Automatic transformer iron core stacking system

A transformer and automatic technology, applied in the directions of transportation and packaging, destacking of objects, conveyor objects, etc., can solve the problems such as the difficulty of stacking the mountain-shaped column cores of power transformers, and achieve stable product quality, strong versatility, and extended use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

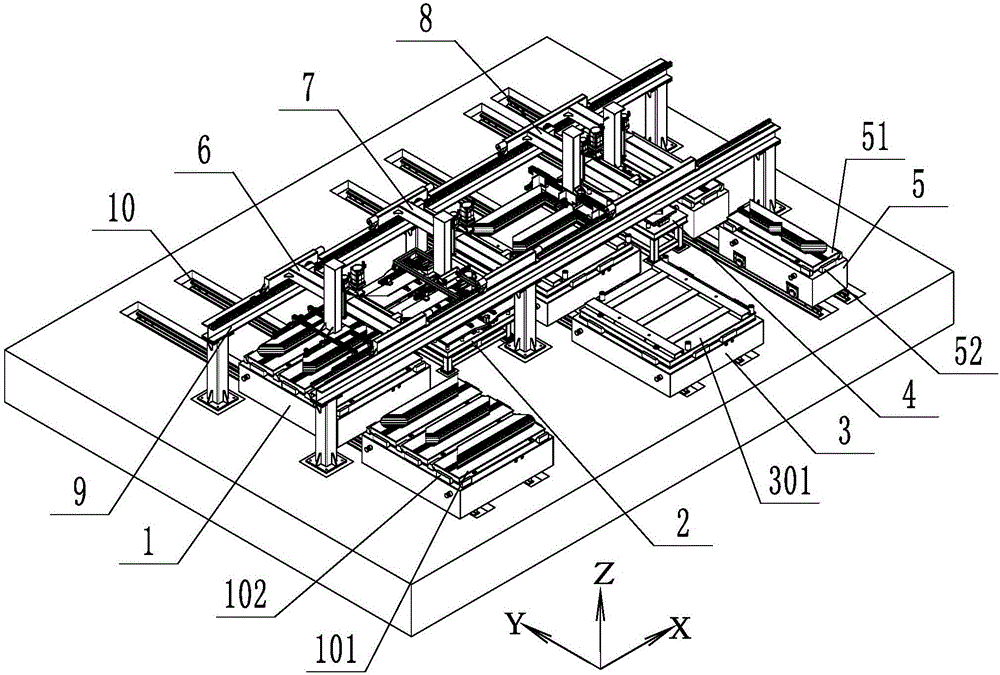

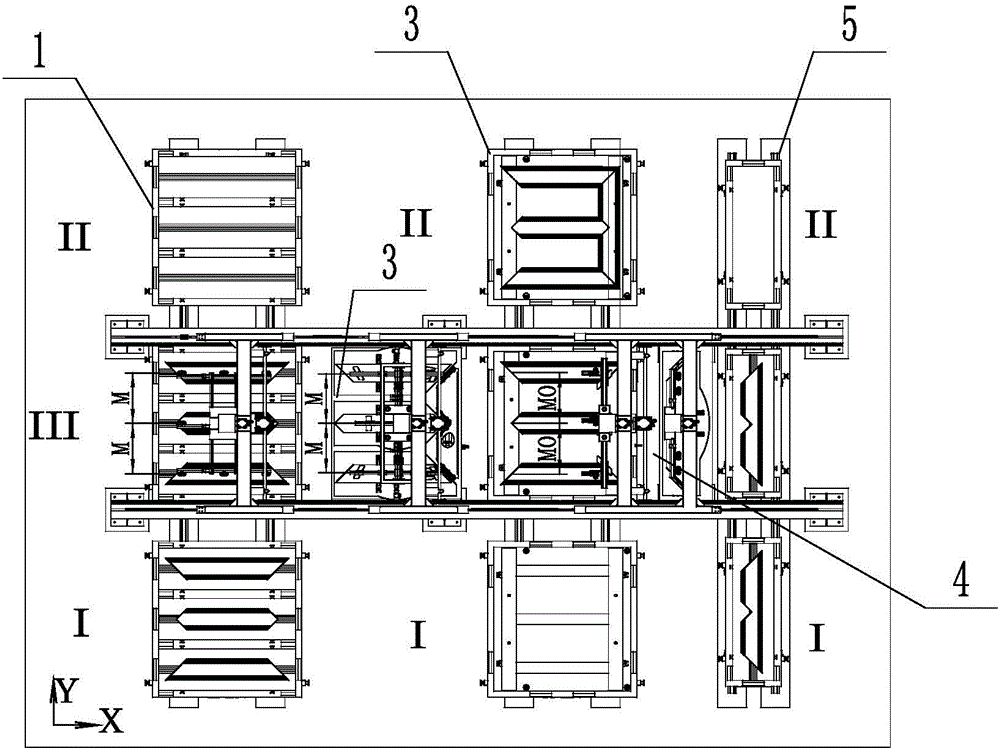

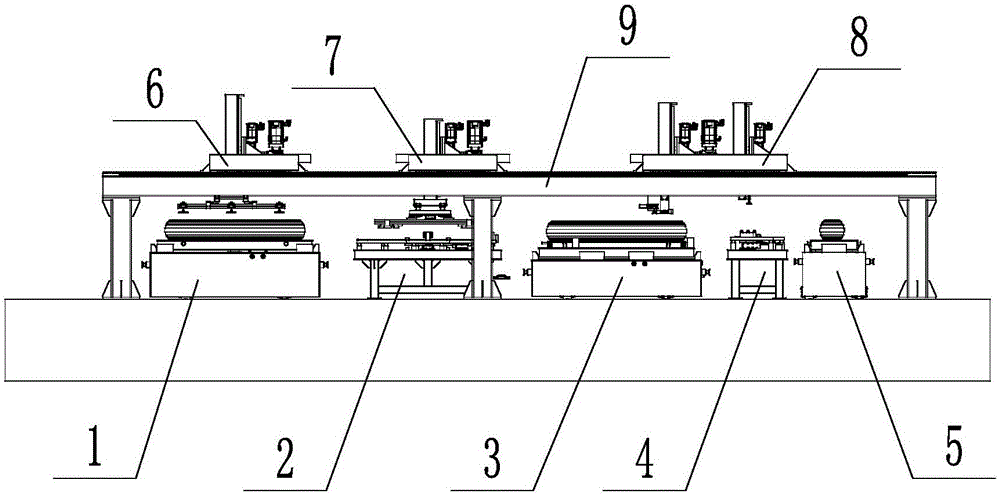

[0047] according to Figure 1 to Figure 3 As shown, an automatic stacking system for transformer iron cores includes a preparation station area I, a turnover station area II, and a work station area III, and the preparation station area I and the turnover station area II are alternately served, so The working station III zone includes a three-column sheet single-layer automatic stacking system, a servo stacking and seaming mechanism, and a polar sheet X-axis Y-axis bidirectional alignment platform. The working station III zone is divided into a ground layer and an air layer. The ground layer is sequentially arranged along the X direction with a column sheet feeding station, a column sheet centering station, a final assembly station, a lower yoke sheet centering station, and a lower yoke feeding station, and the column sheet feeding station is provided with three. The column feeding shuttle trolley 1, the column centering station is provided with a three-column automatic center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com