Automatic pressure connecting testing device for liquid crystal display panels

A liquid crystal panel and testing device technology, which is applied in the field of automatic crimping test devices, can solve problems such as difficulty in integrating into automated assembly lines, reduced efficiency, and damage to the tested liquid crystal panel, so as to reduce repetitive mechanical labor, realize unmanned production, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

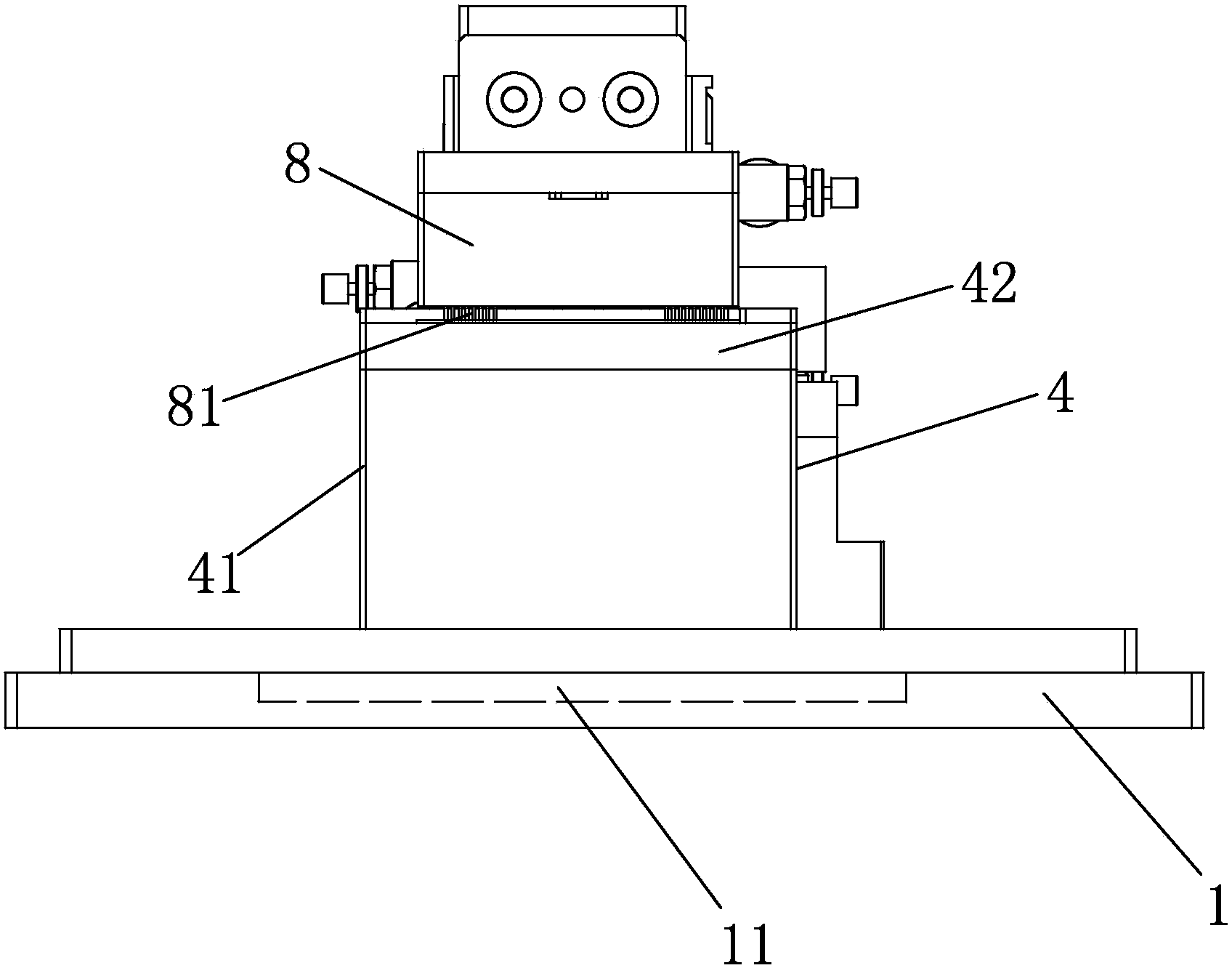

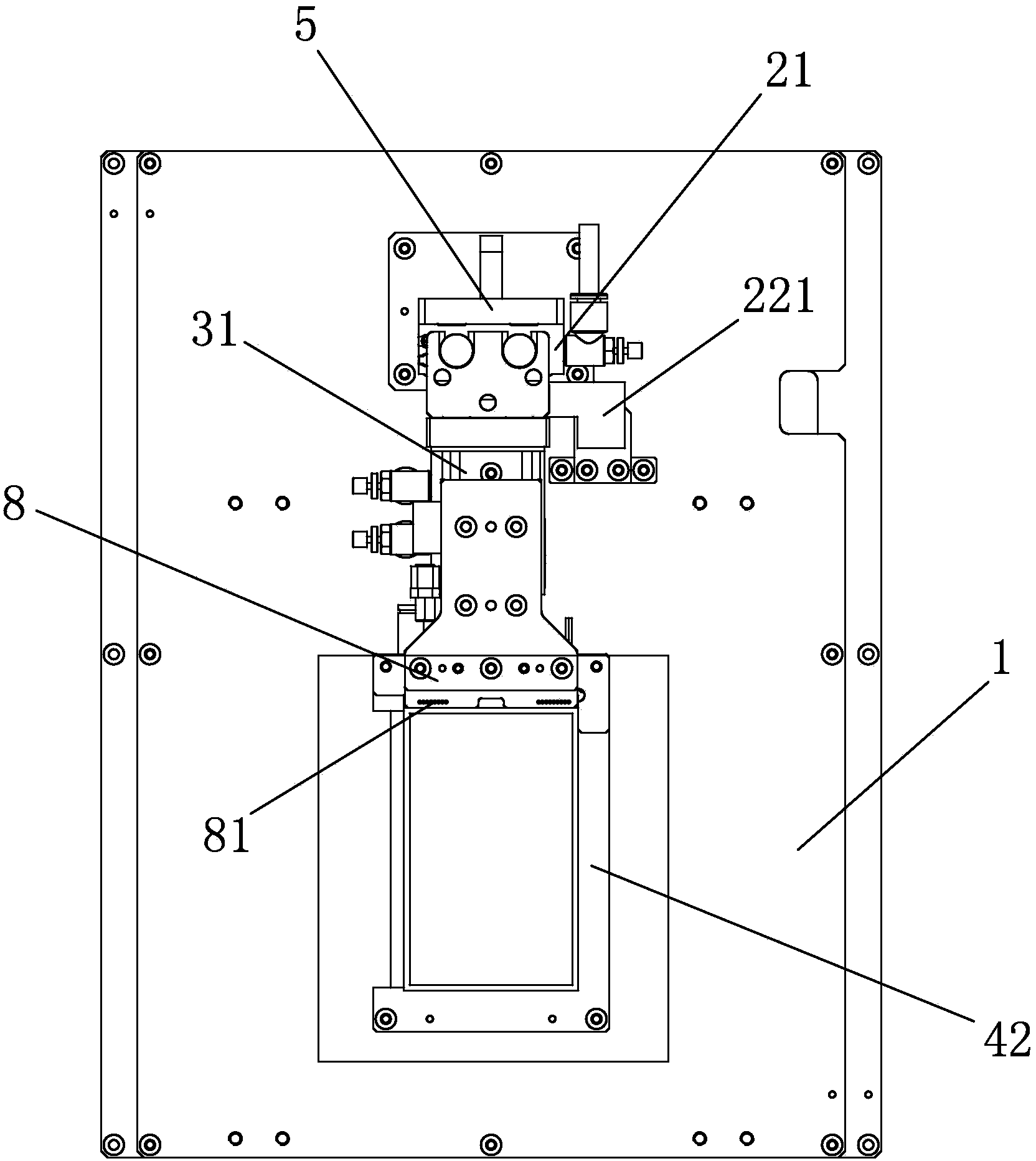

[0034] Such as Figures 1 to 6 As shown, an automatic crimping test device for liquid crystal panels, the test device includes a base plate 1, a vertical cylinder 2, a horizontal cylinder 3 and a support frame 4 for placing a liquid crystal panel to be tested;

