Screening device capable of vibrating parallel to screen plate and efficient screening method

A screening device and sieve plate technology, which is applied in the field of screening device, high-efficiency screening, and selection and classification of long-shaped particles, can solve the problem that it is difficult to meet the requirements of efficient screening and accurate screening of long-shaped particles, etc. problems, to achieve the effect of convenient continuous and stable feeding and receiving, improving screening efficiency and high-efficiency screening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

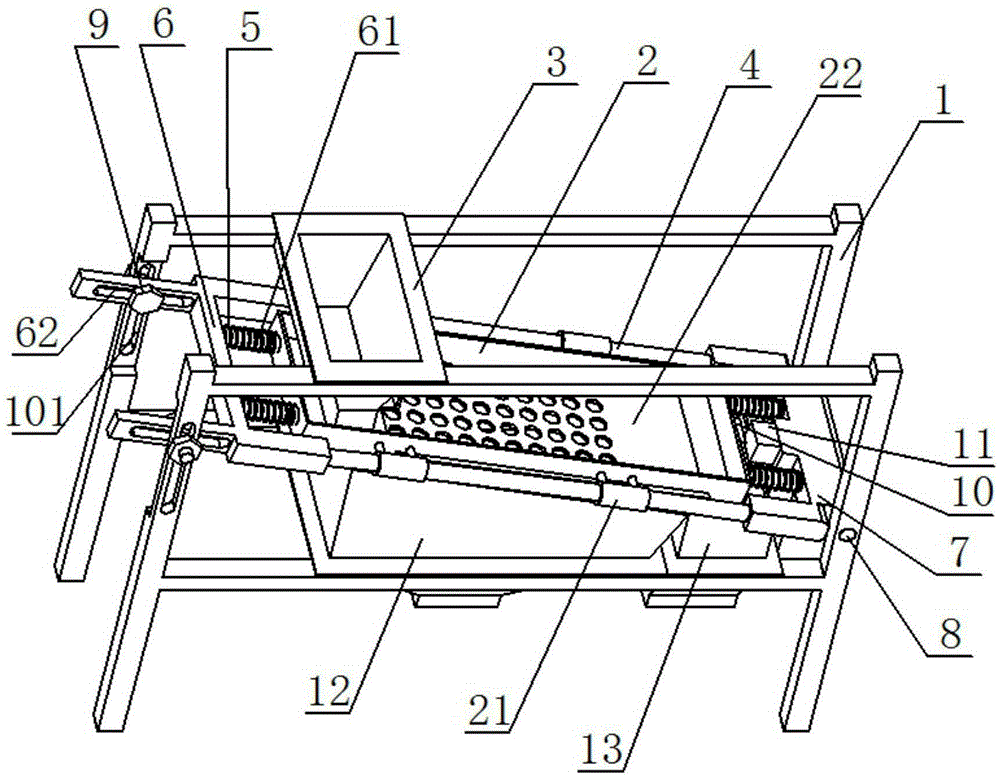

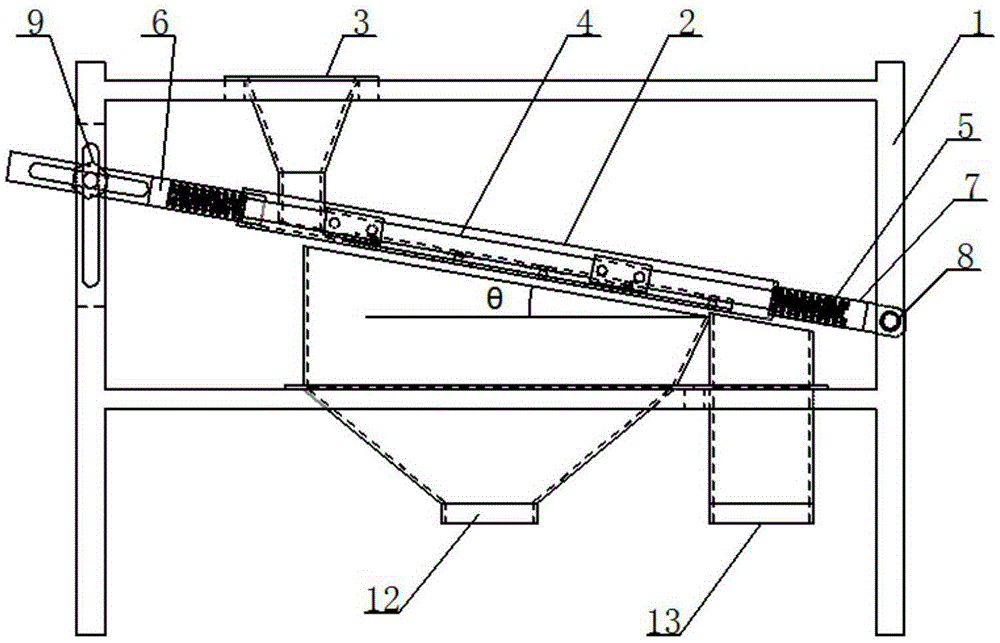

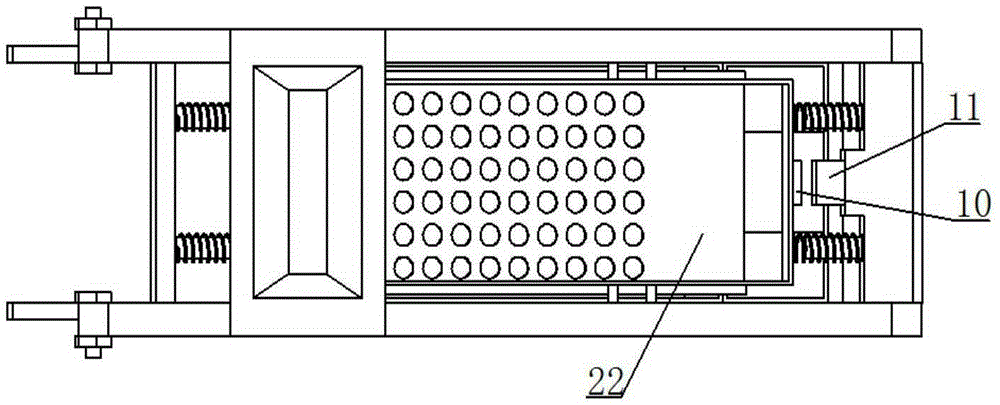

[0040] Such as figure 1 As shown, a vibrating screen with high-precision vibration is mainly composed of a main support 1, a screen box 2, a movable frame 1 7, a movable frame 2 6, a guide rod 4, an electromagnet 10, an excitation coil 11, a spring 5, and a positioning bolt 9 , long pin 8, feed funnel 3, undersize material receiving funnel 12, and oversize material receiving funnel 13 to form.

[0041] Such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, the movable frame one 7 is mounted on the hole 102 of the main bracket 1 through the long pin 8 and the pin hole 71; the movable frame one 7 has threaded holes 72 , threaded hole 63 is arranged on described movable frame two 6, is threadedly connected the threaded hole 72 of described movable frame one 7 and the threaded hole 63 of movable frame two 6 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com