Full-automatic profile stacking equipment and method

A fully automatic, profiled technology, applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve problems affecting product sales, unfavorable production efficiency, and reduce production costs, so as to save storage space and save labor Cost, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

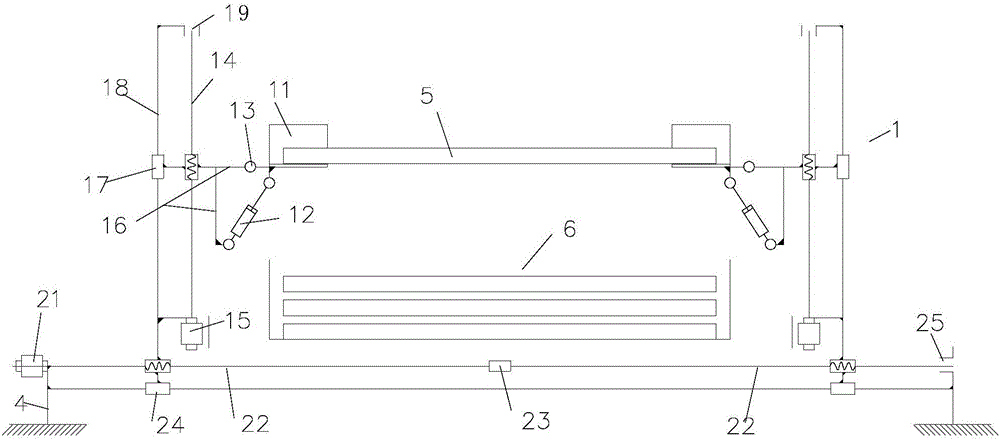

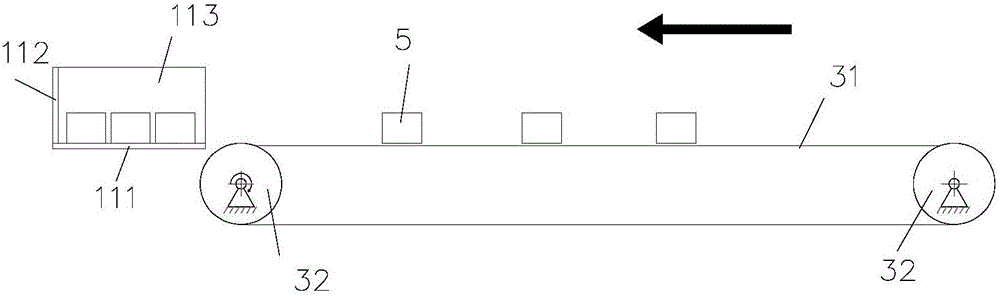

[0035] This embodiment describes a fully automatic profile palletizing equipment, its structure is as follows figure 1 and figure 2 As shown; includes a support 4, a stacking unit 1 located on both sides of the stacking area 6 and a feeding unit 3 for transferring the profile 5 to the stacking unit 1 . The stacking area 6 may be an inner accommodation area of a frame or a box.

[0036] The feeding unit 3 includes a conveyor belt 31 and a rotary driving module 32 for driving the conveyor belt 31 to rotate. figure 2 The middle arrow indicates the direction of profile movement. Adopting the conveyer belt 31 to transmit the profiles 5 can avoid the adverse situations such as scratches or bruises caused by the profiles 5 colliding with each other during the transmission process, and improve product quality.

[0037] Preferably, the stacking units 1 on both sides are respectively arranged on the support 4 through the horizontal movement module 2 to adjust the distance between...

Embodiment 2

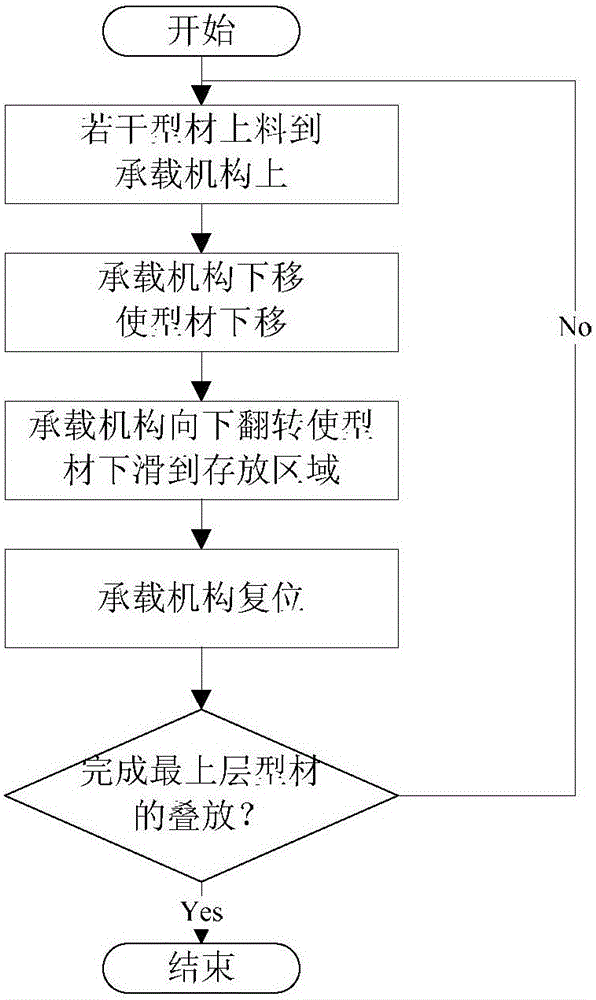

[0046] This embodiment describes a fully automatic profile palletizing method, the process of which is as follows image 3 shown, including the following steps:

[0047] The first step is to feed several profiles above the stacking area, so that each profile is placed side by side and the two ends of each profile are supported by the bearing mechanisms on both sides;

[0048] In the second step, the carrying mechanism moves down to move the profile down until the carrying mechanism reaches the target height;

[0049] In the third step, the bearing mechanisms on both sides are turned down at the same time to increase the distance between the bearing mechanisms on both sides until the distance between the bearing mechanisms on both sides is greater than or equal to the length of the profile; during the process of increasing the distance between the bearing mechanisms on both sides , the profile gradually slides down into the stacking area;

[0050] In the fourth step, the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com