Driving integrated magnetic adsorption wheel type device

A magnetic adsorption wheel and wheel body technology, which is applied in the field of robots, can solve the problems of low reliability, reduced transmission accuracy, and poor versatility of magnetic adsorption devices, and achieve the effects of improving work reliability, simplifying the body structure, and reducing the overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

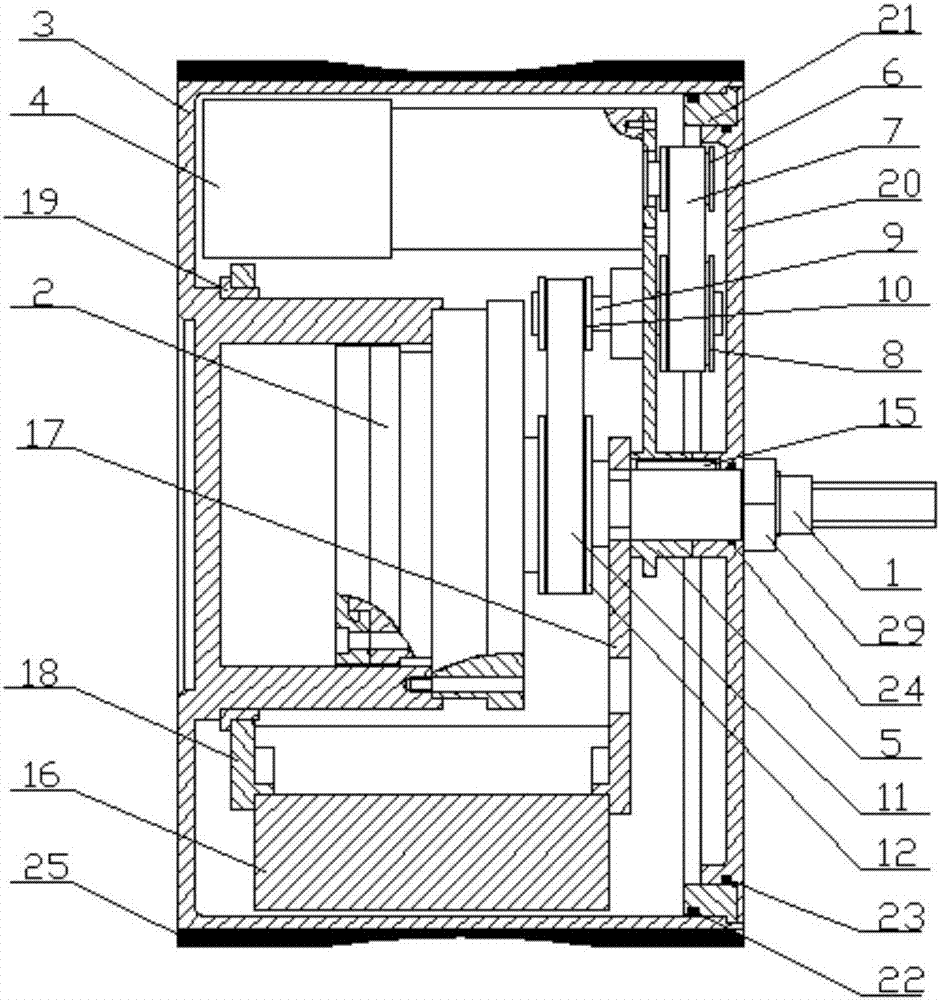

[0029] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof. However, the protection scope of the claims of the present application is not limited to the description scope of the embodiments.

