Mould steel material automatic machining unit module

A technology for processing units and steel materials, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of mass industrial production of difficult molds, unstable processing quality, and low work efficiency, and achieve mass industrialization. Production, conducive to widespread application, and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

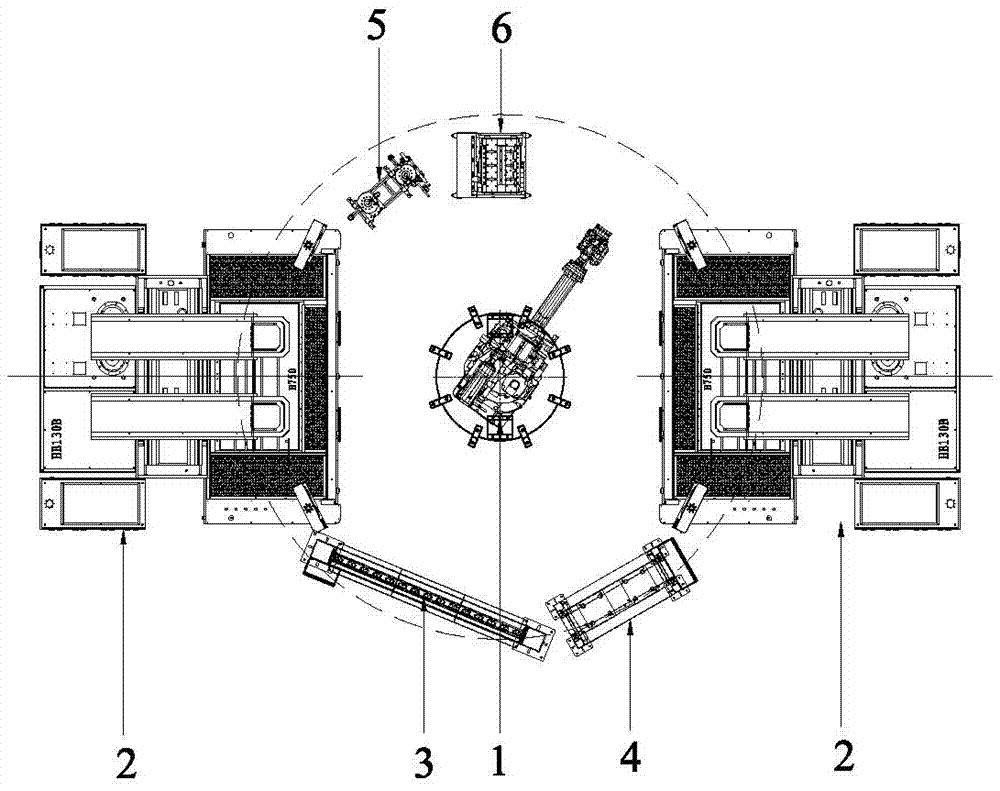

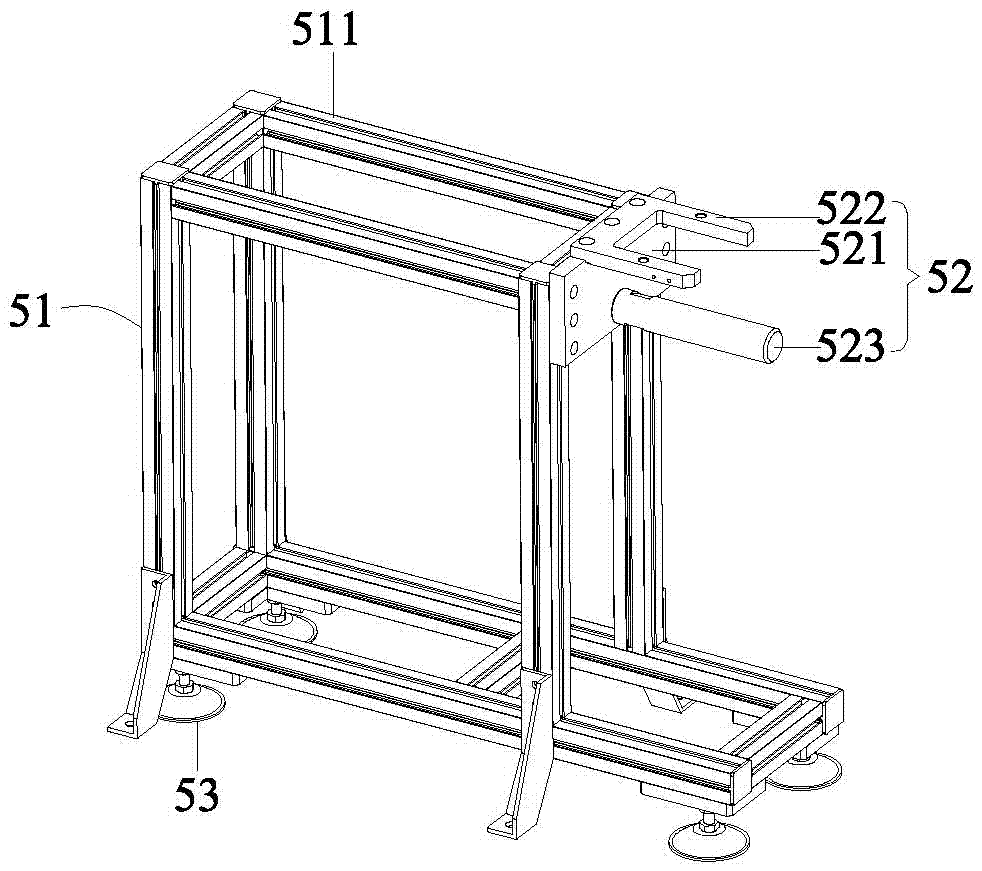

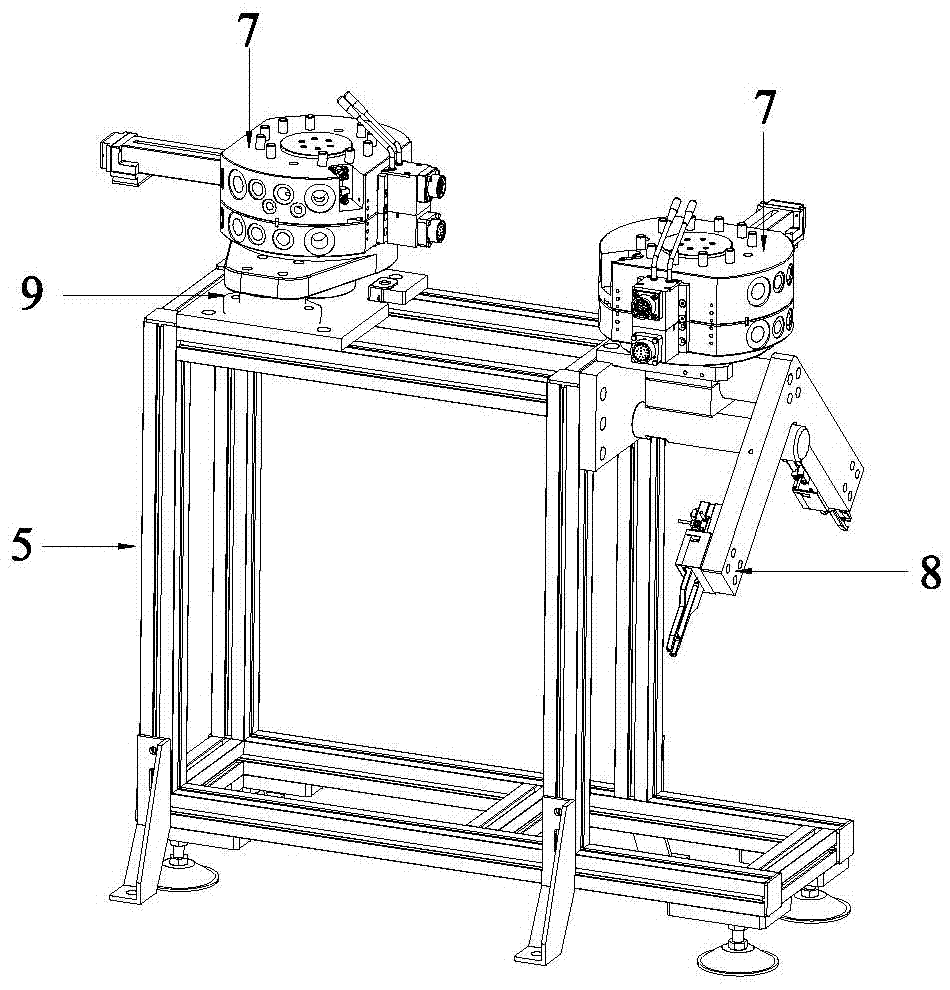

[0015] see Figure 1 to Figure 4 , a mold steel automatic processing unit module provided in this embodiment, which includes a manipulator 1, a spark machine 2, an electrode material rack 3, a steel material placement rack 4, a quick-change fixture placement table 5, and a docking transfer station 6. The spark machine 2, the electrode material rack 3, the steel material placement rack 4, the quick-change fixture placement table 5, and the docking transfer station 6 are correspondingly distributed around the manipulator 1 with the manipulator 1 as the center of the circle; the manipulator 1 is equipped with a quick-change device 7 , the quick-change fixture placement table 5 includes a main frame body 51 and a sub-frame body 52 that can be used to place the electrode gripper 8. The bottom surface of the main frame body 51 is provided with height adjustment support feet 53, and the main frame body 51 One side of the top surface is provided with a placement surface 511 for placin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com