Patents

Literature

313results about How to "Avoid error conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

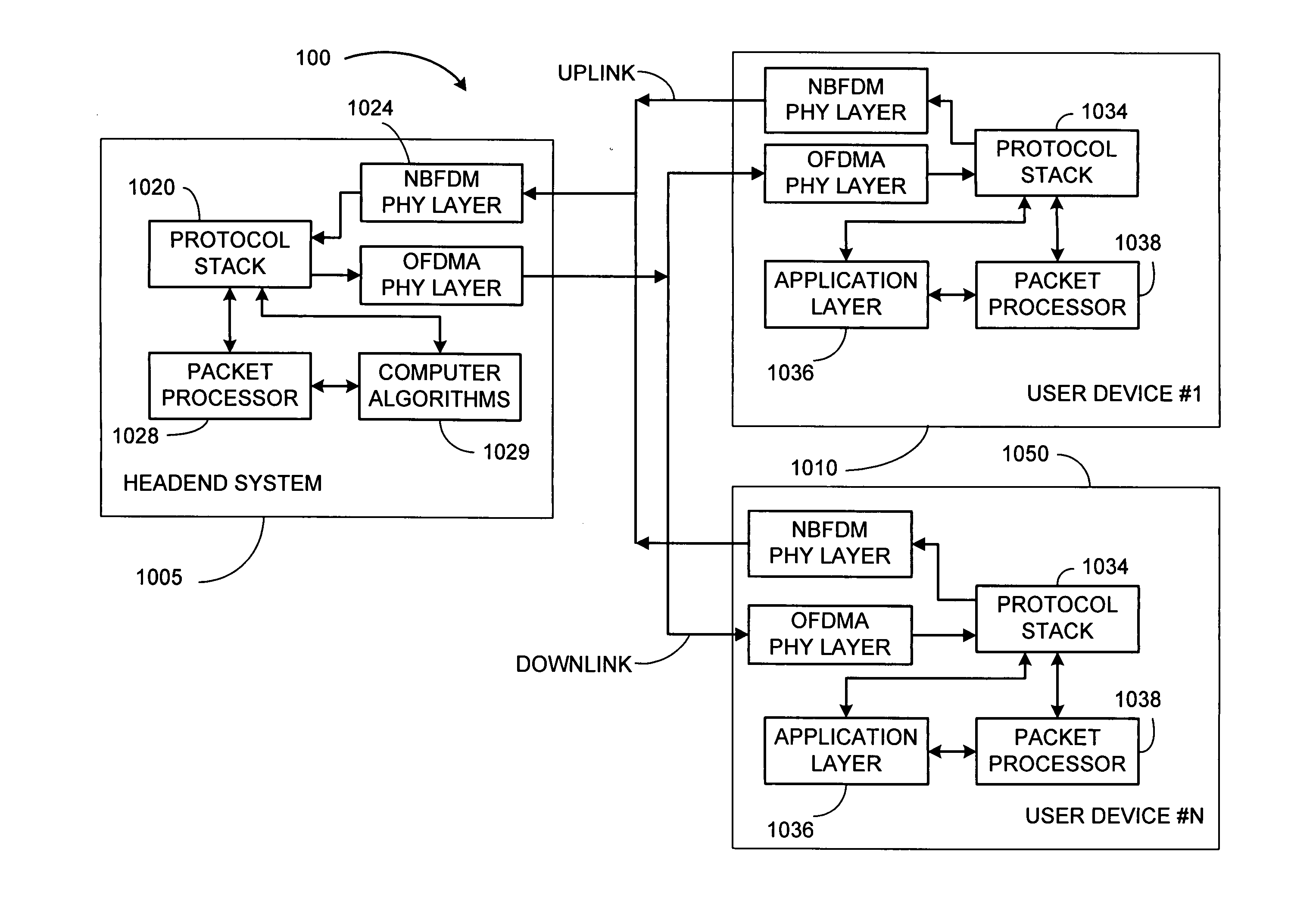

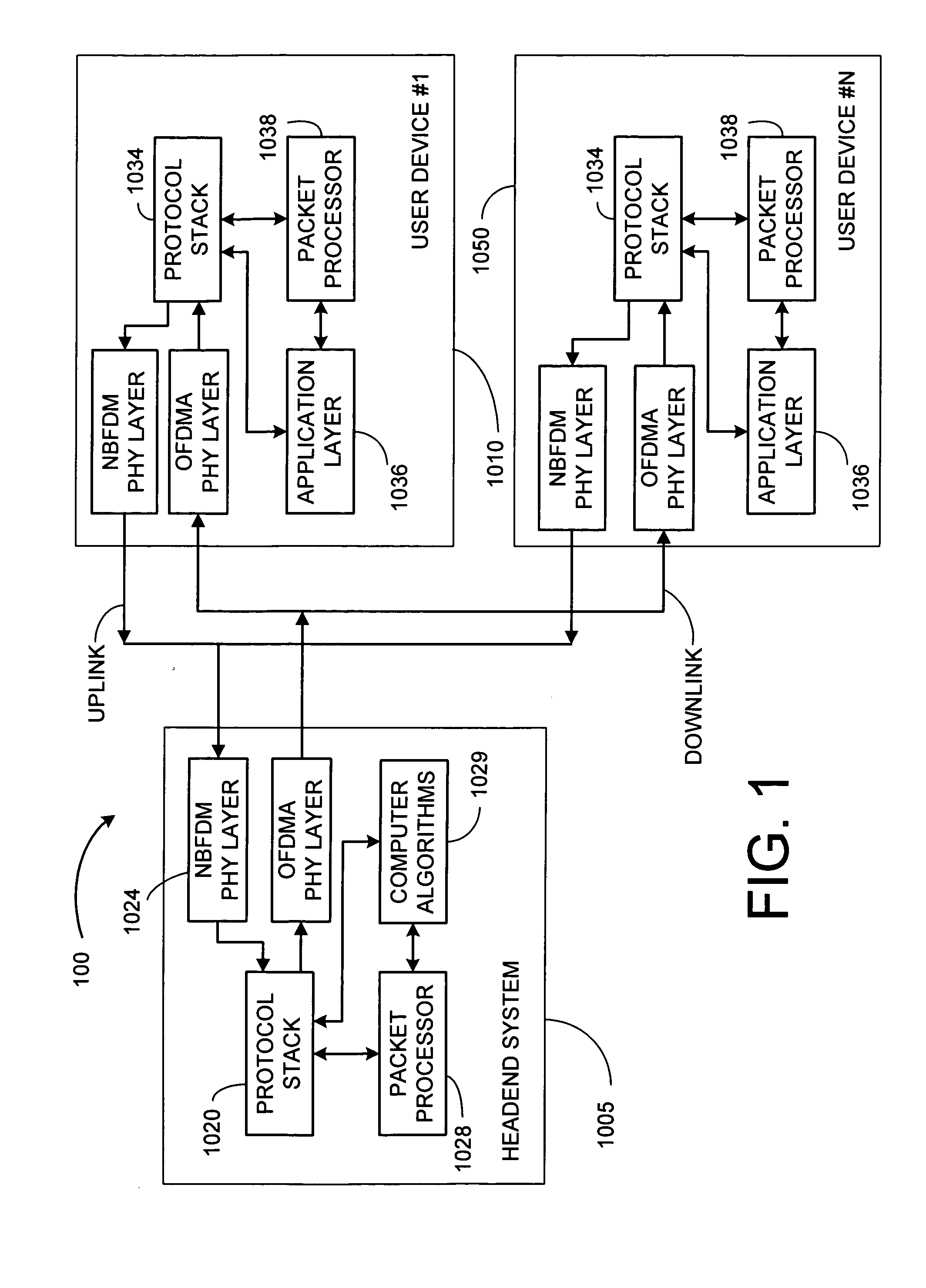

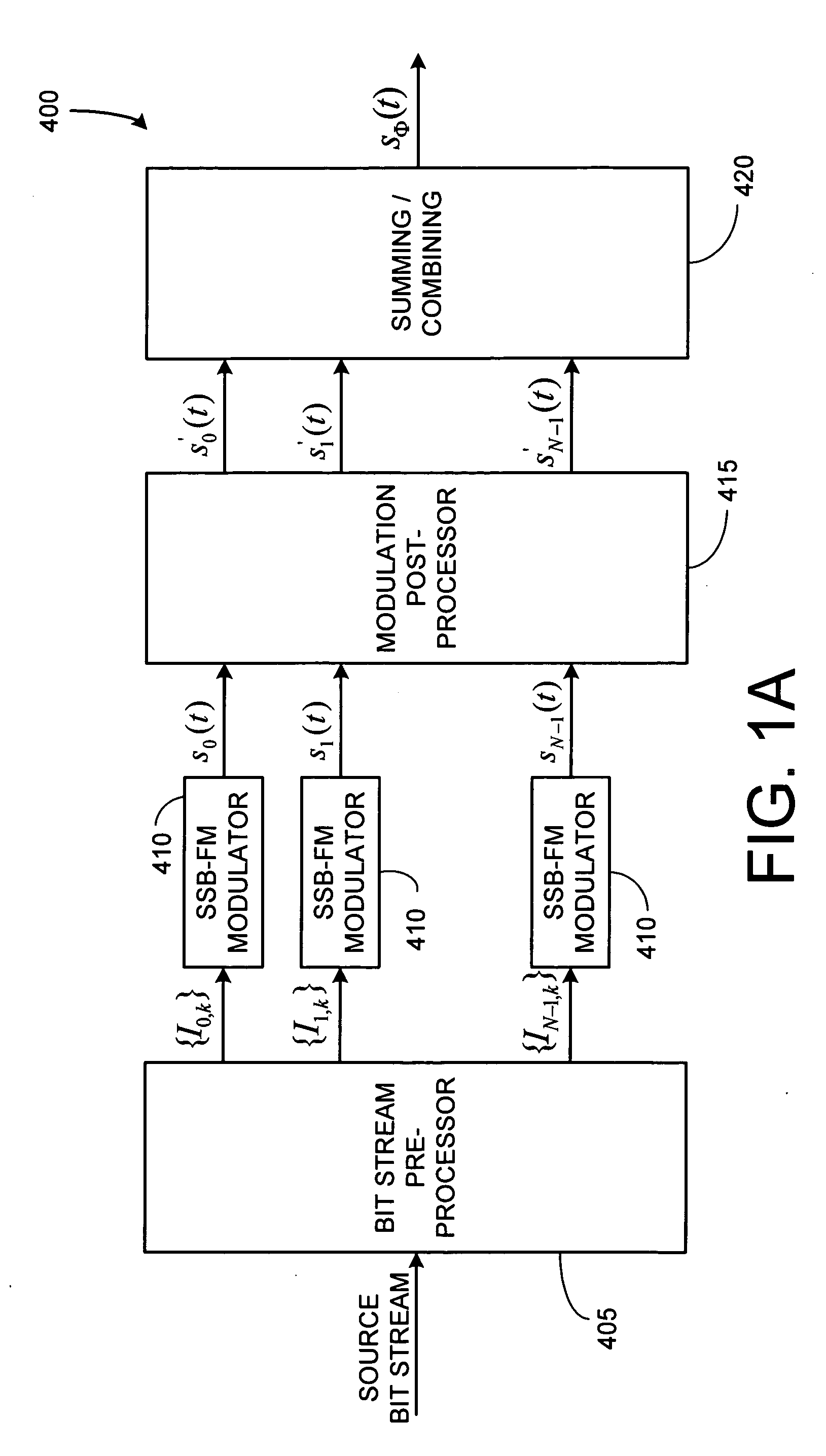

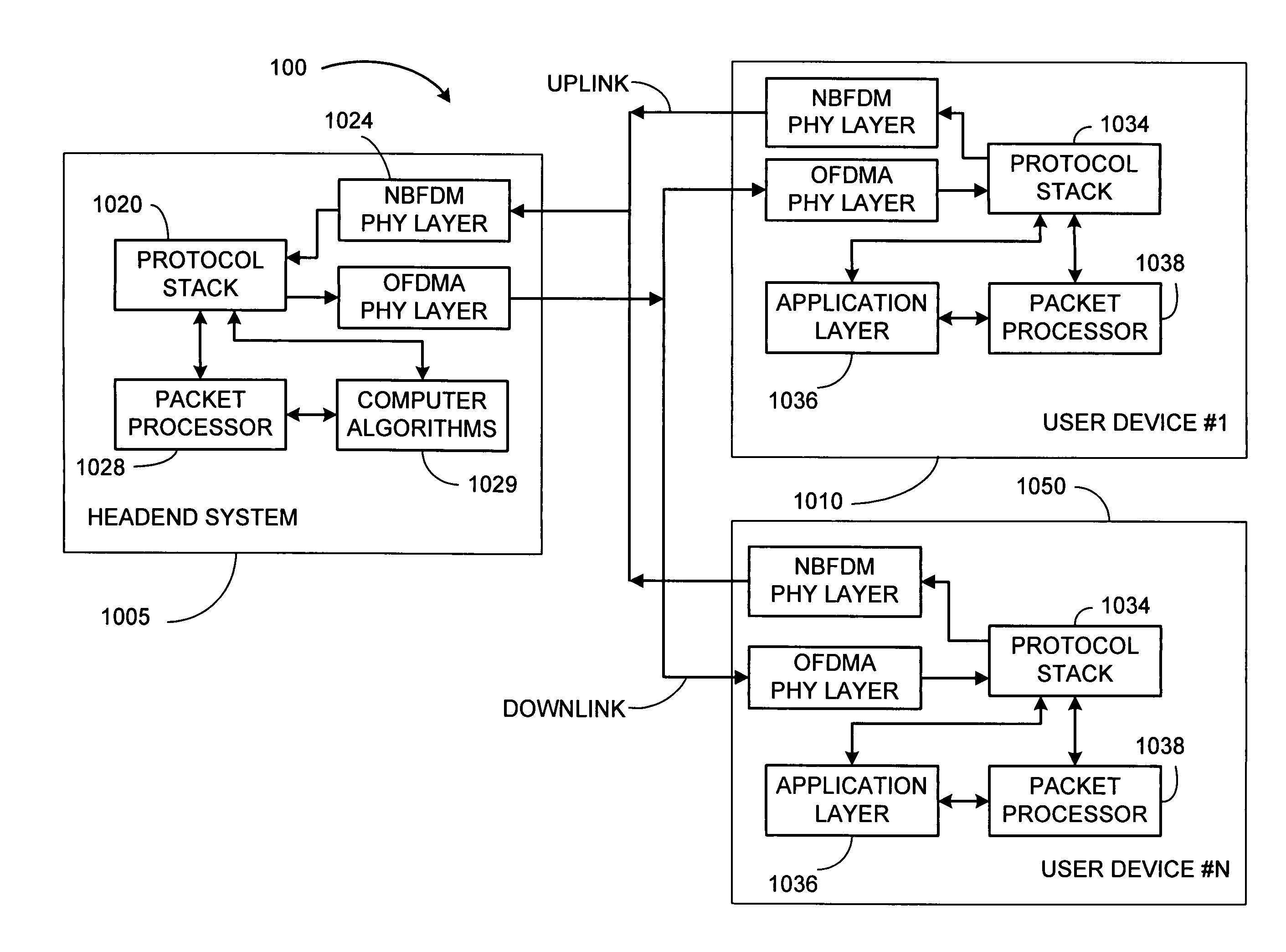

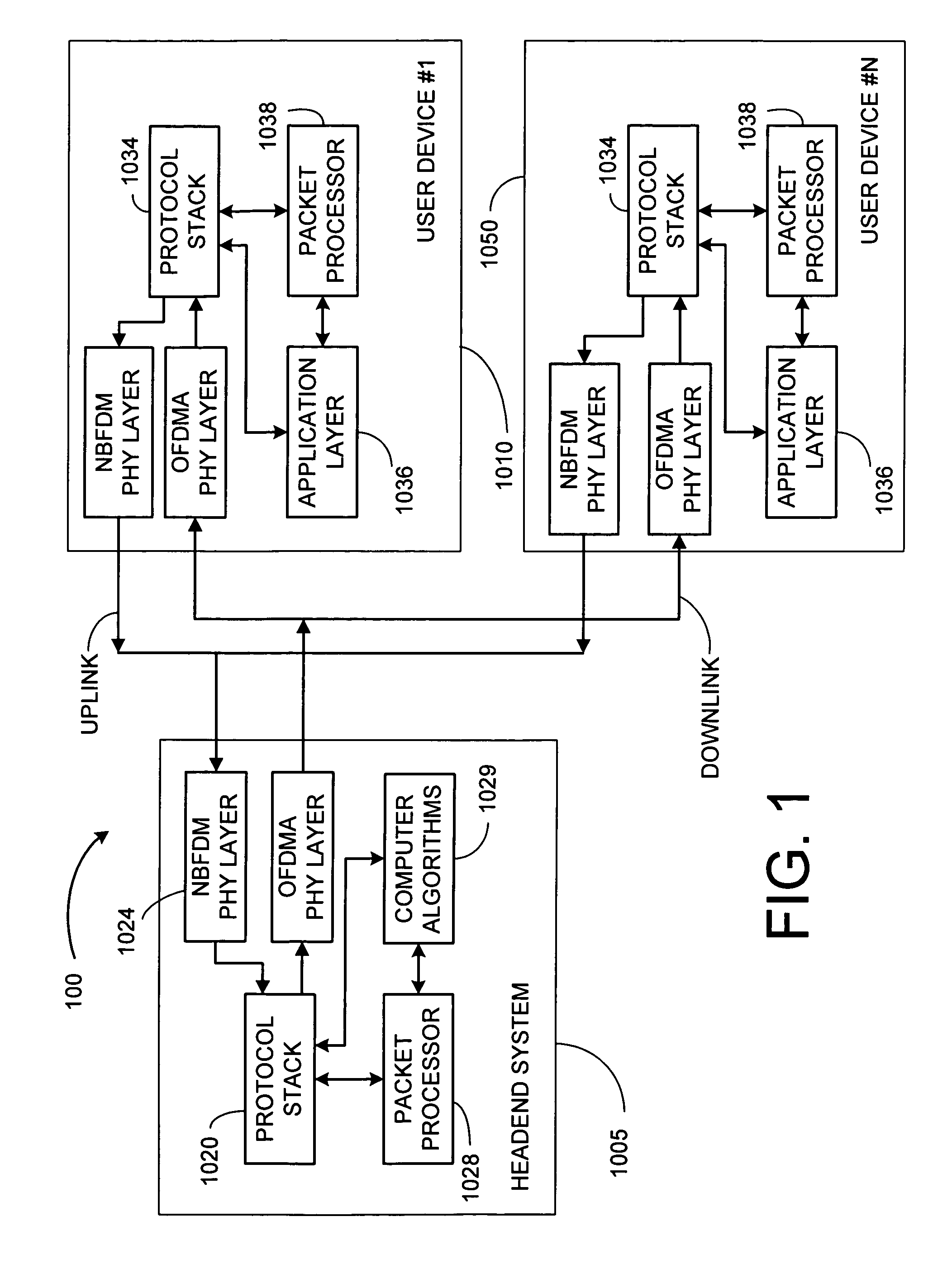

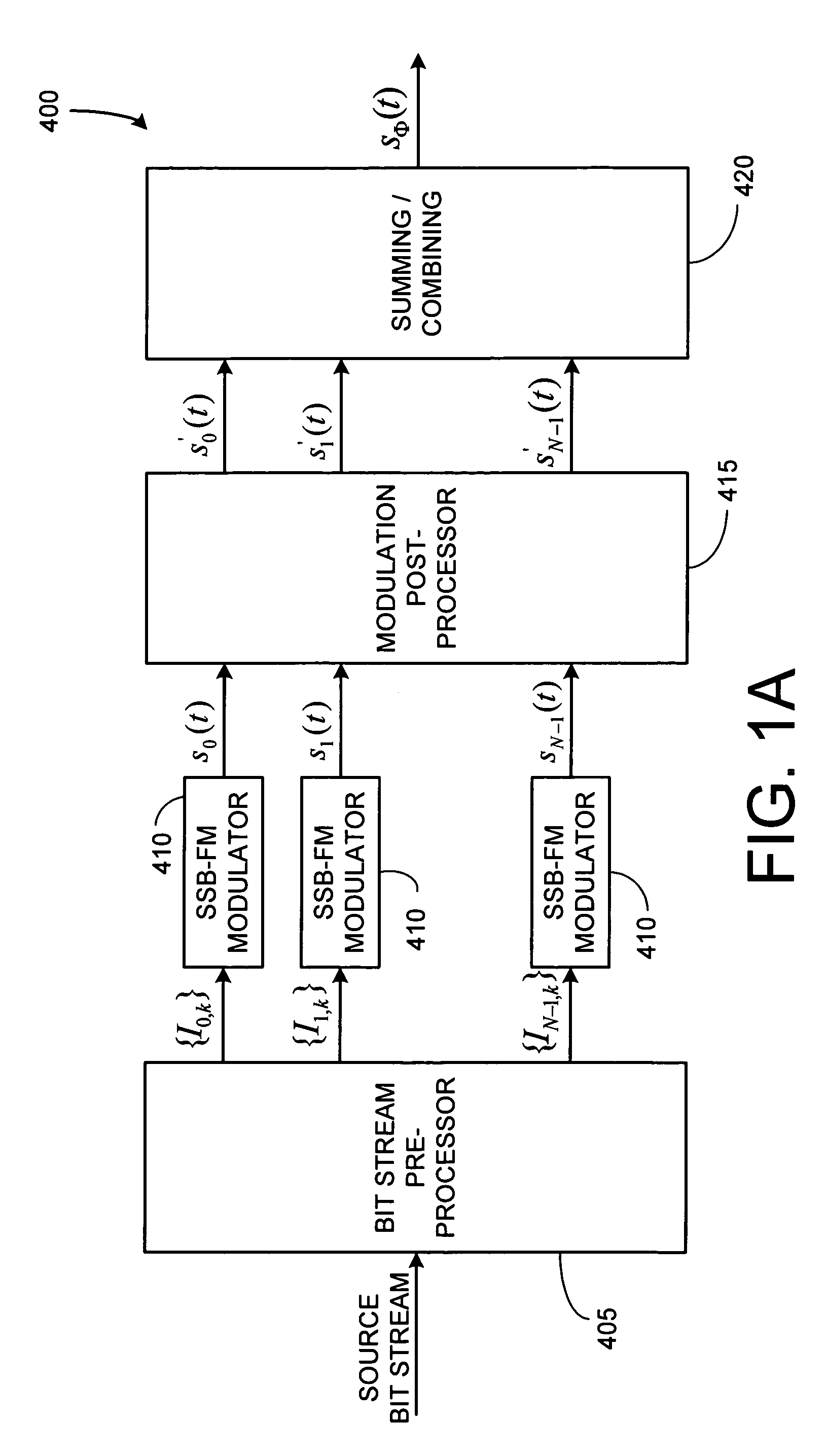

Uplink modulation and receiver structures for asymmetric OFDMA systems

InactiveUS20070115800A1Eliminate needImprove toleranceError preventionOrthogonal multiplexCommunications systemEngineering

The present invention centers upon uplink communication protocols for use primarily with orthogonal frequency division multiple access (OFDMA) communication systems. Aspects of the invention relate to narrow band frequency division multiplexed (NBFDM) modulation protocols primarily for uplink usage in asymmetric OFDMA communication systems. In particular, NBFDM uplinks that use quadrature multiplexed continuous phase modulation are detailed and noncoherent detection schemes are developed to process the uplink channel signals without the need to transmit uplink phase reference signals. Other aspects of the invention relate to burst mode uplink communications in OFDMA systems such as those involving opportunistic beamforming.