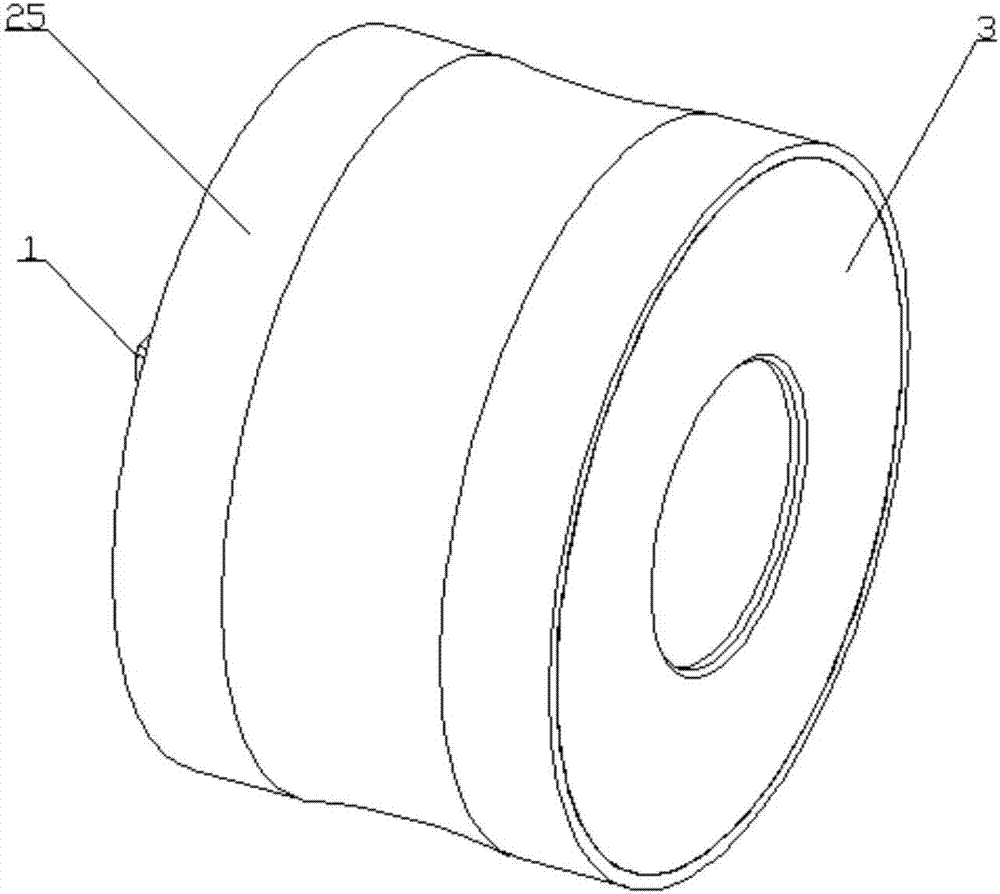

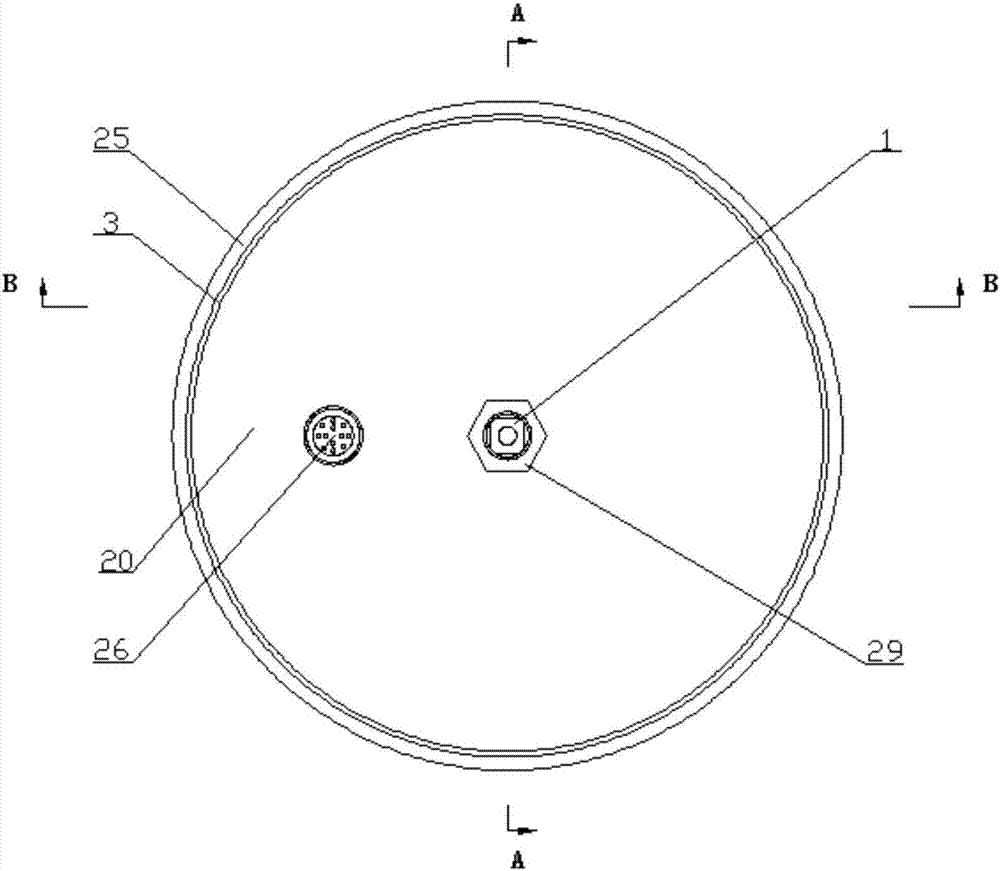

[0030] The drive integrated magnetic adsorption wheel device of the present invention (referred to as the device, see Figure 1-6 ) includes a drive shaft 1, a harmonic reducer 2, a wheel body rubberized shell 3, a motor 4, a transmission bracket 5, a pulley shaft 9, a magnet 16, a No. 1 magnet bracket 17, a No. 2 magnet bracket 18 and a wheel body end cover 20 , the wheel body rubber shell 3 (see Figure 9 ) is a cylindrical cavity without a cover, one end is closed and the other end is open, and a cantilever hollow cylindrical support beam is arranged on the inner surface of the closed end, and the support beam includes the No. 1 shaft section 301 of the rubber-coated wheel shell and the No. Segment 302, a shaft shoulder is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com