Pallet stacking and conveying device

A conveying device and pallet technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of abnormal stacking, poor object alignment, and high maintenance costs, and achieves prevention of position offset and difficulty. Tilt or fall, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

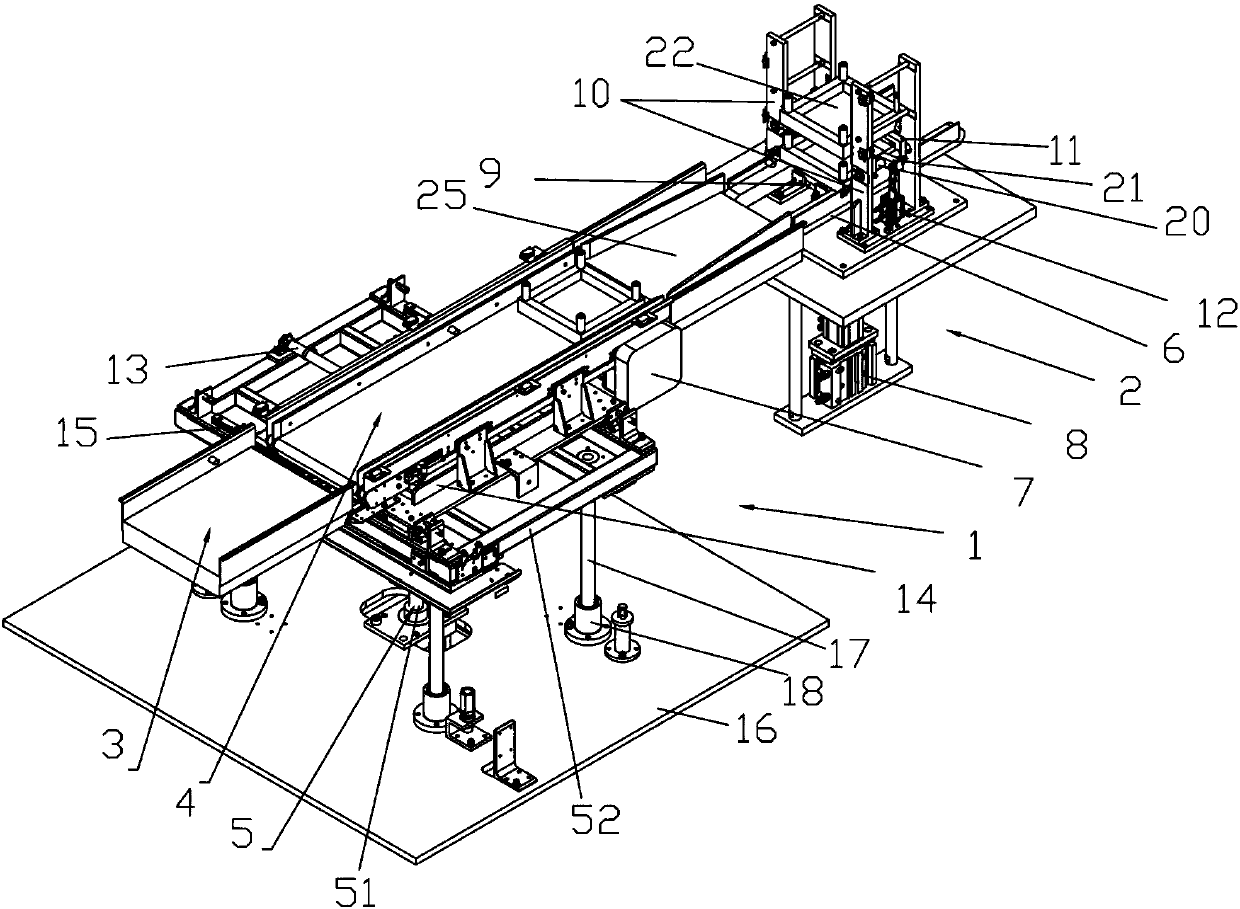

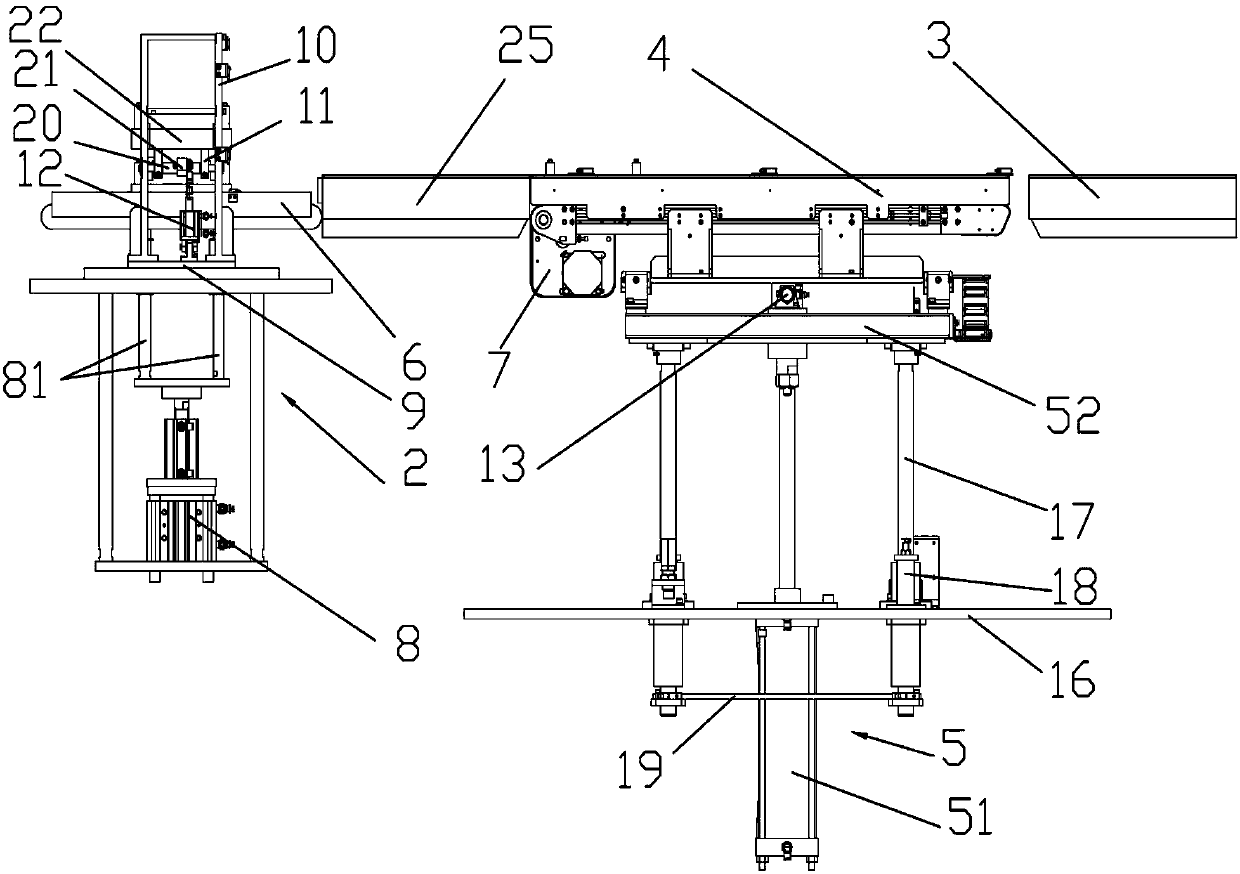

