Pressure control method for brake cylinder of magnetically levitated train

A technology of brake cylinder pressure and maglev train, which is applied to brakes, brake components, pneumatic brakes, etc., can solve the problems of slow pressure boost of the brake cylinder, longer braking distance, and longer idle time of maglev trains. Achieve precise control, improve steady-state performance, and shorten braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

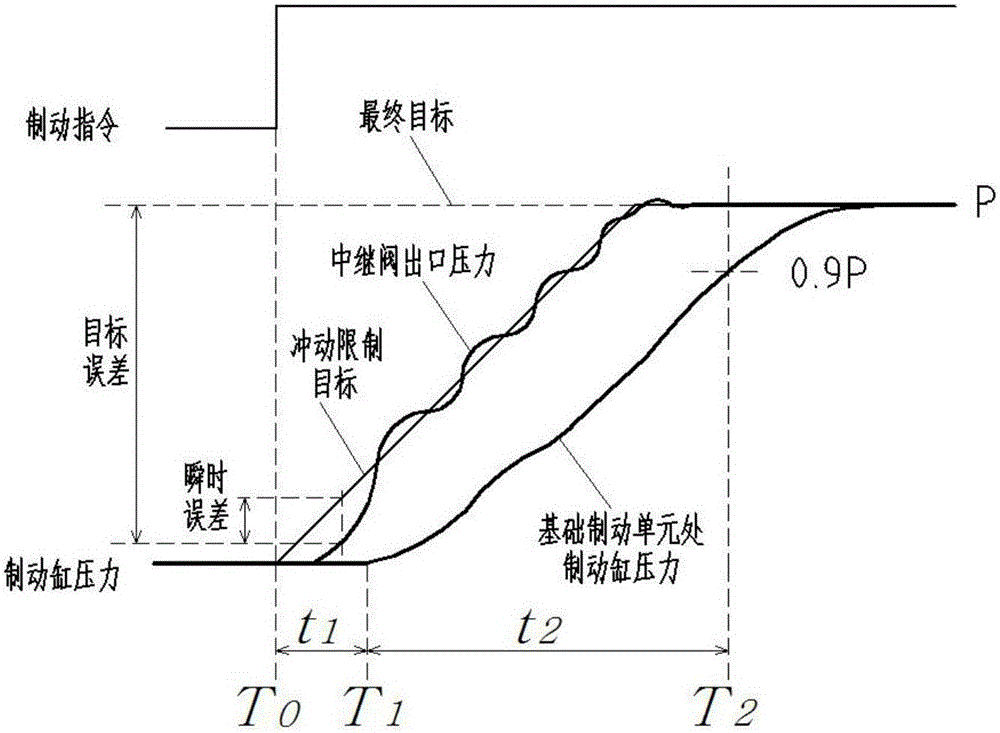

[0035] The brake response time has a great relationship with the mechanical characteristics of the brake system, the volume of the brake cylinder and the length of the pipeline, and also has a great relationship with the control method of the pressure of the brake cylinder. figure 2 is the schematic diagram of brake cylinder pressure and response time, from T 0 Time to issue a braking command to T 1 The moment the brake cylinder pressure starts to rise, during this time t 1 is the idle time, from T 1 From the moment when the pressure of the brake cylinder rises to 90% (0.9P) of the maximum pressure, the time t 2 is the boost time. t 1 +t 2 is the braking response time, so if you want to reduce the braking response time, you can reduce the t 1 and t 2 way to achieve.

[0036] Due to the large average braking deceleration requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com