Special manipulator for producing shoe heels

A technology of manipulators and heels, applied in the field of shoes, can solve problems such as inability to complete mass production, hinder the development speed of factories, and high labor intensity of workers, and achieve the effects of convenient and quick adjustment, increased management difficulty, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

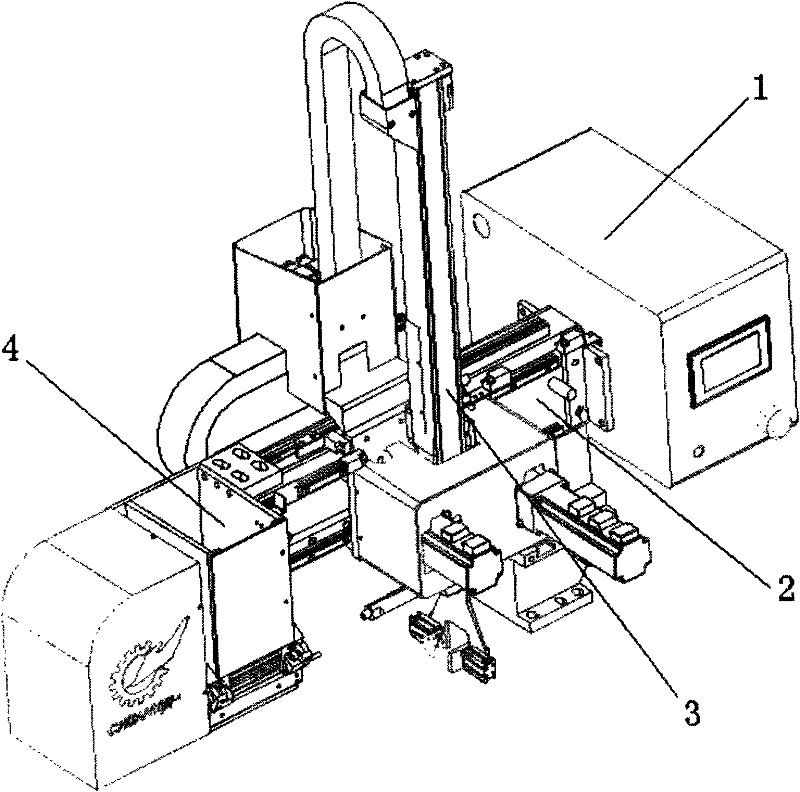

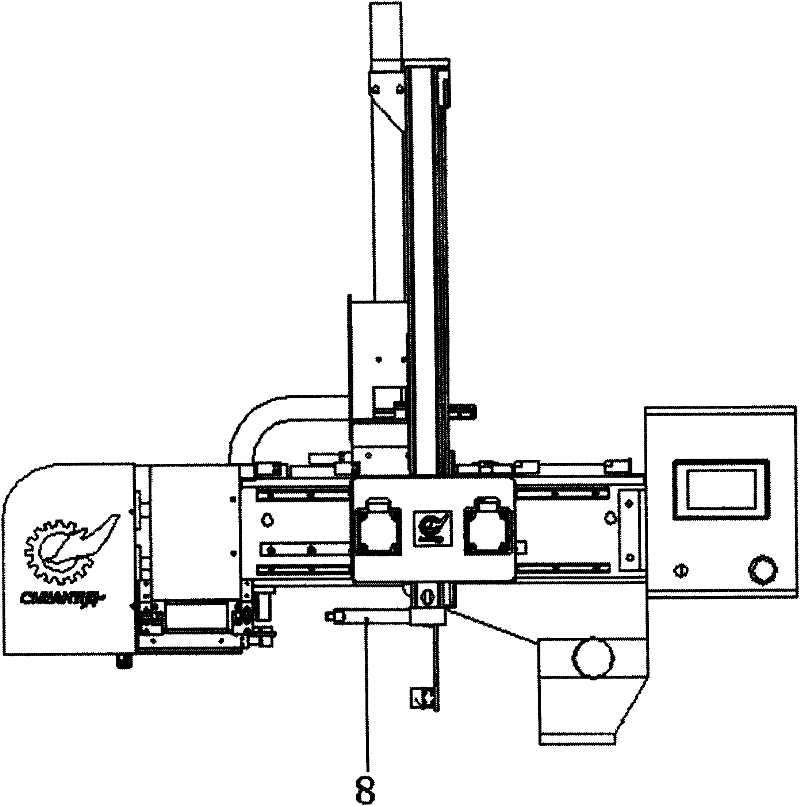

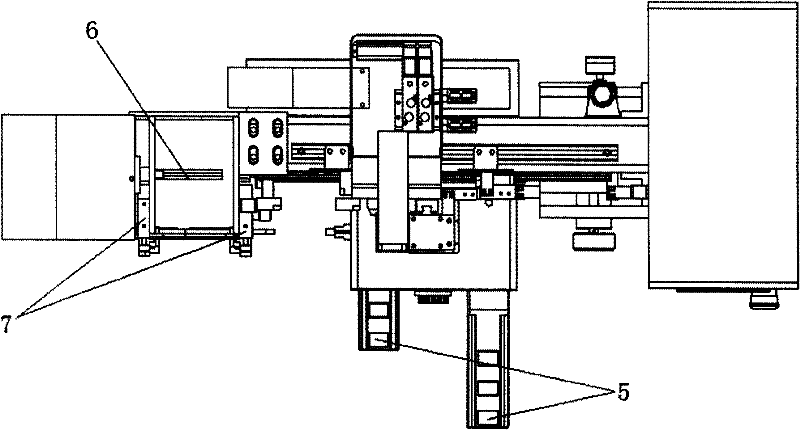

[0025] Such as figure 1 , figure 2 , image 3 As shown, the special manipulator for heels mainly includes an electric control system 1 , a drawing arch 2 , an arm 3 and a needle box 4 . After turning on the air switch and starting the machine, click on the touch screen of the electronic control system 1 to select automatic, the arm 3 goes down to the standby point, and the needle pushing cylinder 7 drives the needle pushing plate to run twice to adjust the position of the inlaid needle 6 in the needle box 4, and then the arm 3 guides the Pull forward to make the needle cylinder 8 close to the needle outlet position of the needle box 4, the thimble cylinder 10 starts to move, and sends the inlaid needle 11 in the needle box 4 to the needle cylinder 8, the arm 3 starts to retreat, and the mold opening action of the injection molding machine is completed, and the arm 3 After descending, the arm 3 moves forward to the position of the product. After the arm 9 hugs the product, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com