Electric brake and automobile

A technology of electric brakes and electromagnetic clutches, applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problem of long time for motor transmission torque to generate brake clamping force, which cannot meet the requirements of brake response time, Poor real-time braking effect and other problems, to achieve good braking effect, compact structure, and shorten the response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

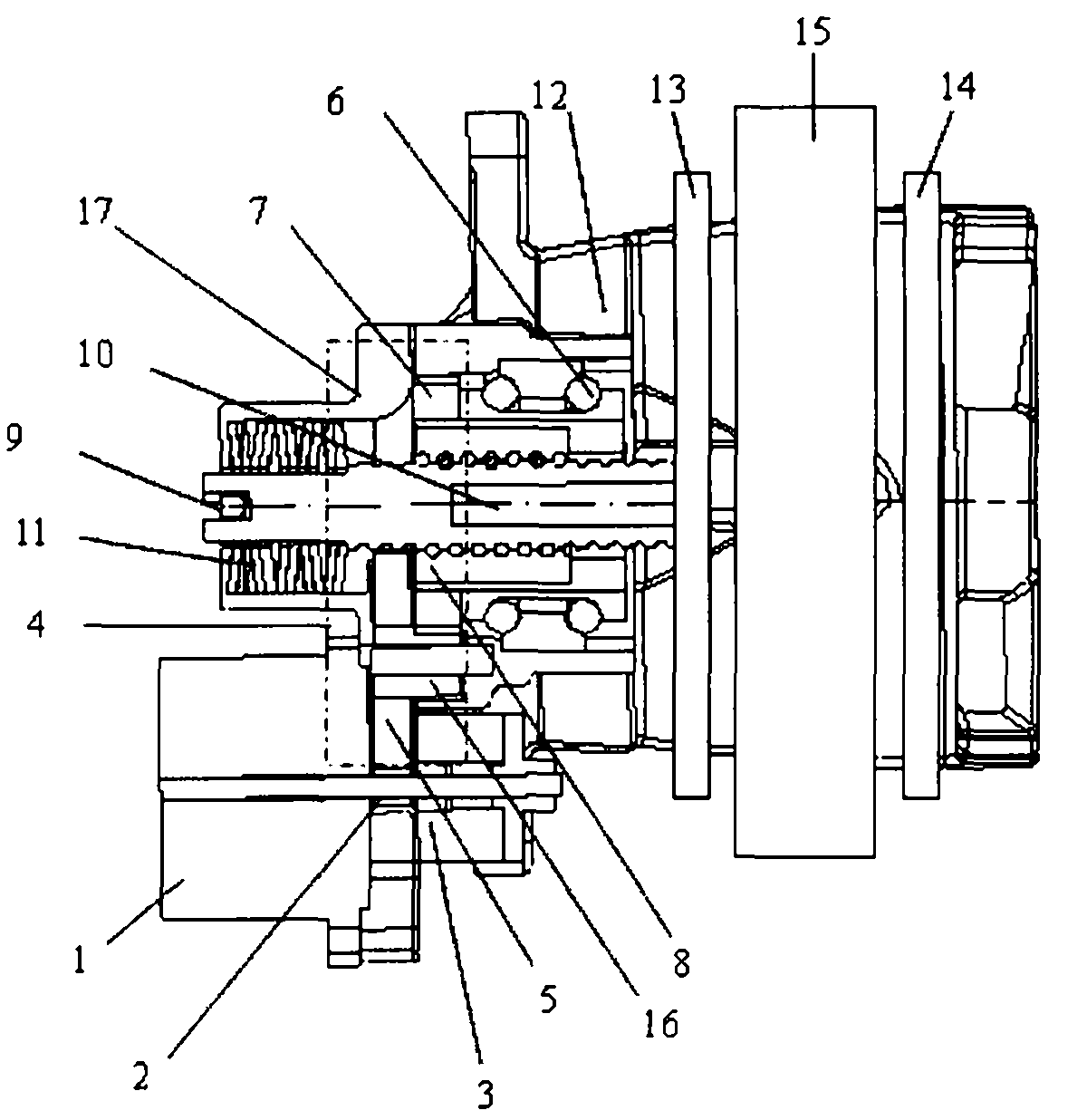

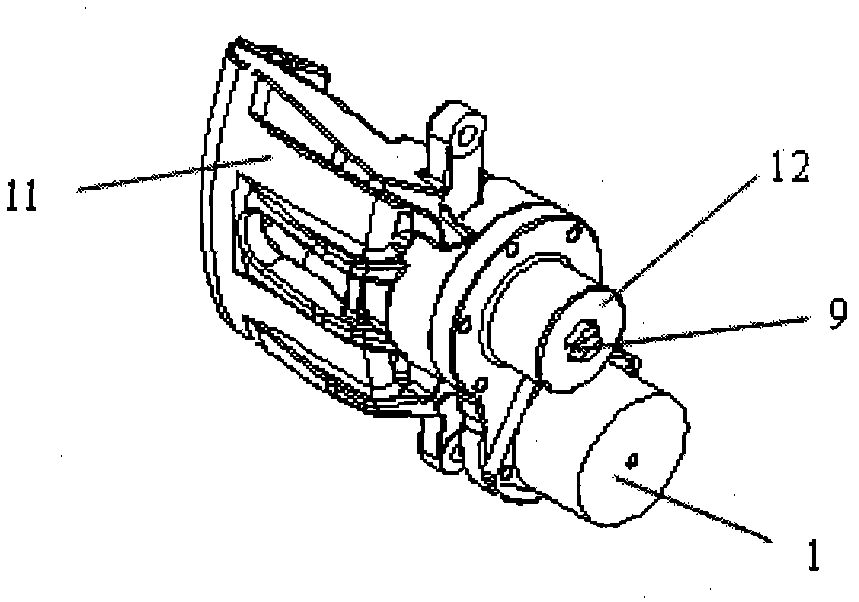

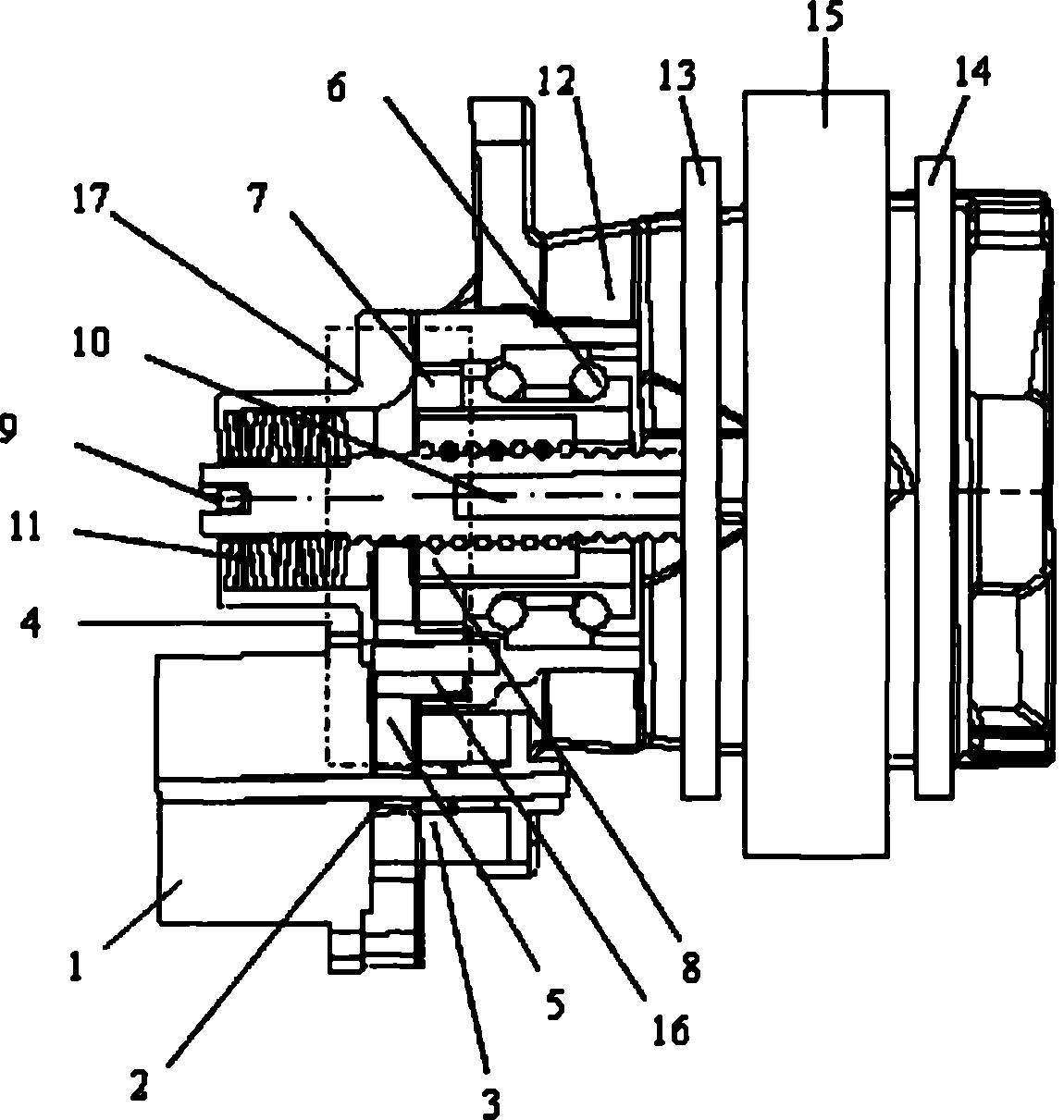

[0024] Such as figure 1 , 2 As shown, in this embodiment, the electric brake includes a housing 17, a brake disc 15, brake pads 13, 14, a floating caliper 12, a power mechanism, a pressure maintaining mechanism, and an energy storage mechanism. The power mechanism includes a motor 1, a torque amplification mechanism and a motion mechanism, the torque amplification mechanism is arranged between the motor 1 and the motion mechanism, the input end of the torque amplification mechanism is connected with the output shaft of the motor 1, Its output end is connected with the motion mechanism.

[0025] In this embodiment, the moving mechanism is arranged in the housing 17, and the moving mechanism adopts a non-self-locking screw mechanism, and the screw mechanism includes a ball screw shaft 10, a screw nut 8, a ball bearing 6, and a limiter. bit agency9. The screw nut 8 is set on the ball screw shaft 10, the inner side of the ball bearing 6 is riveted with the screw nut 8, the oute...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that there is no energy storage mechanism.

[0036] Other structures and uses in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com