Owner:TRELLIS PHASE COMM LP

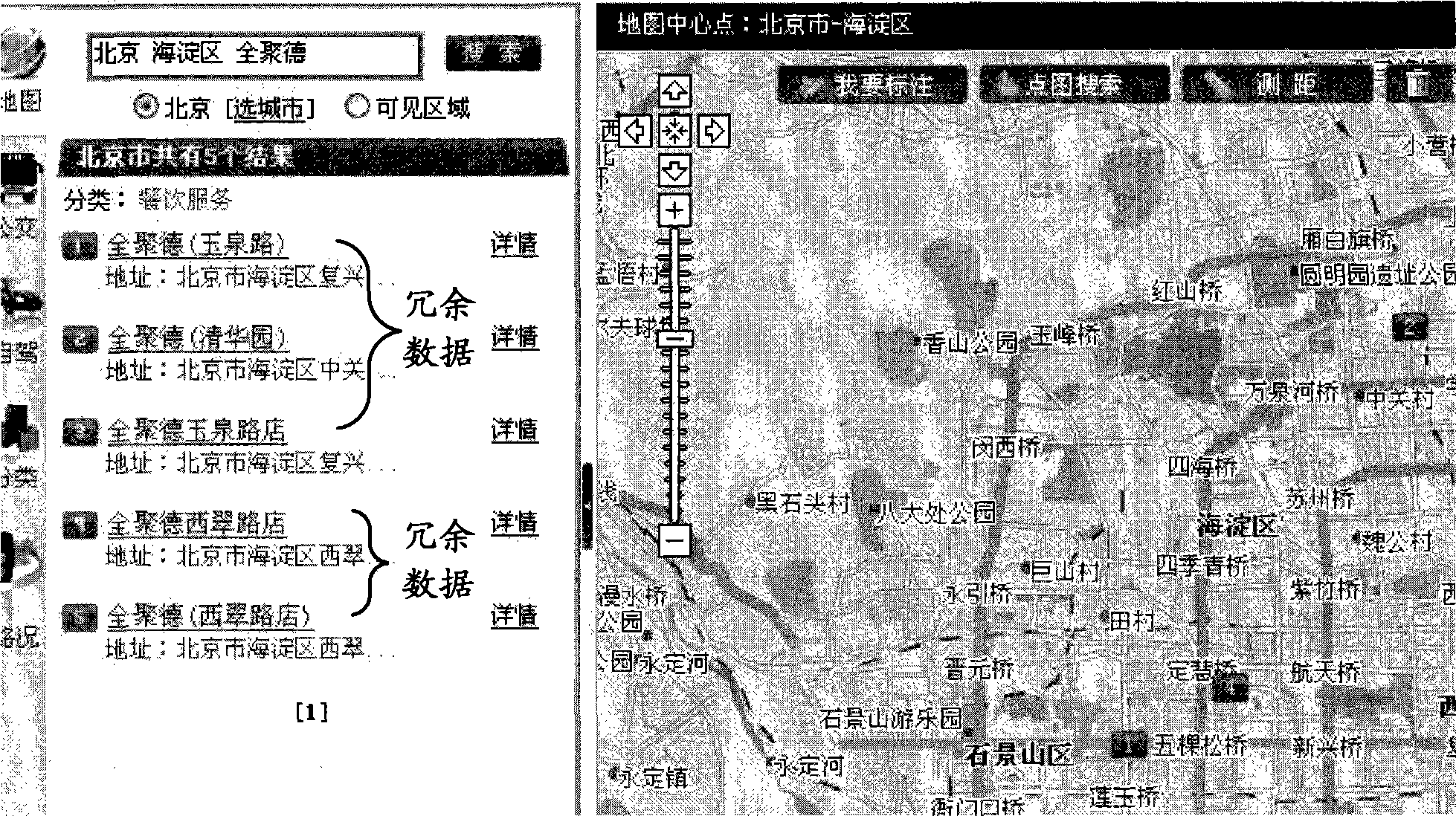

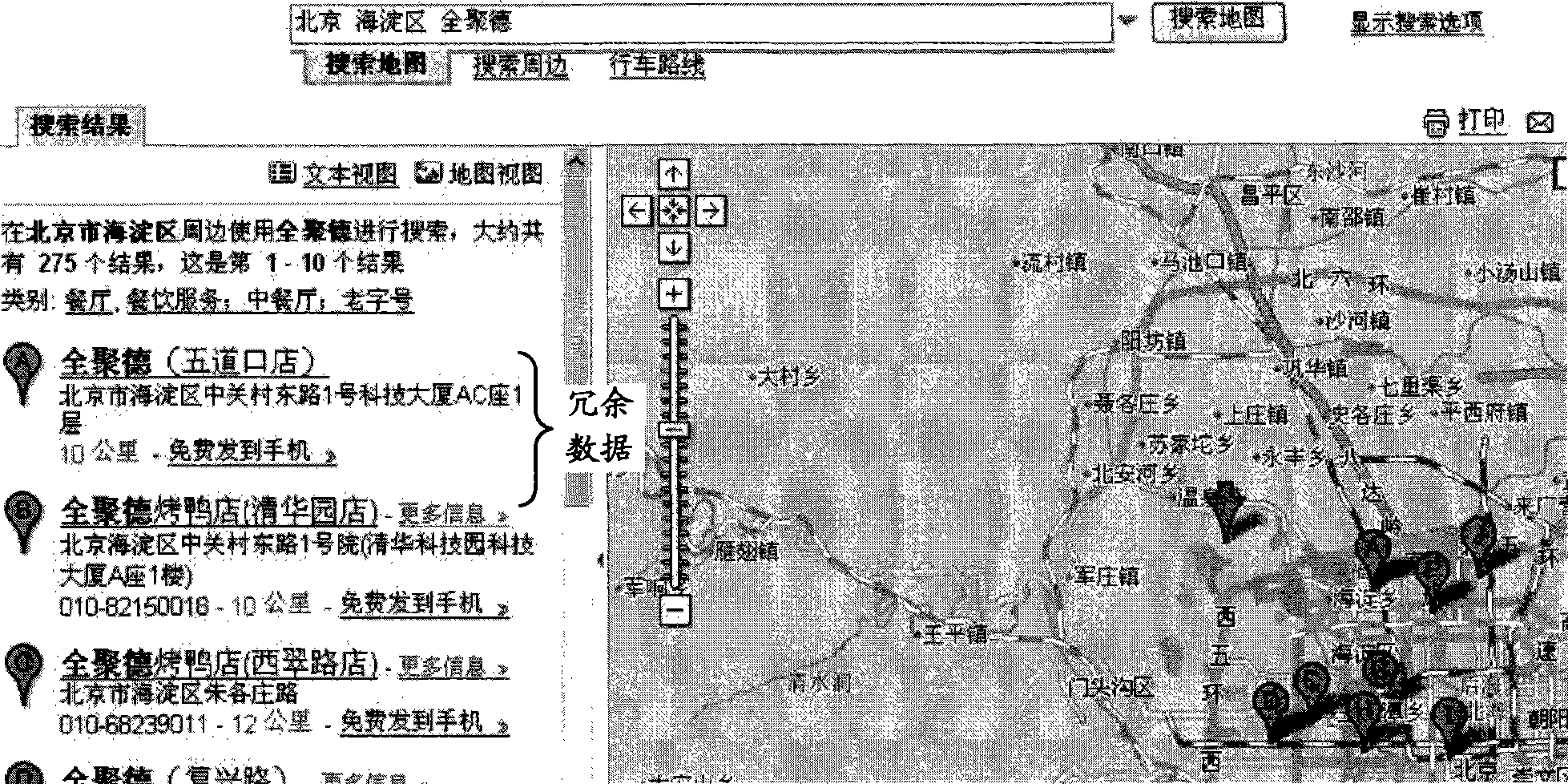

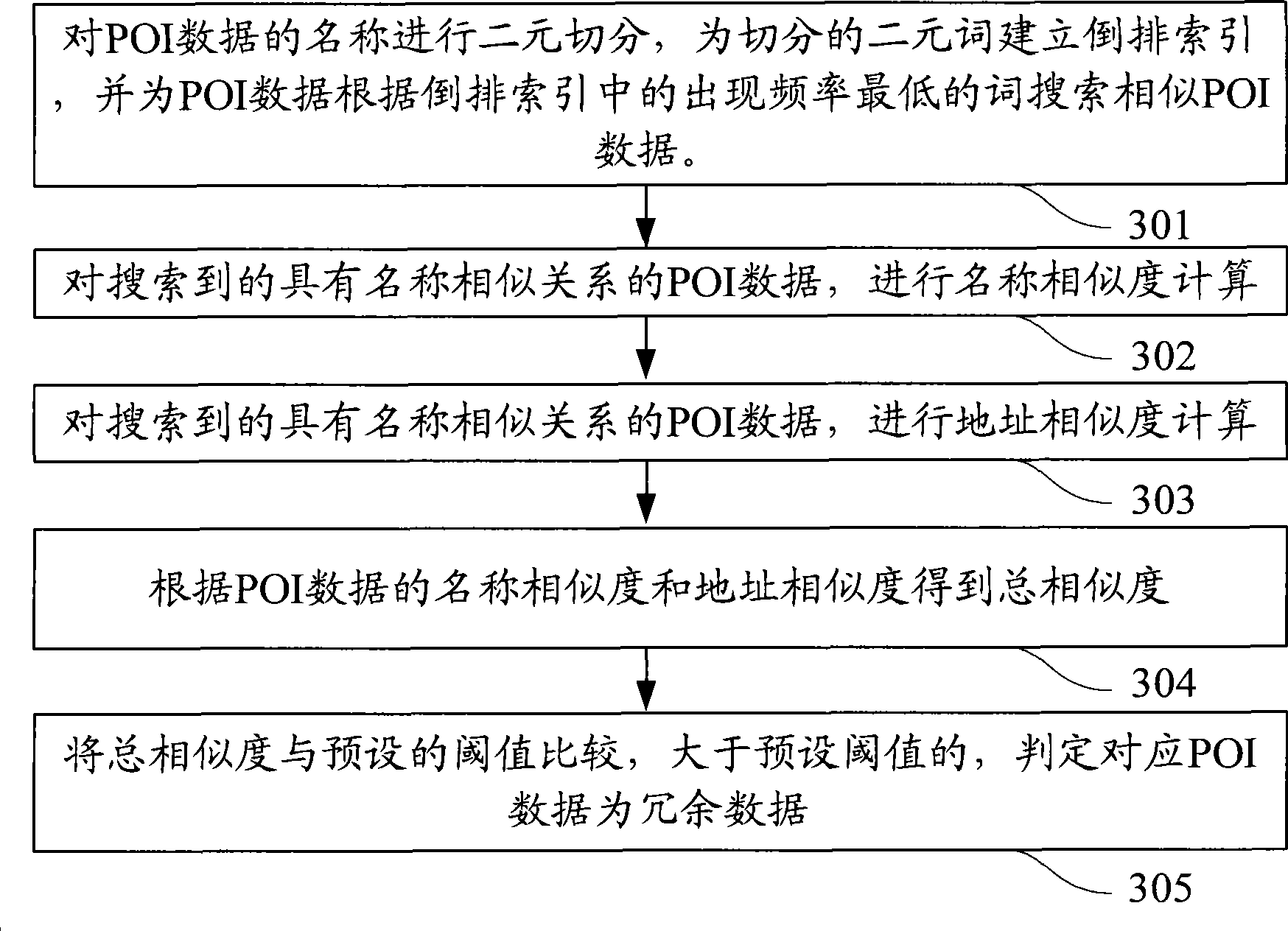

Electronic map interest point data redundant detecting method and system

ActiveCN101388023AGuaranteed accuracyAvoid error conditionsSpecial data processing applicationsData miningElectronic map

An embodiment of the invention discloses a redundancy detecting method and a system thereof. The redundancy detecting method comprises performing binary chopping on titles of POI data, creating an inverted index for chopped binary words, and searching similar POI data for the POI data according to the word with the lowest occurrence frequency in the inverted index, further, calculating similarity of titles and addresses for searched POI data which has title similar relations, obtaining a total similarity according to the title similarity and the address similarity of the POI data, comparing the total similarity with a preset threshold, and if the similarity is larger than the preset threshold, defining the corresponding POI data as redundant data. By utilizing the invention, redundancy detection in POI data of electronic maps can be realized.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

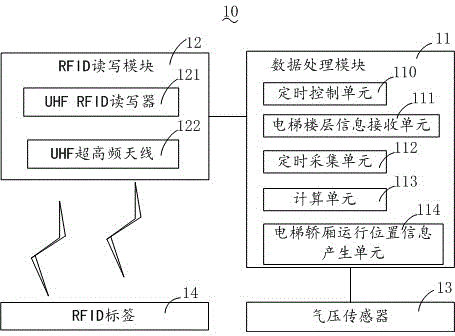

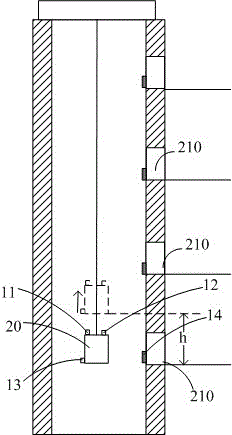

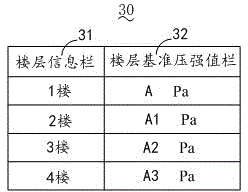

Elevator floor data collecting device and elevator floor operation monitoring and controlling system and method

The invention provides an elevator floor data collecting device. The device comprises a data processing module, an RFID read-write module, an air pressure sensor, and an RFID label; elevator floor information is stored in the RFID label, the air pressure sensor is used for sensing pressure of the current position of an elevator cage and producing a corresponding current pressure signal, the data processing module sends a read-write control signal to the RFID read-write module at regular time and receives the elevator floor information obtained from the RFID label by responding of the read-write control signal by the RFID read-write module, the data processing module is further used for collecting the current pressure signal produced by the air pressure sensor at regular time and producing a corresponding current pressure value according to the collected current pressure signal, and the data processing module is further used for calculating a current height value of a floor where the elevator cage locates according to the elevator floor information, the current pressure value, a pre-stored floor base pressure value and a pre-stored unit pressure height value. The invention further provides an elevator floor operation monitoring and controlling system and method.

Owner:宁夏电通物联网科技股份有限公司

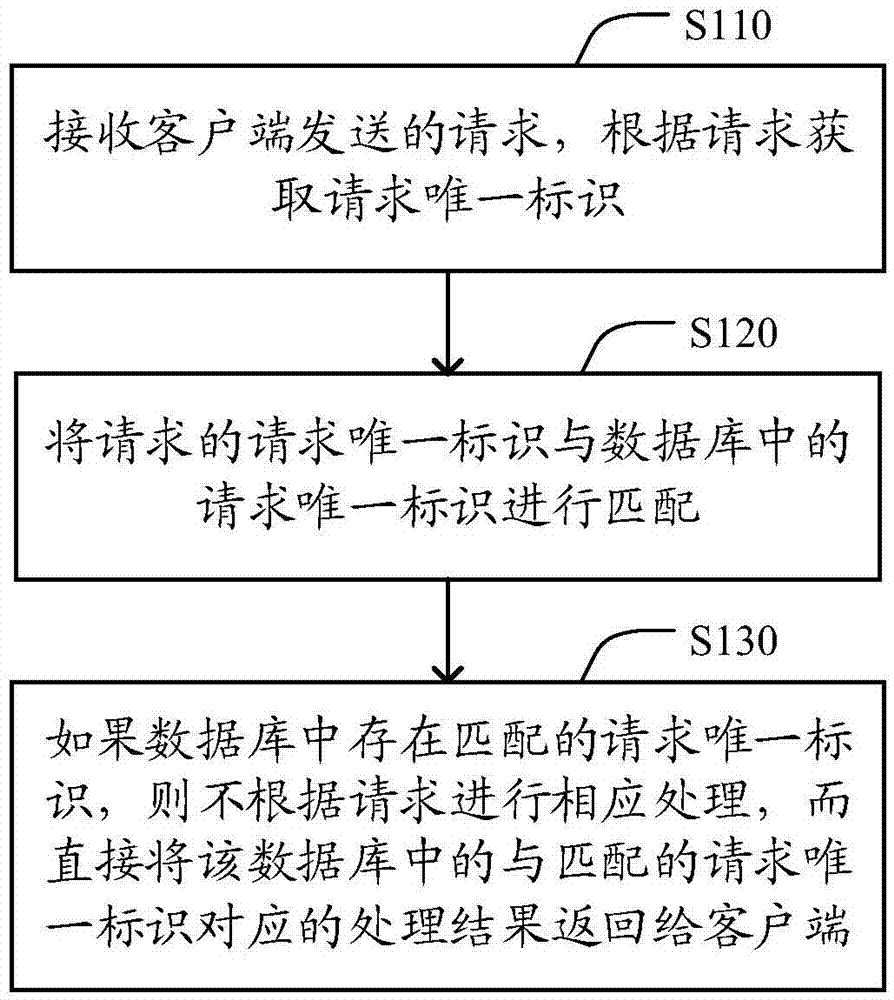

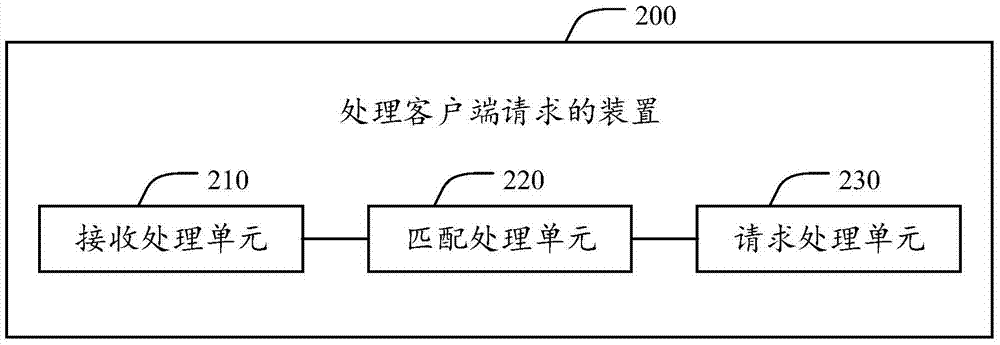

Method and apparatus for processing request from client

The invention discloses a method and apparatus for processing a request from a client. The method comprises: a request sent by a client is received and a unique identifier of the request is obtained according to the request; matching of the unique identifier of the request and a unique request identifier in a database is carried out; and if the matched unique request identifier exists in the database, a processing result corresponding to the matched unique request identifier in the database is returned to the client instead of carrying out corresponding processing is carried out based on the request. According to the technical scheme, problems that time and resources are wasted and a data operation error is caused because request execution equipment like a server needs to carry out repeated operation according to a repeated request sent by the client when a request time-out situation occurs can be solved successfully, so that the request execution efficiency is effectively improved, resources are saved, and wrong operation occurrence due to needless execution of requests of data can be avoided.

Owner:BEIJING QIHOO TECH CO LTD +1

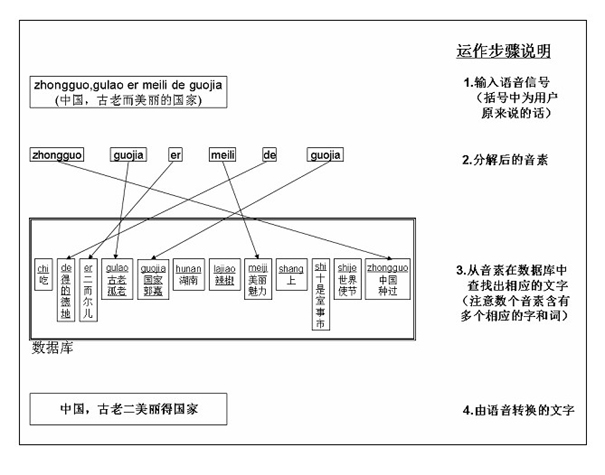

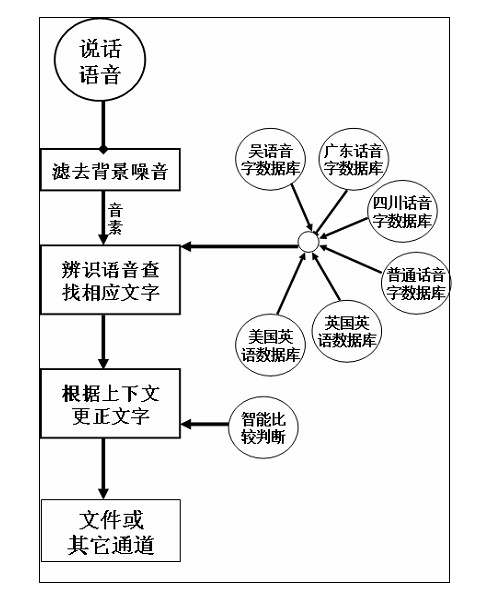

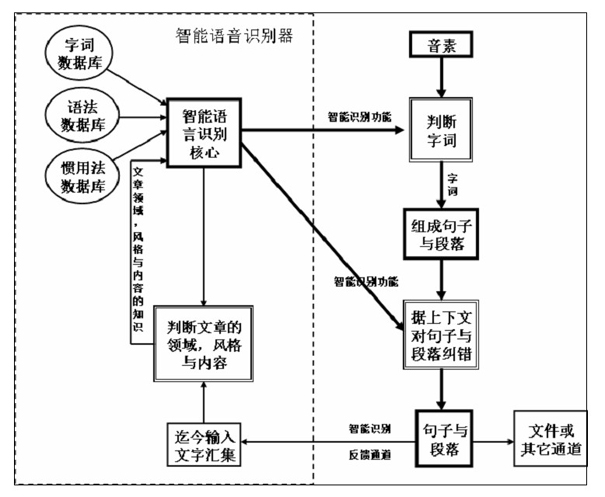

Voice inputting method and device

InactiveCN101876887AHigh resolutionQuality improvementSound input/outputSpeech recognitionSpeech inputSpeech sound

The invention relates to computer voice inputting technology, in particular to a voice inputting method and a voice inputting device for converting speaking voice into relevant characters and mainly aims to provide a voice inputting method which can lower voice recognition error rate and has an intelligent recognition function. The voice inputting method comprises the following steps of: 1) acquiring voice made by a user by using a voice acquisition device; 2) filtering out noise in the acquired voice; 3) recognizing relevant characters according to a voice-character database; 4) correcting input characters according to an input context to obtain correct characters; and 5) displaying all obtained input characters or inputting all the obtained input characters into a file. The invention provides high-resolution and high-quality voice inputting technology for greatly lowering the voice inputting error rate of computers and other electronic devices, so that the way of inputting characters by voice can be accepted generally.

Owner:刘彤

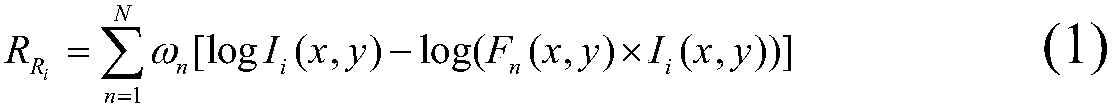

Finger vein recognition method by interested areas and directional elements

InactiveCN103310196AImprove recognition accuracyReduce difficultyCharacter and pattern recognitionVeinFeature vector

The invention discloses a finger vein recognition method by interested areas and directional elements. Existing vein recognition algorithms can be divided into two types, namely local feature utilization and global feature utilization, but the problems of long time consumption, large computing capacity and low image quality cannot be solved simultaneously. The method includes firstly reading a finger vein image, extracting an interested area by the interested area extraction method based on rotation correction, then constructing vectors by adopting gradient magnitude and direction of pixel points on finger vein lines to represent direction feature of the vein lines in the interested area, combining the direction feature and membership degree of image sub-blocks, creating feature vectors of the vein image, finally during the finger vein matching process, measuring similarity of different linear feature vectors by adopting cross-correlation coefficient, and figuring out matching results. The method is used for finger vein recognition.

Owner:HEILONGJIANG UNIV

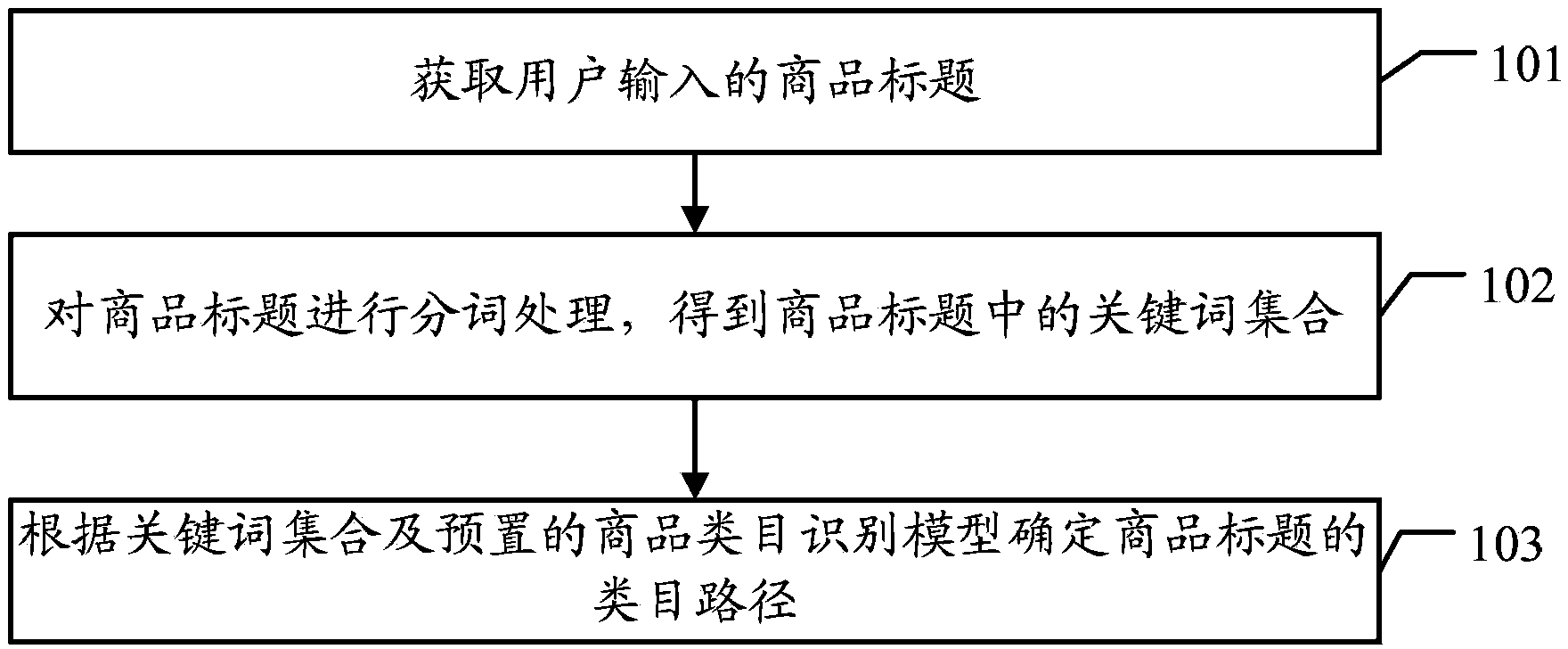

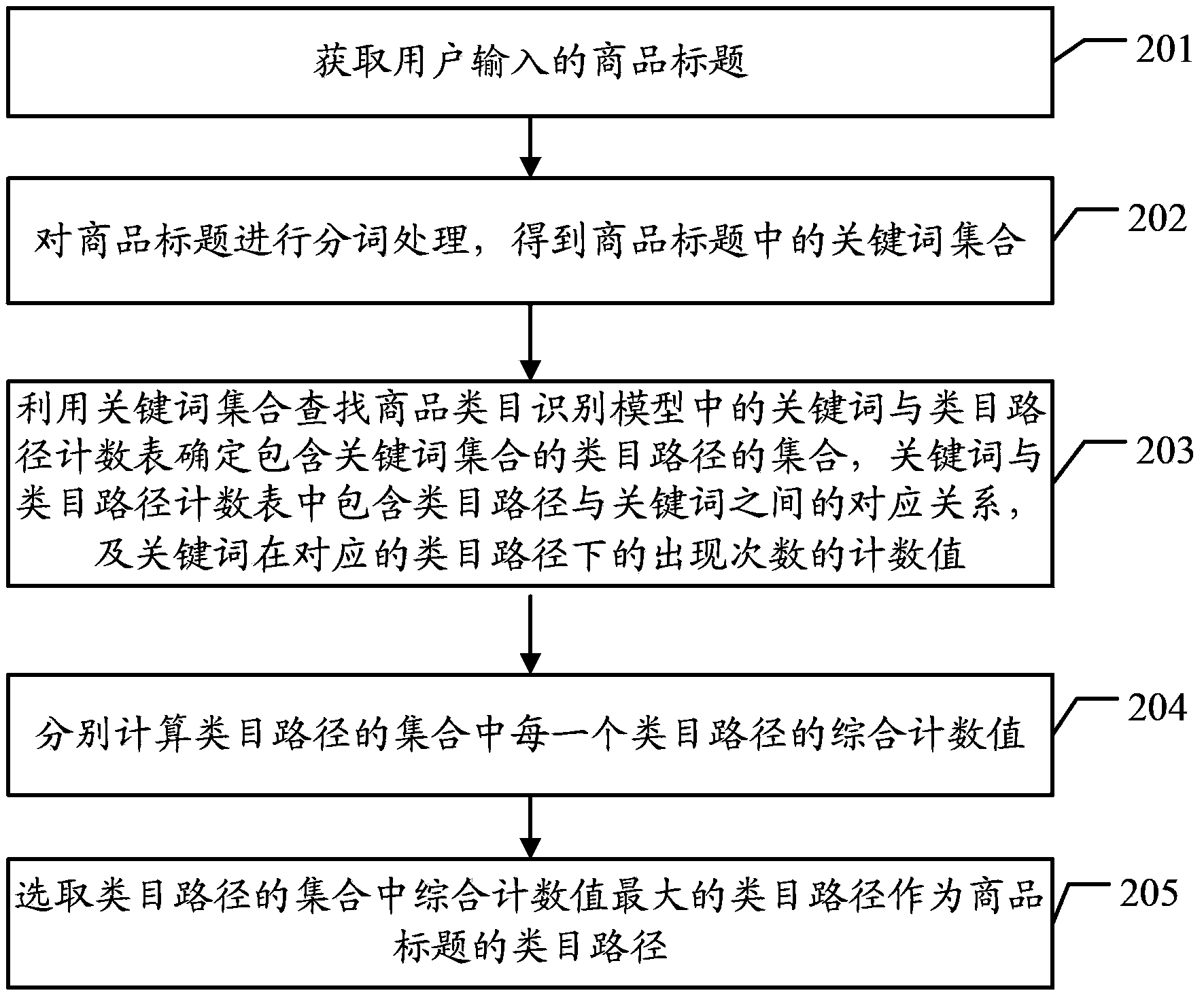

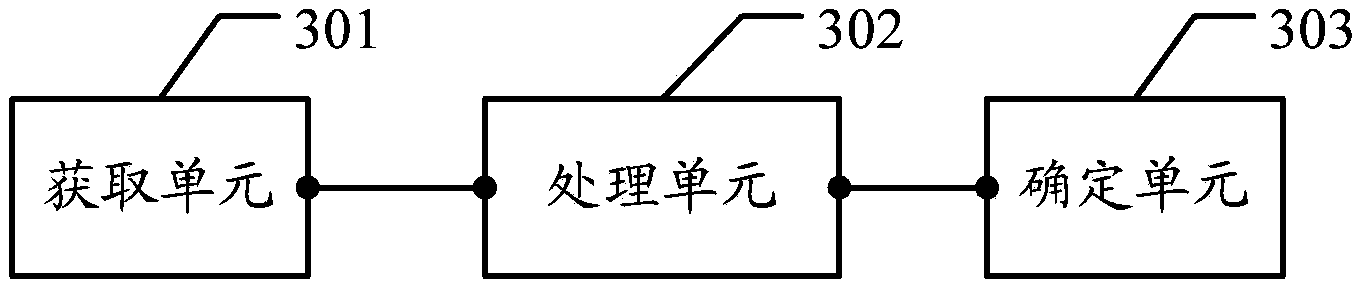

Category path recognition method and system

ActiveCN103902545AAvoid error conditionsRealize identificationWeb data indexingCommerceCategory recognitionUser input

Solutions of category path recognition are described. A commodity title input by a user is obtained. Word segmentation is performed on the commodity title to obtain a keyword set comprising keywords comprised in the commodity title. A category path of the commodity title is determined according to the keyword set and a preconfigured commodity category recognition model, wherein the commodity category recognition model includes correspondences between a plurality of keywords and a plurality of category paths and a counting value of the number of occurrences of each of the plurality of keywords under each corresponding category path.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD

Uplink modulation and receiver structures for asymmetric OFDMA systems

InactiveUS7609614B2Improve toleranceImprove performanceError preventionLine-transmission monitoring/testingCommunications systemEngineering

