Piezoelectric driving brake

A piezoelectric drive and brake technology, applied in the field of vehicles, can solve the problems affecting the braking effect, achieve the effect of improving the braking response time, ensuring driving safety, and providing the braking response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

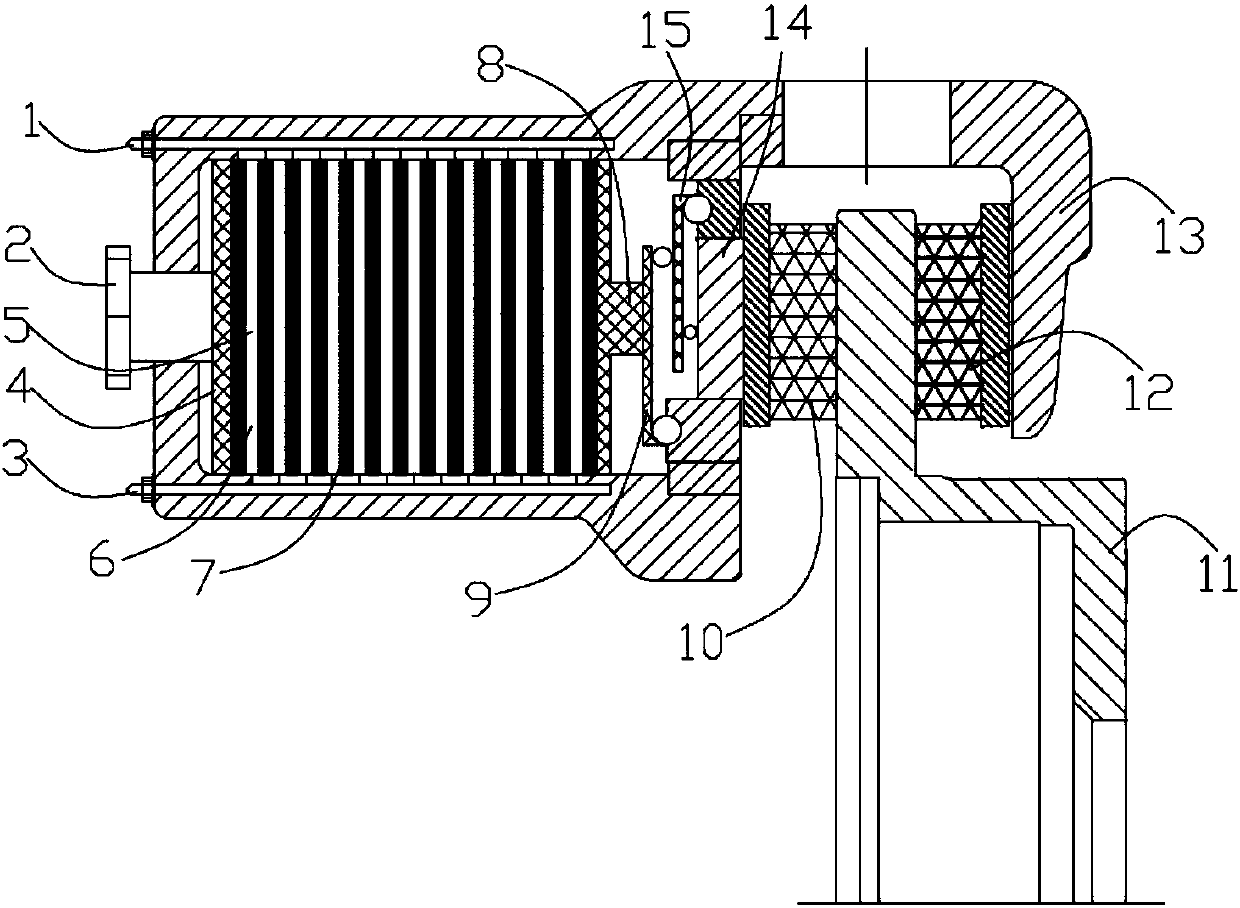

[0017] refer to figure 1 As shown, the present invention provides a piezoelectric-driven brake, which includes a positive terminal 1, a negative terminal 3, a piezoelectric assembly 5, a first end surface 4 located outside the piezoelectric assembly 5, and a The second end surface 8, the displacement amplification mechanism, the inner brake friction plate 10, the outer brake friction plate 12, the gap adjustment bolt 2 for adjusting the gap between the inner brake friction plate 10 and the outer brake friction plate 12, and the floating brake caliper shell Body 13. The piezoelectric assembly 5 includes alternately arranged piezoelectric negative electrode layers 6 connected to the positive electrode 1 of the terminal and piezoelectric positive electrode layers 7 connected to the negative electrode 3 of the terminal. After electrification, the piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com