Detection method of braking response time of brake of elevator

An elevator brake and braking response technology, applied in the elevator field, can solve the problems of low precision and large detection error, and achieve the effect of improving accuracy, easy operation and reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the detection principle and features of the present invention easier to understand, the present invention will be further described below in conjunction with specific embodiments.

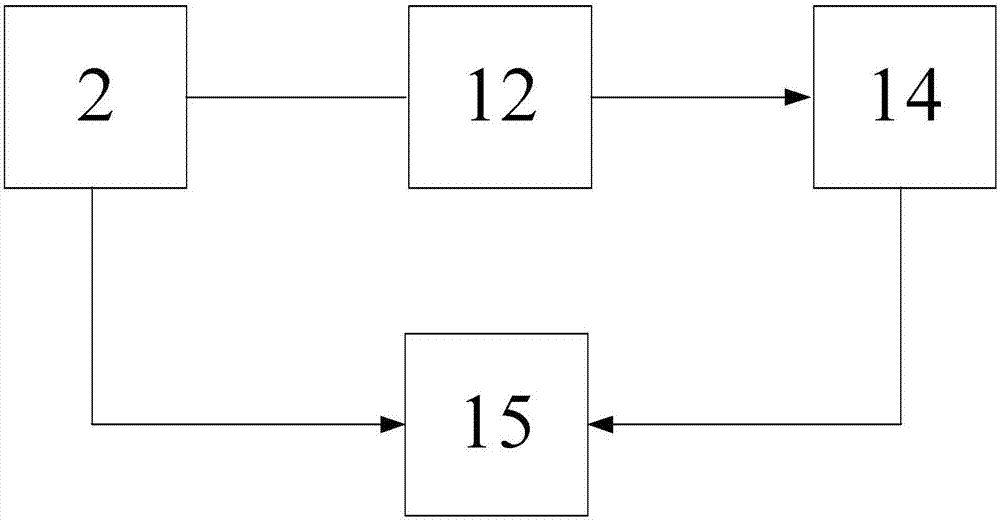

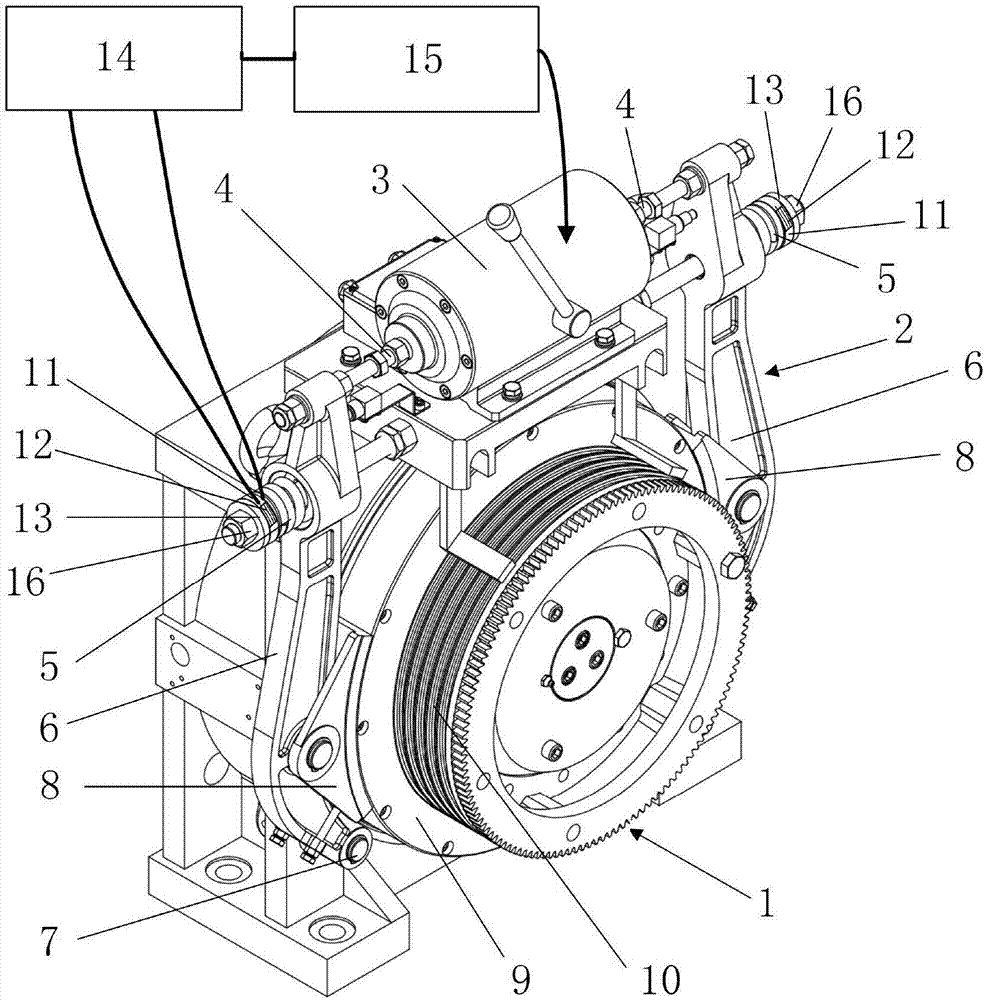

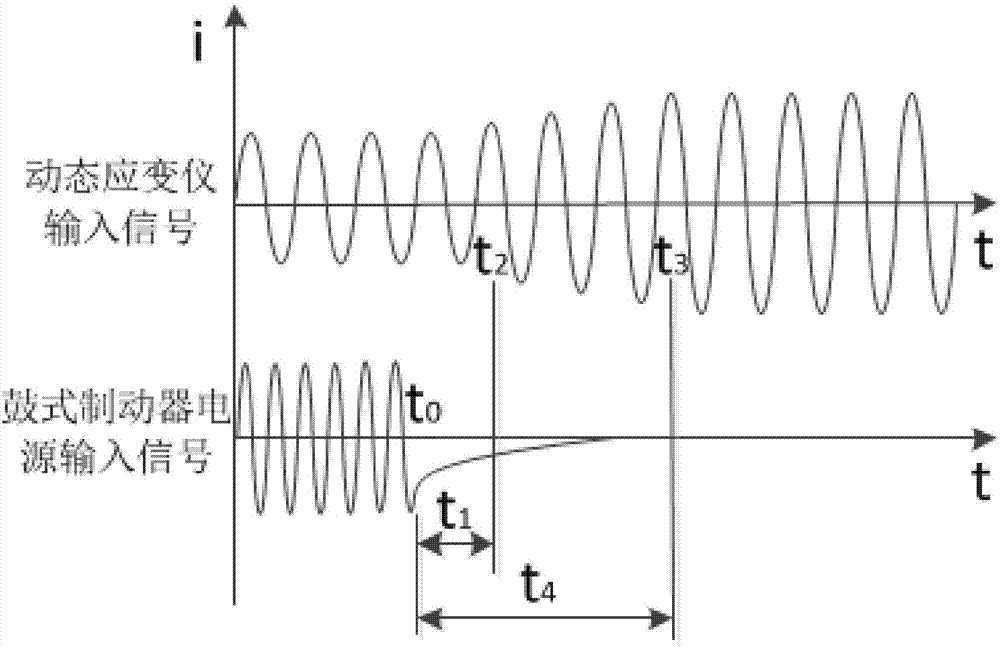

[0024] figure 1 It is the detection principle diagram of the elevator brake brake response time detection device in the present invention. The detection device is composed of a spring plate, a resistance strain gauge, a strain gauge and a dual-channel oscilloscope. The foil resistance strain gauge 13 is a high-precision dynamic strain gauge 14, and the detection object is the drum brake 2 installed on the permanent magnet synchronous gearless traction machine 1. The specific layout of the detection device is as follows: figure 2 As shown, the working principle of the drum brake 2 is: when the drum brake 2 is energized, the electromagnetic device 3 is energized to generate electromagnetic force, and the electromagnetic force drives the ejector rod 4 to move outward, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com