Device and method for detecting longitudinal tearing of large conveyor belt

A conveyor belt, longitudinal tearing technology, applied in the conveyor control device, conveyor, conveyor objects and other directions, can solve the problems of foreign body wear, longitudinal belt tearing, belt damage, etc., to facilitate maintenance and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, a device for detecting longitudinal tearing of large conveyor belts.

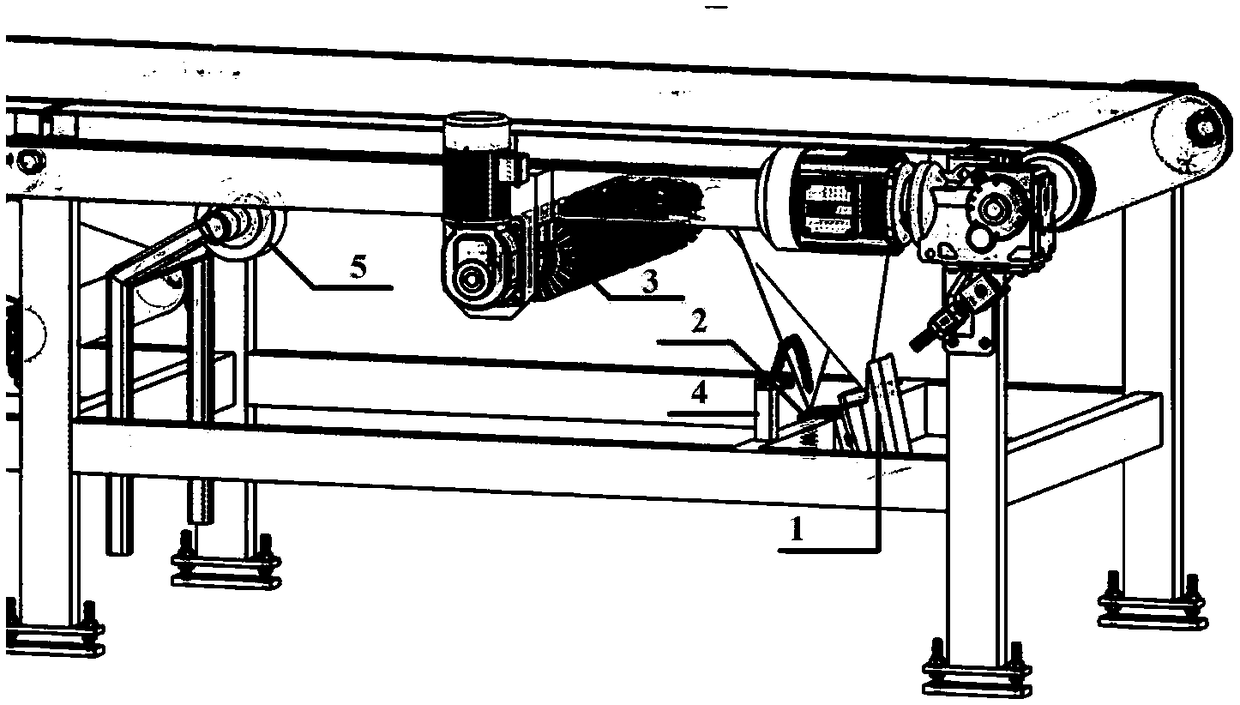

[0034] Such as figure 1 As shown, the device for detecting longitudinal tearing of large conveyor belts provided by the present invention includes an industrial camera 1, a line laser emitter 2, a brush 3, a dust removal air gun 4, a synchronous detection wheel 5, and a PC.

[0035] The industrial camera 1 is installed under the non-bearing surface of the conveyor belt, and the field of view of the camera covers the entire transverse span of the conveyor belt, and is used to collect images of the conveyor belt to be tested.

[0036] The line laser emitter 2 is installed under the non-bearing surface of the conveyor belt, and the line laser irradiated on the conveyor belt is in the field of view of the industrial camera, providing a reference line for tear detection.

[0037] Hairbrush 3 is installed on the upstream of the industrial camera along the direction of movement of the non-car...

Embodiment 2

[0039] Embodiment 2, a method for detecting longitudinal tearing of large conveyor belts.

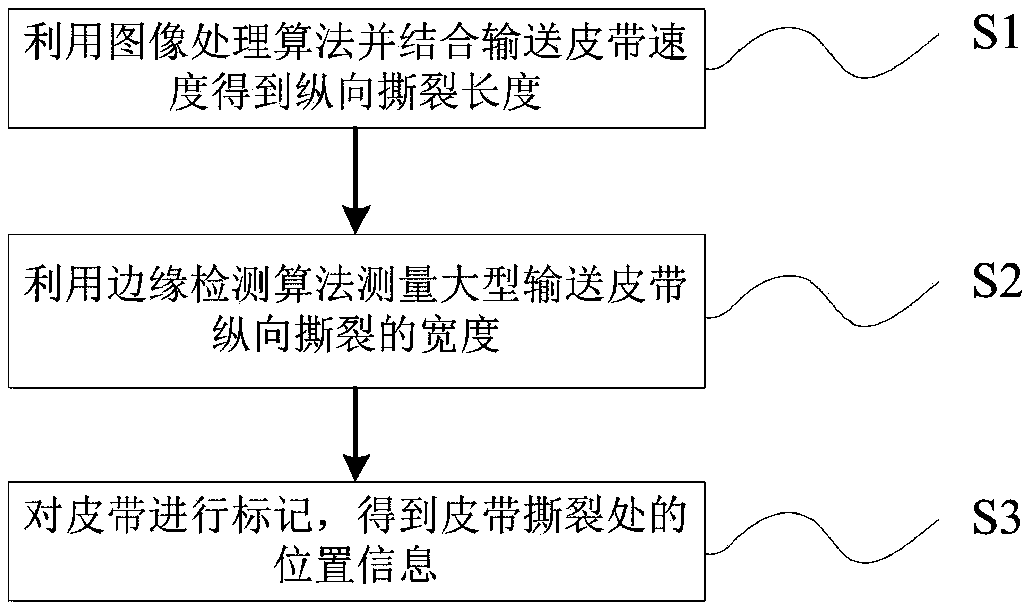

[0040] Such as figure 2 As shown, the method for detecting longitudinal tearing of large conveyor belts provided by the present invention includes the following steps:

[0041] S1. Obtain the longitudinal tear length by using an image processing algorithm combined with the speed of the conveying belt.

[0042] ① Use the Retinex algorithm to enhance the collected image of the non-bearing surface of the conveyor belt containing the laser line;

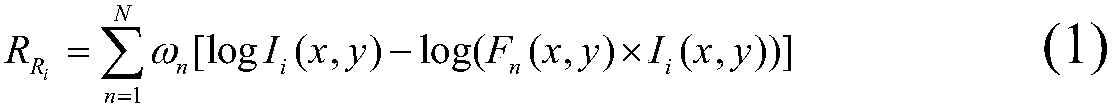

[0043] The advantage of the Retinex algorithm is that it can maintain the high fidelity of the image and compress the dynamic range of the image at the same time, and can also achieve color enhancement, color constancy, local dynamic range compression, and global dynamic range compression. Calculated as follows:

[0044]

[0045] In the formula, I i (x,y) is the i-th pixel of the original input image, F(x,y) is a Gaussian function, N is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com