Owner:TRELLIS PHASE COMM LP

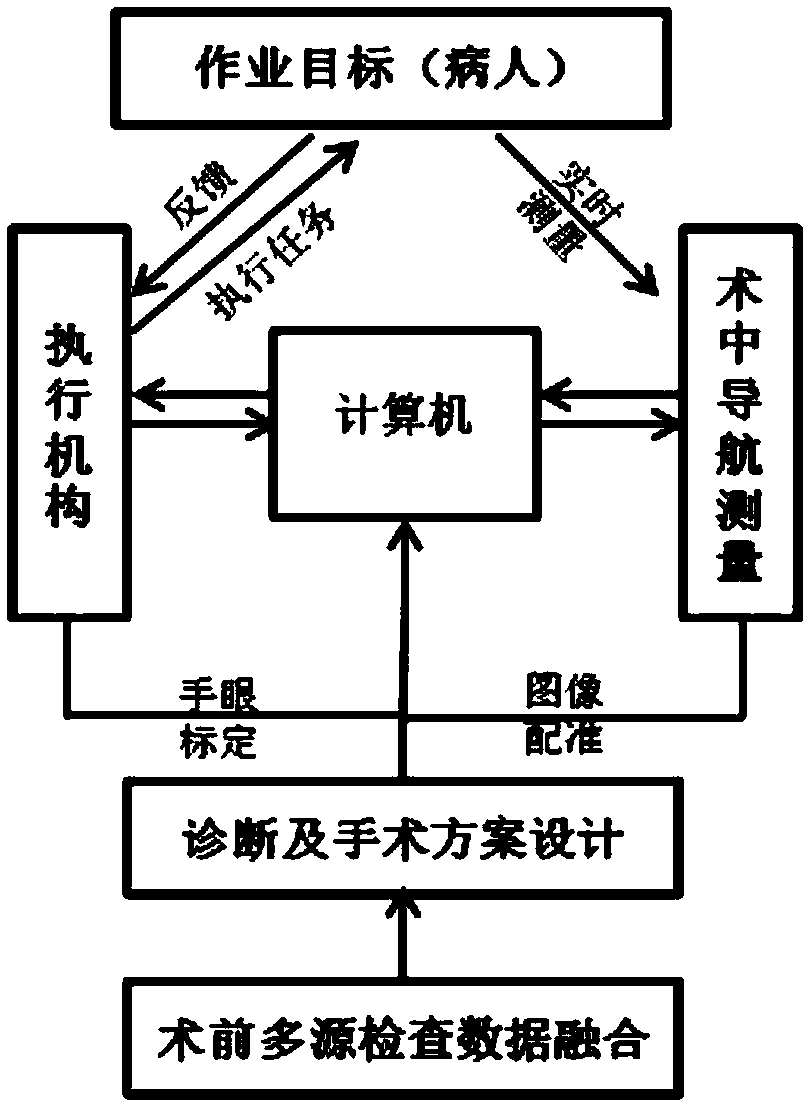

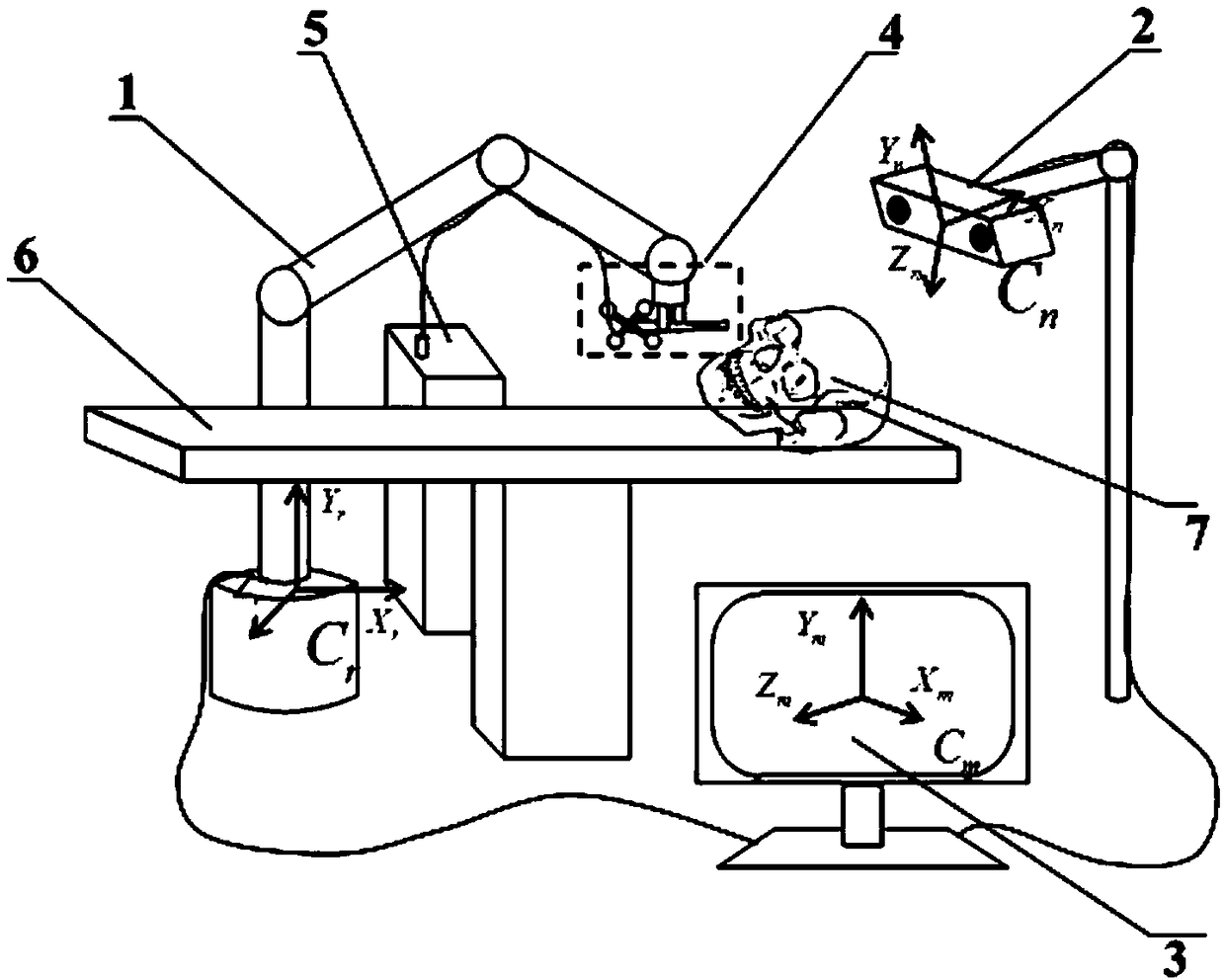

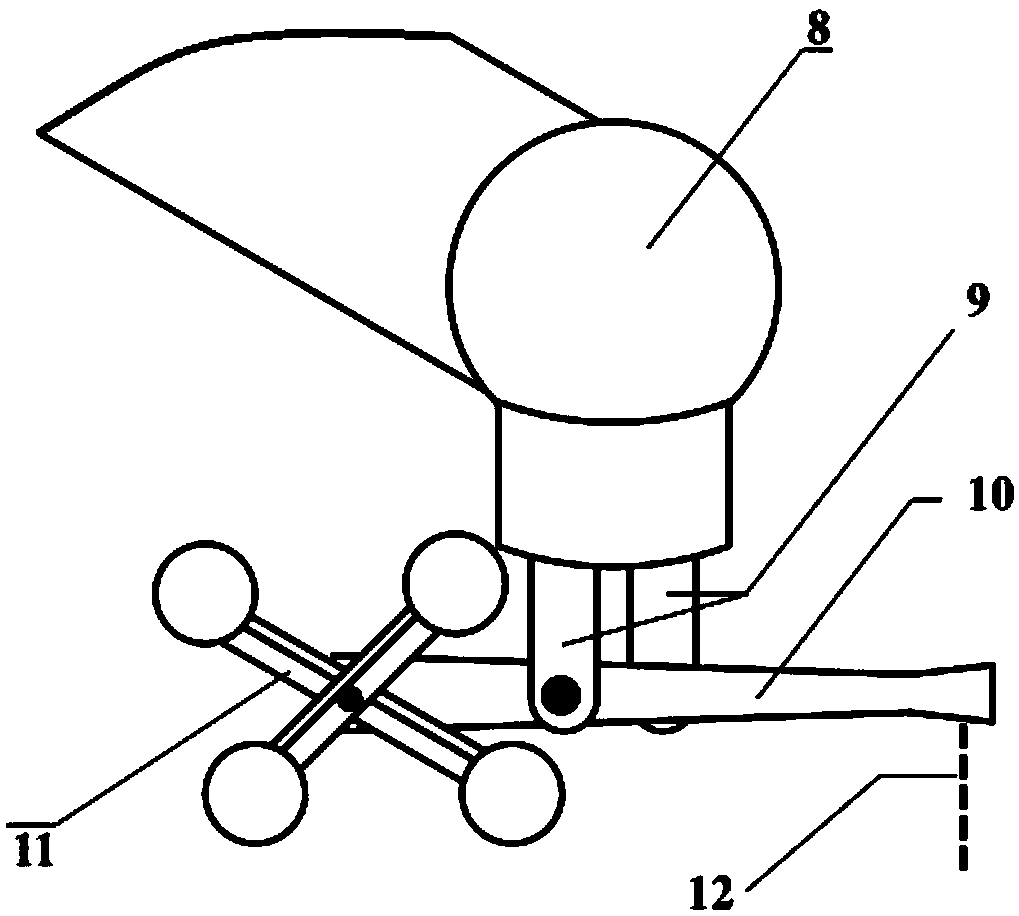

A laser osteotomy robot system and path planning method thereof

ActiveCN109199586ASolve technical problems that cannot be performed precisely in surgeryAvoid fatigueSurgical instrument detailsComputer-aided planning/modellingOphthalmologyPlanning approach

A laser osteotomy robot system and path planning method thereof are disclosed, The invention solves that problem that the position accuracy of the lase osteotomy is not high in the prior art, as thatrobot can be effectively control, the beneficial effect of improving operation efficiency, a path planning method for laser osteotomy robot system is proposed. Medical staff complete the design of surgical osteotomy scheme based on preoperative three-dimensional image reconstruction and editing, extract the position information of osteotomy line in image space, map the position information into the coordinate system of robot manipulator, and obtain the path planning.

Owner:SHANDONG UNIV

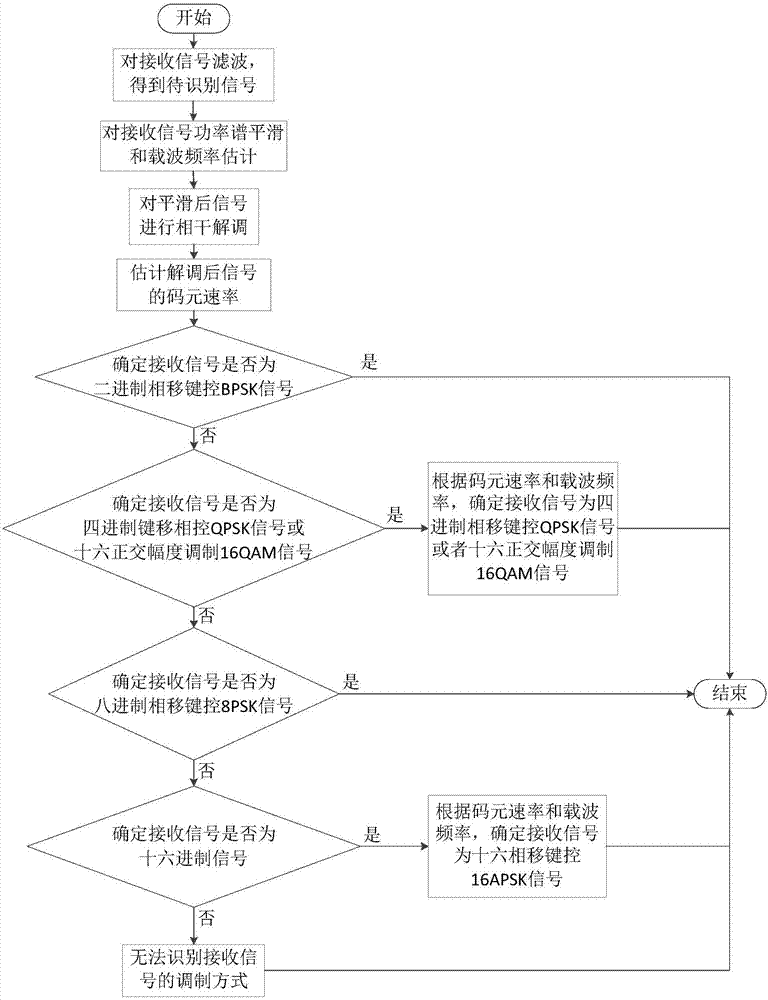

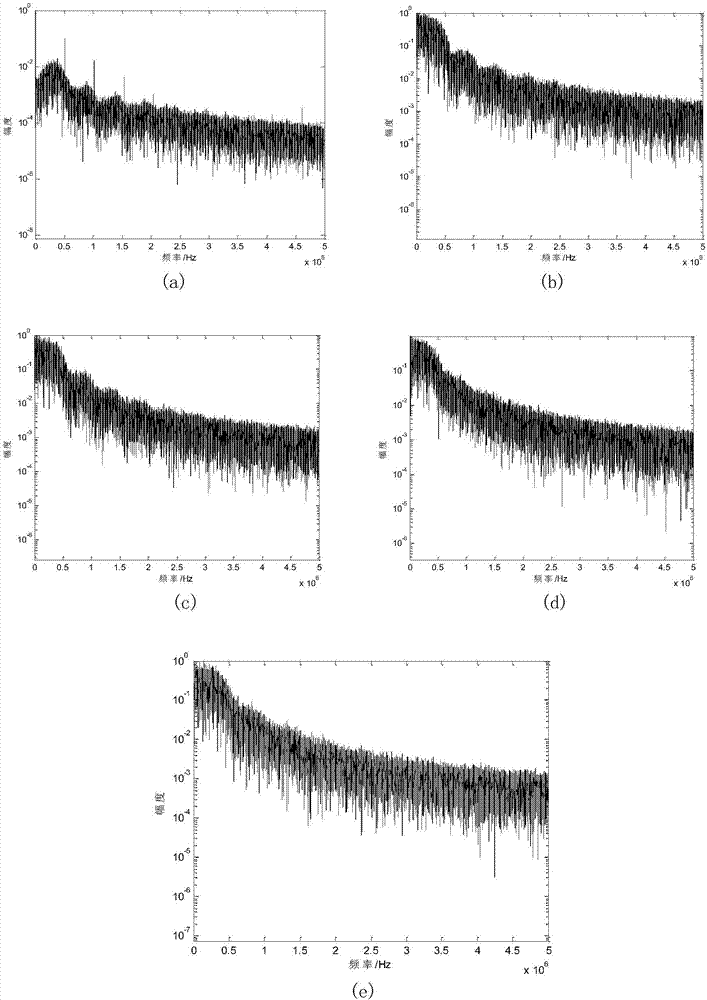

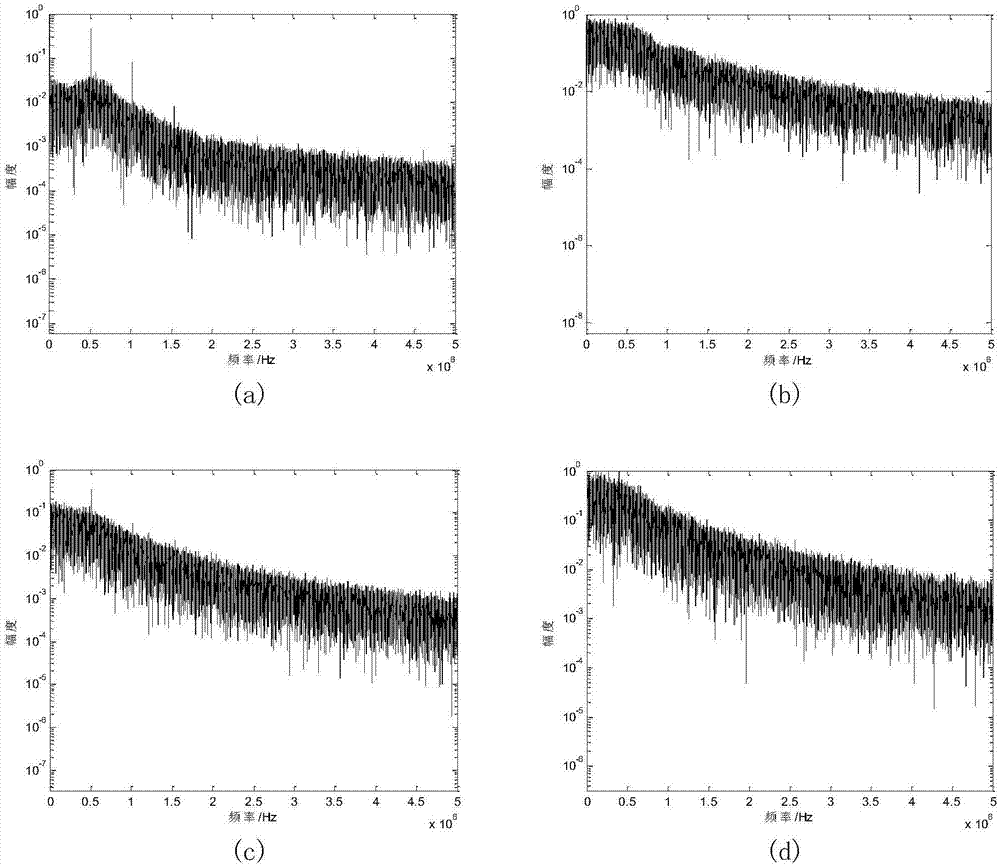

Method for recognizing satellite communication signal modulation way

ActiveCN106899531AImprove recognition rateAvoid error conditionsModulation type identificationCarrier regulationPhase shiftedCoded element

The invention discloses a method for recognizing a satellite communication signal modulation way. According to the scheme, the method comprises the following steps: 1, filtering a received signal to obtain a signal to be recognized; performing power spectrum smoothening, carrier frequency estimation and coherent demodulation on the signal to be recognized to obtain a demodulated signal; 3, estimating the code element rate of the demodulated signal; 4, determining whether the received signal is a binary phase shift keying signal or not by using a square spectrum; 5, determining whether the received signal is a quaternary phase shift keying signal or a hexadecimal quadrature amplitude modulation signal by using a signal quartic spectrum, carrier frequency and the code element rate; 6, determining whether the received signal is an octonary phase shift keying signal or not by using a signal eightfold spectrum; and 7, determining whether the received signal is a hexadecimal amplitude phase shift keying signal or not by using a signal duodenary spectrum, the carrier frequency and the code element rate. The method has high recognition accuracy, and can be applied to real-time monitoring of satellite communication signals. Through adoption of the method, totally-blind real-time recognition of the satellite communication signal modulation way can be realized.

Owner:XIDIAN UNIV

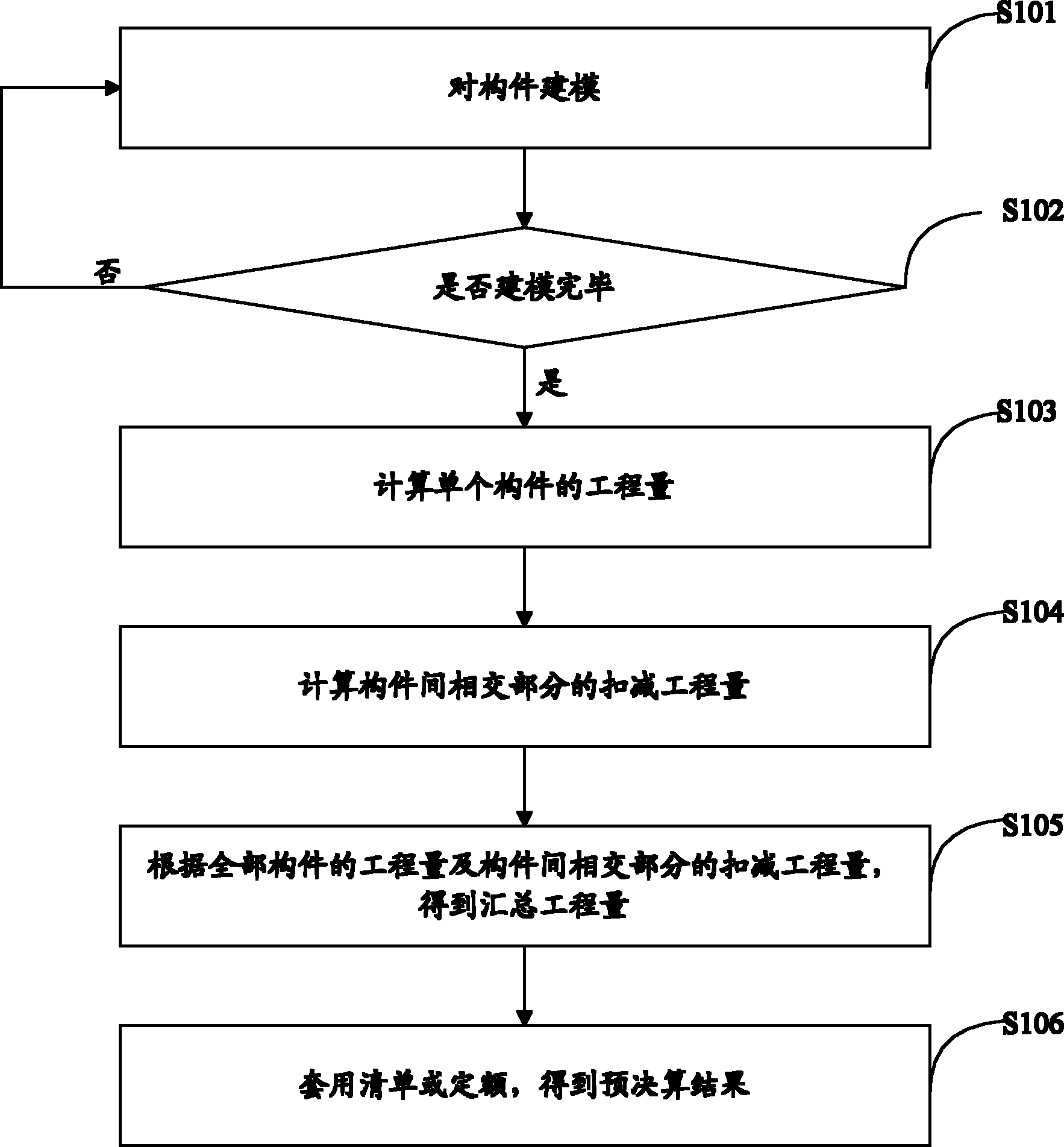

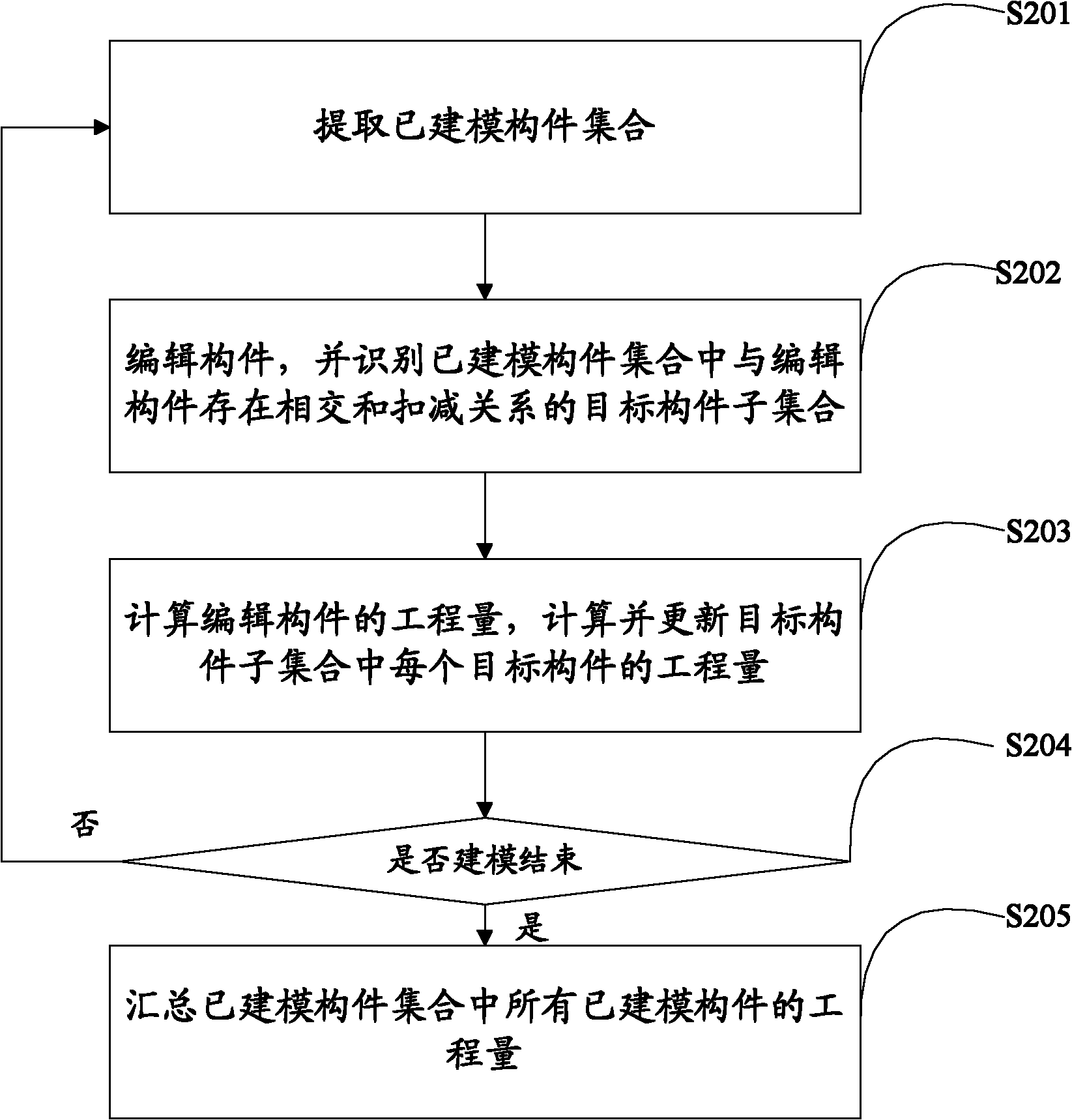

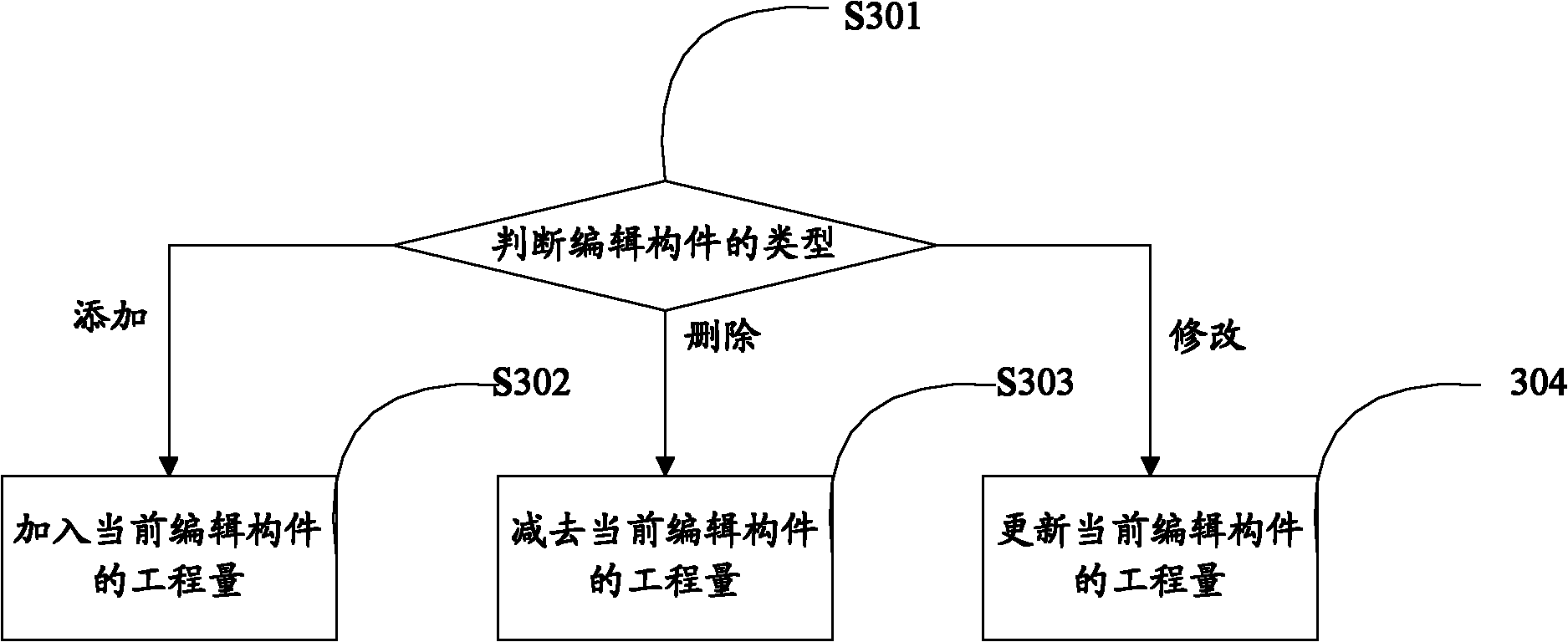

Method for computing work amount

InactiveCN102004828ACalculation speedDoes not affect experienceSpecial data processing applicationsComputer scienceCalculation methods

Owner:CHENGDU PENGYE SOFTWARE

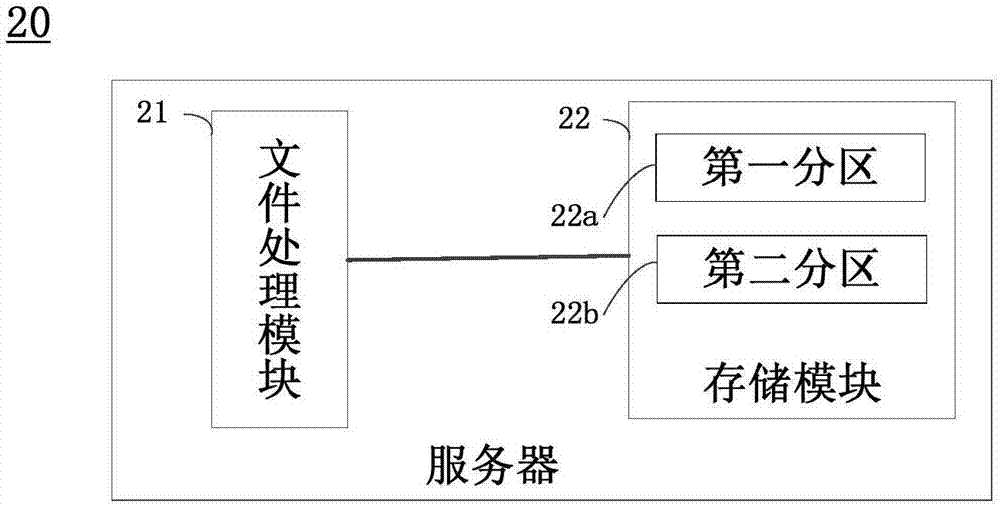

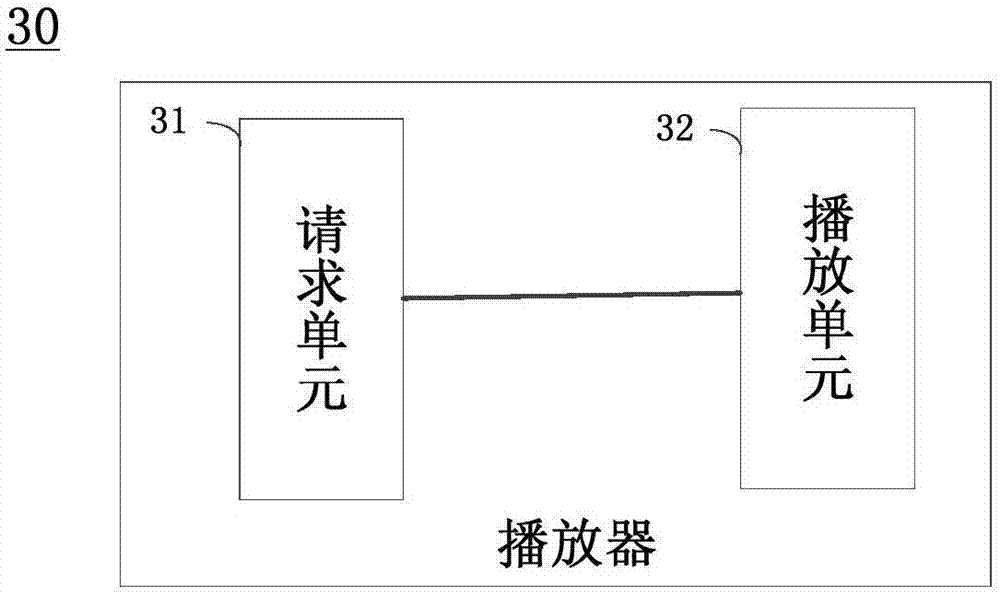

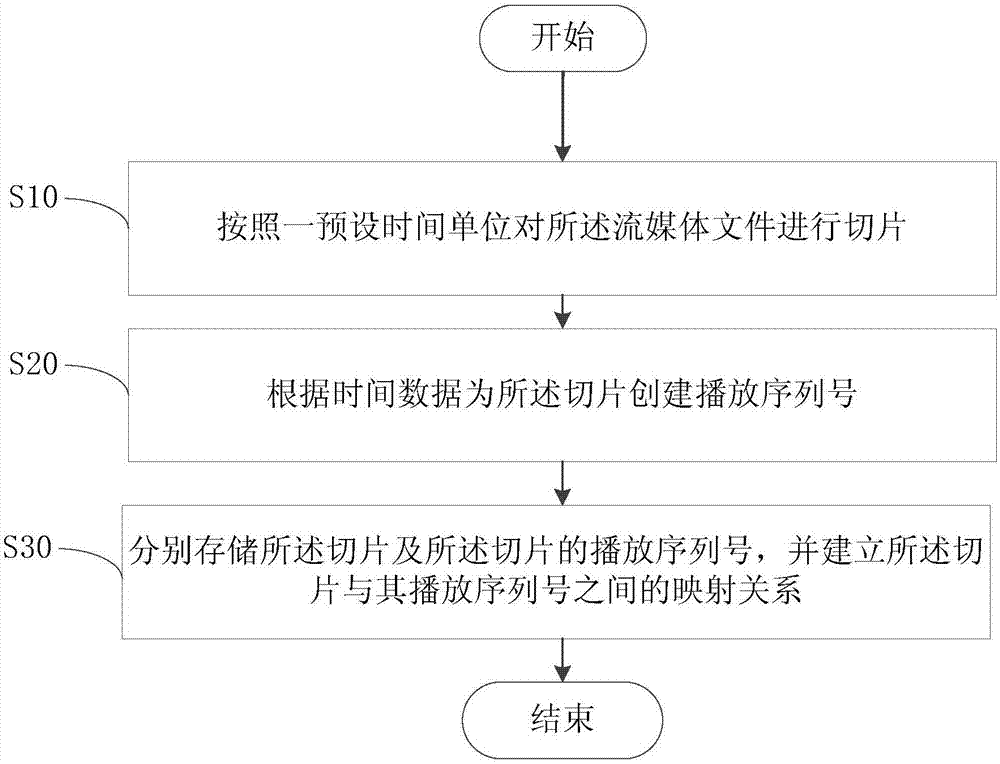

Streaming media file processing method and live broadcast system

InactiveCN107426629APromote recoveryAdjust in timeSelective content distributionTime informationTime data

The invention provides a streaming media file processing method used in a live broadcast system. The method comprises the steps of slicing the streaming media file according to a preset time unit; creating play serial numbers for the slices according to time data, wherein the play serial numbers are used for determining a play order of the slices; and storing the slices and the play serial numbers of the slices, and creating a mapping relationship between the slice and corresponding play serial number. According to the method, the streaming media file is sliced based on the preset time unit, and the play serial numbers of the slices are created according to time data, so that the sliced file corresponding to the paly serial number can be selected and processed directly according to time information, and the sliced file can be operated conveniently in following steps. In addition, the invention further provides a live broadcast system.

