Intelligent stacker and stereoscopic warehouse system using same

A technology of intelligent stacker and three-dimensional warehouse, which is applied in the field of storage, can solve the problems of low space utilization rate of low-level shelves, ineffective quality inspection effect, hidden safety hazards of high-level shelves, etc., and achieves simple structure, quick start and smooth stop, The effect of great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

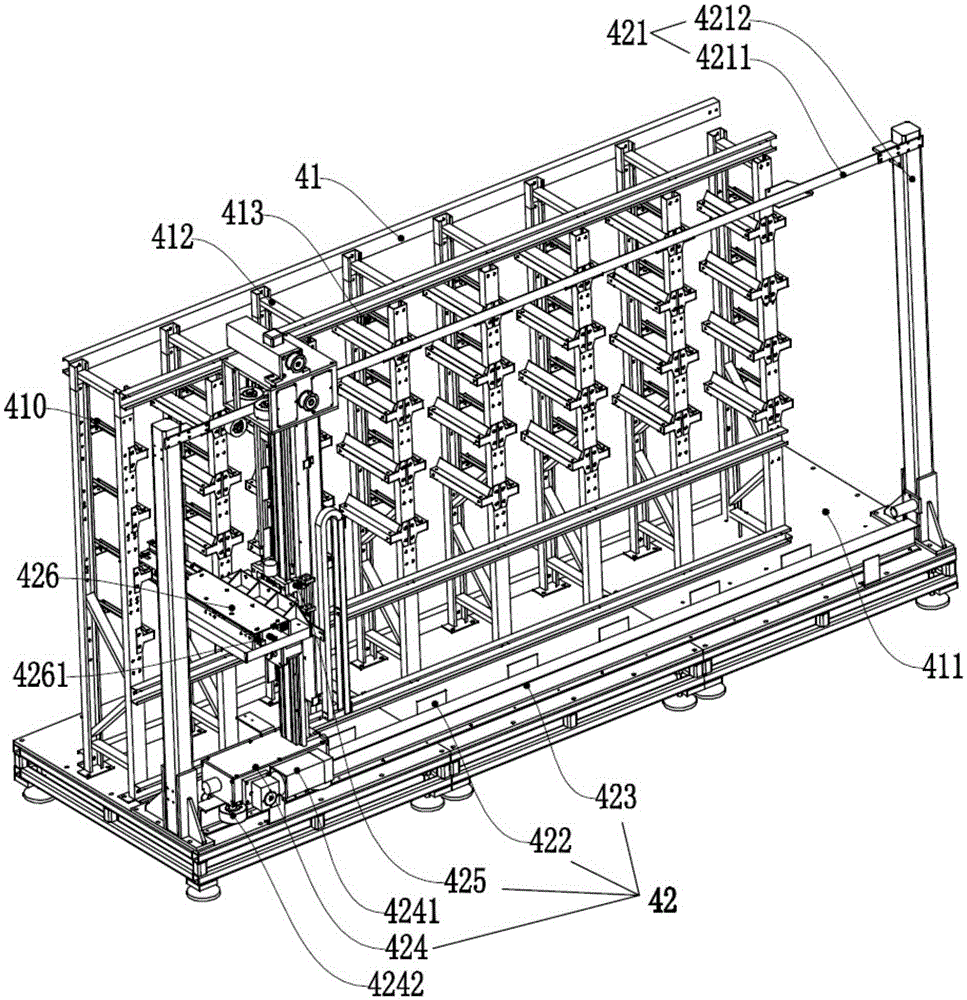

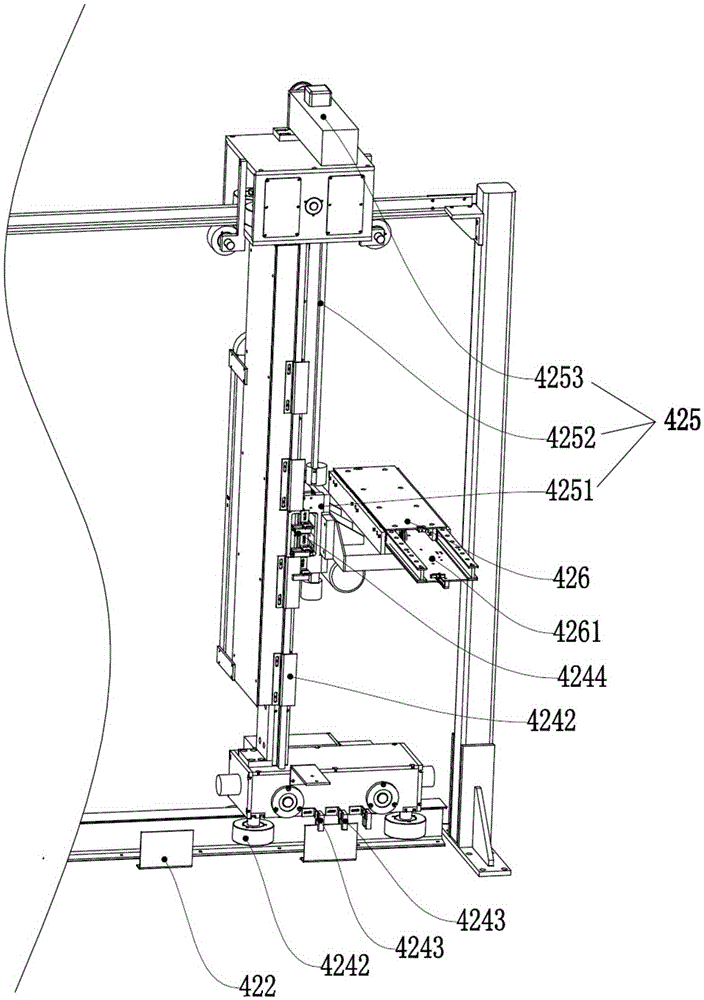

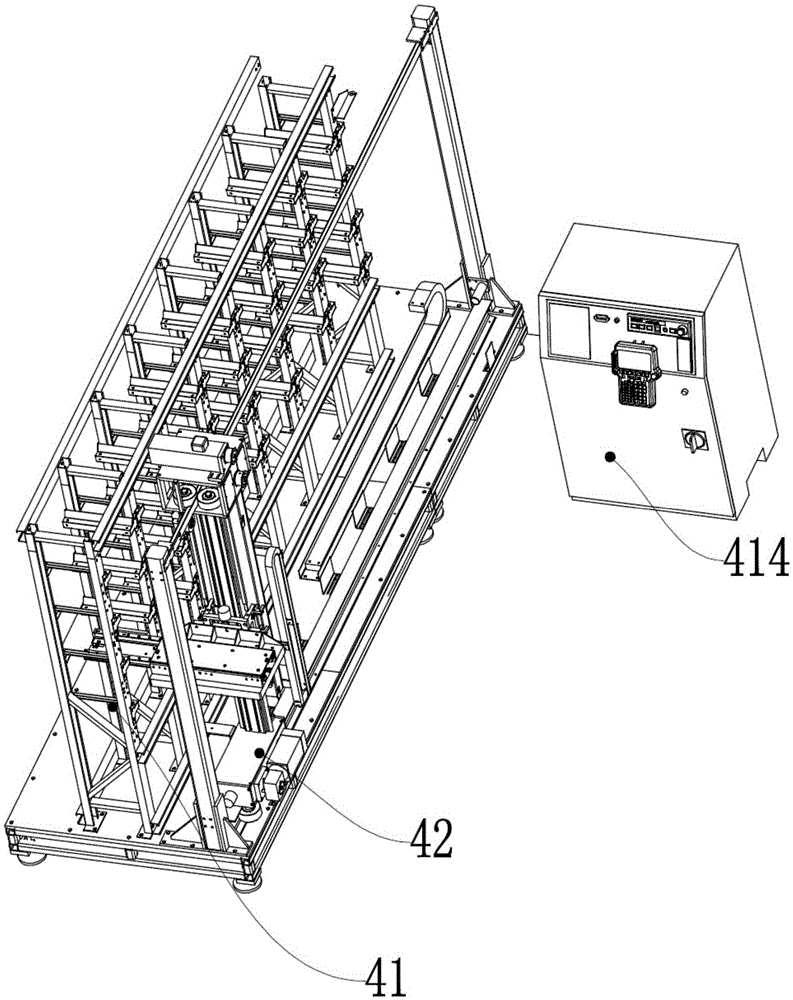

[0027] Such as Figure 1-2 As shown, an intelligent stacker is used in a three-dimensional warehouse 41, including a frame 421, an induction plate 422, a light rail 423, a traveling mechanism 424, a lifting mechanism 425 and a loading platform 426 that can move horizontally back and forth. 421 is a rectangular frame composed of transverse guide rails 4211 and vertical columns 4212. The light rail 423 is parallel to the transverse guide rails 4211 and is arranged at the bottom of the frame 421. The traveling mechanism 424 drives its transverse direction through the traveling drive assembly. The set wheels 4242 walk along the light rail 423, the lifting mechanism 425 is vertically installed on the running mechanism 424, and the loading platform 426 is driven and guided by the lifting mechanism 425 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com