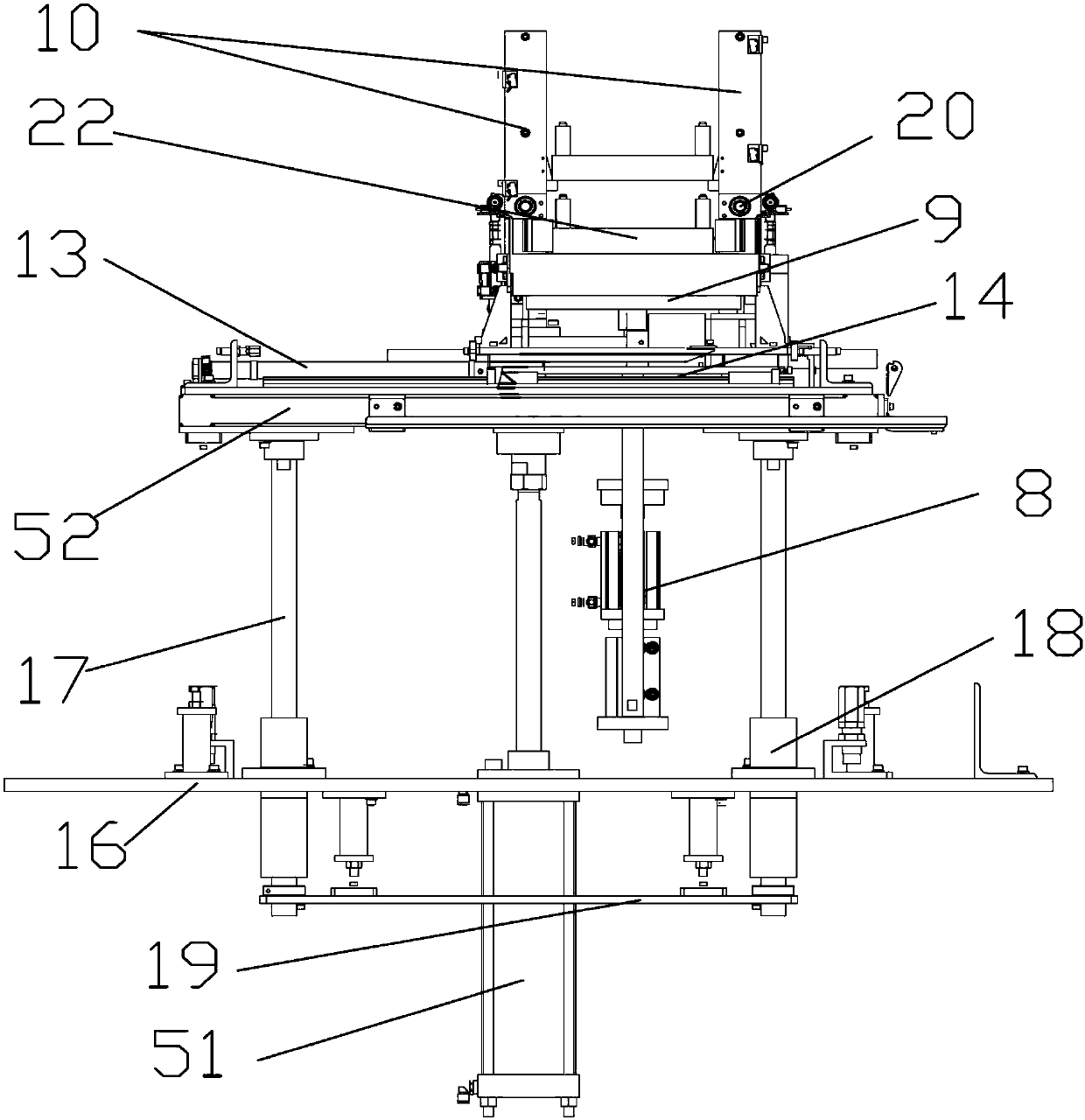

[0019] according to figure 1 , figure 2 , image 3 The pallet stacking conveying device includes a conveying elevating mechanism 1 and a pallet stacking mechanism 2. The conveying elevating mechanism 1 includes: a first conveyor belt 3, a second conveyor belt 4, and a lifting mechanism that drives the second conveyor belt 4 to rise and fall. Mechanism 5 and the third conveyor belt 6, in the production workshop, because the heights of the machinery and equipment in each processing link are different, the heights of the matching conveyor belts are also different, in order to better connect the conveyor belts to keep the workpiece For smooth transmission, the height of the second conveyor belt 4 needs to be adjusted by the lifting mechanism 5, so that workpieces can be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com