Owner:CHINANETCENT TECH

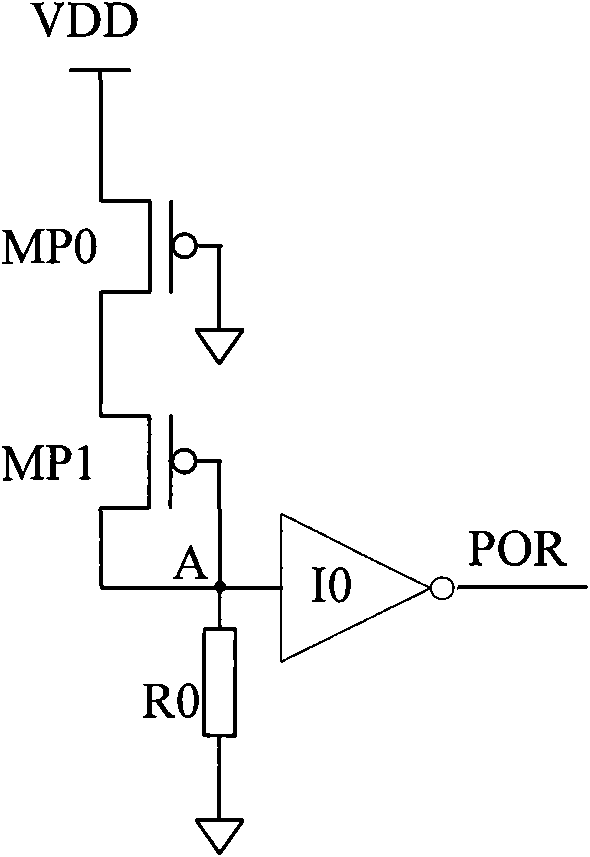

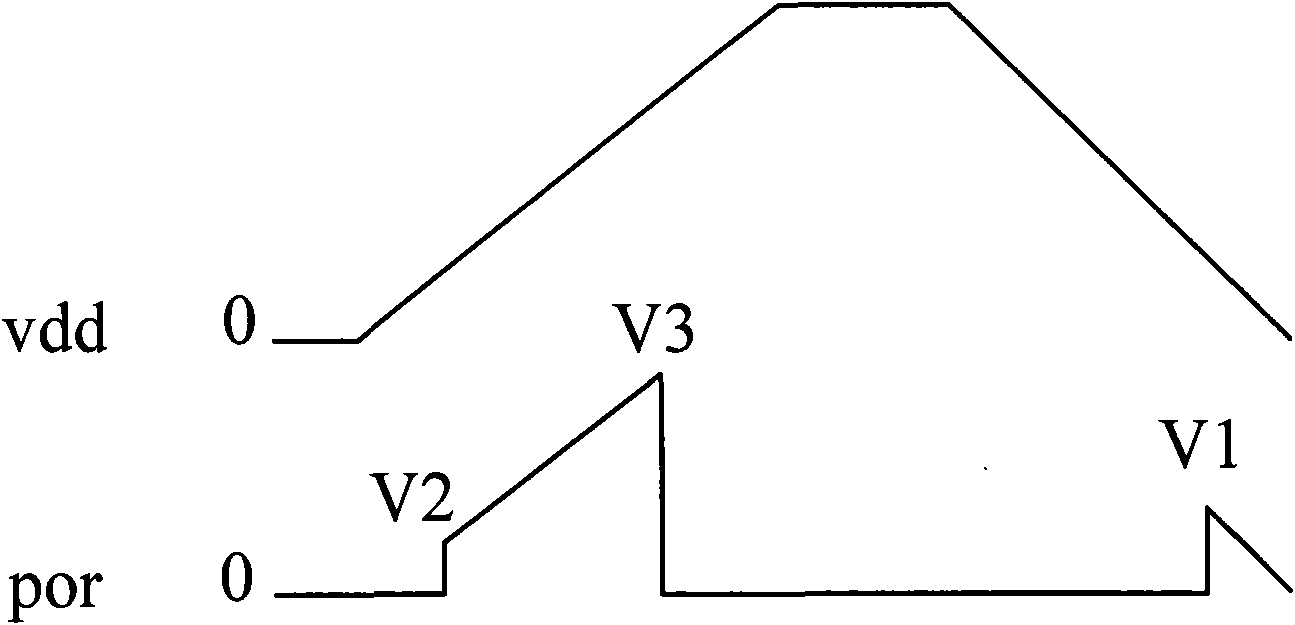

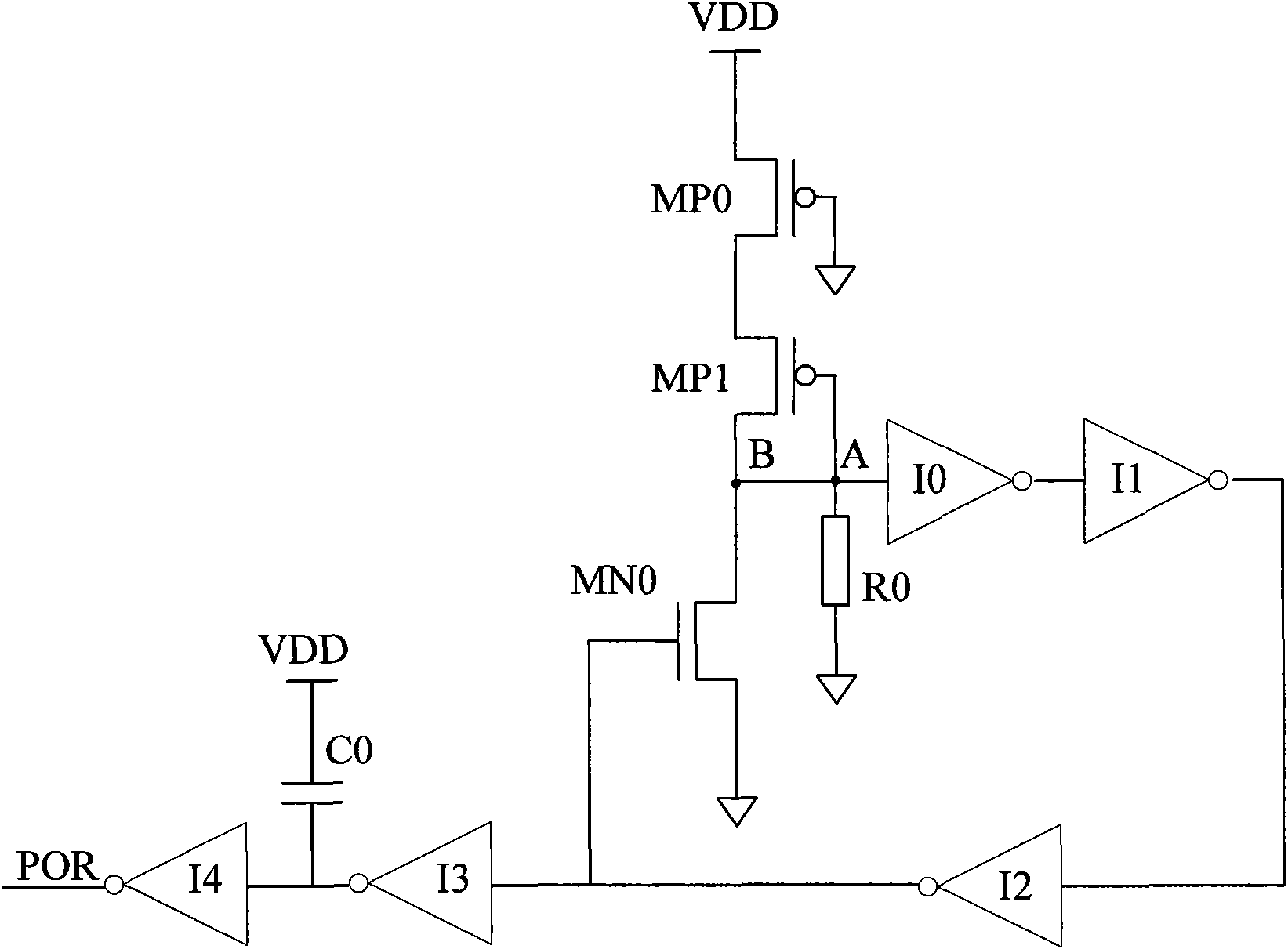

Reset circuit

The invention discloses a reset circuit, which comprises an MOS tube branch which is connected between a power supply and the ground and an inverter branch which is connected with the MOS tube branch through a partial pressure connection point, wherein the inverter branch comprises an inverter which is used for triggering voltage signal lower than the overturn voltage thereof and generating a reset signal; and the reset circuit further comprises an impedance component which is connected with the MOS tube branch and is used for reducing the voltage of the partial pressure connection point to be lower than the overturn voltage of the inverter when the voltage of the power supply is reduced to a first preset voltage, wherein the first preset voltage is higher than the threshold voltage of the MOS tube branch. Under the premise of saving power consumption and cost, the invention can prevent error condition from being generated during the voltage reduction process of the power supply.

Owner:GIGADEVICE SEMICON (BEIJING) INC

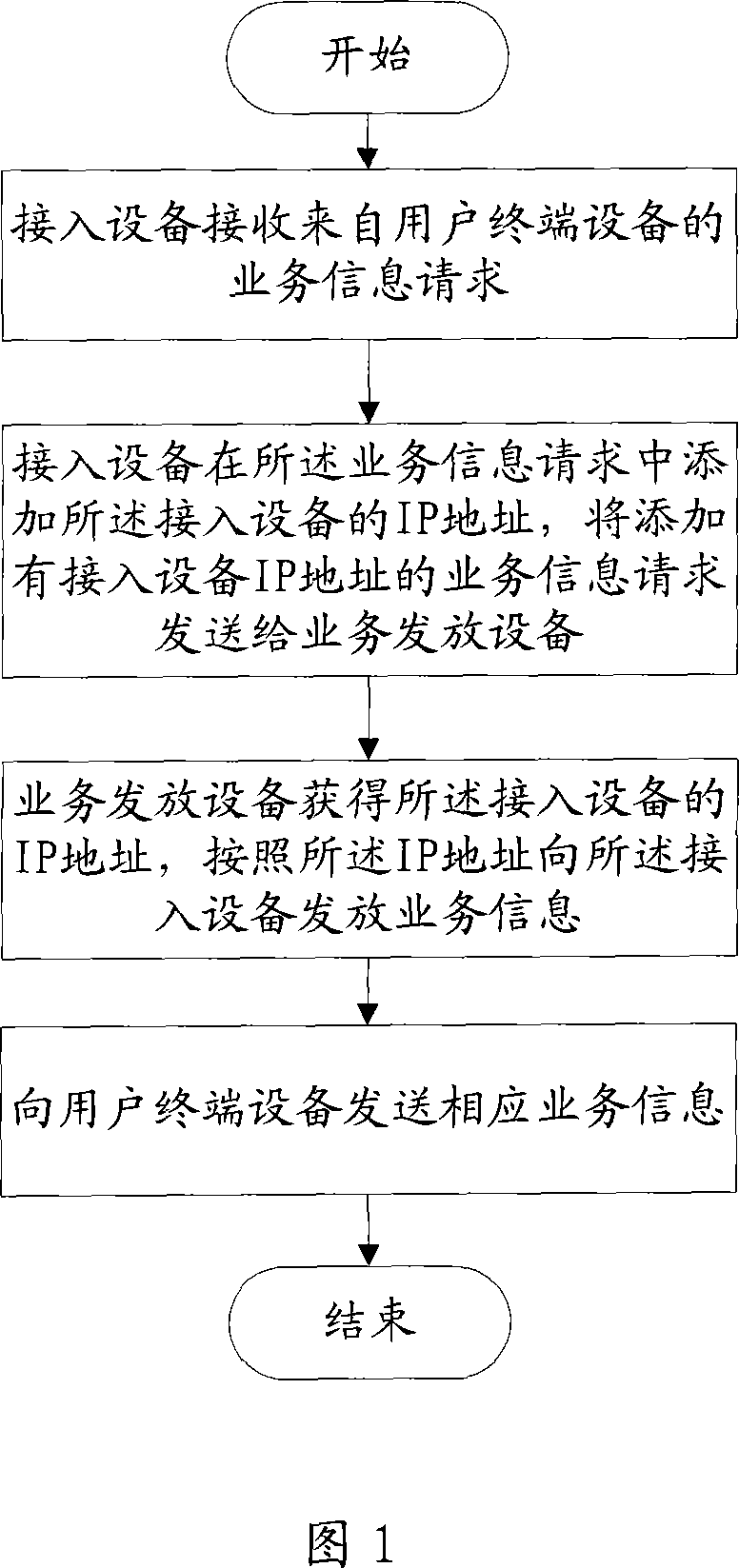

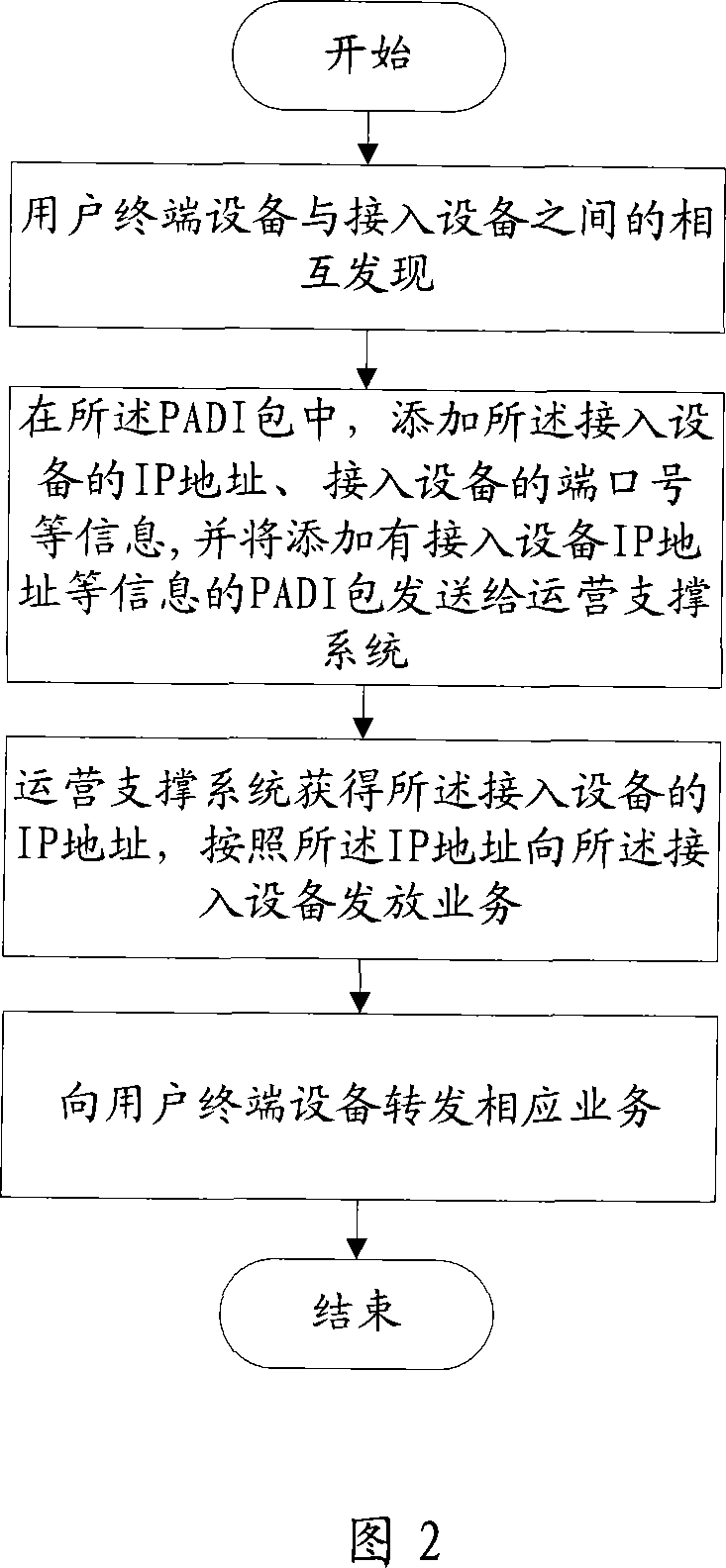

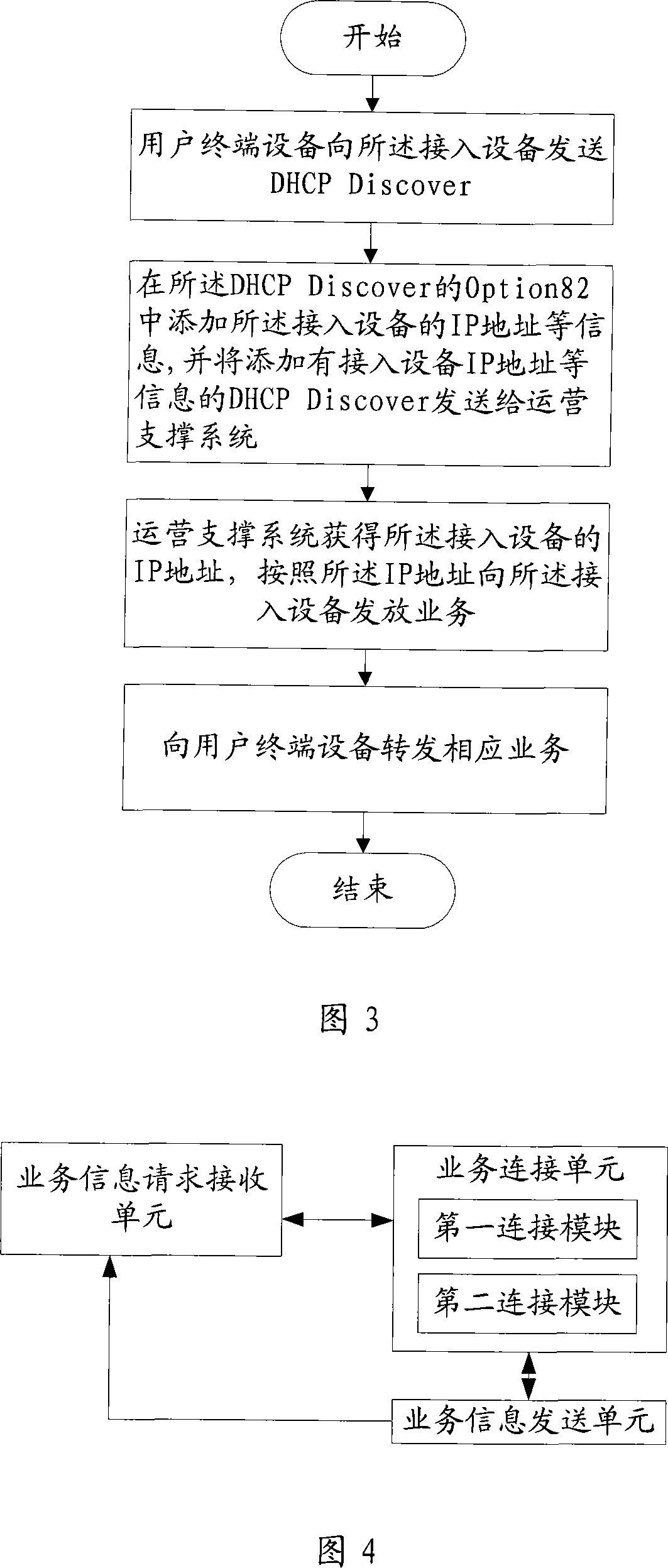

Method, system, network and service information distribution device for distributing service information

InactiveCN101188628AImprove accuracyImprove reliabilityData switching by path configurationIp addressTerminal equipment

The invention discloses a method of issuing service information and a system thereof, the network and the service information issuing equipment thereof. The invention relates to the network communication technology field, which aims at enhancing the accuracy of service issuing. The method comprises steps that service request information sent by subscriber terminal equipment is received; the IP address of access equipment is added in the service request information, and the service request information adding the IP address of the access equipment is sent to the service issuing equipment; the service issuing equipment obtains the IP address of the access equipment, and the service is issued to the access equipment according to the IP address. Network equipment comprises a service request information receiving unit and a service connecting unit. The service information issuing equipment comprises a service information receiving unit and a service information issuing unit. A network system comprises the access equipment and the service issuing equipment. The invention can enhance the service accuracy dispersed by the service dispensing equipment, and is mainly applied to the issuing of service.

Owner:HUAWEI TECH CO LTD

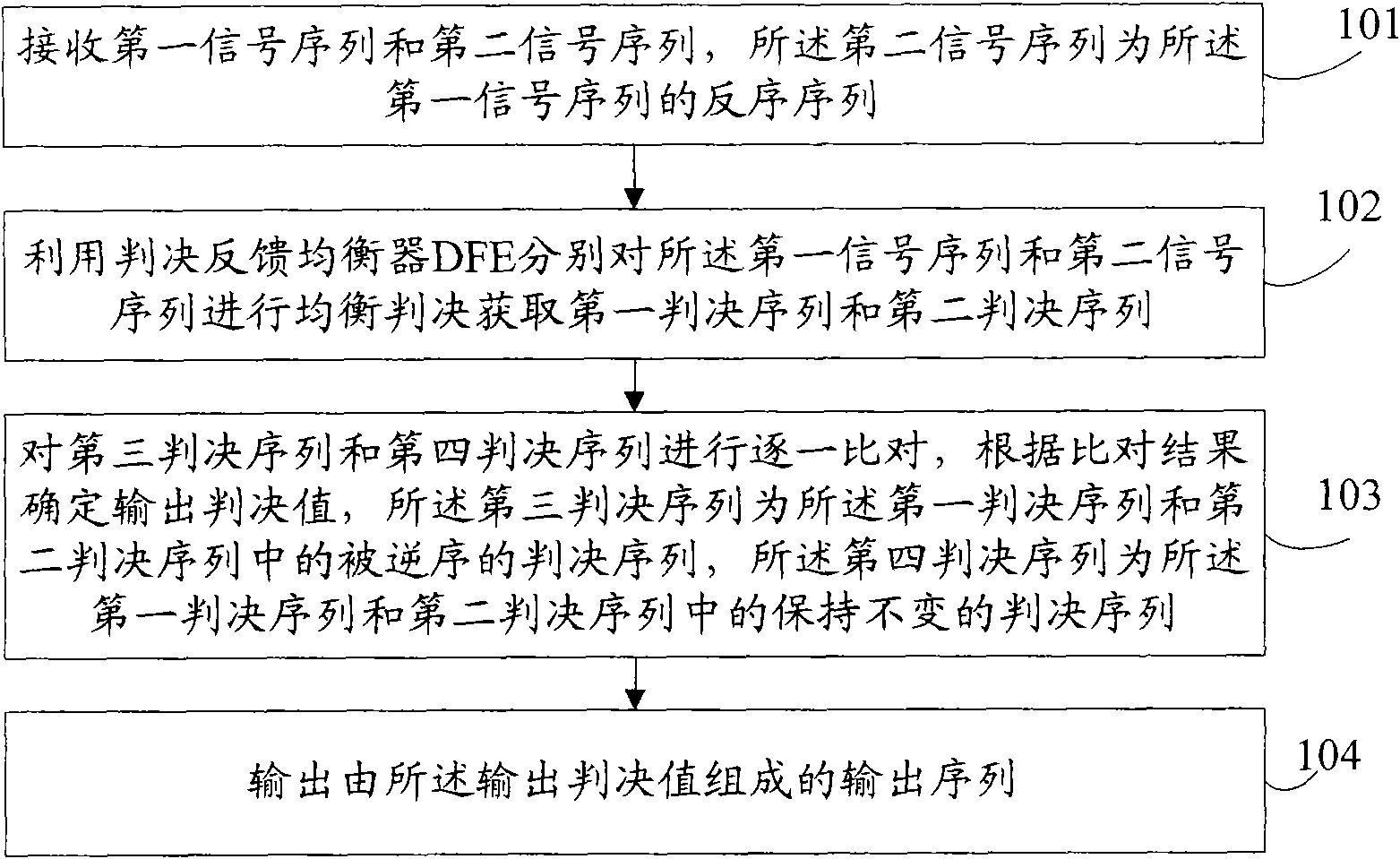

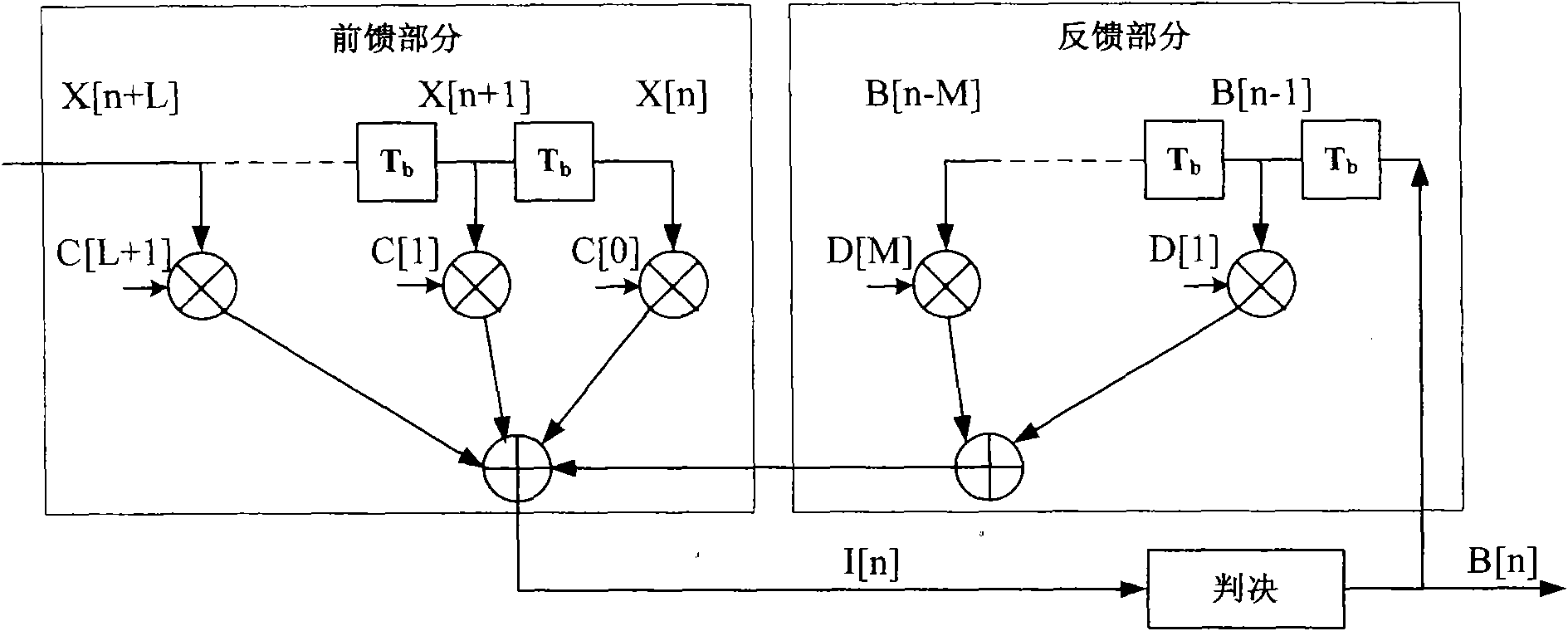

Signal compensation method and device

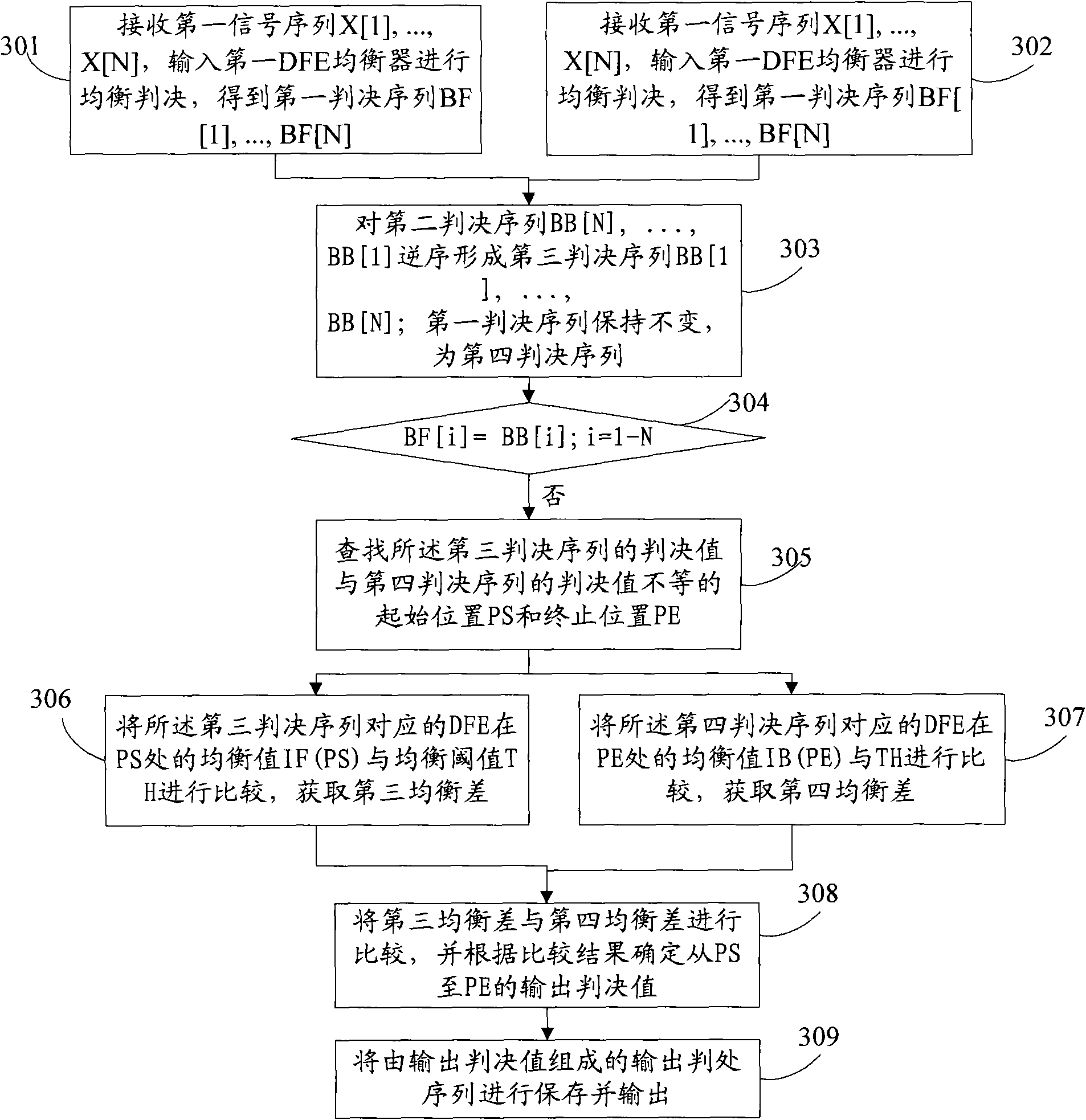

InactiveCN101964765AQuality improvementAvoid error conditionsDistortion/dispersion eliminationTransmitter/receiver shaping networksReverse orderAlgorithm

