Conveying-chain stacking device and method for seedling plugs

A technology for seedling trays and conveyor chains, which is applied to conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as difficulty in adapting to the requirements of high-speed sowing operations, increasing the number of raised trays, affecting the quality of seedlings, etc. The effect of controlled use, simple structure and high stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

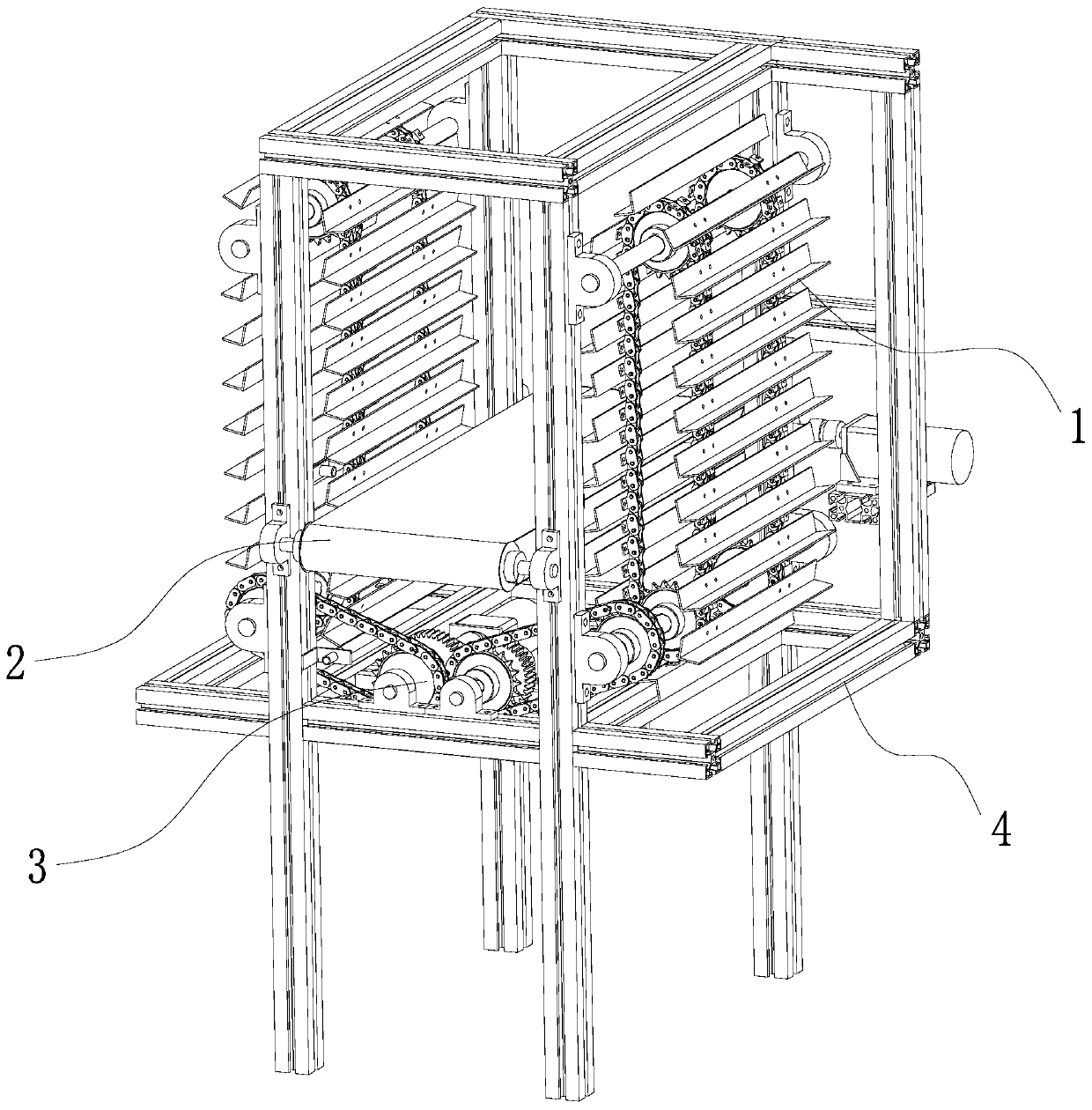

[0038] In this embodiment, a conveyor chain type seedling tray stacking device, such as figure 1 As shown, it includes two sets of tray lifting mechanism 1, tray conveying mechanism 2, lifting drive mechanism 3 and frame 4. The tray conveying mechanism is installed in the middle of the frame, and the two sets of tray lifting mechanisms are installed on both sides of the upper part of the frame. , arranged symmetrically with respect to the tray conveying mechanism, the lifting drive mechanism is installed at the bottom of the frame, and connected with the two sets of tray lifting mechanisms. The specific structure of each institution is as follows:

