Full-automatic overlapping and packaging processing equipment for bearing retainer

A bearing cage and processing equipment technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of high labor costs, loose cage packaging film, and affecting appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

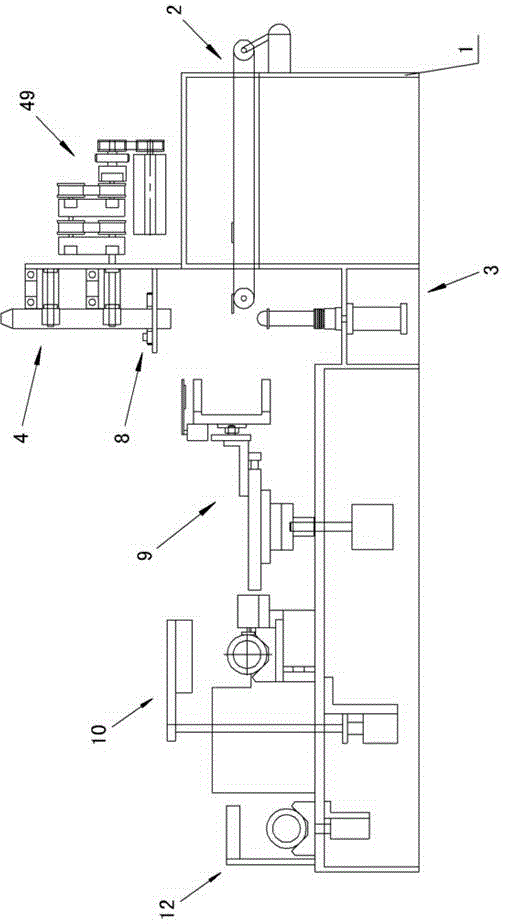

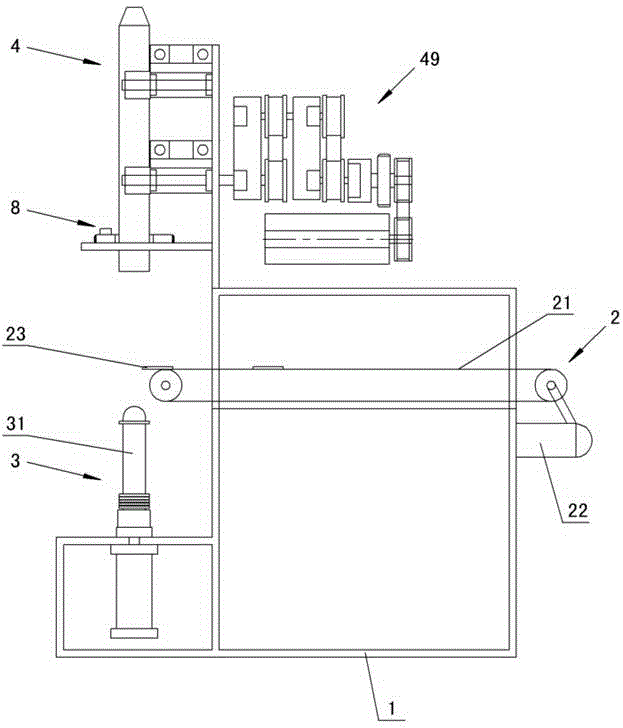

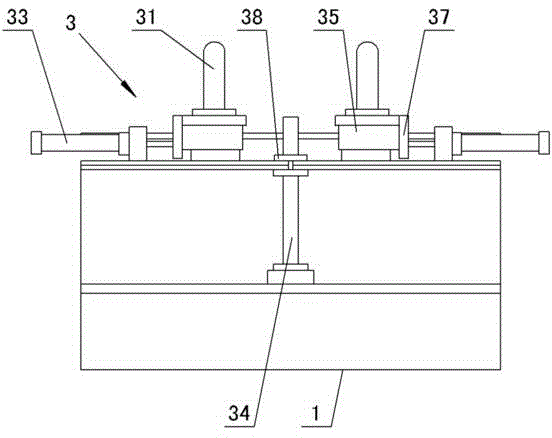

[0027] The invention relates to a fully automatic stacking and packaging processing equipment for bearing cages, such as figure 1 — Figure 20As shown, it is characterized in that it includes a frame 1, an automatic stacking film mechanism 17 and an automatic edge sealing heat shrinking mechanism 18 are arranged on the frame, and the automatic stacking film mechanism 17 includes a cage conveying and loading device 2 , the stacking mandrel conveying device 3, the film tube set conveying device 4, the film cutting device 8 and the manipulator transfer device 9, the cage conveying and feeding device 2 includes a conveyor belt 21, and the conveyor belt is installed in the middle of the frame 1, The conveyor belt is driven by the conveying motor 22, and a cage 23 is set on the conveyor belt. The stacked mandrel conveying device 3 includes a stacked mandrel 31, a side mandrel clamping cylinder 32, a mandrel pushing cylinder 33 and a core rod. Rod lifting cylinder 34, the stacking m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com