The embodiment of the invention discloses a signal compensation method and a signal compensation device. The method comprises the following steps of: receiving a first signal sequence and a second signal sequence, wherein the second signal sequence is a reverse order sequence of the first signal sequence; performing equalization decision on the first signal sequence and the second signal sequencerespectively by using a decision feedback equalizer (DFE); acquiring a first decision sequence and a second decision sequence; comparing a third decision sequence and a fourth decision sequence one by one; and determining an output decision value according to a comparison result. In the method, a problem in signal compensation is found by comparing decision values obtained after performing the equalization decision on two groups of signal sequences in a positive order and a reverse order by using the DFE and a final output value is determined according to the comparison result, which effectively avoids the situation that a plurality of continuous error results are generated by only compensating an input sequence in the positive order when the signal is compensated by using the DFE in the prior art, and improves the quality of signal compensation.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

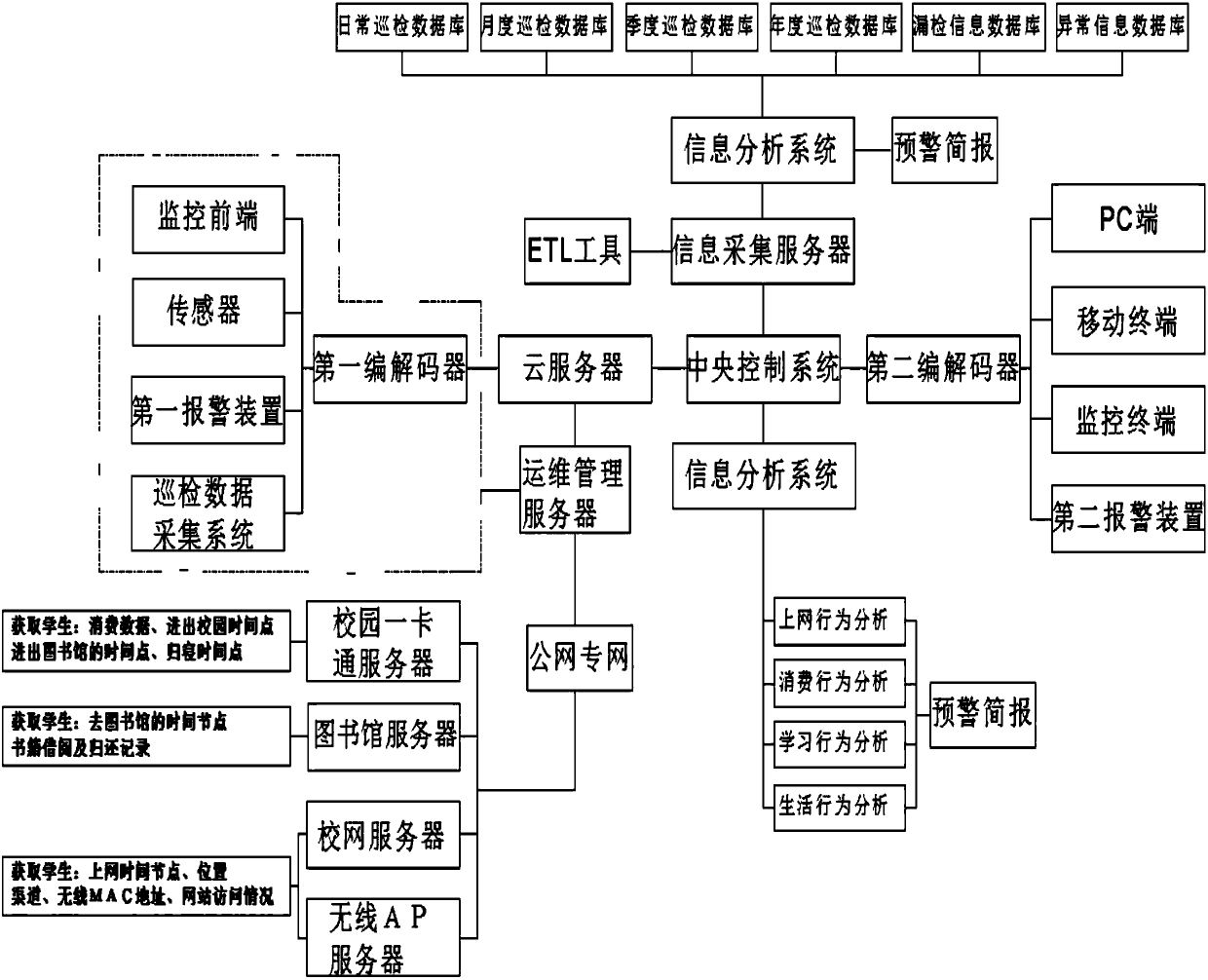

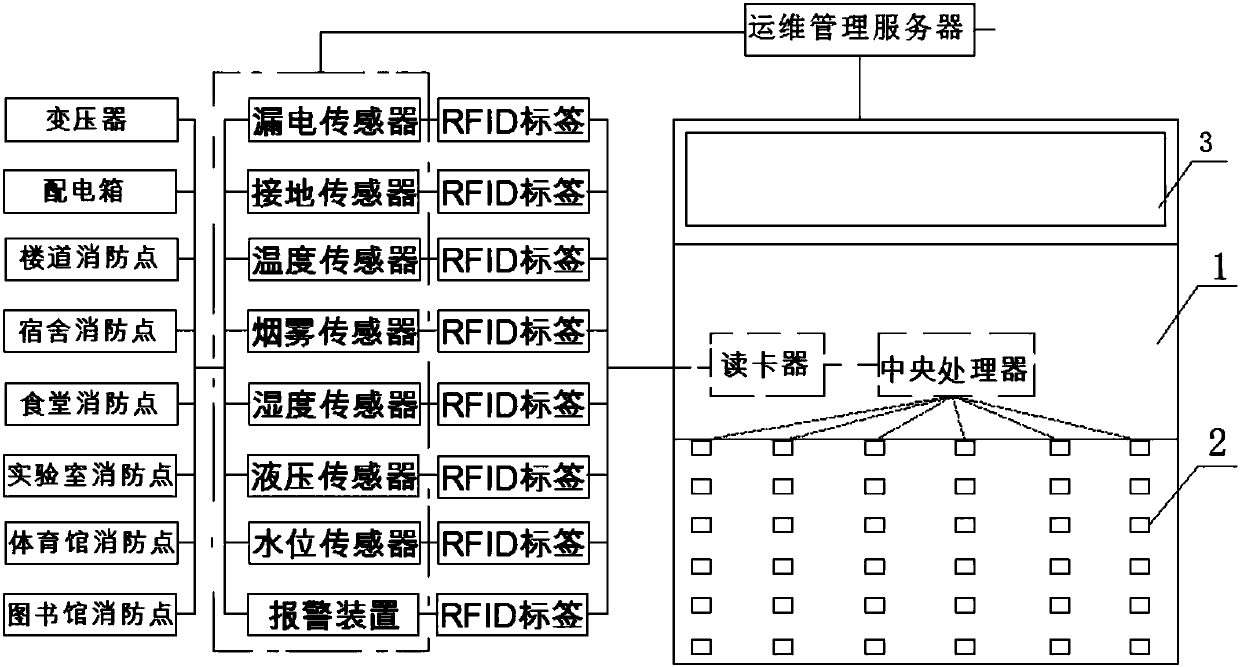

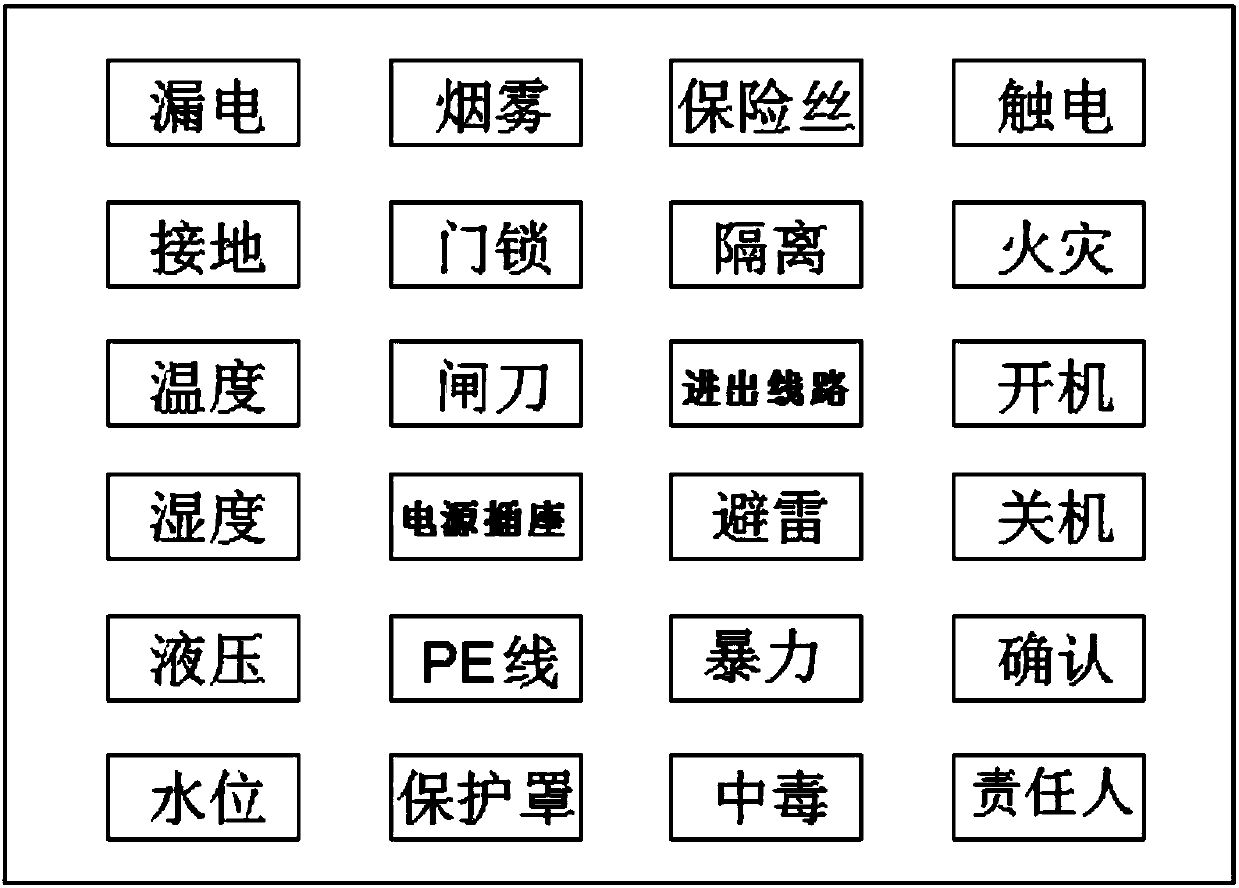

Smart and safe campus big data safety early warning platform

InactiveCN107918993AReal-time managementPrecise implementation of campus safety warningAlarmsData acquisitionCard reader

The invention provides a smart and safe campus big data safety early warning platform, which comprises a monitoring front end, a sensor and warning devices, wherein the monitoring front end, the sensor and a first warning device are connected with a cloud server through a first codec respectively; the cloud server is connected with a central control system; the central control system is connectedwith a monitoring terminal and a second warning device through a second codec; the first codec is connected with an inspection data acquisition system; the inspection data acquisition system comprisesa data acquisition box and an RFID label; an instruction key and a display screen are arranged outside the data acquisition box; the data acquisition box is internally provided with a card reader anda central processor; and the card reader is connected with the RFID label. The acquired data can be transmitted to the monitoring terminal through the codec, the manual inspection condition can be inputted to the inspection data acquisition system through an instruction input device and is then transmitted to the monitoring terminal, campus safety early warning is realized accurately, and real-time management on a related responsible person is carried out.

Owner:重庆厚盾安全技术股份有限公司

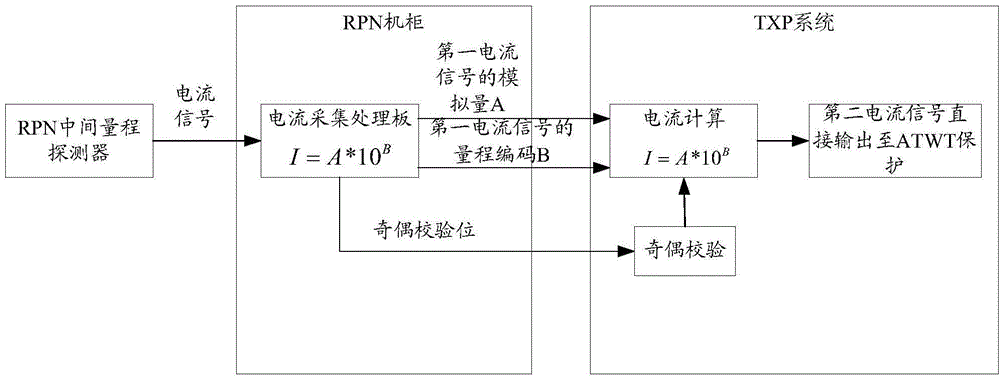

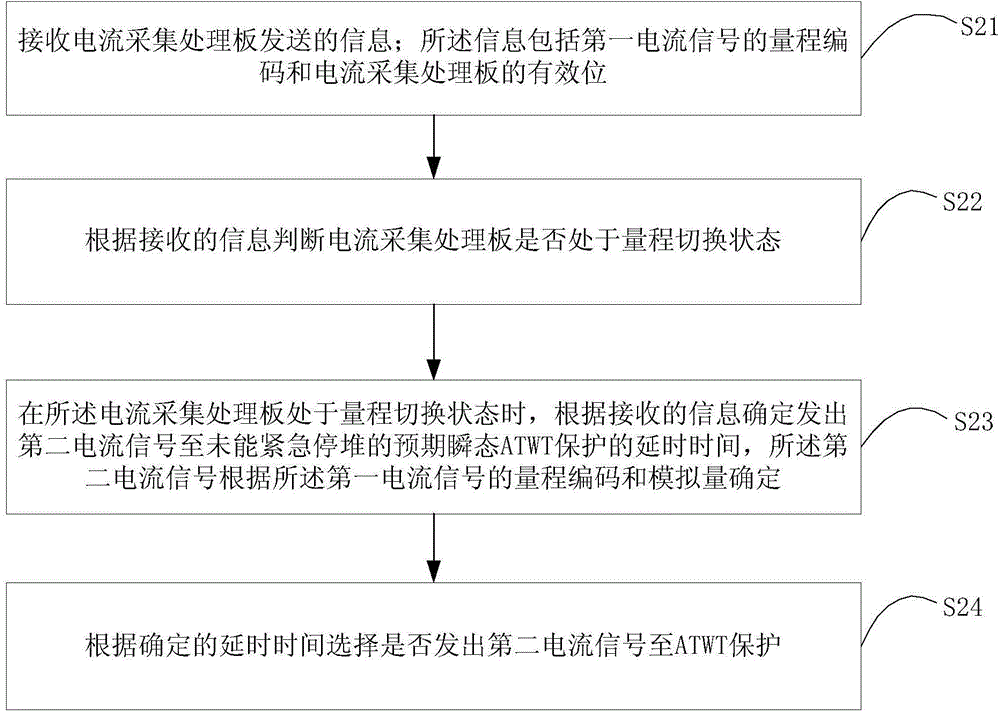

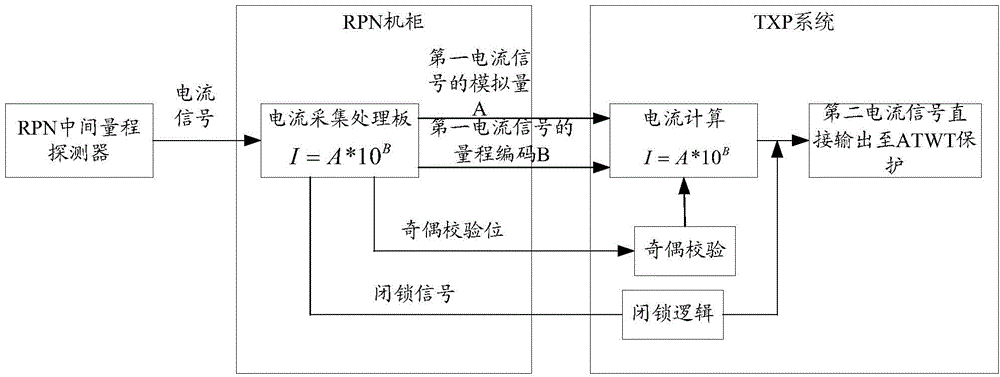

Processing method and system of nuclear power plant distributed control system

ActiveCN104485143AReduce the probability of misoperationAvoid error conditionsPower plant safety arrangementNuclear energy generationInstrument controlNuclear power plant

The invention belongs to the nuclear power plant instrument control field and provides a processing method and system of a nuclear power plant distributed control system. The method includes the following steps that: information transmitted by a current acquisition and processing board is received, wherein the information includes ranging codes of first current signals and significance bits of the current acquisition and processing board; whether the current acquisition and processing board is in a ranging switching state is judged according to the received information; and when the current acquisition and processing board is in the ranging switching state, delay time for transmitting second current signals to anticipated transients without trip (ATWT) protection is determined according to the received information which is transmitted by the current acquisition and processing board, wherein the second current signals are determined according to the ranging codes and analog quantity of the first current signals. With the processing method and system provided by the embodiment of the invention, the probability of misoperation of the ATWT protection can be decreased.

Owner:DAYA BAY NUCLEAR POWER OPERATIONS & MANAGEMENT +2

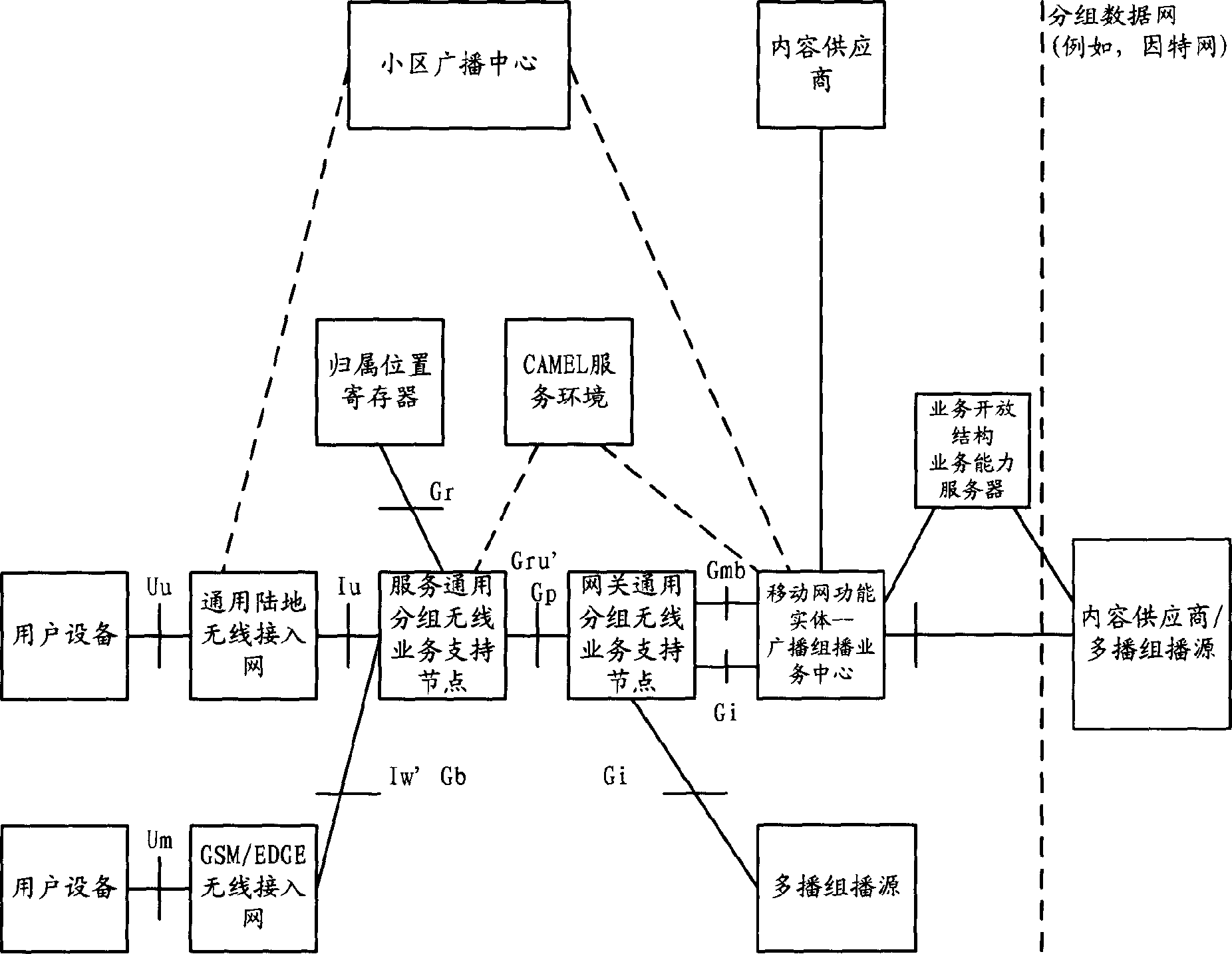

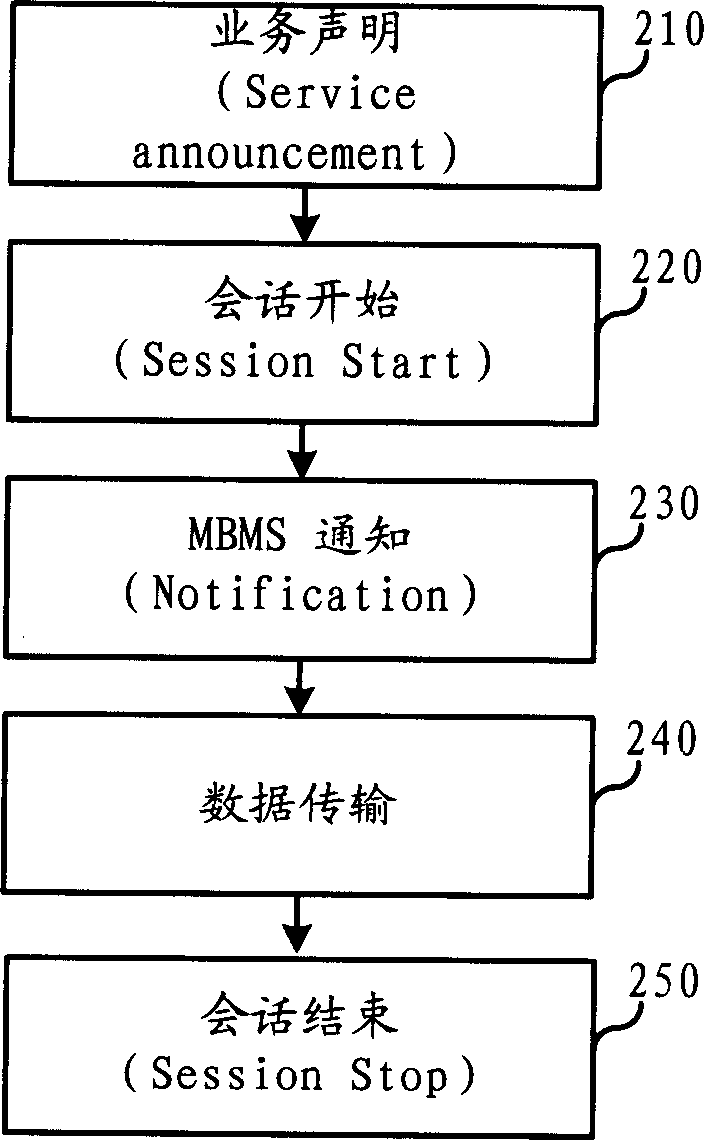

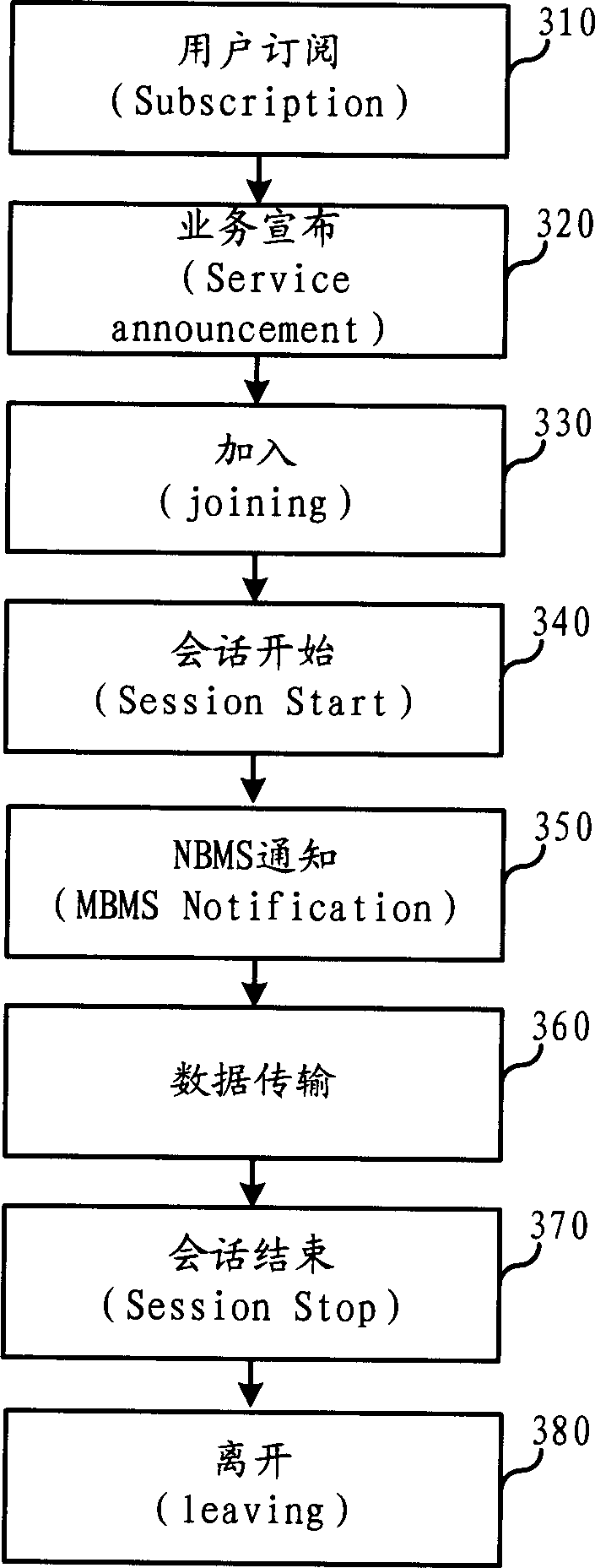

Method for responding MBMS correction service message

InactiveCN1801961AImprove reception qualityClearly reacquire MCCH" methodRadio/inductive link selection arrangementsData switching networksTelecommunicationsOperating point

Present invention relates to Present invention relates to multimedia broadcast / multicasting service, and discloses a method to response MBMS modification service so as to obtain MBMS modification service messages response in compromising user experience and preventing error precondition. In said invention, when receiving point-to-point professional subscriber equipment received í‹MBMS re - obtaining MCCH íŒset to true in IE of MBMS MSI messages, increasing step of judging whether needs stopping operated point-to-point service, according to judging result releasing current point-to-point connection to monitor MCCH or ignoring said MSI or forced releasing current point-to-point connection to monitor MCCH, Said invention also can execute not to transmitting MSI messages containing IE í‹MBMS re - obtaining MCCH íŒto subscriber equipment in receiving point-to-point service, when MBMS occurring error and needing re - obtaining controlling messages, to notify subscriber equipment by DCCH point to point controlling messages.

