Steel plate surface treatment device and steel plate surface treatment method

A surface treatment device and steel plate technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve the problems of industrial wastewater polluting the environment and occupying a large area, so as to avoid pollution and occupy an area Small area, the effect of ensuring production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

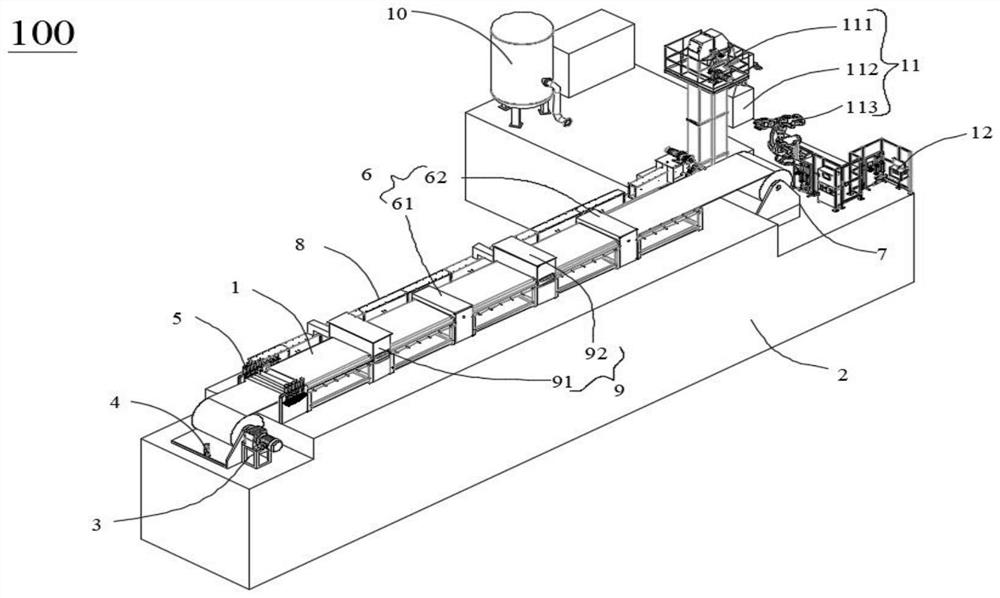

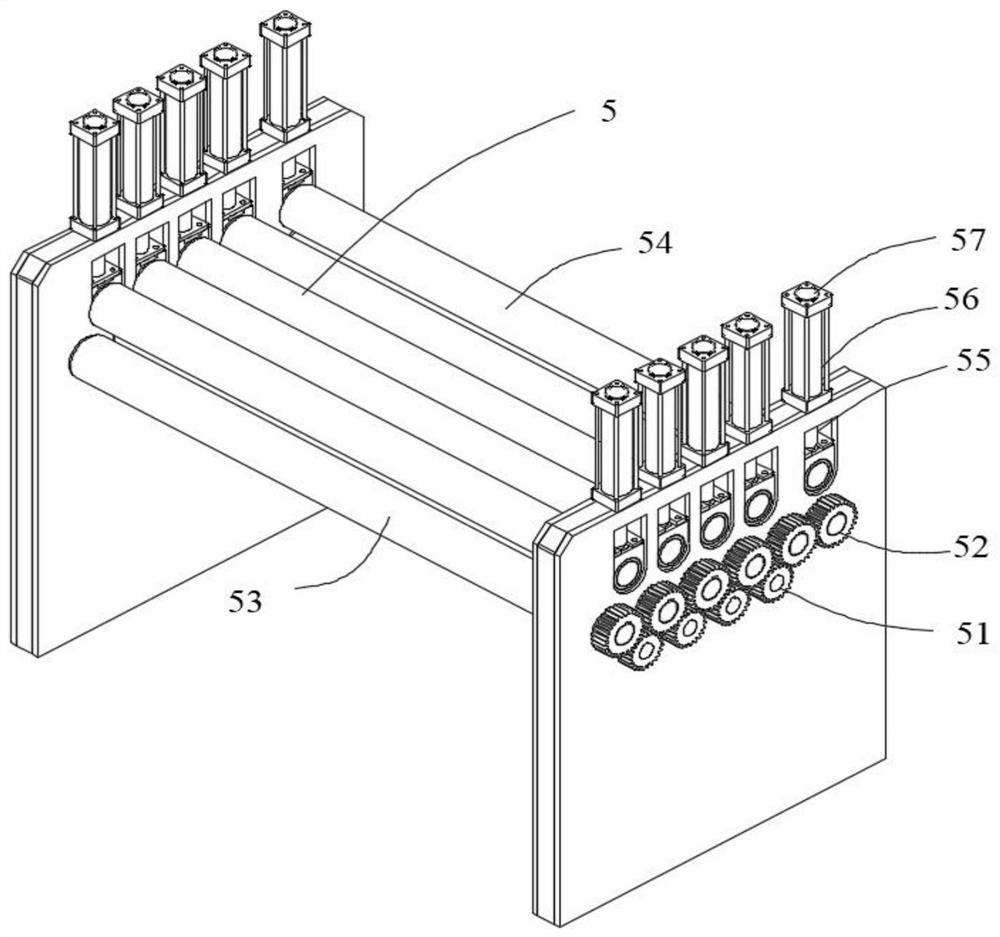

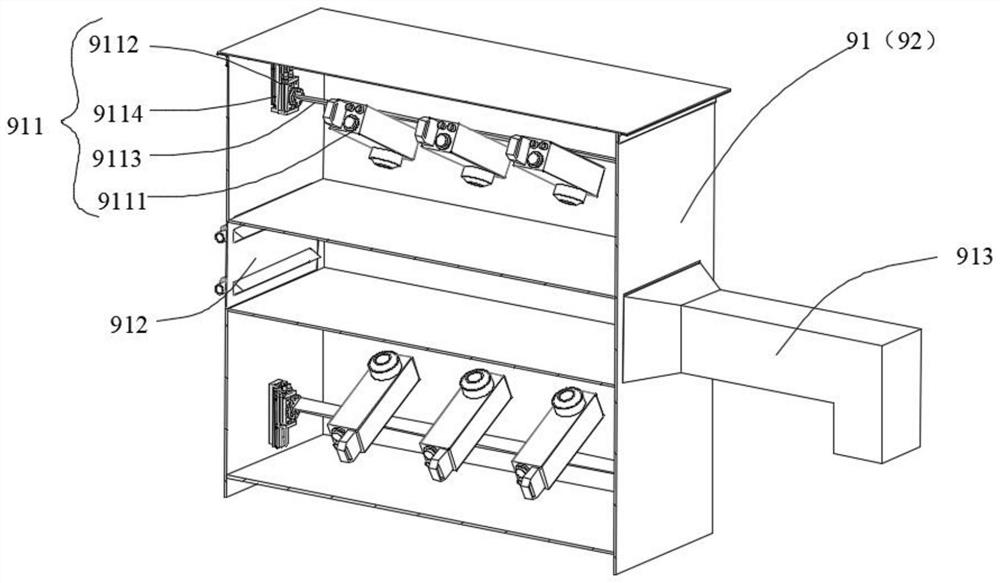

[0035] Such as figure 1 As shown, the present invention discloses a steel plate surface treatment device 100 for removing metal oxides on the steel plate surface, including a frame 2 and a feeding device 3 arranged on the frame 2, a monitoring device 4, and a roller plate device 5 , a cleaning device 6 and a blanking device 7, and also includes a scraper dust removal device 8, a laser double-sided cleaning device 9, an air source supply device 10, an oxidation waste treatment device 11, a control device 12 and a safety protection device 13.

[0036] The feeding device 3 is used to feed the steel plate 1 into the steel plate surface treatment device 100, which includes a roller. After the steel plate 1 is installed on the feeding device 3, the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com