Automobile braking system adopting electric execution mechanism

A technology of automobile braking system and electric actuator, applied in the direction of brake actuator, gear transmission mechanism, mechanical equipment, etc., can solve the problems such as difficult to achieve fixed ratio transmission, easy to leak, large pressure loss, etc., to achieve shortened braking Increased distance, improved safety, and stable braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

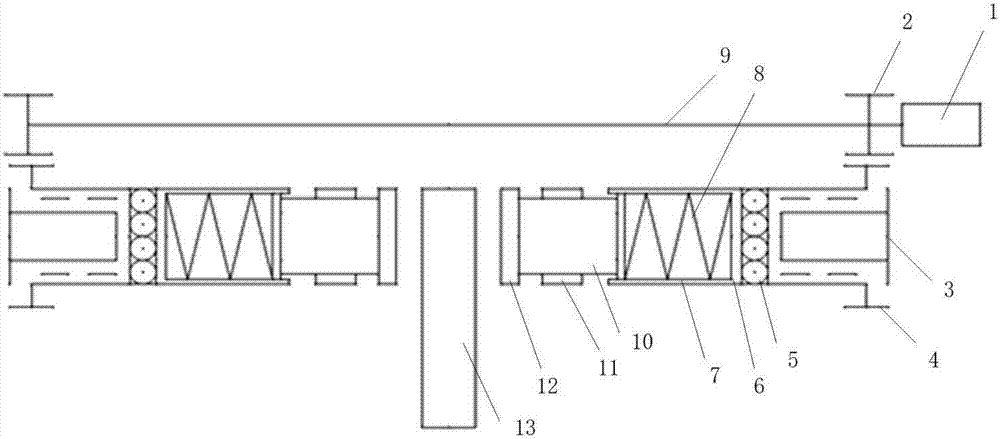

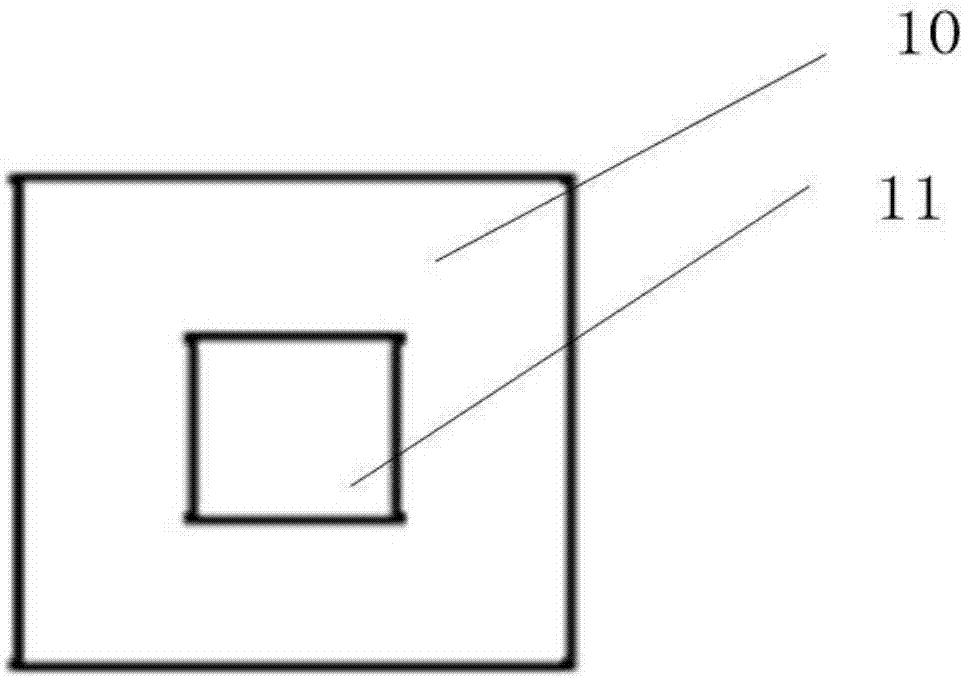

[0020] Such as figure 1 and figure 2 As shown, this embodiment provides an automobile braking system using an electric actuator, which uses a motor as a brake actuator to convert the rotational motion of the output shaft of the motor into the linear motion of the friction plate, including the actuator motor 1, fixed on the The two fixed gears 2 on the executive motor 1 and the two rotating nuts 4 meshing with the two fixed gears 2 respectively, the two fixed gears 2 and the two rotating nuts 4 are symmetrically arranged on the two sides of the brake disc 13 respectively. On the side, the two rotating nuts 4 are respectively fixedly connected with the two plane be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com