Start-stop control system and control method of mine conveyer

A start-stop control and conveyor technology, which is applied in the direction of the conveyor control device, the conveyor object, the program control in the sequence/logic controller, etc. The effect of convenience, energy saving and simplified operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, but the required protection scope is not limited to the description;

[0026] The invention provides a start-stop control system and a control method of a mine conveyor;

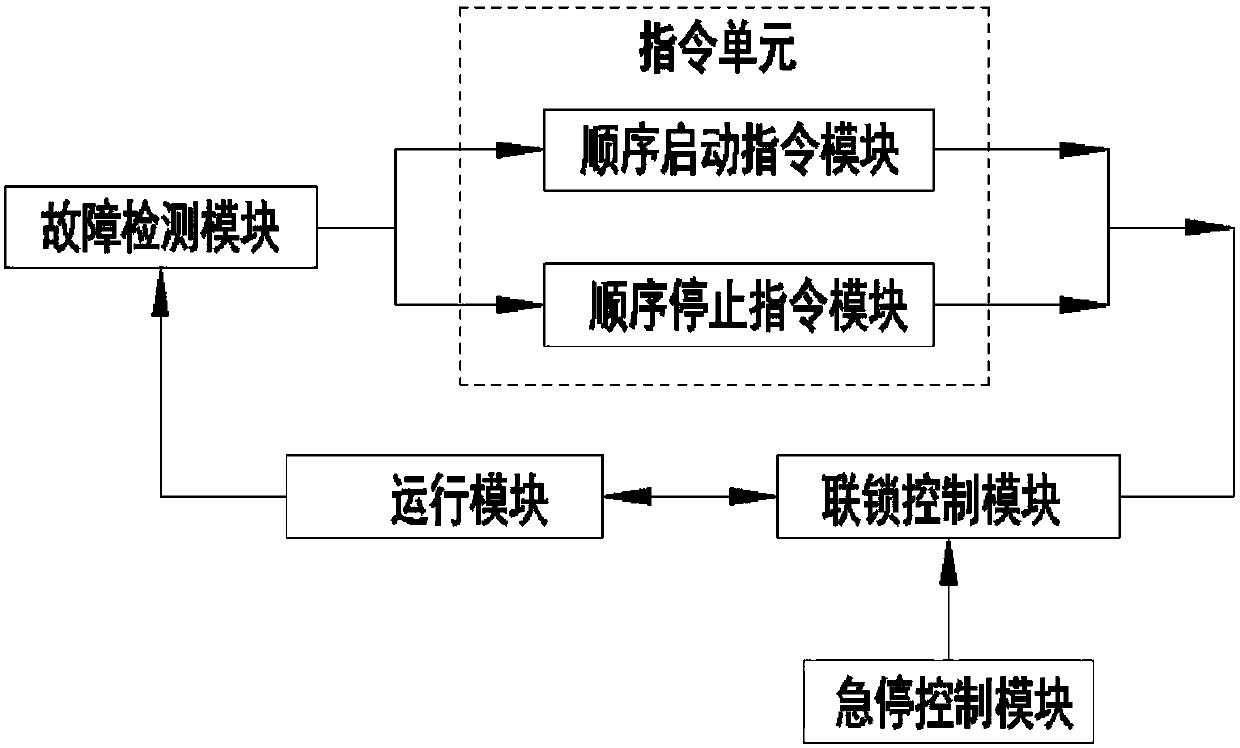

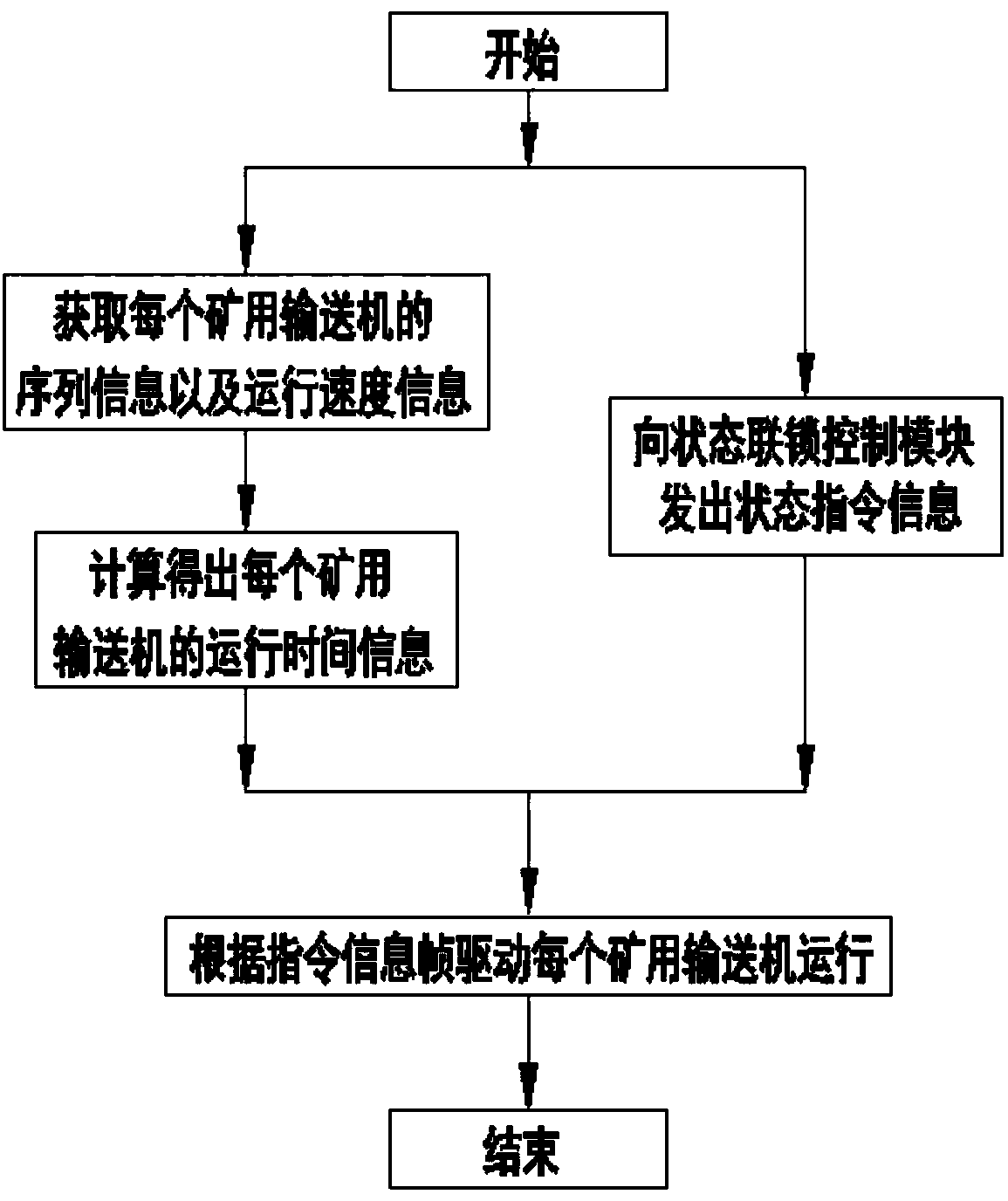

[0027] Such as figure 1 , figure 2 As shown, the start-stop control system of the mine conveyor includes a command unit, an interlock control module and an operation module, the interlock control module is connected to the operation module in two-way communication, and the output end of the command unit is connected to the The input terminal connection of the interlock control module;

[0028] Command unit: used to send status command information to the interlock control module;

[0029] Interlocking control module: used to obtain the sequence information and running speed information of each mining conveyor, combined with the status command information from the command unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com