An automatic crushing and screening device for port chemical ore inspection

A screening device and automatic technology, which is applied in measuring devices, sieves, chemical instruments and methods, etc., can solve problems such as difficulty, difficulty in screening ore of different specifications, and unfavorable ore screening work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

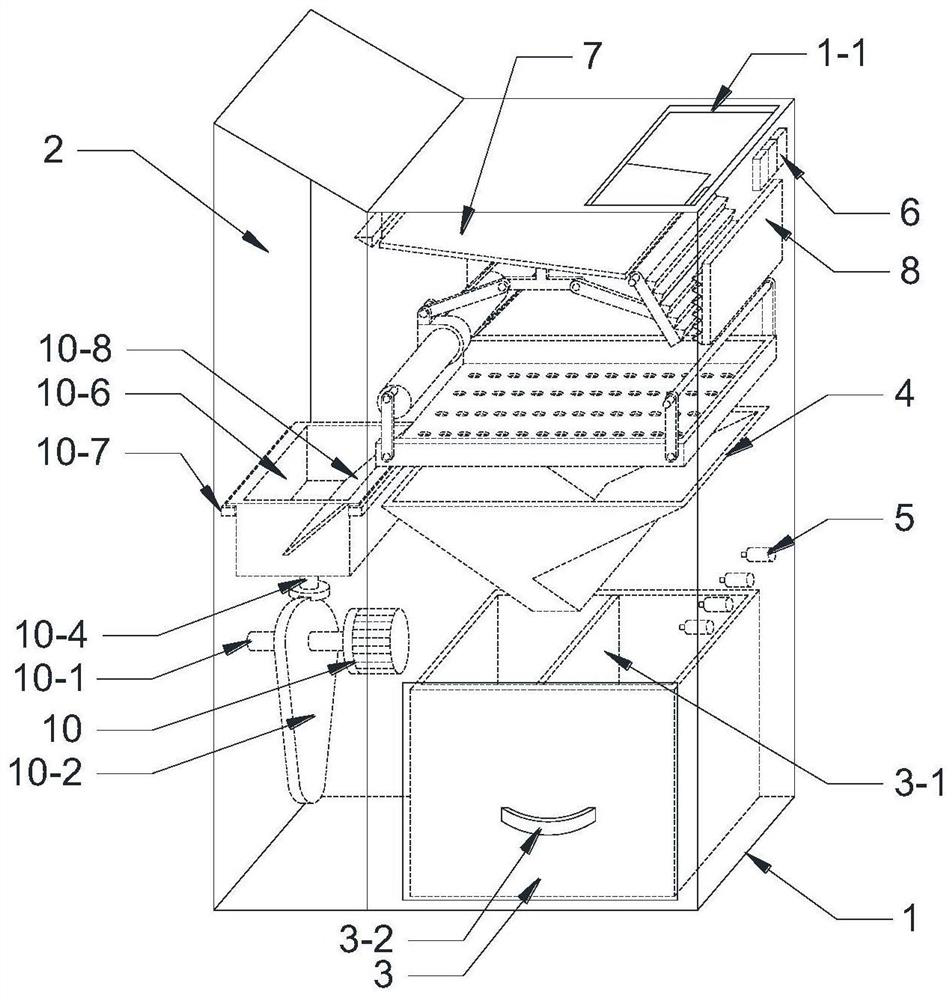

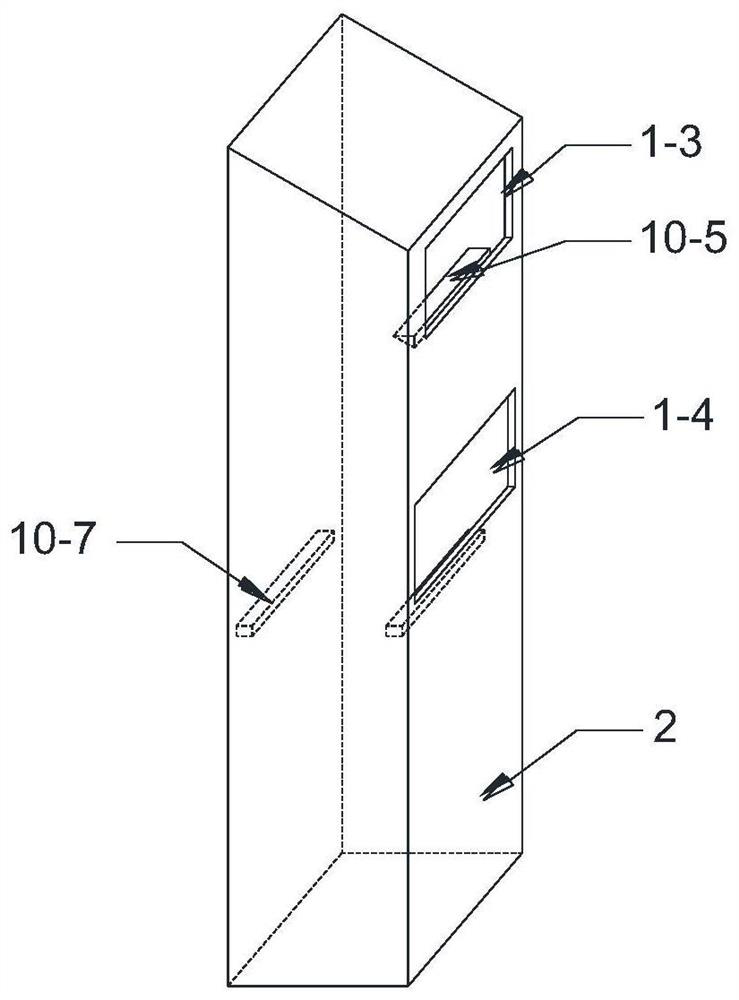

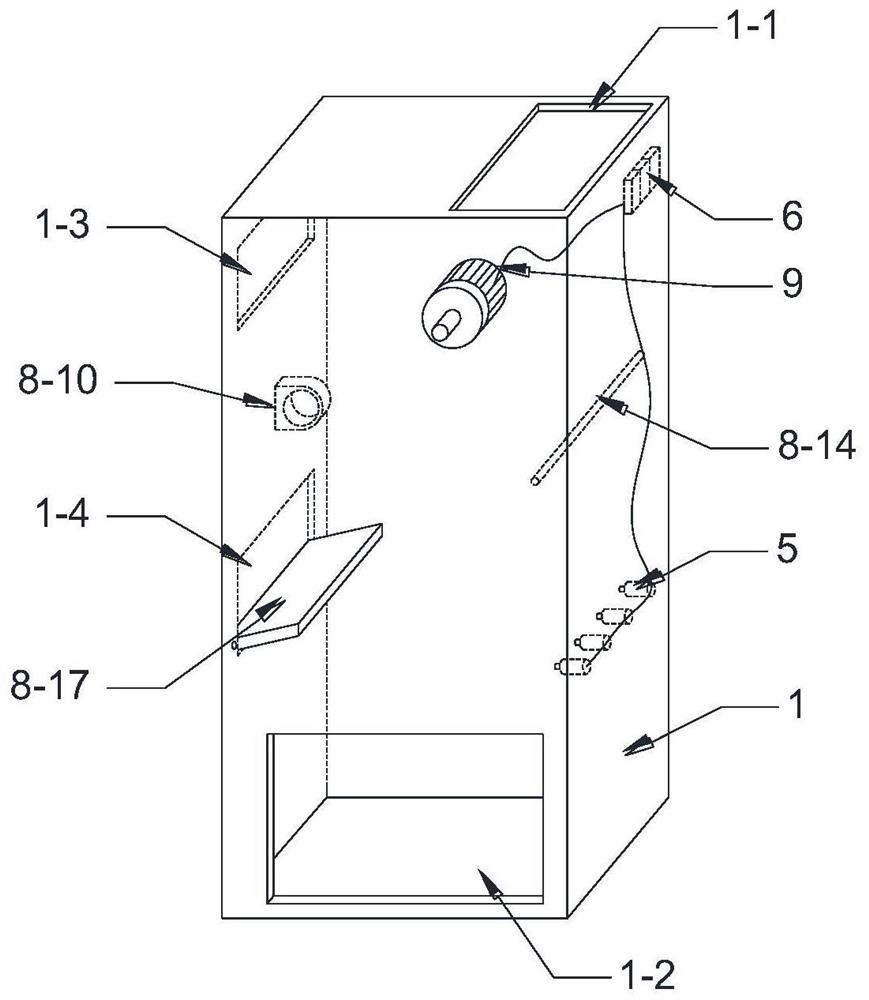

[0017] Attached below Figure 1-7 The present invention is described in detail below.

[0018] Such as Figure 1-7As shown, the present invention includes a first box body 1, a second box body 2, a first material storage box 3, a funnel 4, an automatic crushing and screening device and a pushing device, and the upper right end of the first box body 1 is provided with a first inlet The material port 1-1 and the lower part of its front end are provided with the first discharge port 1-2, the left end of the first box body 1 is fixedly connected with the second box body 2, and the fixed joints of the two are sequentially provided with the first box body 2 from top to bottom. The second feed port 1-3 and the second discharge port 1-4, the lower right end of the second feed port 1-3 is inclined downward at 30 degrees and is fixedly connected with a baffle plate 7 and the front and rear ends of the baffle plate 7 are connected to the first A box body 1 is fixedly connected to ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com