Un-pressed part detection device for conical roller bearing

A technology of tapered roller bearing and detection device, applied in the field of bearings, can solve the problems of small size, influence of the assembly of the main engine of the automobile, large processing batch, etc., and achieve the effect of reducing operating costs and avoiding product supply risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The patent of the present invention is described in conjunction with accompanying drawing and specific embodiment:

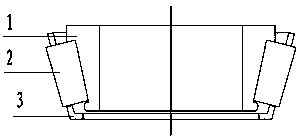

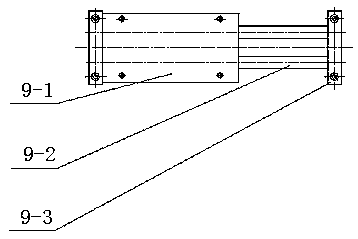

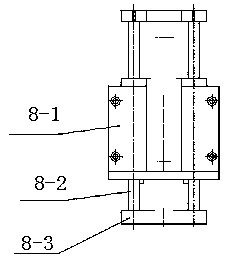

[0020] combine Figure 5 , a tapered roller bearing unpressed parts detection device, the detection device has a bottom plate 7 fixed on the upper side of the bearing conveyor belt; the bottom plate 7 is fixed with a cylinder I9 for the detection device to move left and right and for the detection device to move up and down Cylinder II 8; Combined figure 2 , the cylinder I9 is located on one side of the bottom plate 7, and the cylinder I9 has two bases I9-3; the two bases I9-3 are connected as a whole by two horizontal guide rods I9-2 ; The two guide rods Ⅰ 9-2 are sleeved with a cylinder block Ⅰ 9-1 that can move horizontally along them; image 3 , the cylinder body II 8-1 of the cylinder II is fixed on the cylinder body I9-1; the cylinder body II is sleeved on two guide rods II8-2 symmetrically arranged on the left and right; the guide rod II8- 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com