Owner:HUAWEI TECH CO LTD

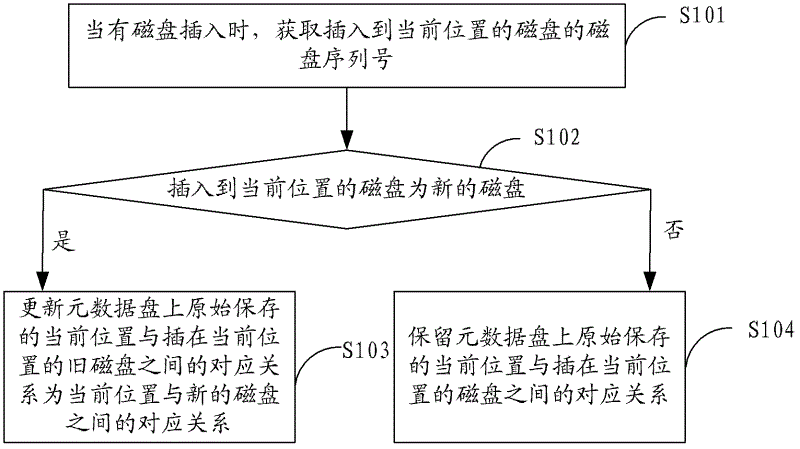

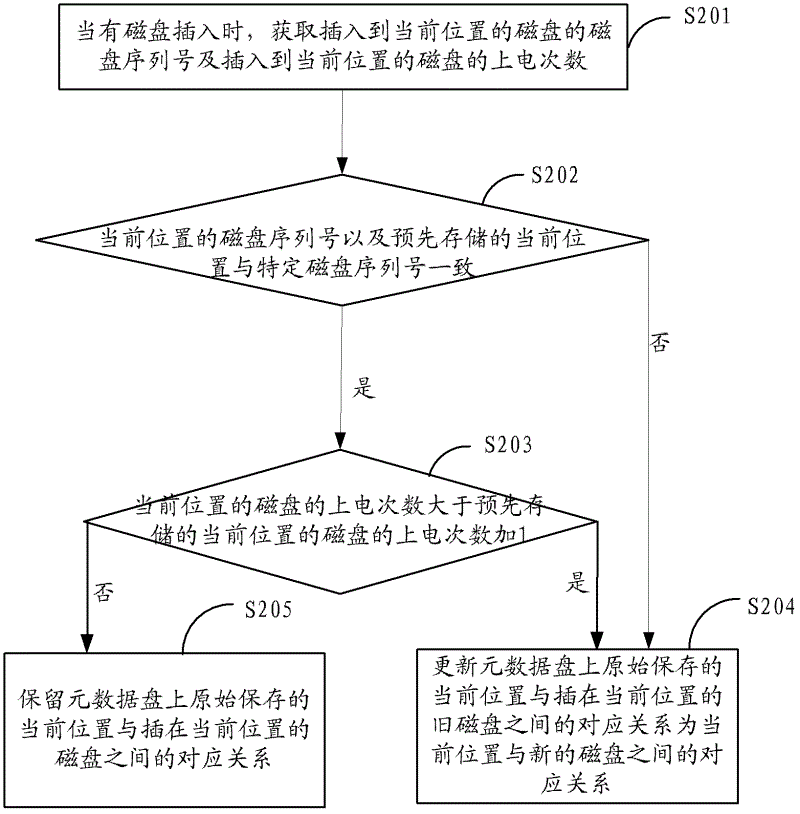

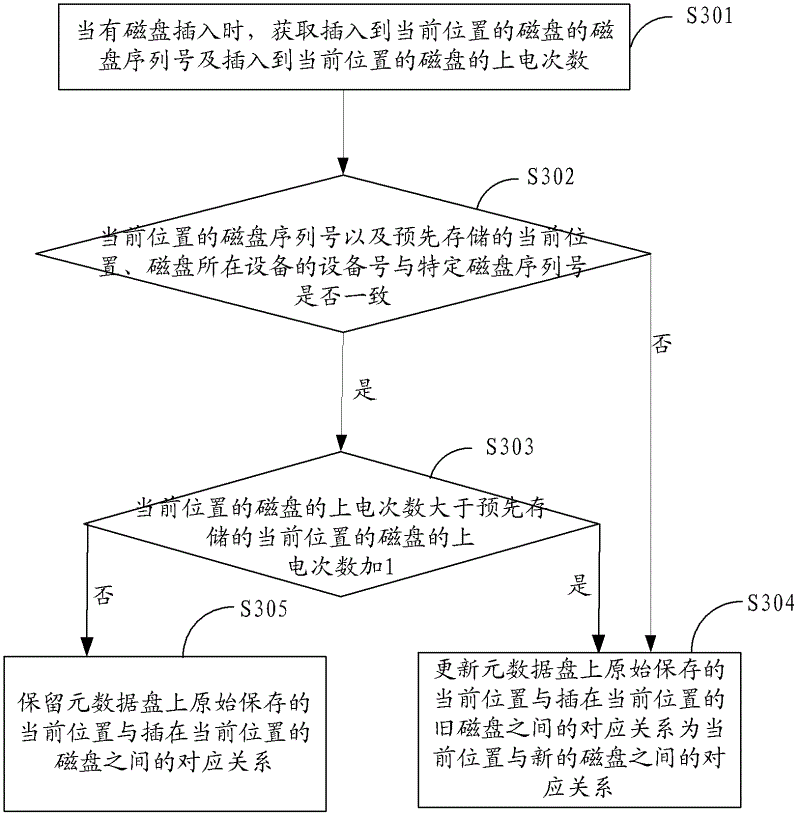

Method, device and system for controlling disc visiting

ActiveCN102622315AAccurate replacementAvoid access errorsElectric digital data processingData lossComputer science

The invention is applicable to the technical field of discs, and provides a method, a device and a system for controlling disc visiting. The method comprises judging whether a disc is a new one or not according to disc serial number of the current position and the congruent relationship between preset stored current position and specific disc serial number, or according to the disc serial number of the current position and the congruent relationship among the preset stored current position, equipment number of equipment of the disc and the specific disc serial number; on yes judgment, the congruent relationship between the current position originally stored on a metadata disc and an old disc inserted in the current position is refreshed; and on no judgment, the congruent relationship between the current position originally stored on a metadata disc and an old disc inserted in the current position is stored. According to the disc serial number of the disc at the current position, the file control information of the disc recorded on the metadata disc is deleted or retained, and the condition that users cannot visit the data on the original disc due to the fact of disc data loss is avoided.

Owner:TANGSHAN CAOFEIDIAN LIANCHENG TECH CO LTD

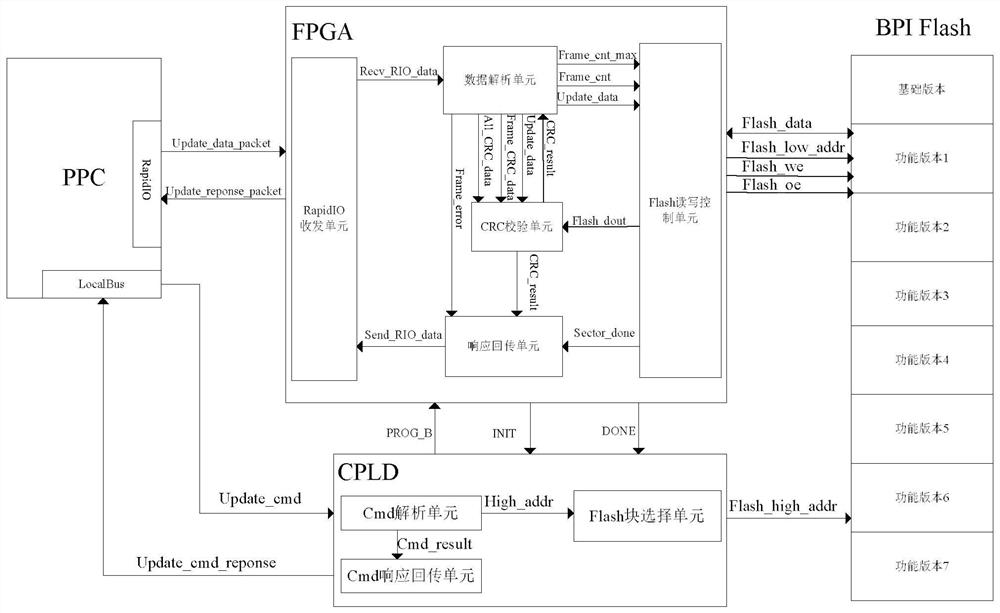

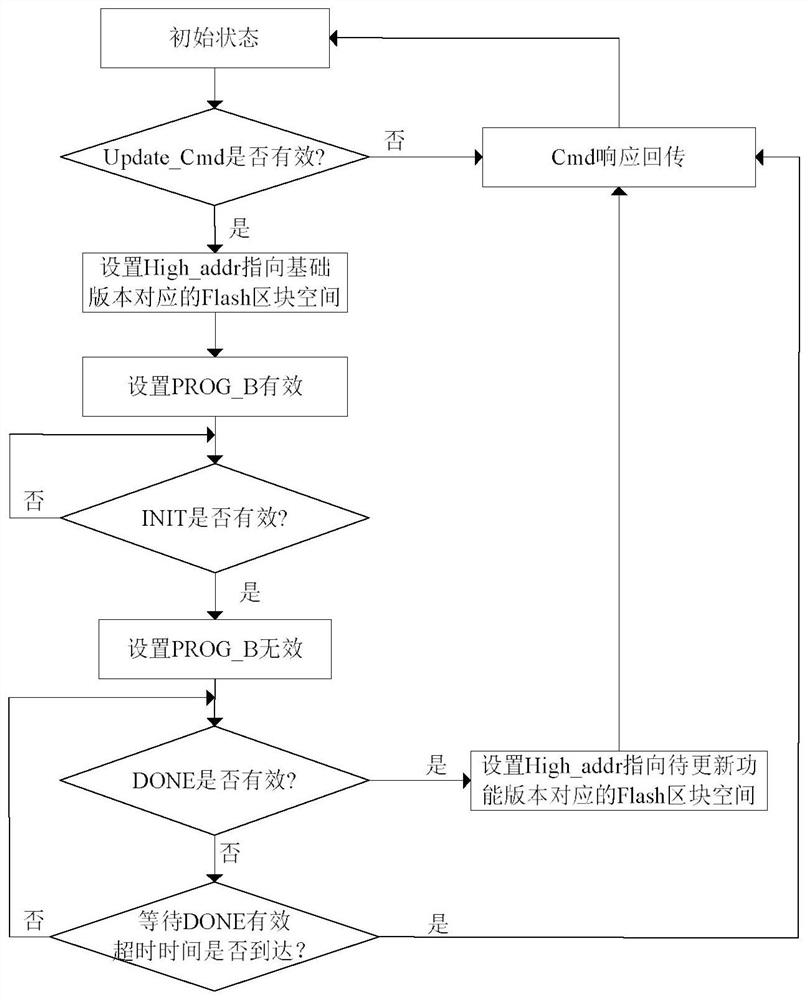

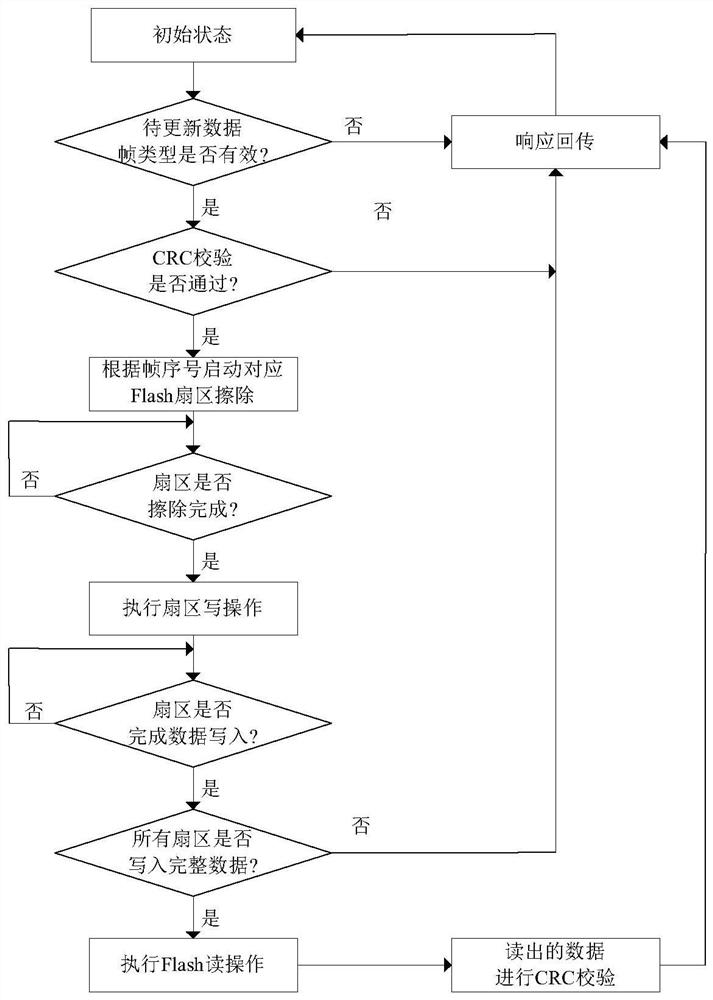

Method for remotely updating multi-version program of FPGA online

ActiveCN113434162ANo increase in design complexitySimplify hardware designVersion controlSoftware deploymentComputer architectureEngineering

According to the method for remotely updating the multi-version programs of the FPGA online, hardware is simple, the real-time processing efficiency is high, and the fault-tolerant capability is high. According to the technical scheme, a PPC processor receives an FPGA program remote updating instruction and sends the updating instruction to a CPLD, after the CPLD verifies that the updating instruction is correct, an FPGA basic version program is loaded into the FPGA from Flash to run, then a Flash high-order address is switched to point to a Flash block space corresponding to a to-be-updated function program version, the FPGA receives a to-be-updated program file from the PPC, after data frame CRC (Cyclic Redundancy Check) is recieved and all program files to be updated are written, all data updated and written by the Flash at this time are read, the data is written into a corresponding Flash address space, the previously written data are read from the Flash, and secondary CRC is carried out, and a check result is reported to the PPC.

Owner:10TH RES INST OF CETC

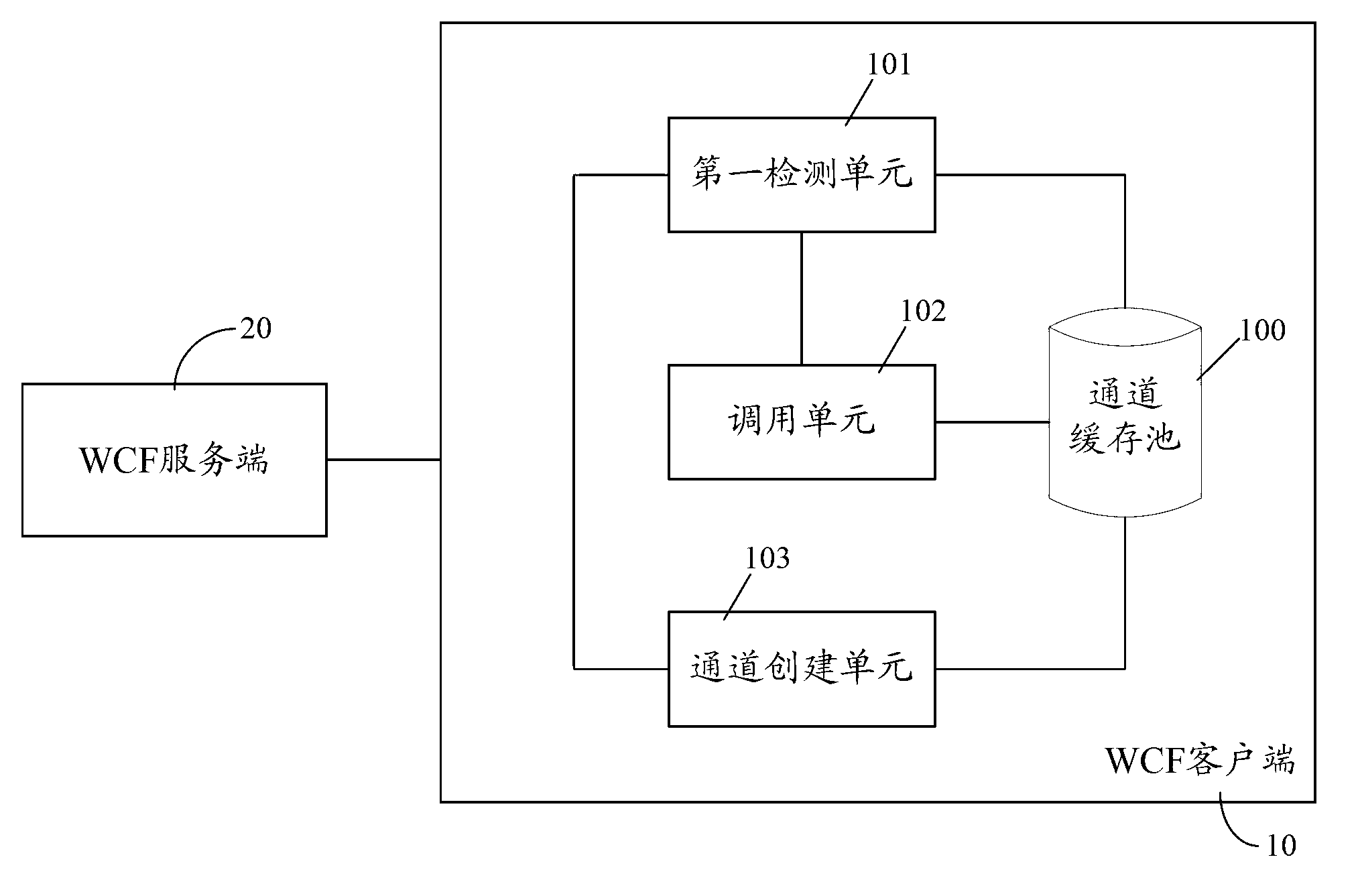

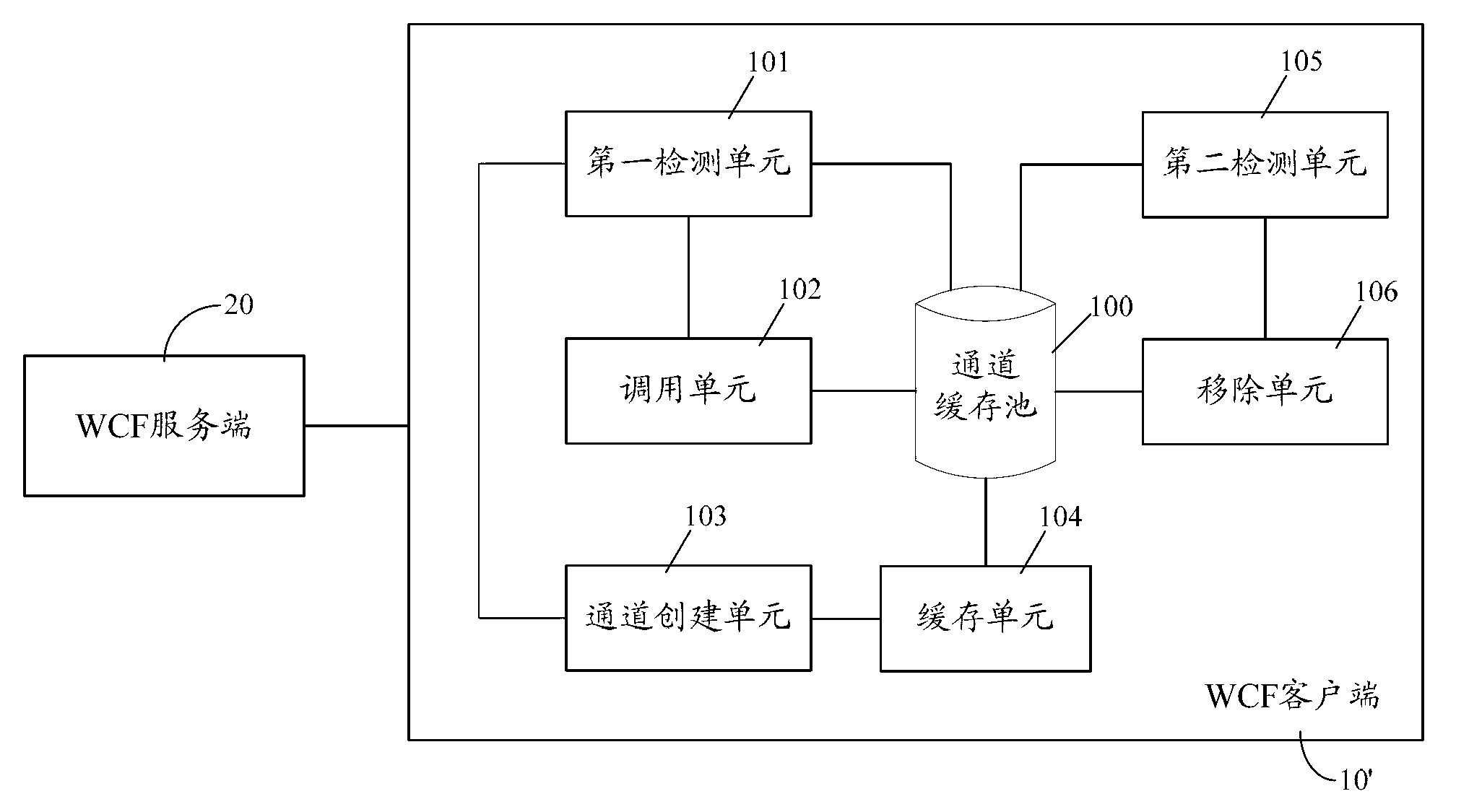

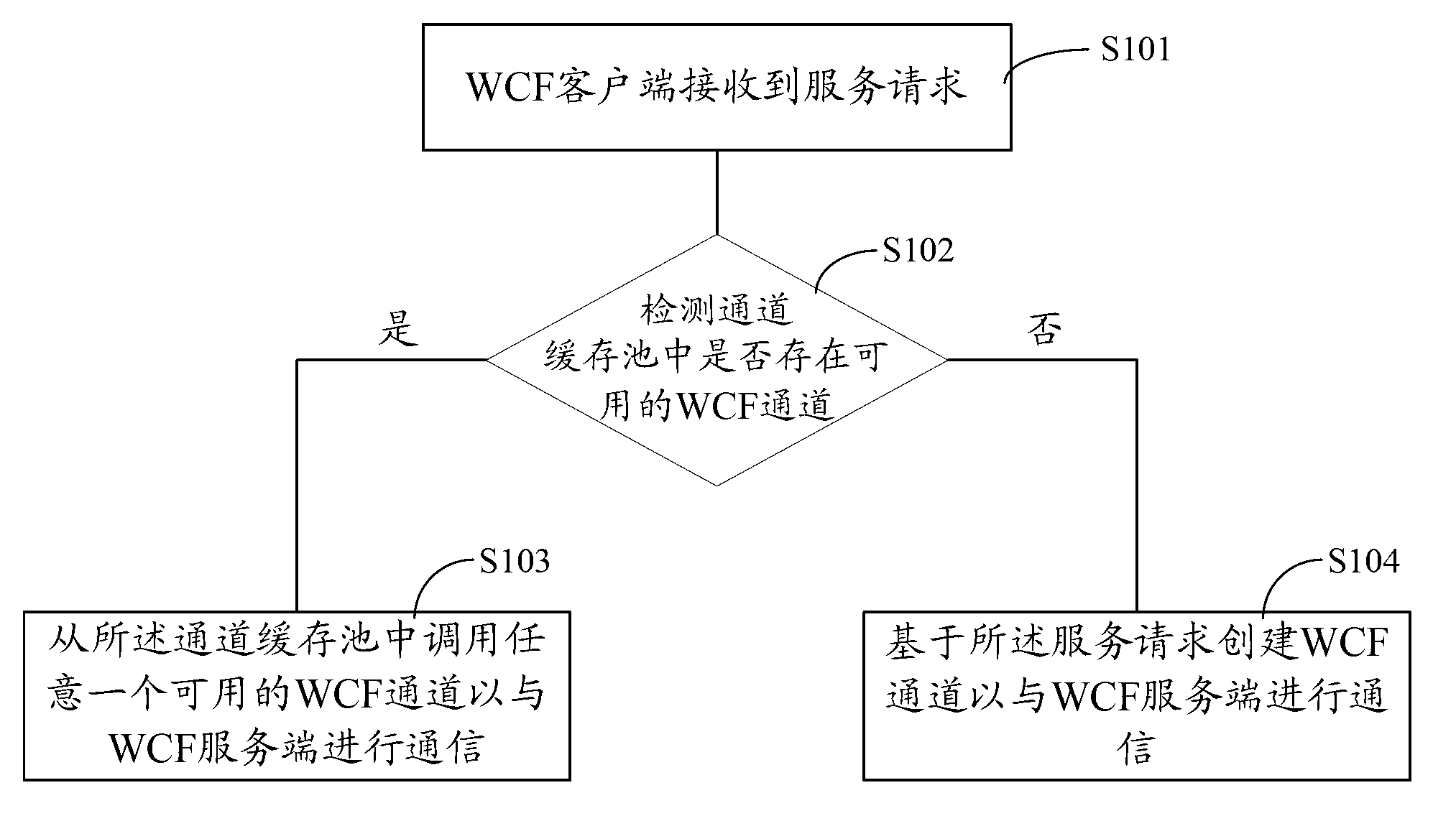

Communication system and communication method between client and server side

The invention relates to a communication system and a communication method between a client and a server side. The communication method between the client and the server side comprises the steps: detecting whether WCF (Windows Communication Foundation) channels are available in a channel caching pool or not after a WCF client receives a service request; if so, invoking any one available WCF channel from the channel caching pool to be communicated with the WCF server side; and if not, creating the WCF channel to be communicated with the WCF server side based on the service request. The technical scheme provided by the invention can enhance the performance of the WCF client.

Owner:沿海西本供应链南通有限公司

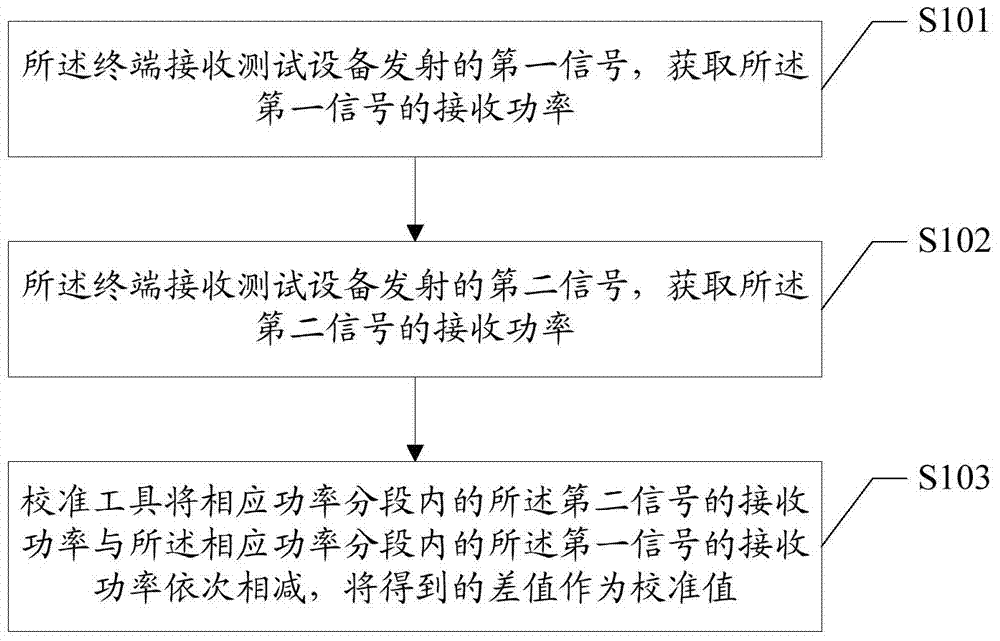

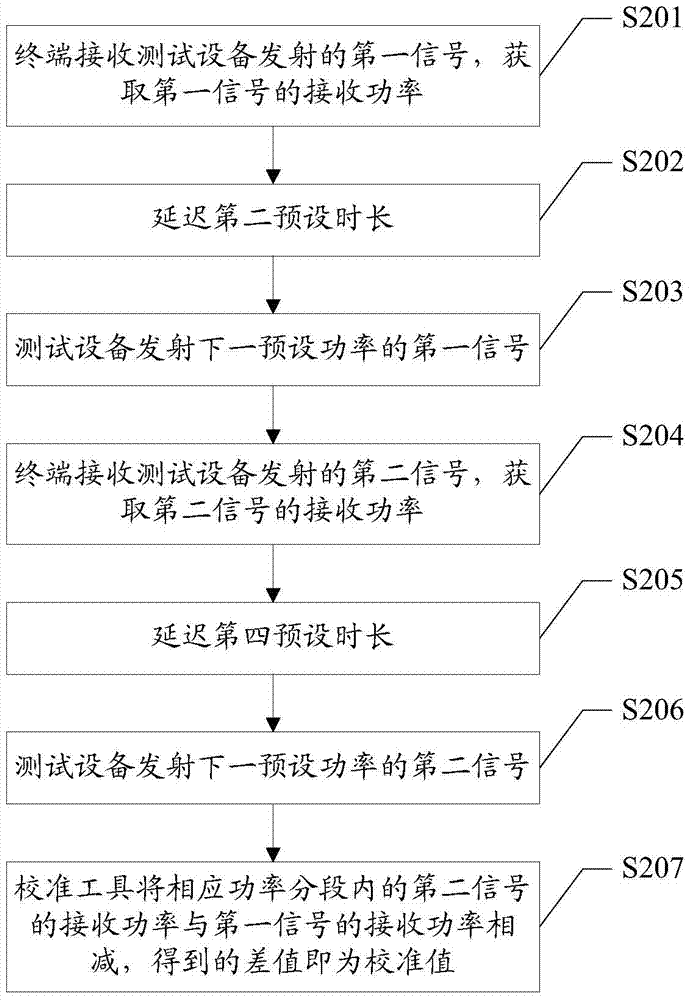

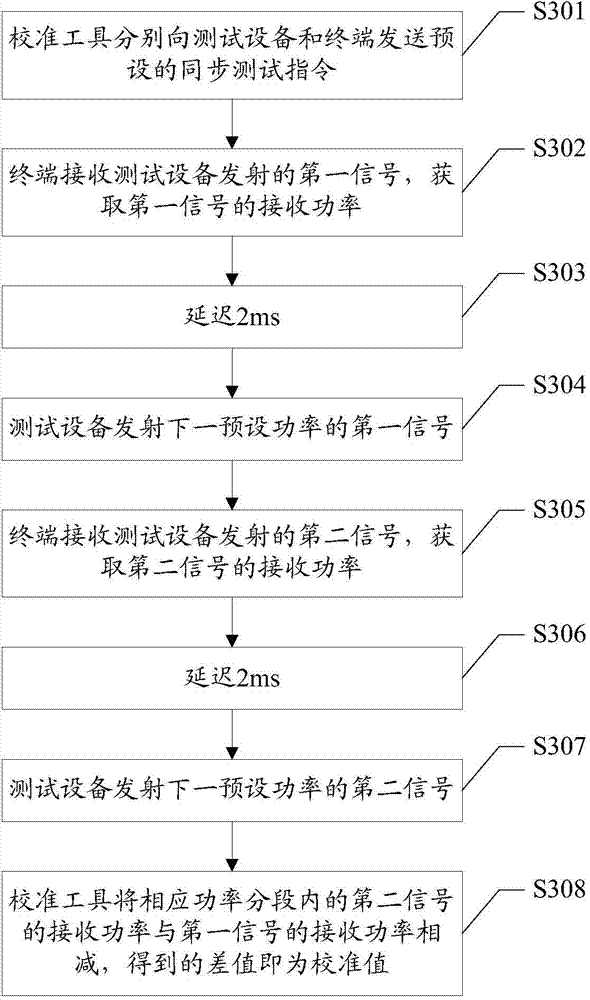

Power calibration method and system for radio frequency receiver of terminal

ActiveCN104753544AImprove calibration efficiencyReduce calibration timeTransmissionTuned radio frequency receiverComputer terminal