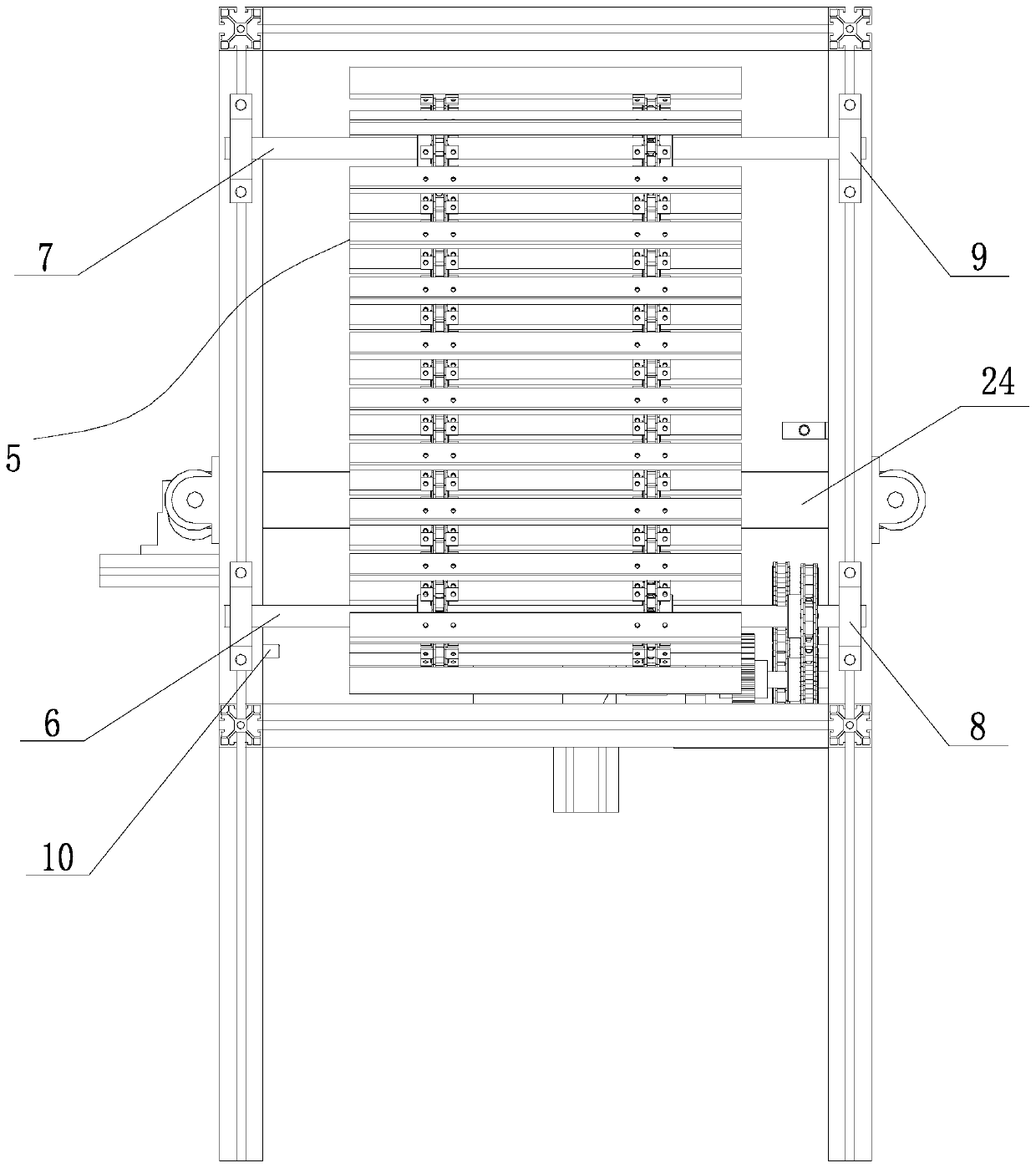

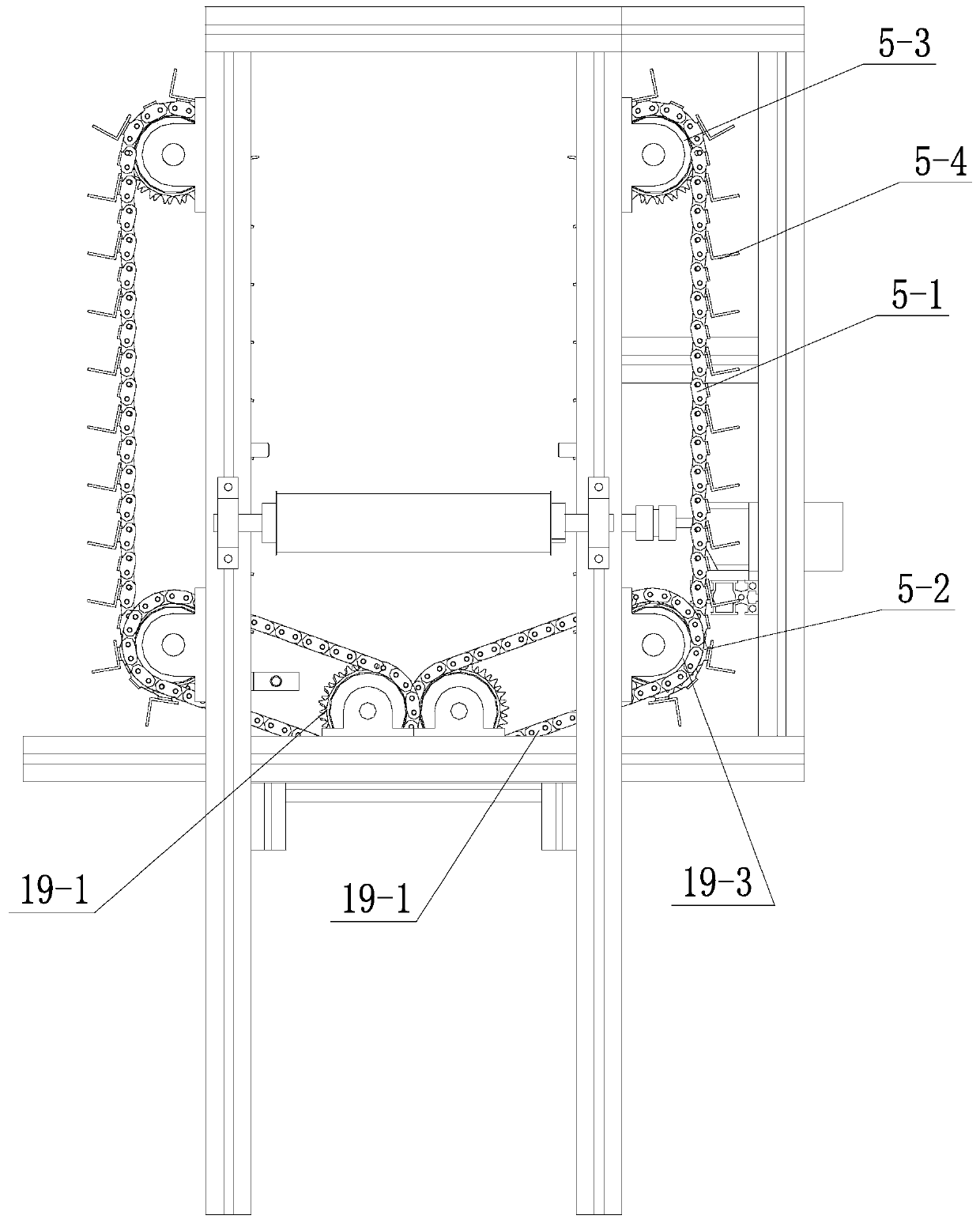

[0039] Such as figure 2 As shown, the tray lifting mechanism includes a conveyor chain assembly 5 (mainly composed of a conveyor chain, an active lifting sprocket, and a driven lifting sprocket), a lifting driving shaft 6, a lifting driven shaft 7, a pair of first bearings 8, a For the second bearing 9 and the zero position sens...

Embodiment 2

[0050] This embodiment is a transport chain-type seedling tray stacking device. Compared with Embodiment 1, the difference is that: in the tray lifting mechanism, the tray lifting member is a lifting assembly composed of several L-shaped hook-shaped parts arranged side by side. , each L-shaped hook-shaped component is installed on a chain link of a conveyor chain, and the height consistency between the L-shaped hook-shaped components is maintained by ensuring that the heights of the corresponding chain links on multiple conveyor chains are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com