Unmanned intelligent production system with multiple production lines for battery plastic housings

An intelligent production and production line technology, applied in packaging/bundling items, packaging, wrapping items, etc., can solve the problems of poor workshop environment affecting product quality, large labor and low automation, and achieve efficient and reasonable production processes. The process is compact and the effect of reducing dust carry-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

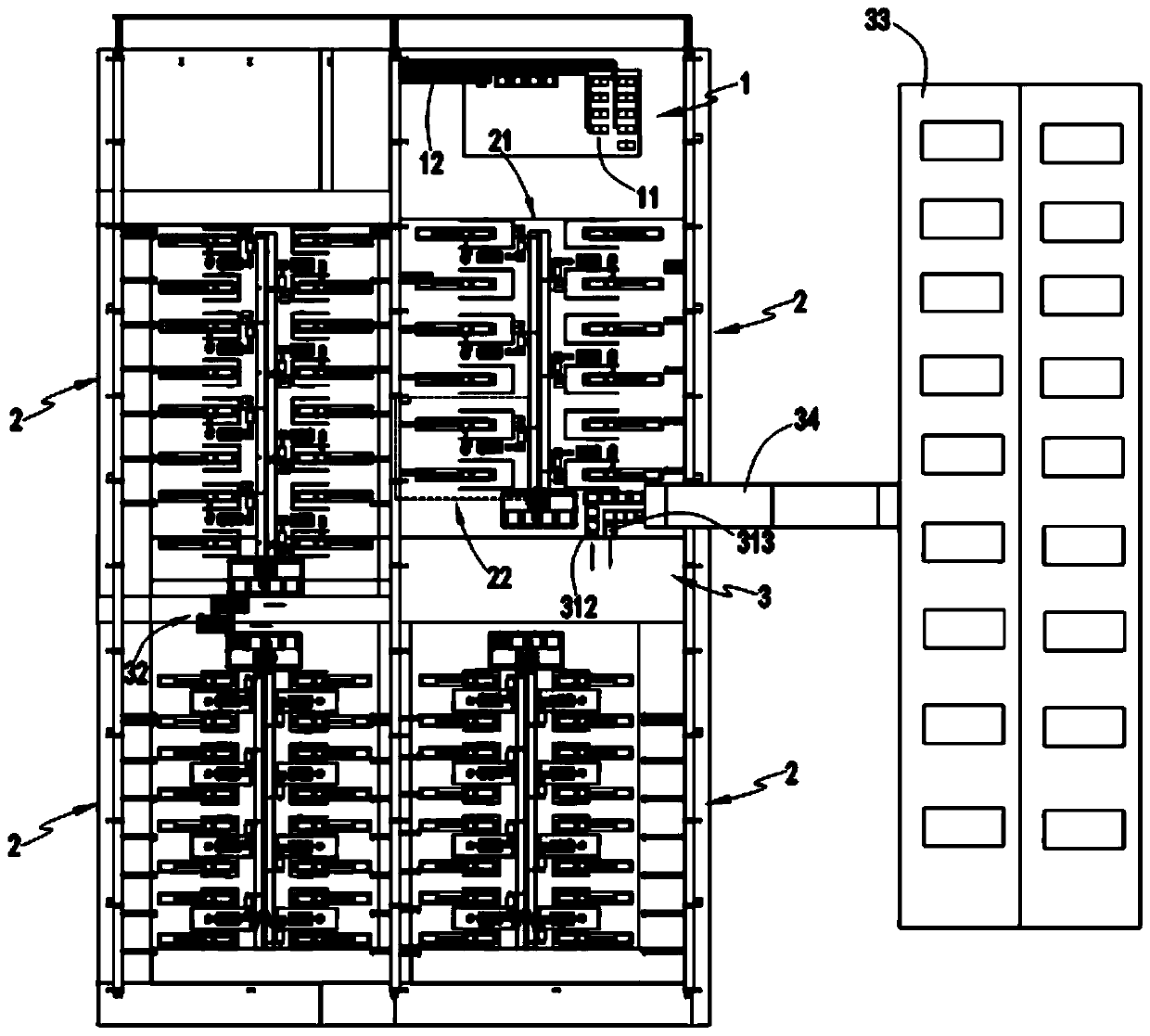

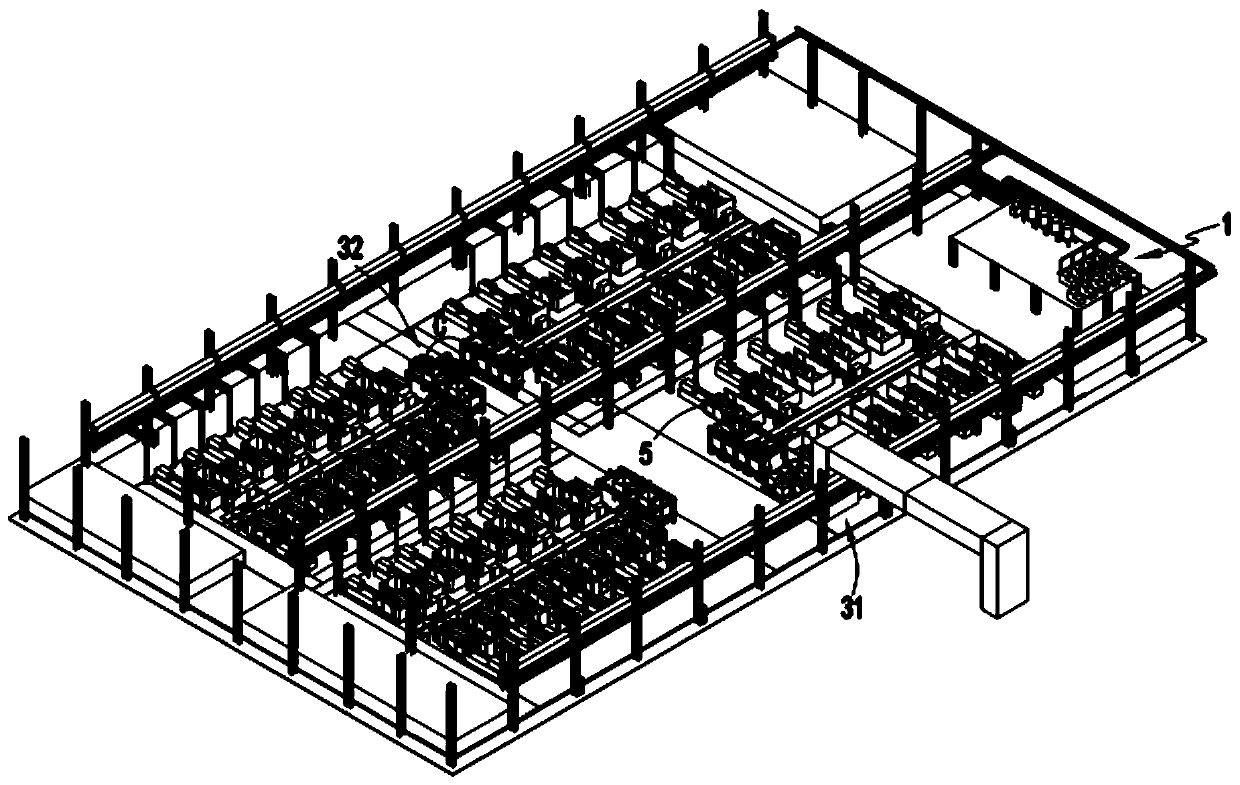

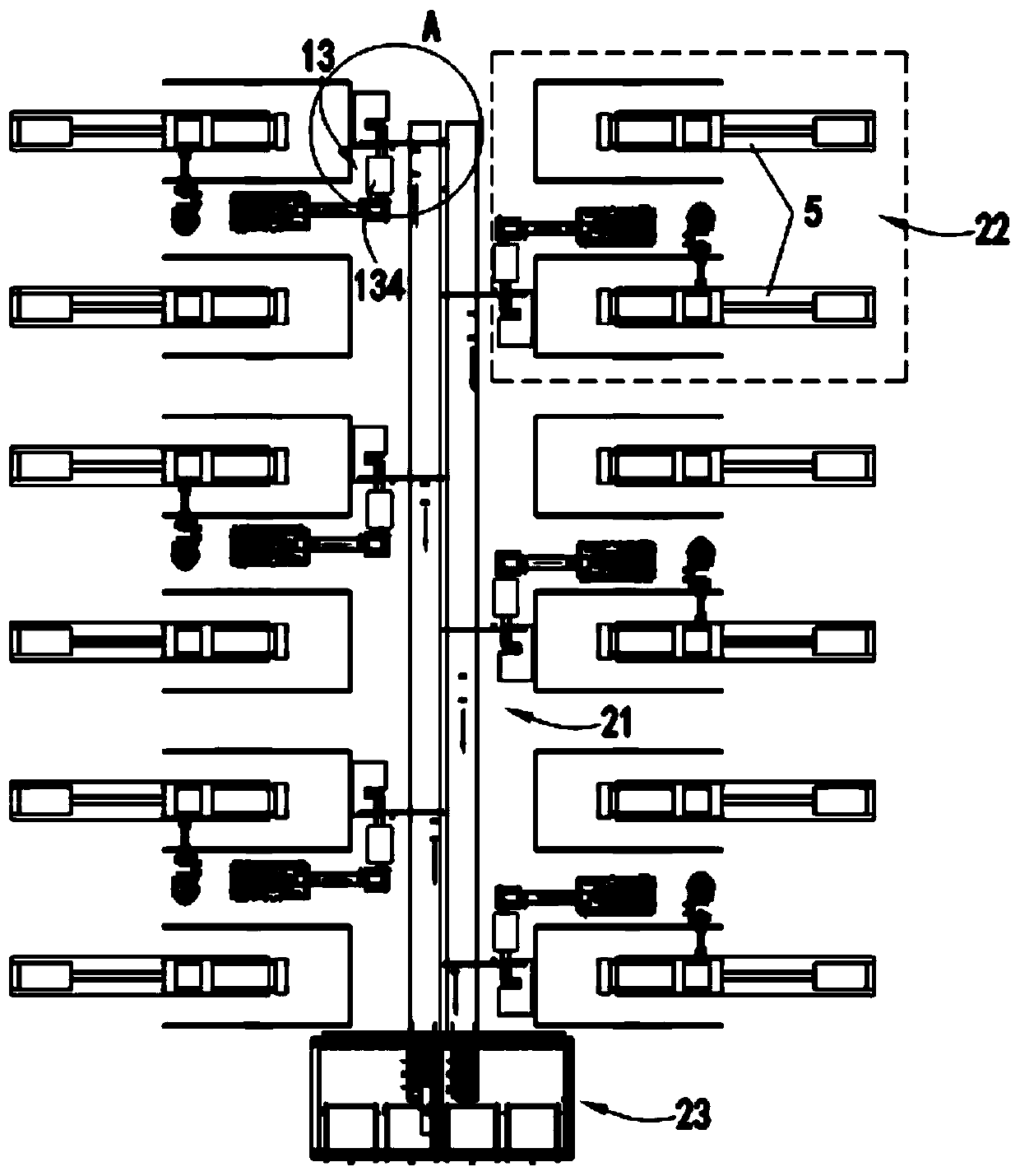

[0062] Such as Figure 1 to Figure 18 As shown in the figure, an unmanned intelligent production system for battery plastic cases with multiple production lines includes a feeding part 1, several production parts 2 and a transfer part 3, and the feeding part 1 is used to process each production part 2 centralized supply of raw materials;

[0063] The transfer part 3 includes an entry and exit device 31 and several transfer devices 32. After each production part (2) automatically processes and shapes, trims, detects, and rejects a plurality of battery boxes 20, each production part 2 is matched accordingly. The set packaging device 23 is automatically stacked into the packaging box 10 one by one and in an orderly manner, and then the transfer device 32 transports the full packaging box 10 to the in-out device 31 and automatically transfers to the next process; at the same time, the transfer device 32 Load the empty packing box 10 at the entry and exit device 31 and transfer it...

Embodiment 2

[0093] Such as Figure 12 and 13 In the illustration, the parts that are the same as or corresponding to those in the first embodiment use the corresponding reference numerals as those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: further, the four corners of the positioning groove 713 are provided with arc-shaped through grooves 715, and the upper ends of the four sides are provided with guide stops. Bit block 716.

[0094] In this embodiment, arc-shaped through slots are provided at the four corners of the positioning slot so that the frictional collision between the four corners of the battery box and the inner wall of the positioning slot can be avoided during the process of putting the battery box into the positioning slot. , can further guarantee the quality of the battery box.

[0095] The working process is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com