The invention discloses a power calibration method and system for a radio frequency receiver of a terminal. The power calibration method for the radio frequency receiver of the terminal includes that the terminal receives a first signal emitted from test equipment and acquires the received power of the first signal; the terminal receives a second signal emitted from the test equipment and acquires the received power of the second signal; a calibration tool subtracts the received power of the second signal in the corresponding power section and the received power of the first signal in the corresponding power section in sequence, and the difference value is used as the calibration value. The method and system are capable of effectively improving the power calibration efficiency for the radio frequency receiver of the terminal.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

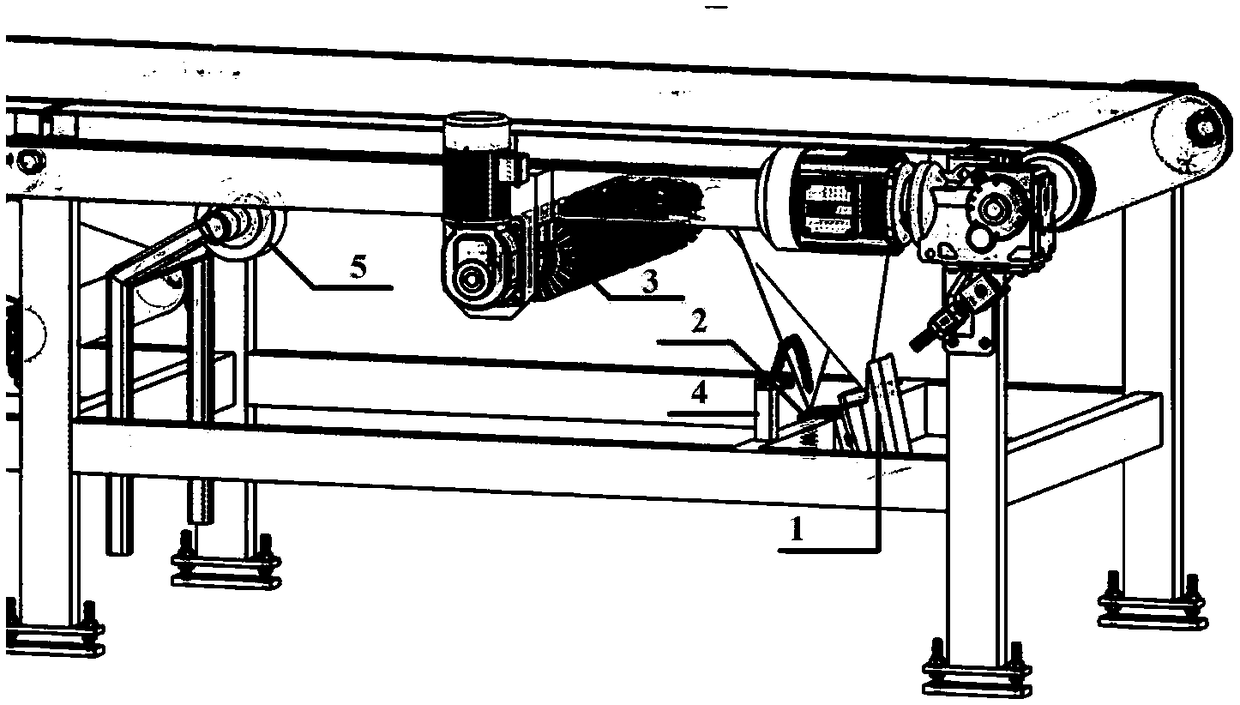

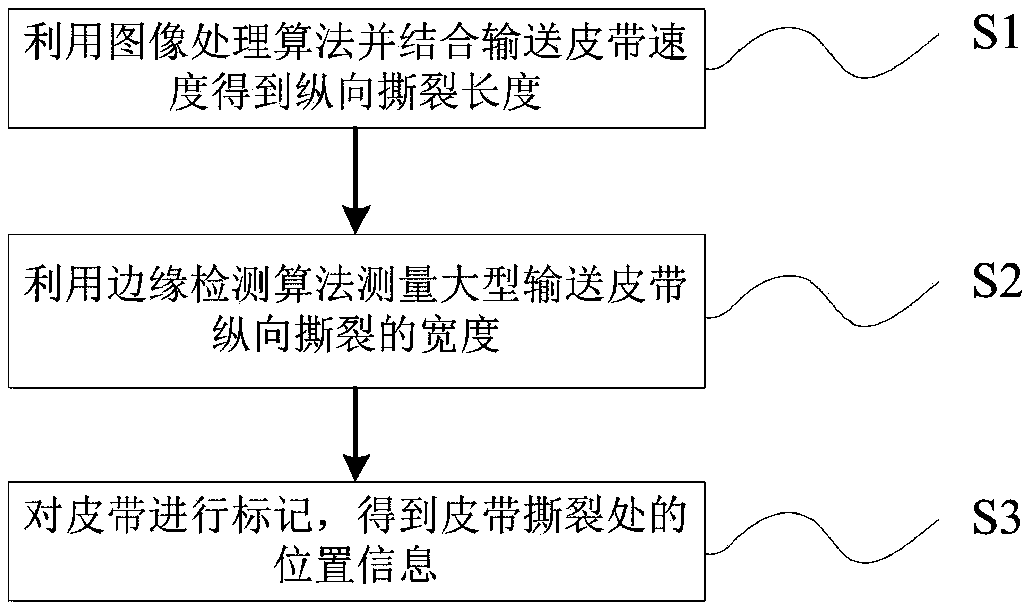

Device and method for detecting longitudinal tearing of large conveyor belt

ActiveCN109335575AAccurate online measurementAvoid error conditionsConveyorsControl devices for conveyorsLaser transmitterSynchronous detection

Theinvention provides a device and method for detecting longitudinal tearing of a large conveyor belt. The device comprises an industrial camera, a line laser transmitter, a brush, a dust removal airgun, a synchronous detection wheel and a PC machine; the industrial camera is installed below the non-carrying surface of the conveyor belt; the line laser transmitter is installed below the non-carrying surface of the conveyor belt and emitted line laser is in a view field of the industrial camera; the brush is installed on the upstream of the industrial camera in the movement direction of the conveyor belt and used for cleaning the conveyor belt; the dust removal air gun is installed close to the industrial camera to prevent dust from falling and contaminating a lens; the synchronous detection wheel is used as a passive wheel to be in contact with the conveyor belt, installed below the conveyor belt, rotates with movement of the conveyor belt, and is used for detecting the moving speed of the conveyor belt; and the PC machine processes collected images, generates a tearing alarm, and displays length, width, depth and position information of longitudinal tearing of the large conveyorbelt, so as to complete detection of longitudinal tearing of the large conveyor belt.

Owner:河北省机电一体化中试基地有限公司

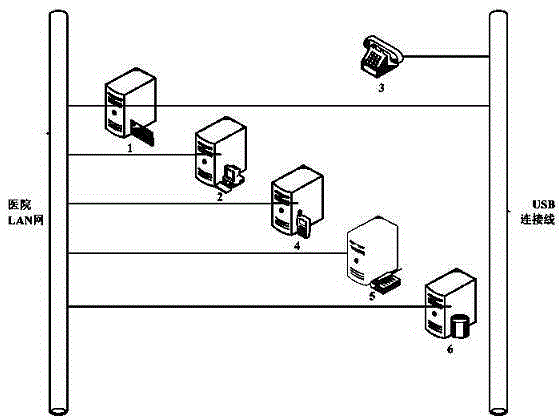

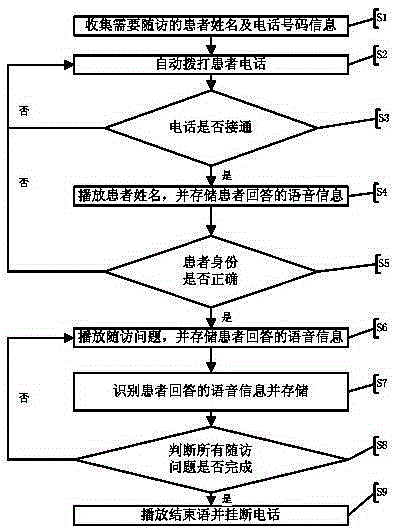

Full-automatic hospital telephone follow-up method and telephone device thereof

ActiveCN105426675AWork lessNo manual service requiredData processing applicationsTelemedicineSpeech identificationHospital information system

The invention discloses a full-automatic hospital telephone follow-up method and a telephone device thereof. The telephone device comprises a hospital follow-up management server, a hospital information system, a recording telephone, a voice recognition server, a voice synthesis server and an information database. Due to the information means and design of hardware equipment, all follow-up process are integrated through the existing mature hospital information system, the recording telephone technology, the voice recognition technology, the voice synthesis technology, the database technology and the like; a function of full-automatically following up patients through a telephone can be realized; and the method disclosed by the invention can be applied to following up patients through a hospital telephone.

Owner:JIANGSU UNIV

Formal analysis method for parallel system performance

InactiveCN105512018AAvoid error conditionsImprove performanceSoftware testing/debuggingSpecific program execution arrangementsComputational scienceAnalysis method

The invention discloses a formal analysis method for parallel system performance. The method comprises: step 1, establishing a parallel program performance model and a parallel machine model; step 2, establishing mapping relations between the parallel program performance model and the parallel machine model, to form a parallel system performance model, and performing parallel system performance analysis. The invention provides the efficient parallel system performance analysis method.

Owner:SHANGHAI PRECISION METROLOGY & TEST RES INST

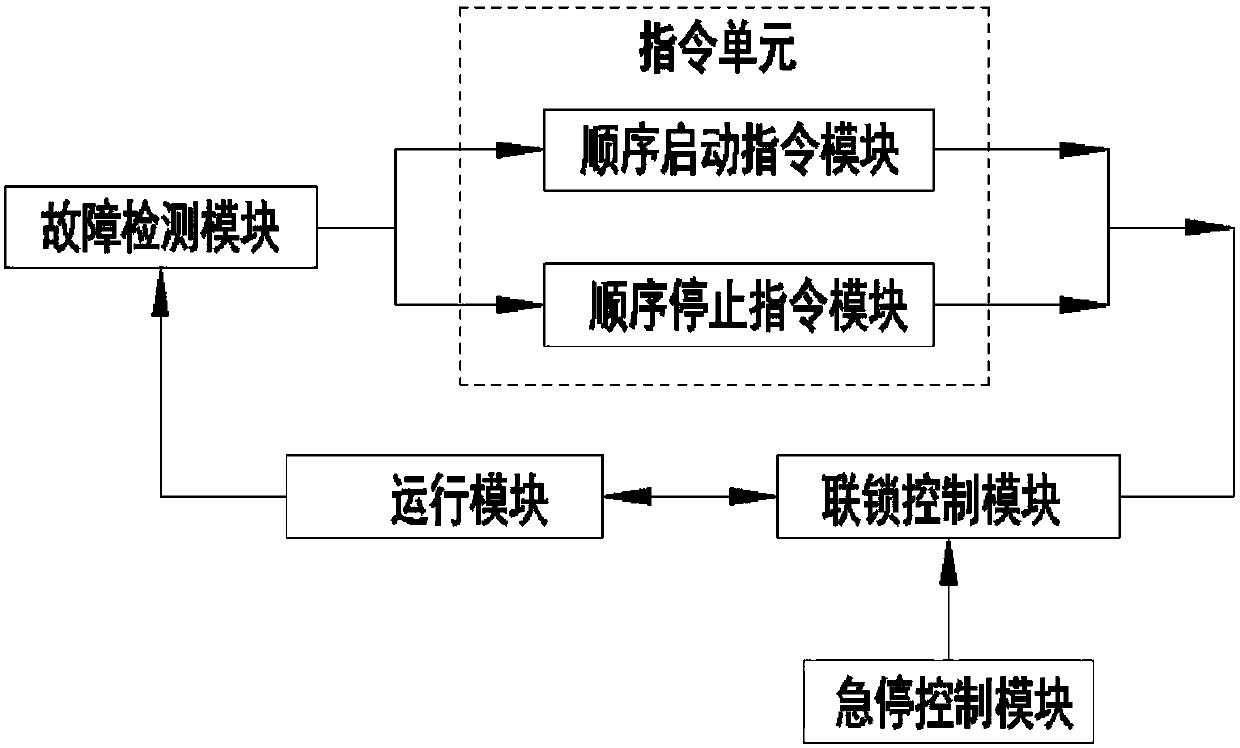

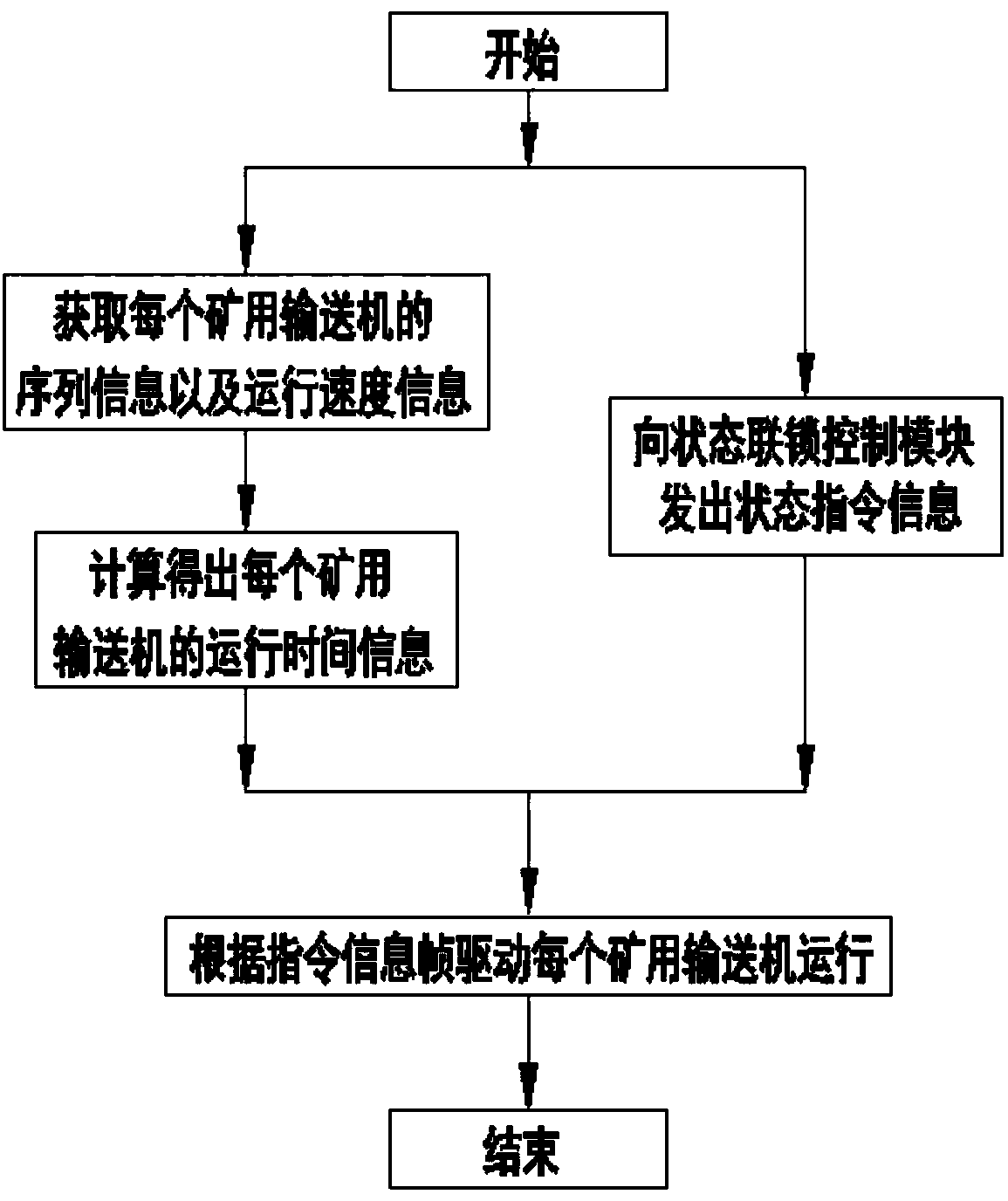

Start-stop control system and control method of mine conveyer

InactiveCN107894743AReduce physical exertionShorten the timeControl devices for conveyorsProgramme control in sequence/logic controllersInstruction unitStart stop

The invention provides a start-stop control system and a control method of a mine conveyer. The start-stop control system comprises an instruction unit, an interlock control module and an operation module. The interlock control module and the operation module are in bidirectional communication connection; and the output end of the instruction unit is connected with the input end of the interlock control module. The control method comprises the following steps: obtaining sequence information and operation speed information of each mine conveyer; sending status instruction information to the interlock control module; calculating operation time information of each mine conveyer; converting the status instruction information into an instruction information frame of each mine conveyer; and driving the corresponding conveyer to operate according to the instruction information frame. According to the technical scheme, start and stop of each mine conveyer can be controlled automatically through the unified control system, thereby reducing physical output of operation personnel, allowing each mine conveyer to start or stop reliably according to preset sequence, simplifying work process, reducing idle running time of the equipment and improving efficiency.

Owner:GUIZHOU KAILIN GRP CO LTD

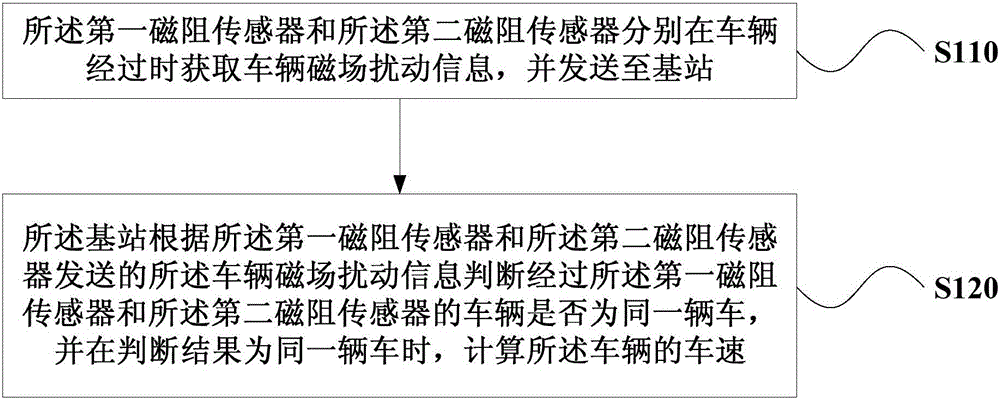

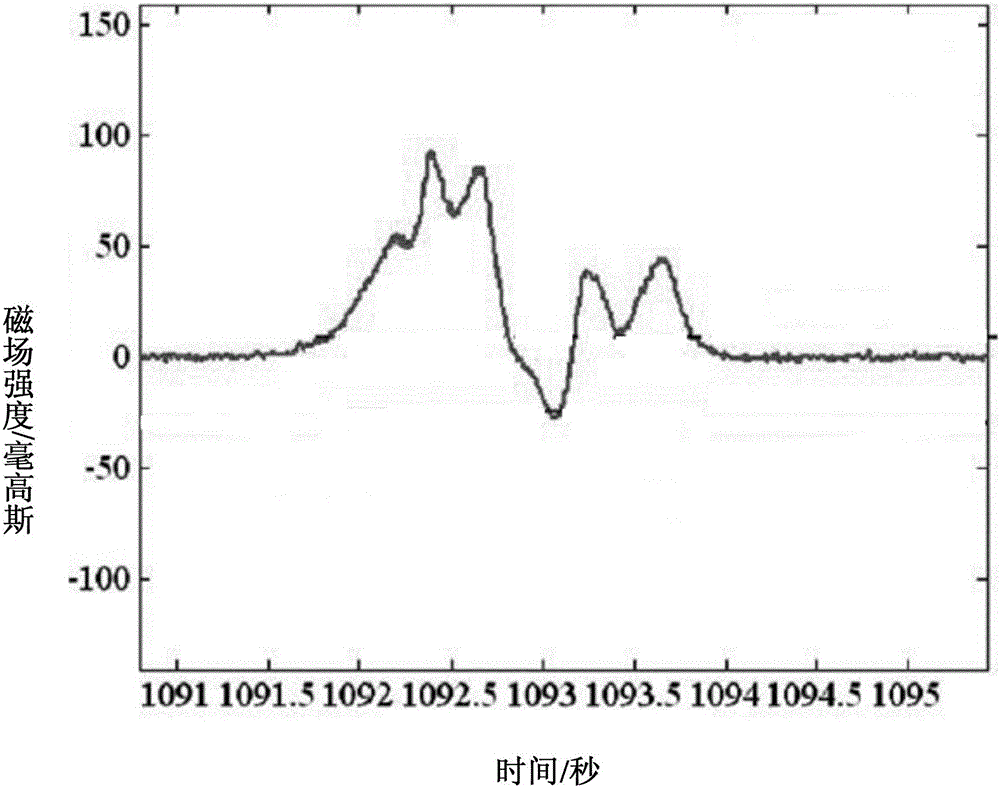

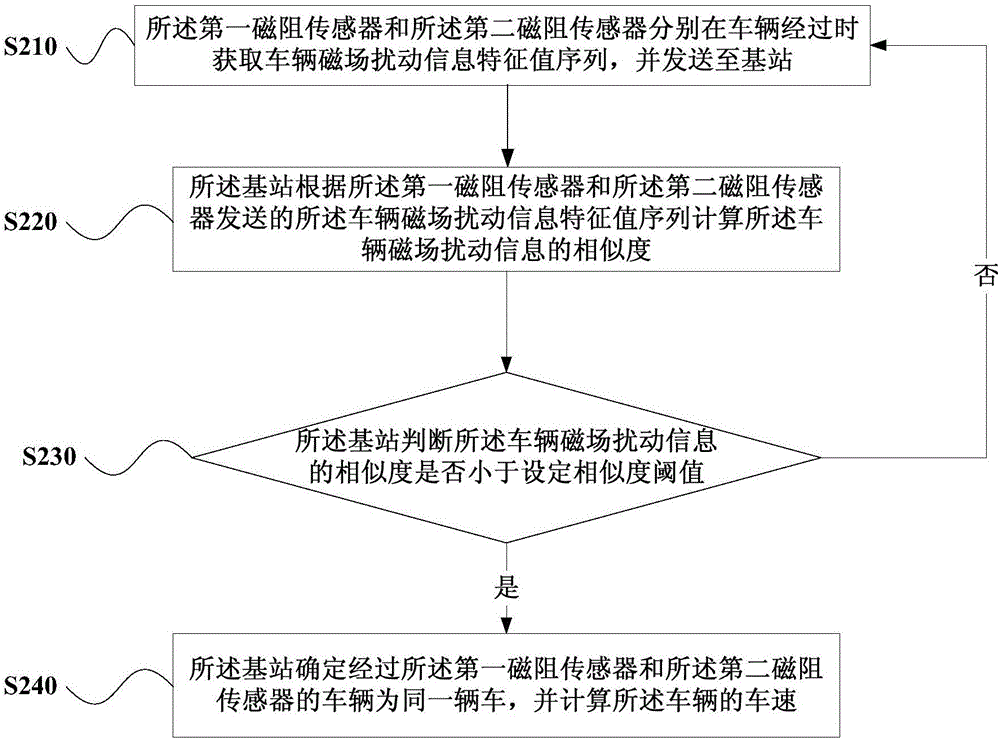

Vehicle speed measuring method

ActiveCN105957355AAvoid error conditionsImprove detection accuracyRoad vehicles traffic controlResistive sensorsEngineering

The invention discloses a vehicle speed measuring method. A first magneto-resistive sensor and a second magneto-resistive sensor are arranged at an interval along a direction parallel to a lane direction. The method comprises: the first magneto-resistive sensor and the second magneto-resistive sensor obtain vehicle magnetic field disturbance information when a vehicle passes by and send the information to a base station; and the base station determines vehicles passing by the first magneto-resistive sensor and the second magneto-resistive sensor is the same vehicle based on the vehicle magnetic field disturbance information sent by the first magneto-resistive sensor and the second magneto-resistive sensor; and if so, the speed of the vehicle is calculated, so that the detection precision of the vehicle speed is improved.

