Automatic beverage machine

A beverage machine and automatic technology, applied in beverage preparation devices, coin-operated equipment for distributing discrete items, instruments, etc., can solve the problem of high labor costs and achieve the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

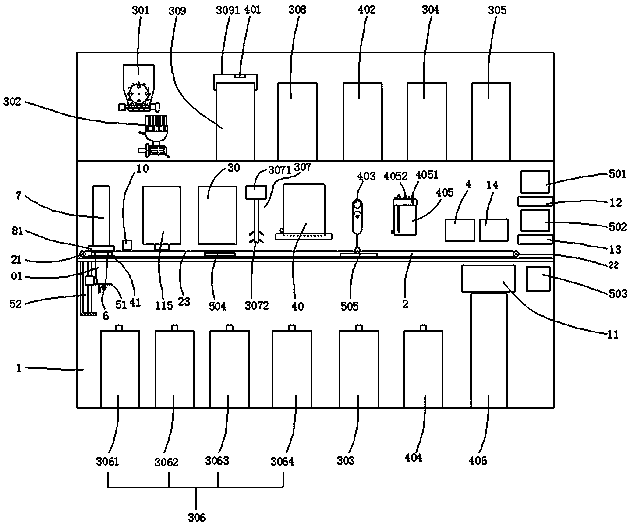

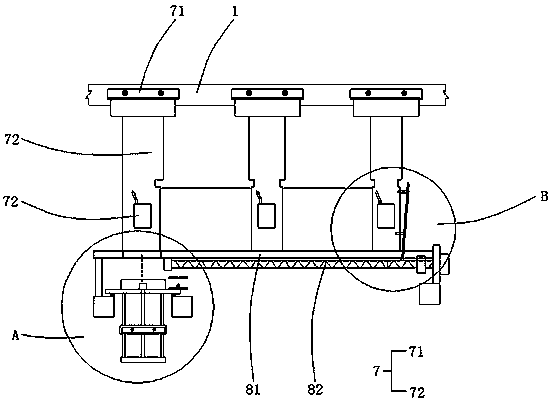

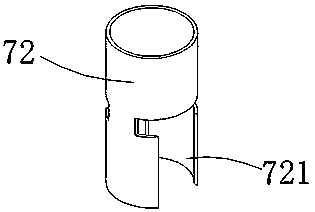

[0051] A specific embodiment of an automatic beverage machine of the present invention, such as figure 1 As shown, the automatic beverage machine includes a cabinet 1, which is provided with a cup delivery system for transporting the cup 01 to a set station, a cup drop system and a lemon slice system arranged in sequence according to the cup delivery direction of the cup delivery system. system, rotary quantitative sauce output system, quantitative fructose output system, quantitative powder output system, quantitative tea output system, liftable stirring system, quantitative ice cube output system, quantitative fresh milk output system, quantitative cover material output system, Quantitative water material output system, liftable liquid level measurement system, quantitative sparkling water output device, cup sealing system, straw delivery system, autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com