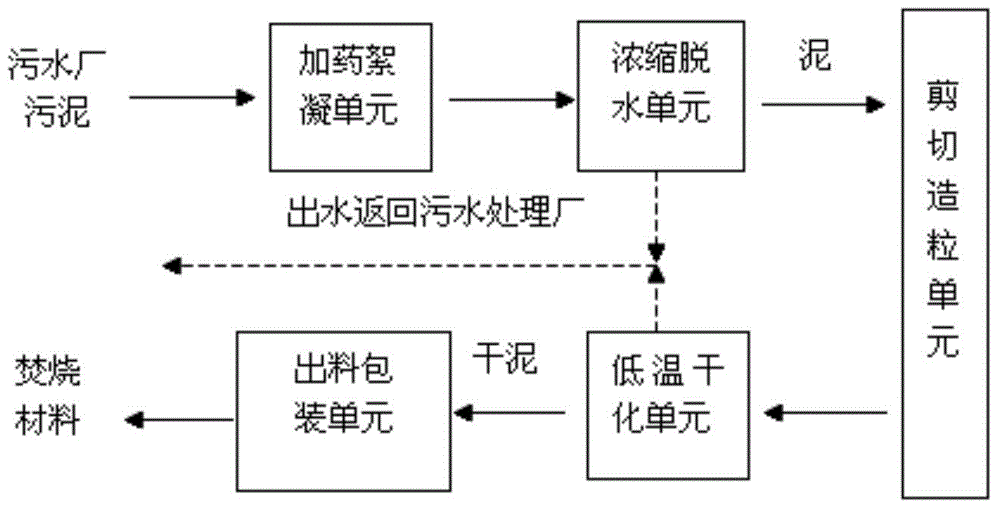

Low-temperature sludge drying treatment system and technology

A treatment system and treatment process technology, applied in the low temperature drying treatment system, sludge treatment system and process field, can solve the problems of not meeting the environmental protection requirements of sludge volume, dust environment pollution, high operating cost, and reaching the floor area. Small, high degree of equipment, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

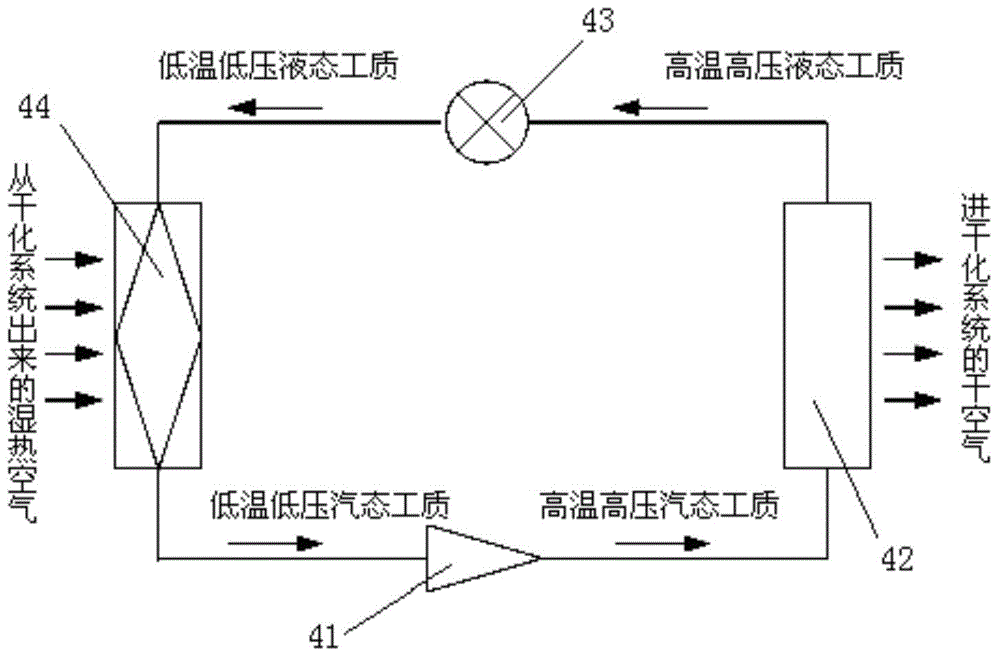

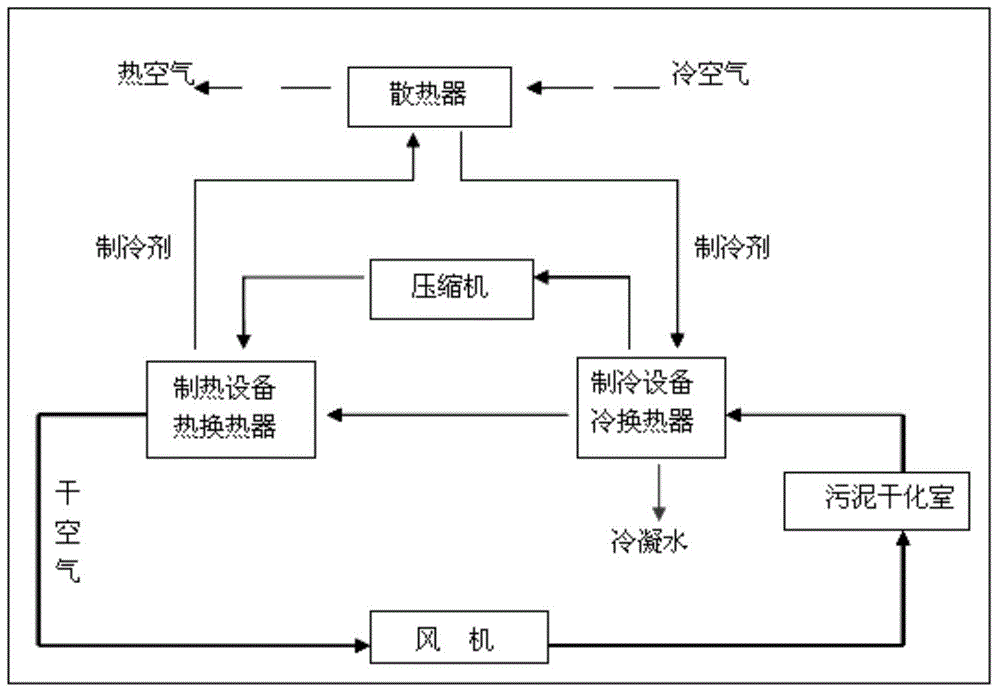

Embodiment 1

[0039] Using the above-mentioned low-temperature sludge drying treatment system and process, the sludge with a moisture content of 98% produced in a sewage treatment plant is treated, and the treatment capacity is 75 tons per day. Among them, the volume of the flocculation tank is 10m 3 The model of the stacked screw sludge dewatering machine is MDQ-204, the installation size is 2800×2100×2050mm, and the power is 2.35kw. The main body of the sludge low-temperature drying machine is a drying box, which is connected to the heat pump and the fan in a closed manner. The overall size of the box is 1200×2400×1800mm, the internal network bandwidth is 1.2m, and the length is 6m. The maximum treatment capacity of dry sludge is 100kg / h, the total power is 50kw, and the total power of the vacuum discharge packaging machine is 2.1kw.

[0040] The low-temperature sludge drying process is as follows: 1) The sludge with a moisture content of 98% is pumped into the flocculation tank of the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com