Owner:DONGGUAN UNIV OF TECH

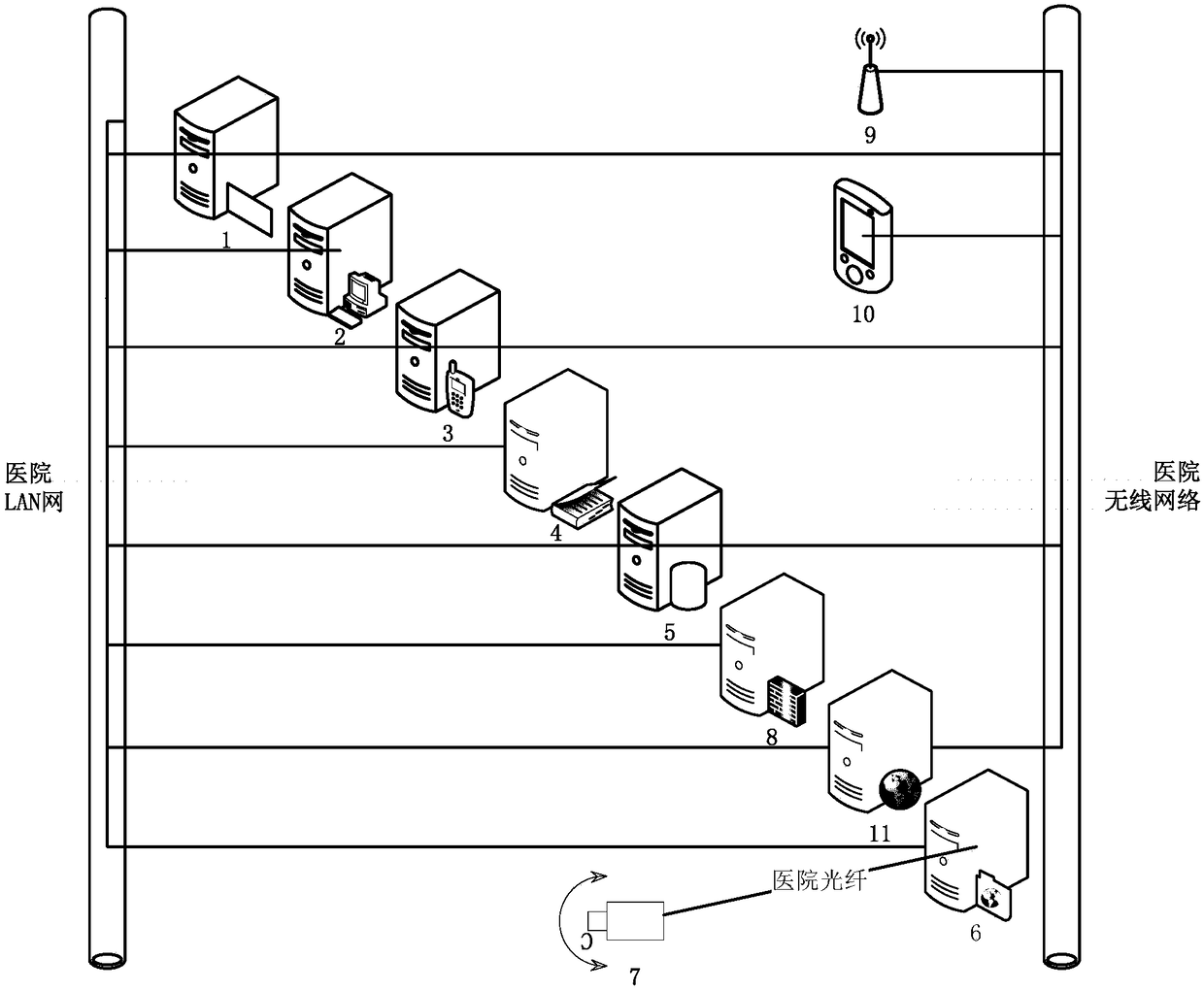

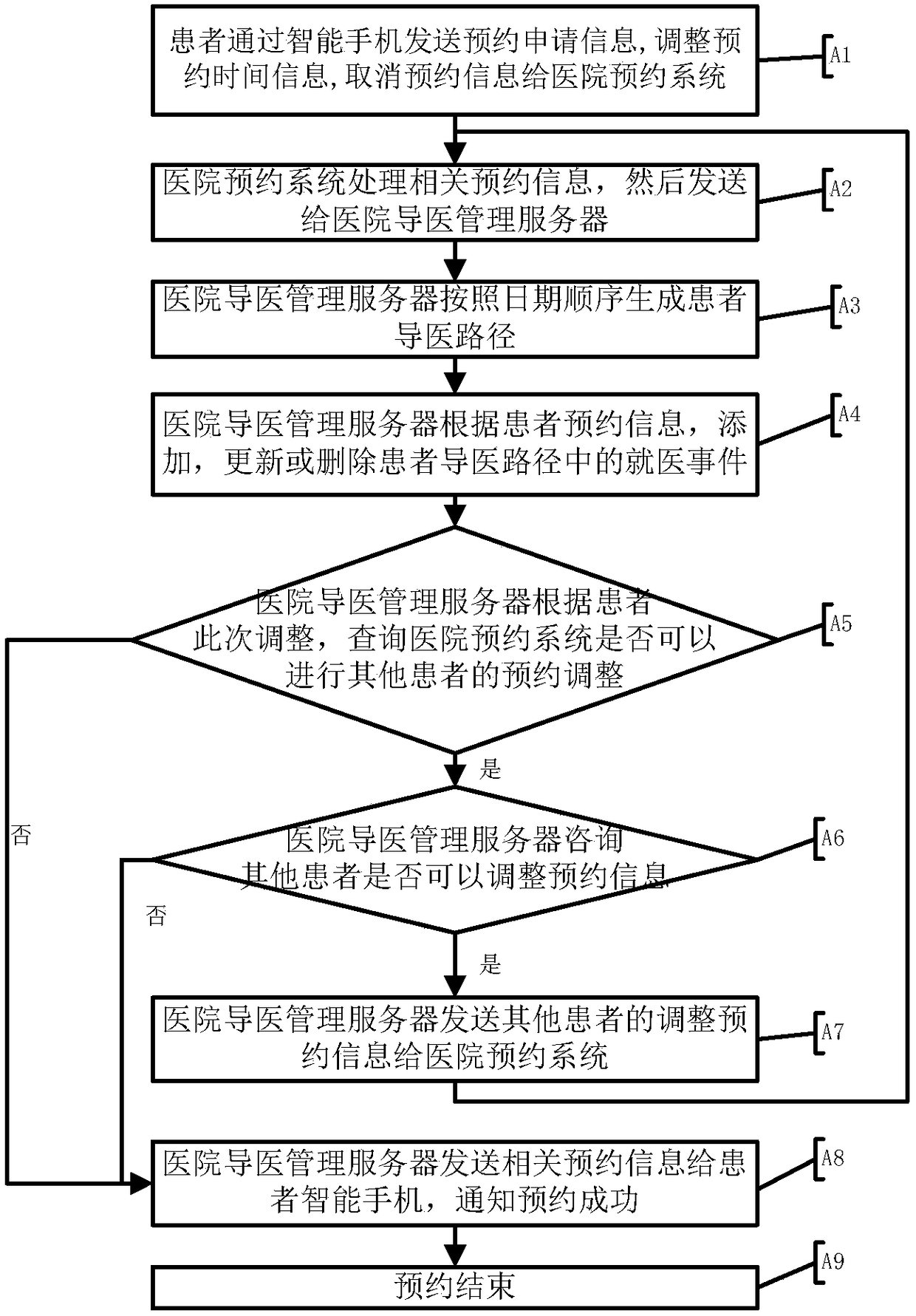

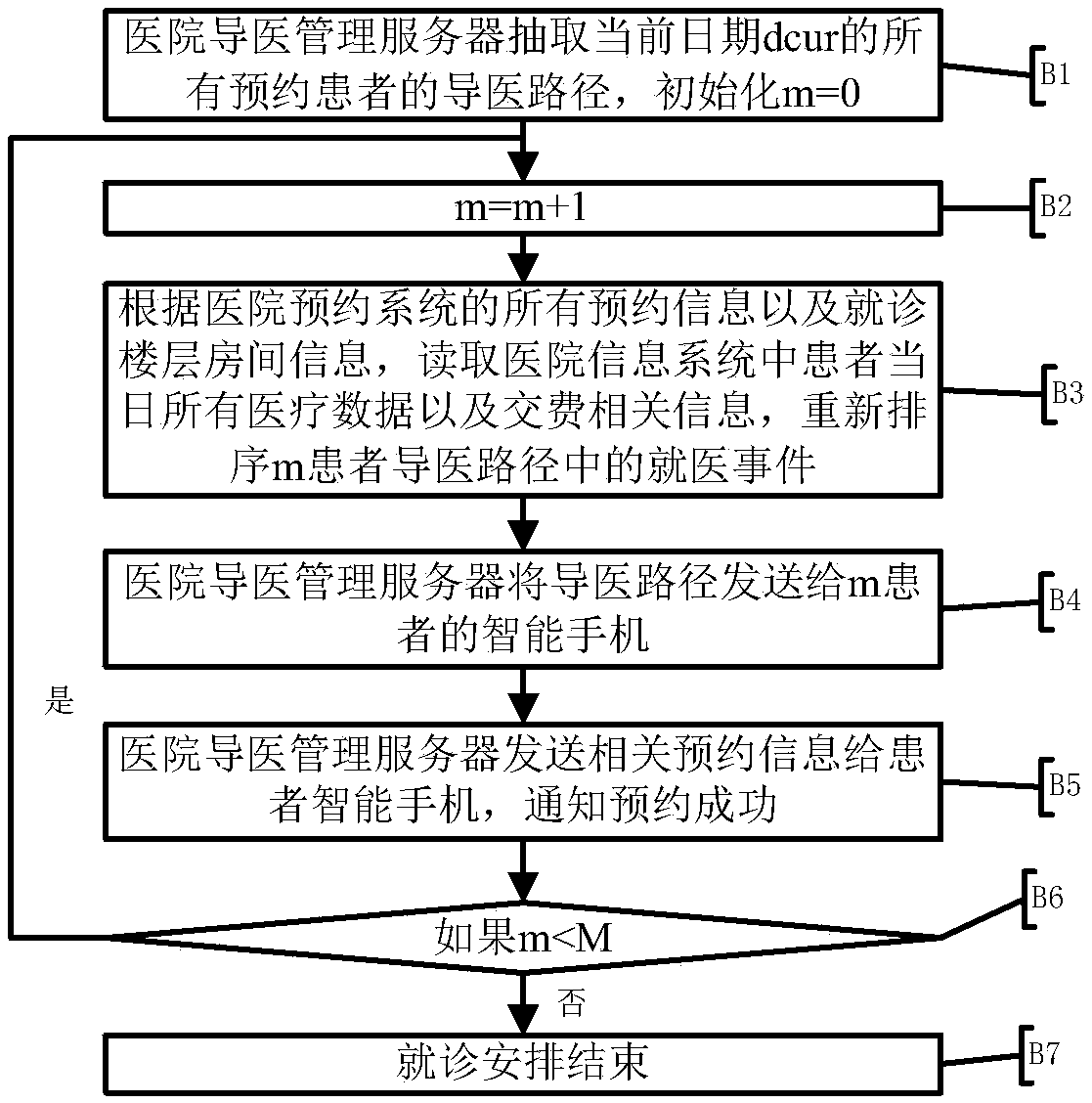

Hospital intelligent medical guiding device and method

ActiveCN108346455ARealize two-way communicationCause wasteTherapiesParticular environment based servicesEmergency medicineHospital information system

The invention discloses a hospital intelligent medical guiding device and method which use the existing mature hospital information system, GPS technology, face recognition technology, wireless positioning technology, and intelligent map technology, integrate all medical guiding procedures by information means and hardware equipment design, and achieve intelligent hospital medical guidance. The hospital intelligent medical guiding device and method can be applied to hospital patients for medical consultation.

Owner:AFFILIATED HOSPITAL OF JIANGSU UNIV

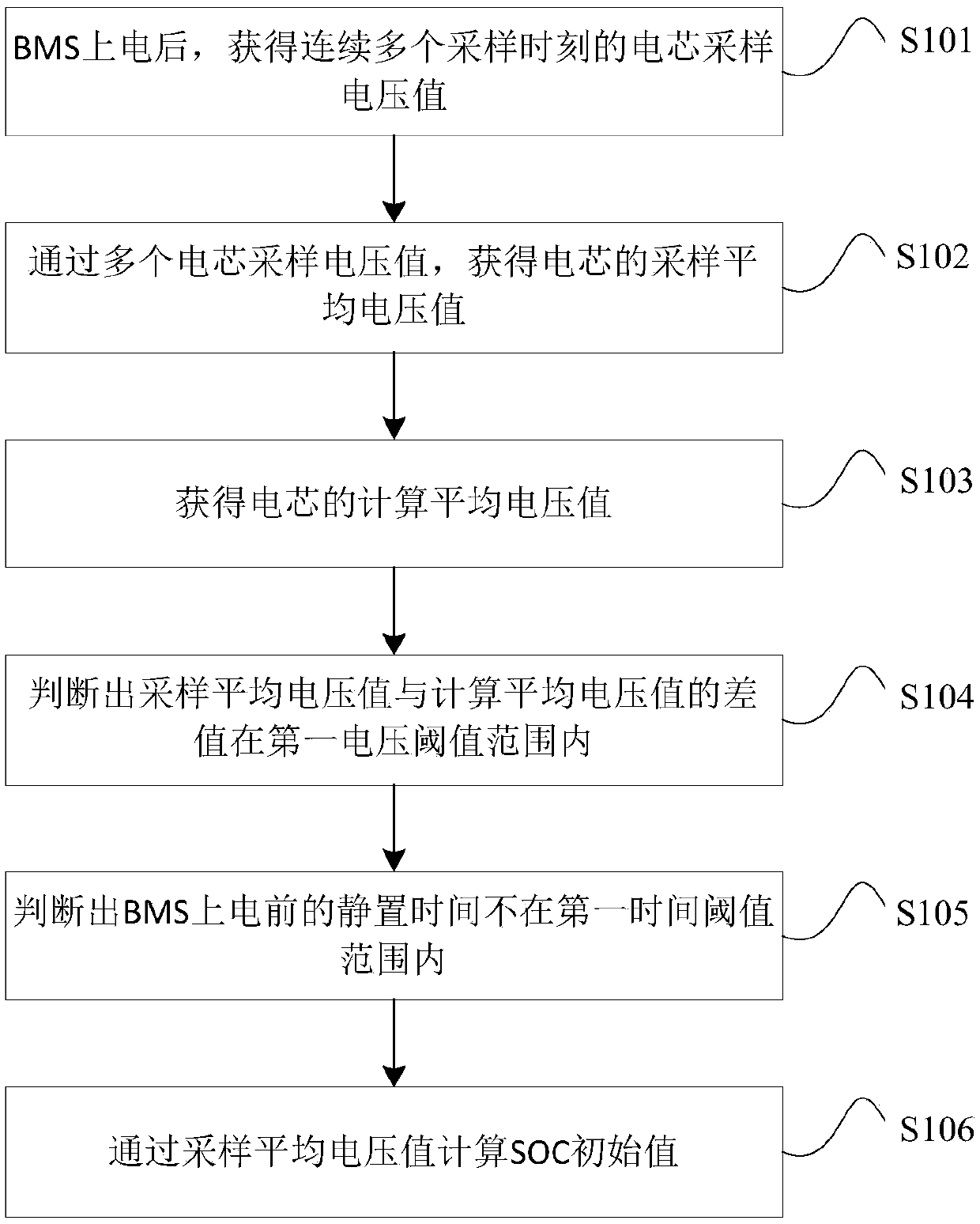

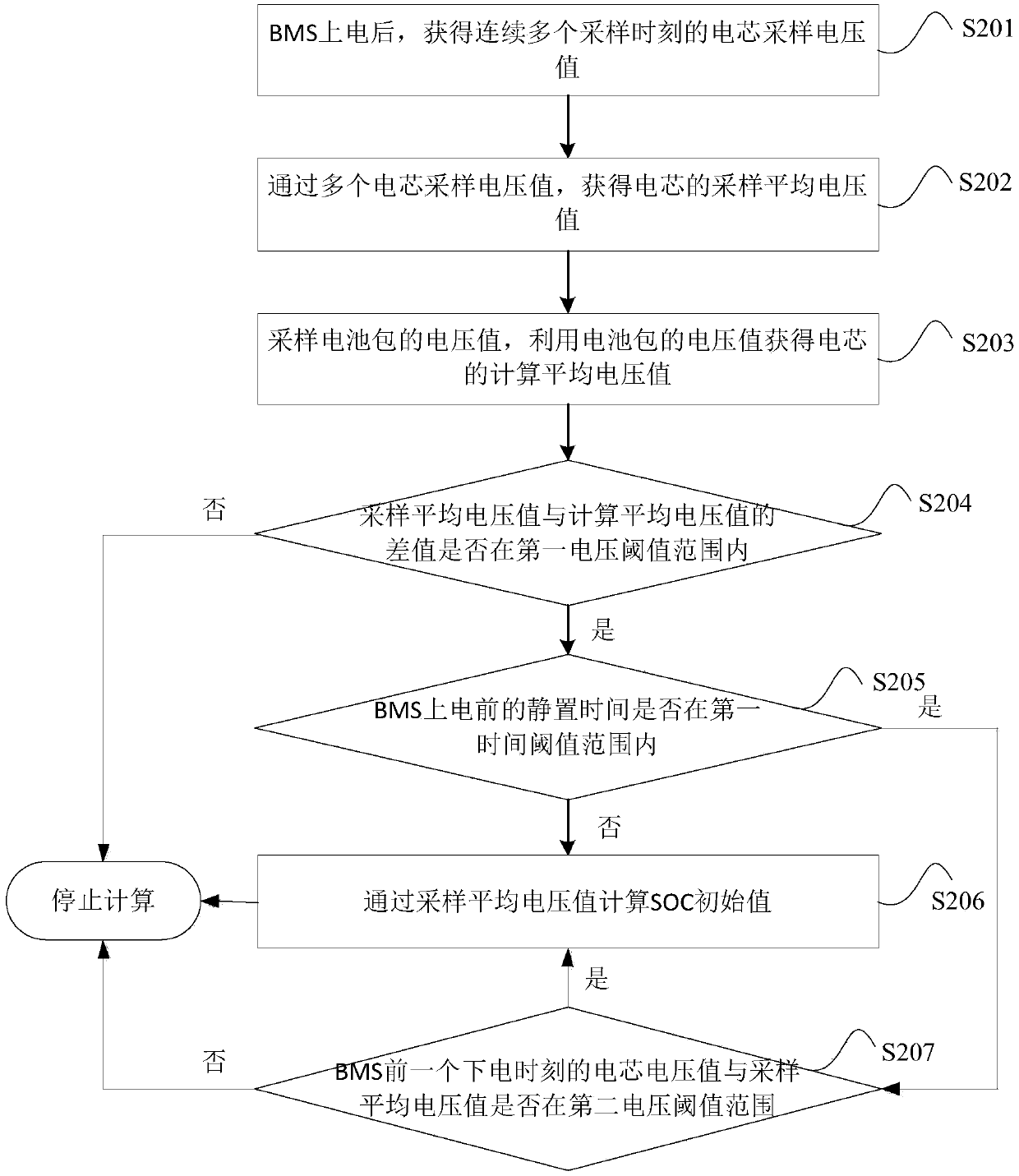

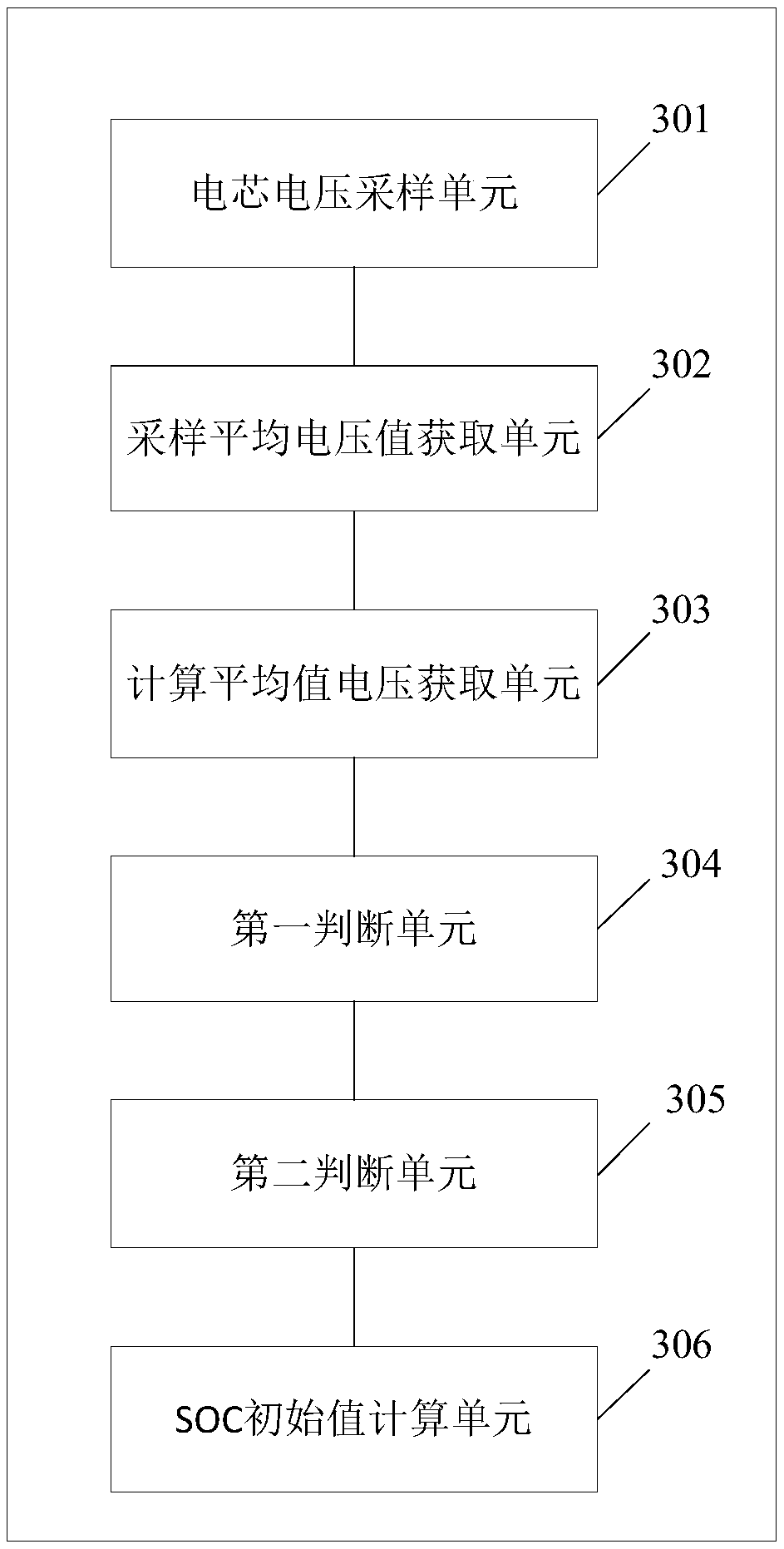

Voltage determination method and device for SOC initial value calculation

ActiveCN110888074AAvoid error conditionsImprove estimation accuracyElectrical testingElectrical batteryControl theory

The invention provides a voltage determination method and device for SOC initial value calculation. The method comprises steps that after a BMS is powered on, battery core sampling voltage values at multiple continuous sampling moments are obtained; a sampling average voltage value of the battery core is obtained through a plurality of battery core sampling voltage values; a voltage value of the battery pack is obtained within the sampling time, and a calculated average voltage value of the battery core is obtained through the voltage value of the battery pack; whether a difference value between the sampling average voltage value and the calculation average voltage value is within a first voltage threshold range or not is determined; if yes, whether the standing time before the BMS is powered on is within a first time threshold range or not is determined; if not, an SOC initial value is calculated through the sampling average voltage value. The method is advantaged in that the batterypack voltage is utilized to verify the core voltage, and further determination is carried out through the standing duration of the BMS, so the situation that the SOC initial value is wrong when the voltage is abnormal is avoided, and estimation accuracy of the SOC initial value is improved.

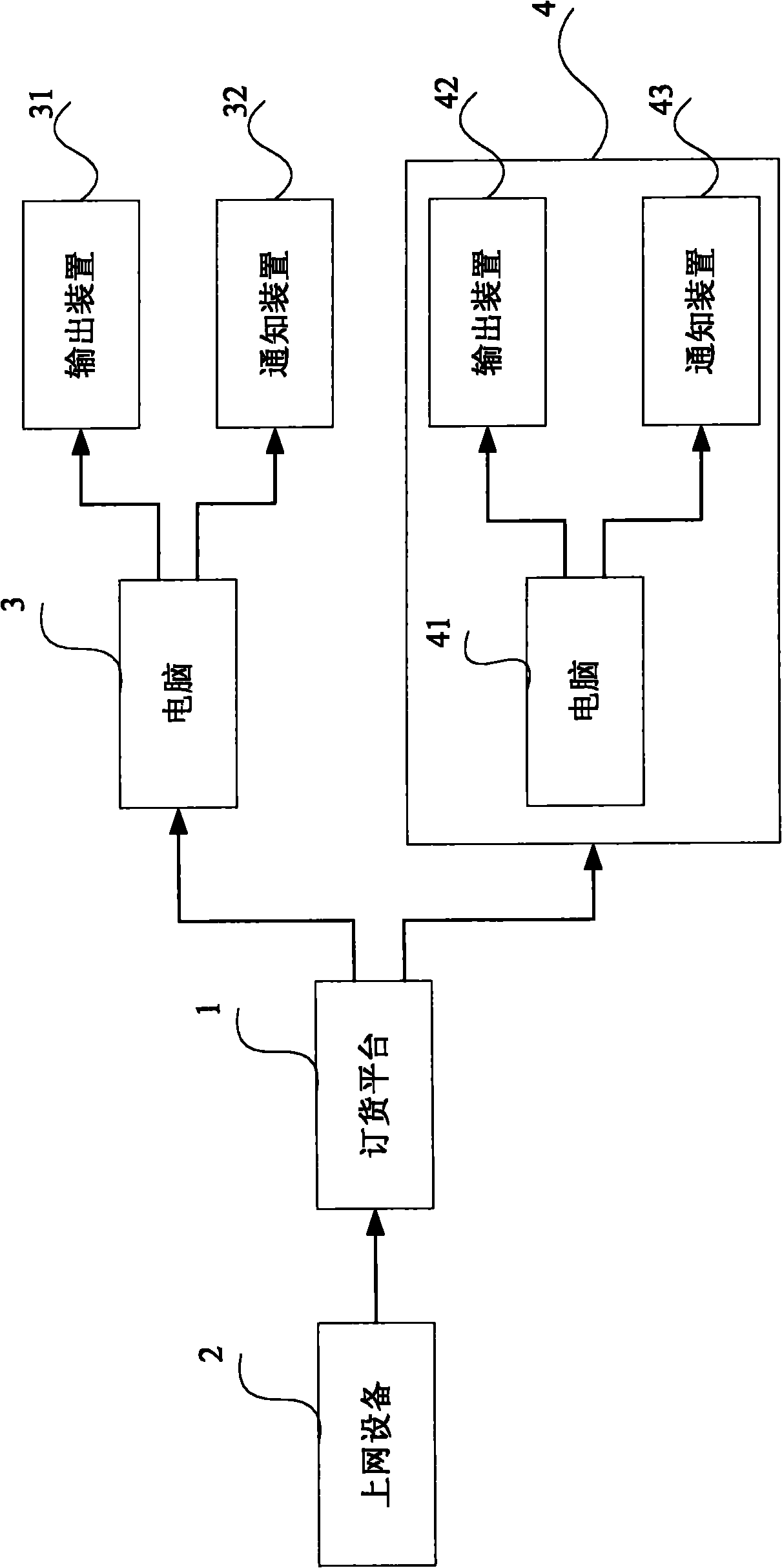

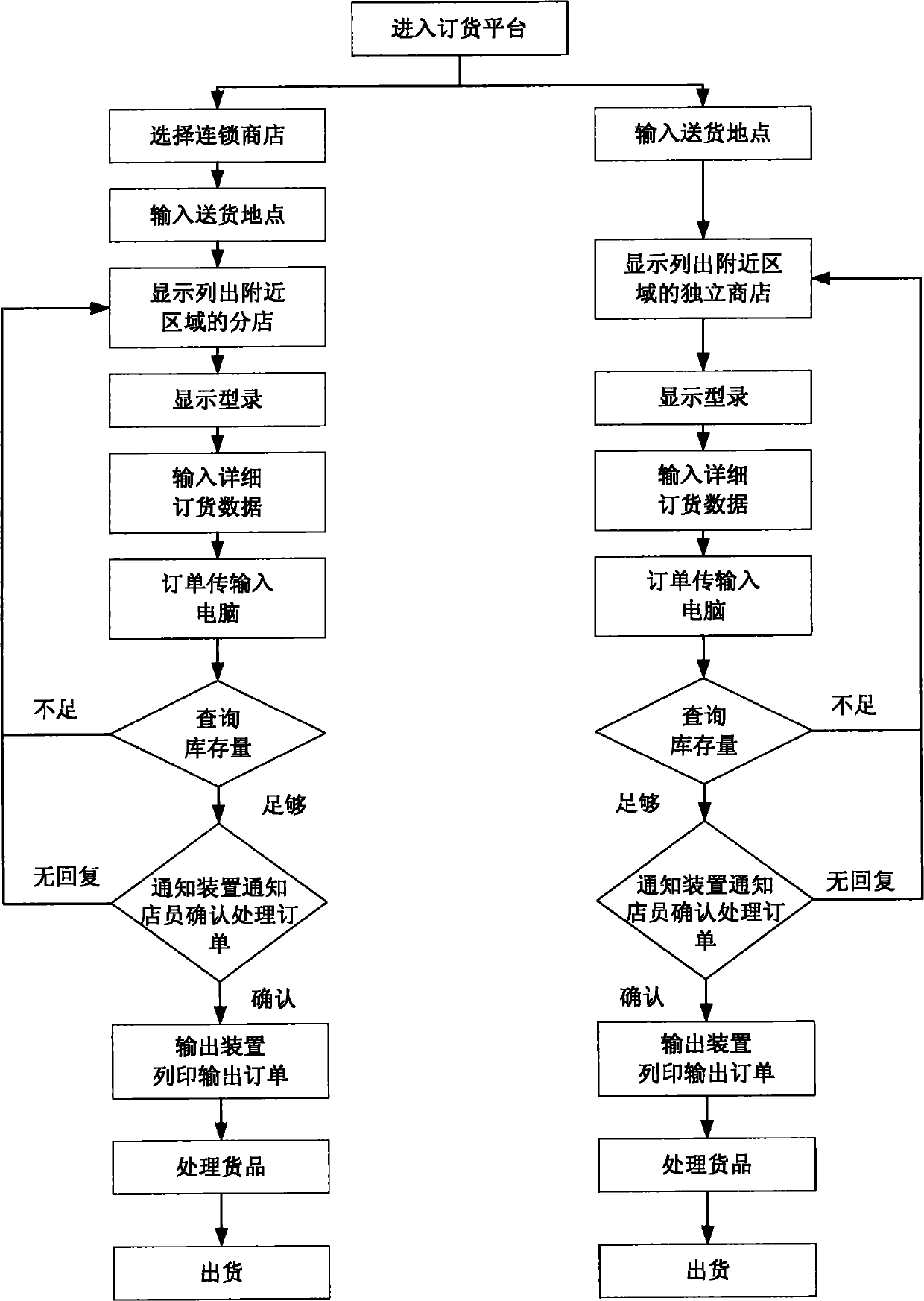

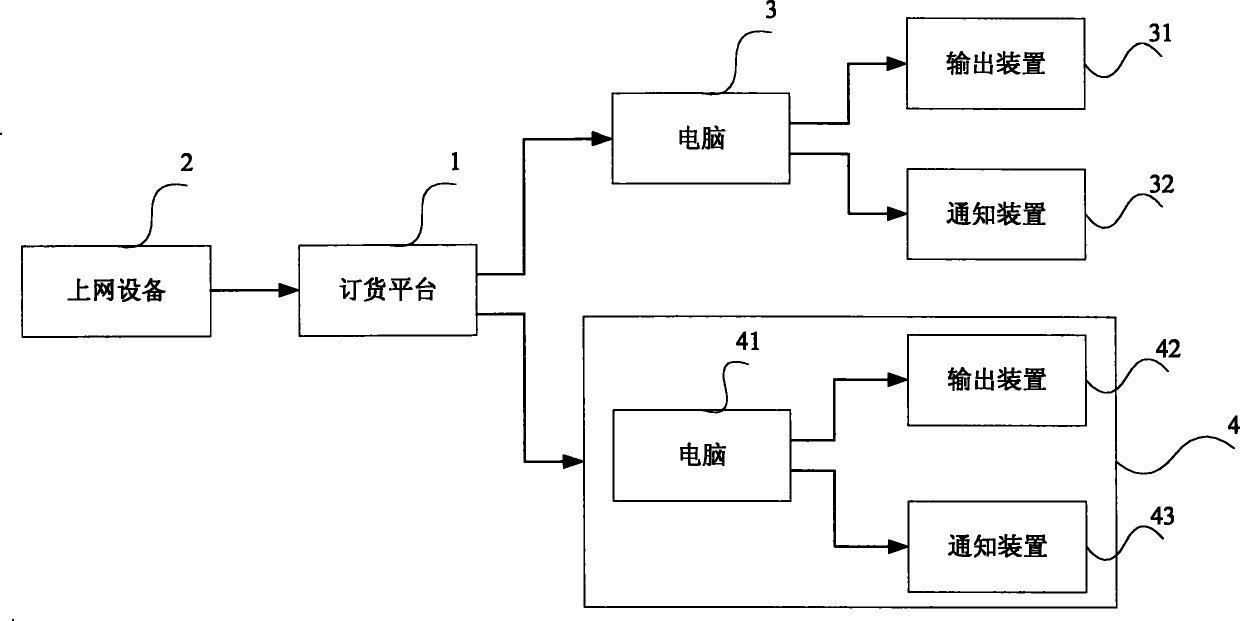

Online shopping delivery automatic ordering method

The invention discloses an online shopping delivery automatic ordering method. The method mainly comprises the following steps: a consumer enters an ordering platform through network connection to order a product; the ordering platform gives a list of independent stores or branch stores of chain stores near the delivery place of the consumer for consumer selection; the order data is transmitted to a computer in the selected store through the Internet for displaying; and a notice device sends out a signal to notify a shop assistance to deal with the order; each single ordering requirement data and delivery data of the consumer in the order are automatically printed and output; and after each product in the order is processed, the products are delivered according to the delivery data appointed by the consumer. Therefore, the consumer does not need to record data of the store, and can conveniently enjoy delivery service; misunderstanding condition occurring when people answer the telephone can be prevented, and time spending in ordering can be reduced.

Owner:吴凤瑞 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com