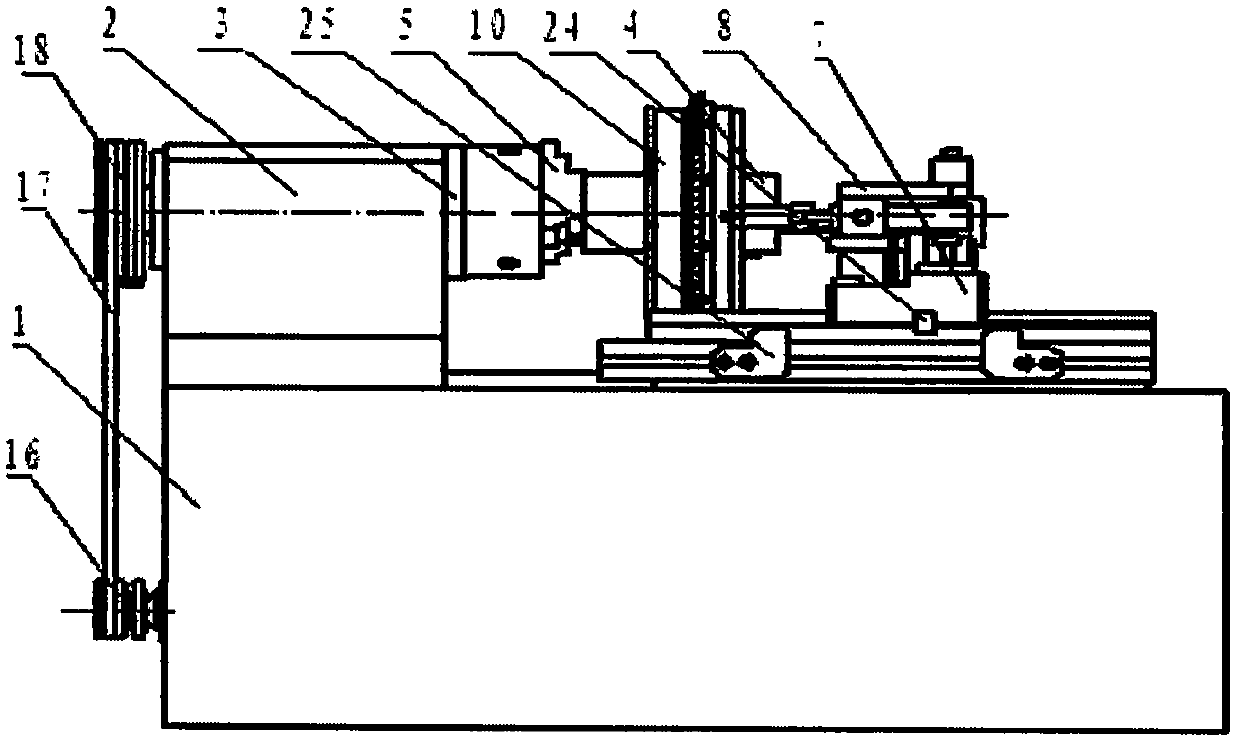

[0014] refer to Figure 1-4 , a complete machine for precision grinding threaded ring gauges described in the present invention, including a bed 1, a head frame body shell 2 is fixed on the left side of the bed 1, a head frame spindle 3 is installed in the head frame body shell 2, and the head frame A clamping device 5 for clamping a grinding tool 4 is fixed on the end face of the frame spindle 3; a linear guide rail 6 is fixed on the right side of the bed 1, and a bracket 8 is fixed on the guide rail slider 7 sliding on the linear guide rail 6, The top surface of the bracket 8 is fixed with a pneumatic clamping mechanism 10 for clamping the threaded ring gauge 9, and the outer circle of the pneumatic clamping mechanism 10 is equipped with a transmission large sprocket 11; The transmission mechanism, described transmission mechanism is made up of the rotating shaft 13 that the support 12 that is fixed on the bed rear is installed on the support 12, the transmission small sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com