Electronic control relay valve assembly of anti-lock brake system

A relay valve and assembly technology, which is applied to the ABS control system, control valve, air release valve, brake, etc., can solve the problems of slow reaction time and poor braking comfort, and achieve accurate and timely judgment, rapid braking, Responsive pedal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

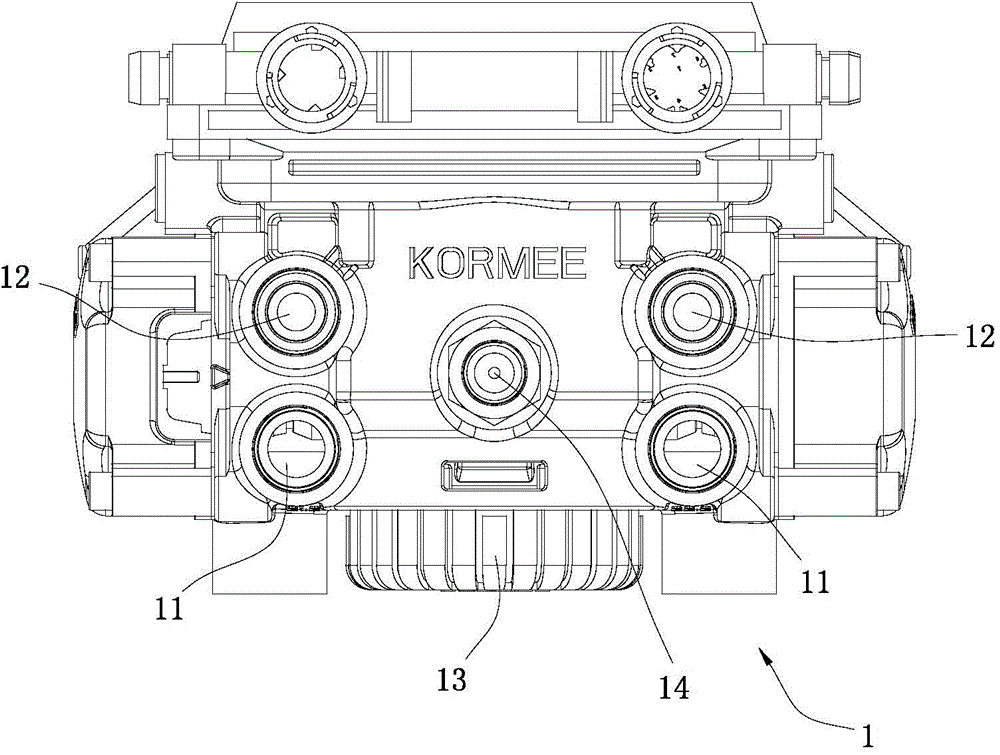

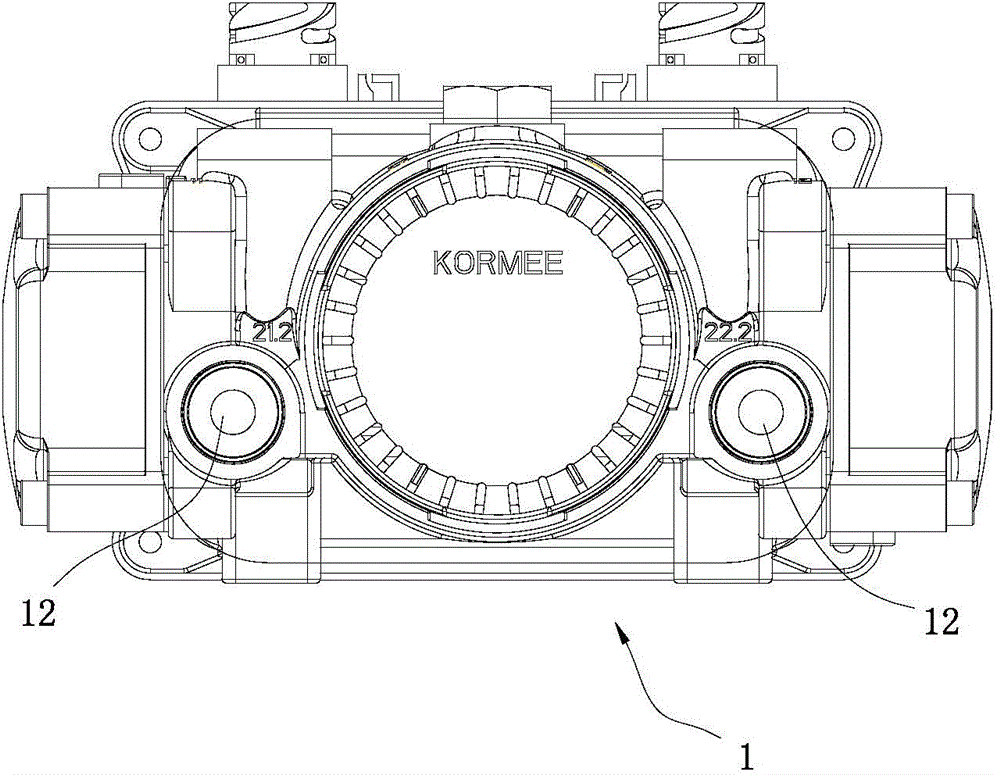

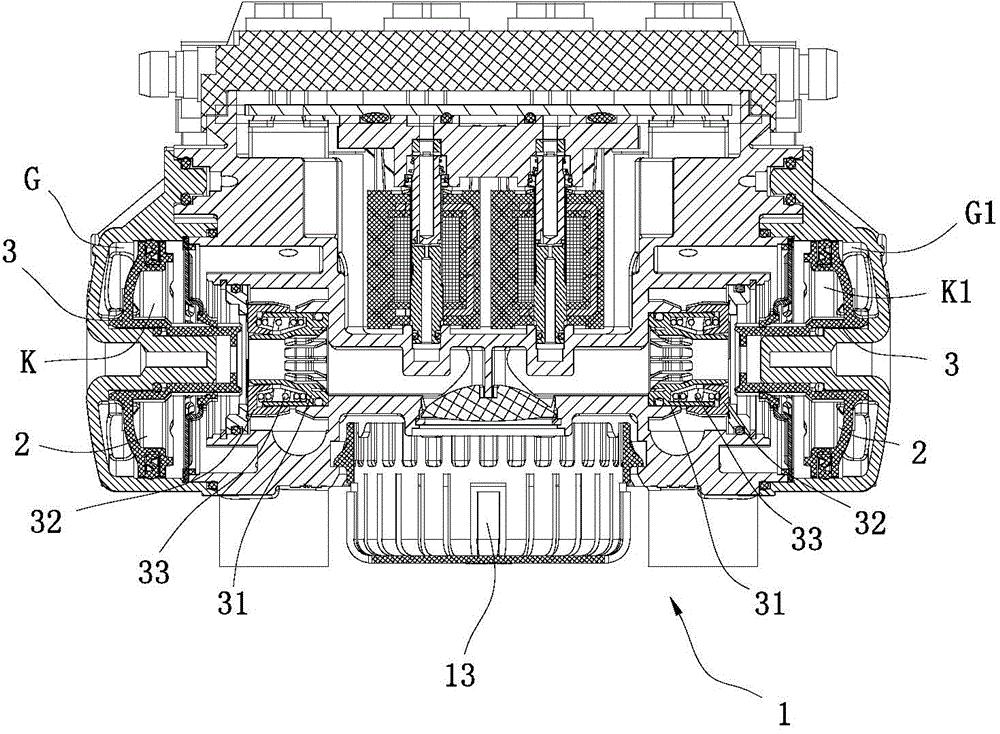

[0015] refer to Figure 1 to Figure 4 , an ABS electric control relay valve assembly of the present invention, including a valve body 1 and a solenoid valve assembly, a pressure sensor for detecting the pressure of the brake air chamber is provided in the valve body 1, and the valve body 1 has two main intake air 11, four air outlets 12 and an exhaust port 13, two main air inlets 11 are respectively connected to the vehicle air storage tank, and the four air outlets 12 are respectively connected to each brake chamber of the vehicle, and there are two symmetrically distributed in the valve body 1. Air chamber 2, one air chamber 2 communicates with one main air inlet 11, two air outlets 12 and exhaust port 13 respectively, the air chamber 2 is provided with a controllable main air inlet 11 and air outlet 12 connected or not. The air chamber 2 is provided with a main control piston 3 that can abut against the valve, and the valve is controlled by a solenoid valve group connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com