Coke oven head and tail coke unmanned transfer control system

A control system, head and tail coke technology, applied in the coke oven field, can solve the problems of low efficiency, inability to achieve high automation of equipment, unsafe, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

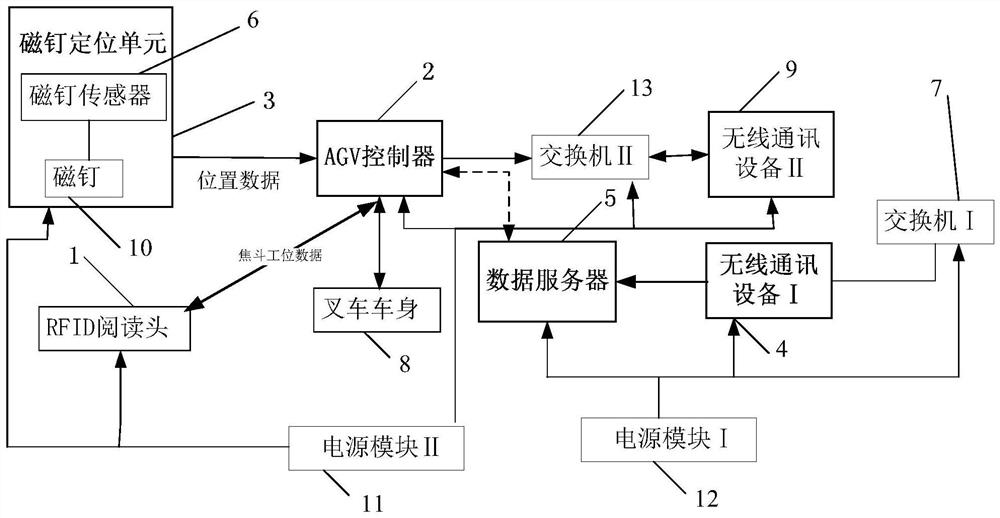

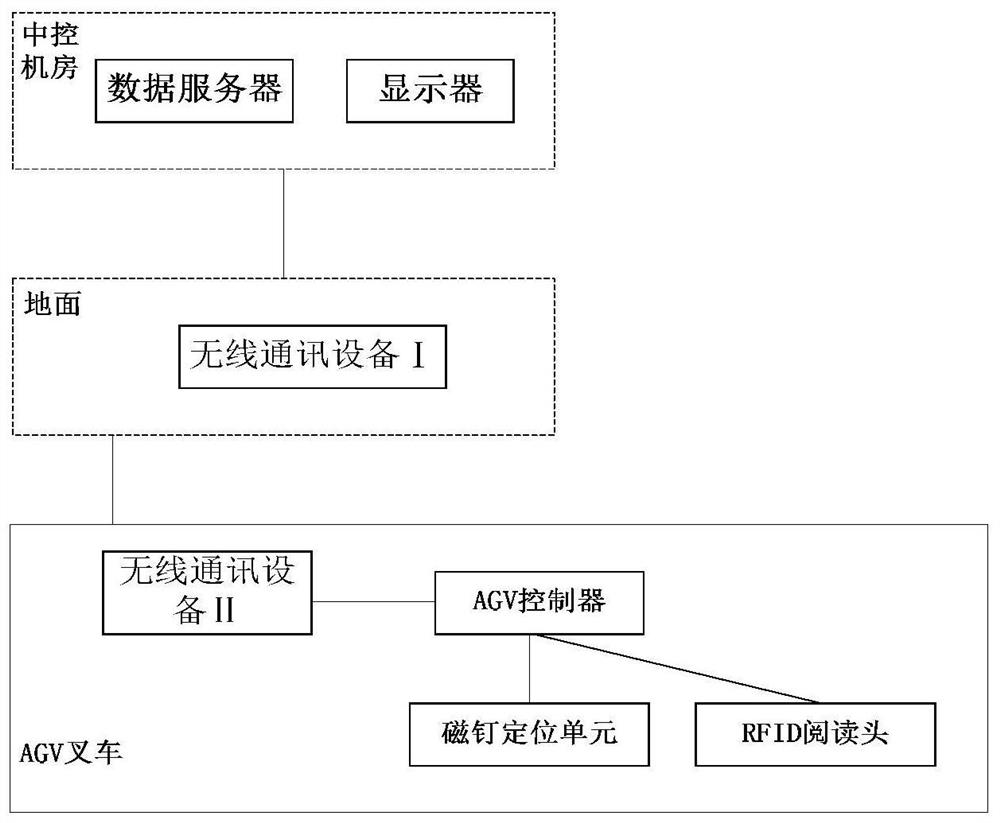

[0023] figure 1 It is a schematic diagram of the unmanned coke transfer control system on the ground of the coke oven, an unmanned transfer control system of the coke oven head and tail, including: RFID reading head 1, AGV controller 2, magnetic nail positioning unit 3, wireless communication equipment Ⅰ 4 , data server 5, switch I7, forklift body 8, wireless communication equipment II9 and switch II13, power module I12 and power module II11;

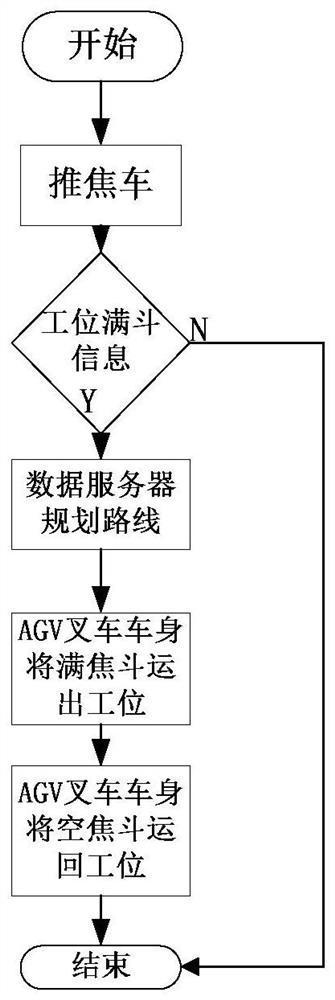

[0024] The data server 5 receives the station signal that the coke pushing car detects that there is a head and tail coke bucket full of coke, and plans the route to the head and tail coke bucket full of coke;

[0025] The AGV controller 2 receives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com