Laser-assisted cold spraying method for manufacturing additives

An additive manufacturing and laser-assisted technology, which is applied in the field of laser-assisted cold spray additive manufacturing, can solve the problems affecting the quality of cold spray additive manufacturing, affecting the effect of cold spray additive manufacturing, and the combination of coating and substrate is not tight enough. Achieve the effect of improving the internal bonding quality, good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] (1) Preheating the substrate by preheating the laser can make the surface of the substrate reach a higher active state, thereby improving the bonding effect of cold spray deposition. After the substrate is polished, the oxide layer is removed, etc., the preheating laser is used to preheat the substrate, which can improve the bonding strength of the cold spray buildup coating and the substrate. The laser power of the preheating laser depends on the composition and properties of the substrate. Generally, a low-power laser is used. The temperature of the substrate is raised to 300-400°C by adjusting the preheating laser, and is at least 200°C lower than the melting point of the substrate. If the temperature of the substrate is not lower than the melting point of the substrate by 200°C, the preheated substrate temperature can be reduced to below 300°C.

[0024] (2) The use of cold spray technology to perform additive stacking on the preheated substrate includes: the cold spray...

Embodiment 1

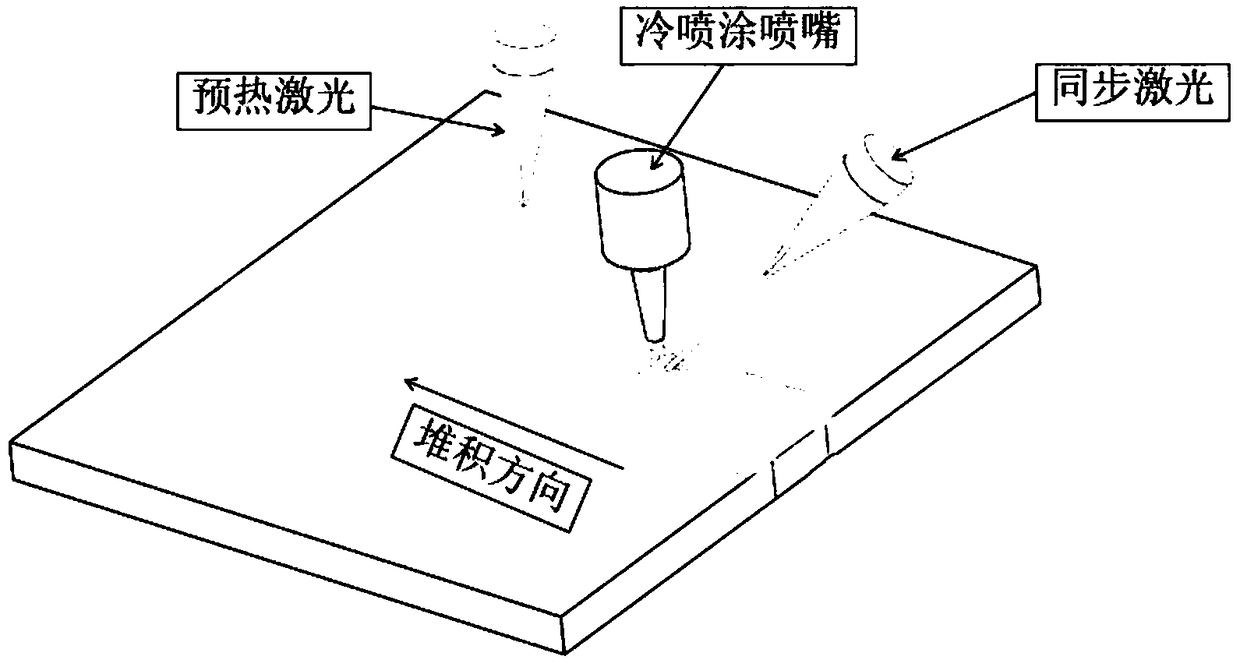

[0034] Such as figure 1 As shown, a laser-assisted cold spray additive manufacturing method includes the following steps:

[0035] Step a: Preheat the aluminum alloy 2219 sheet as the base material by using a low-power laser to increase the temperature of the base material to 300° C., thereby obtaining the preheated base material.

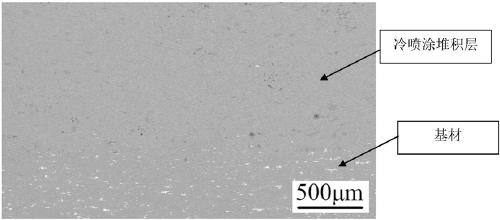

[0036] Step b. Using cold spraying technology to add material to the preheated substrate at a higher temperature, the cold spray gas preheating temperature is 500°C, and the powder particles used for additive stacking are 2219 aluminum with a size of 5-50 μm Alloy particles, the powder feeding rate is 30g / min, and the powder feeding distance is 25mm; the cold spray acceleration gas uses nitrogen; at the same time, the synchronous laser is used to simultaneously perform surface treatment on the cold spray layer deposited by the additive. The laser power of the synchronous laser The laser gun head and the cold spray nozzle move synchronously to realize th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com