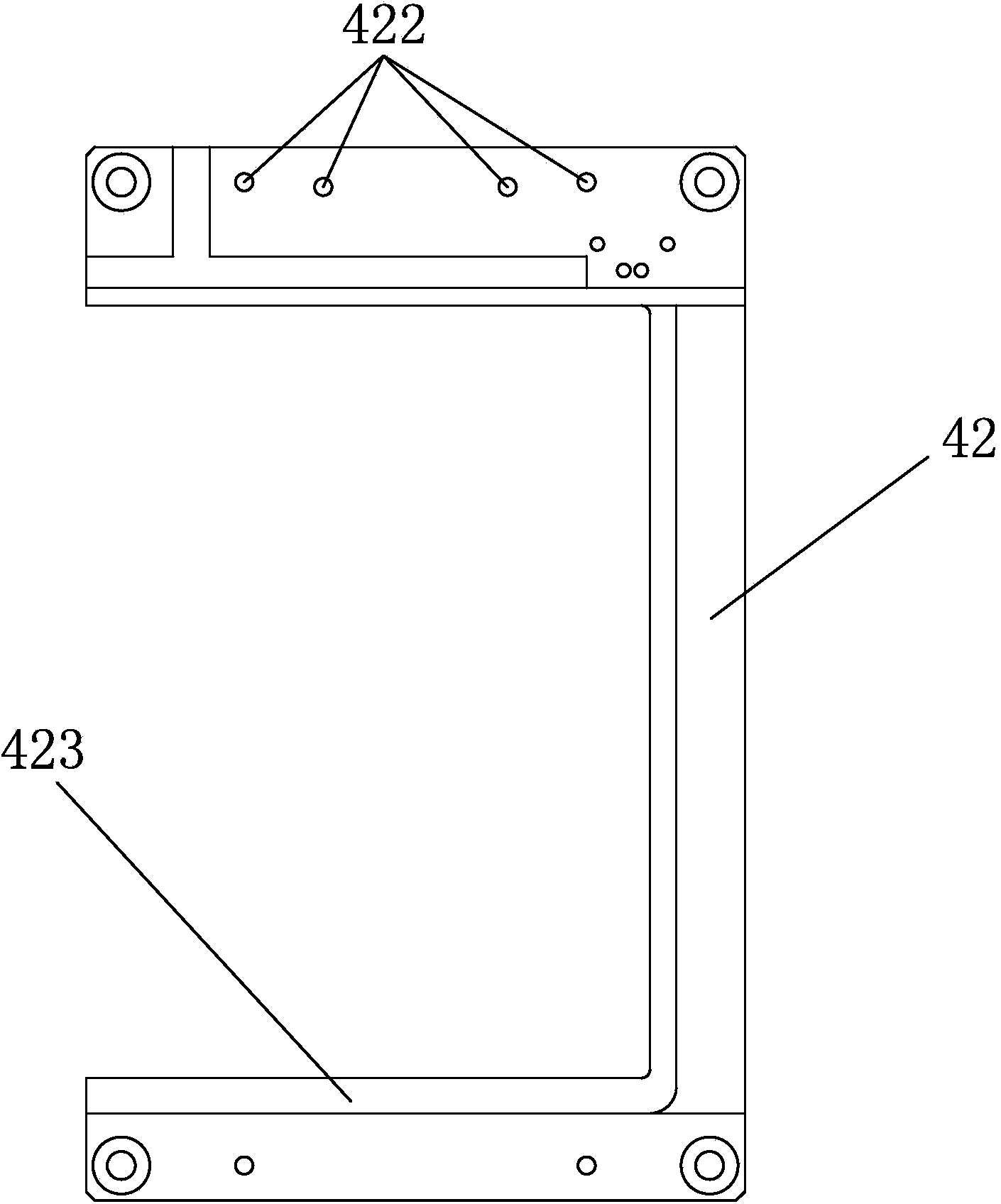

[0035] The support frame 4 includes a vertical support frame 41 and a horizontal support frame 42 for placing the liquid crystal panel to be tested; the horizontal support frame 42 is fixed on the board surface of the base plate 1 through the vertical support frame 41 .

[0036] An air joint 421 is provided on the horizontal support frame 42, and an air hole 422 for absorbing and fixing the liquid crystal panel to be measured is provided on the frame upper surface of the horizontal support frame 42, and the air hole 422 is communicated with the air joint 421; Its purpose is to abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com