Mechanical lifting device for fluorescent lamp tubes

A technology for mechanical lifting and fluorescent lamps, which is applied to manipulators, program-controlled manipulators, and the manufacture of discharge tubes/lamps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

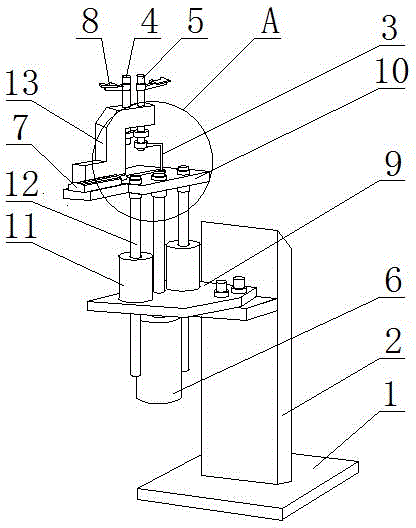

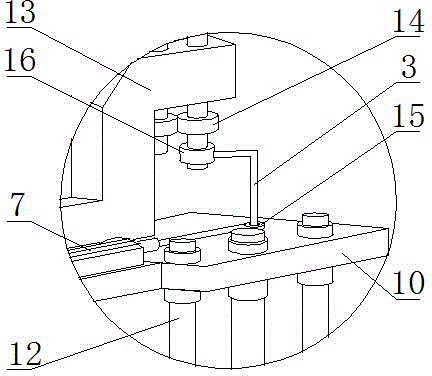

[0011] The mechanical lifting device for fluorescent lamp tubes consists of a base 1, a support arm 2, a crank connecting rod 3, a rotating shaft A4, a rotating shaft B5, a lifting cylinder 6, a rotating cylinder 7 and jaws 8. The support arm 2 is welded on the base 1, and the support arm 2 is fixedly equipped with an installation base plate 9. The lifting cylinder 6 is installed on the lower surface of the installation base plate 9, and the piston rod of the lifting cylinder 6 extends to the installation base plate 9. The end of the piston rod The head is fixedly equipped with a top plate 10 for installation.

[0012] Linear bearings 11 are installed symmetrically on both sides of the piston rod on the upper surface of the bottom plate 9, and guide rods 12 are installed symmetrically on both sides of the piston rod on the lower surface of the top plate 10, and the guide rods 12 are slidably connected with the linear bearings 11.

[0013] The upper surface of the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com