Accurate feeding apparatus and method for low-pressure post-mixed type micro abrasive jet

A post-mixing and abrasive jet technology, which is applied in the direction of abrasive feeding devices, used abrasive processing devices, abrasives, etc., can solve the problems of inability to achieve accurate abrasive feeding and difficulty in inhaling fine abrasives, and achieve feeding The effect of continuous and stable process and convenient automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

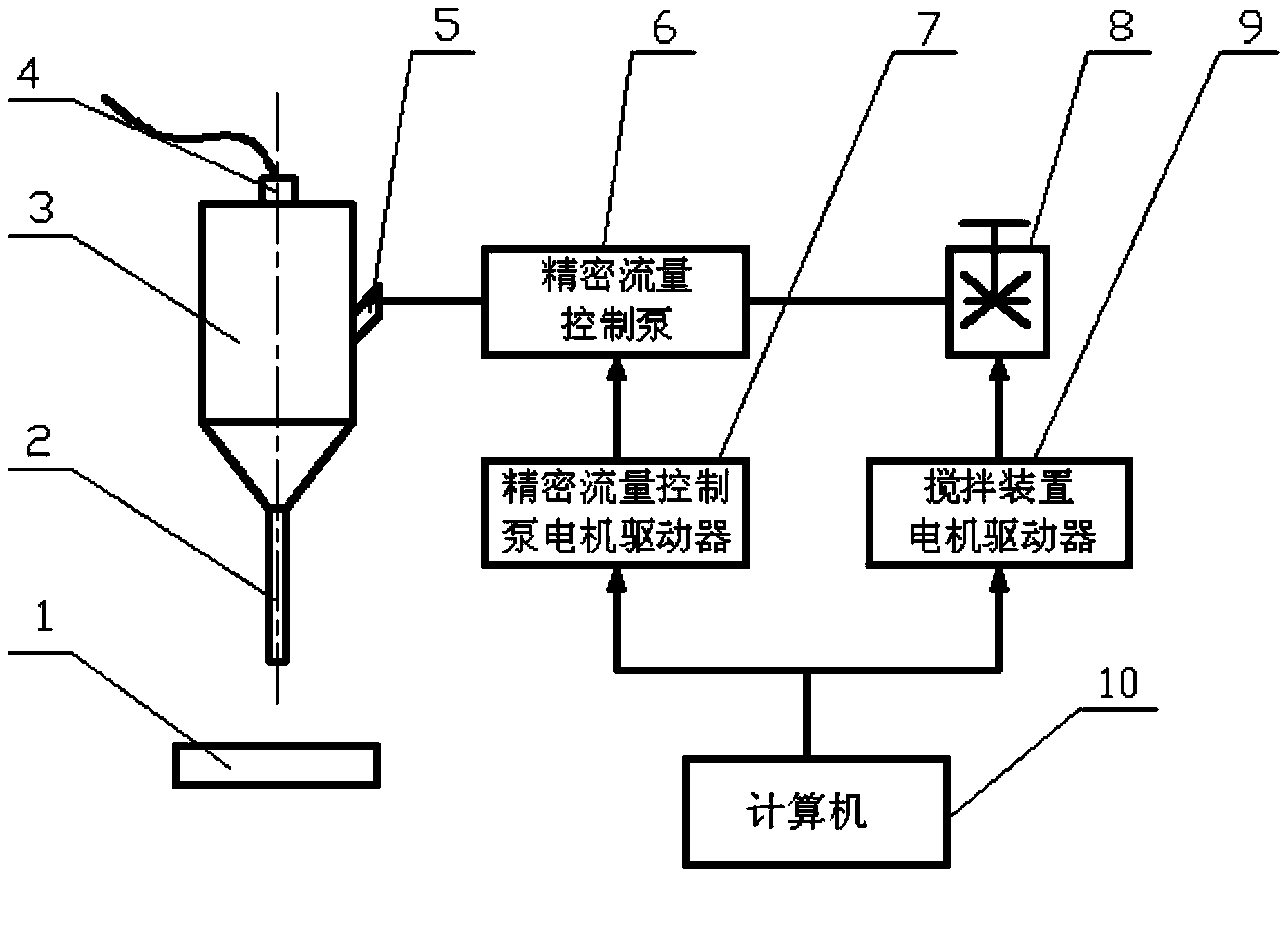

[0022] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the low-pressure post-mixing fine abrasive jet precision feeding device described in this embodiment includes a post-mixing injection device, a precision flow control pump 6, a precision flow control pump motor driver 7, an abrasive mixed liquid stirring device 8, Stirring device motor driver 9 and computer 10,

[0023] The post-mixing injection device has a nozzle 2, a post-mixing chamber 3, a working fluid inlet 4 and an abrasive mixed liquid inlet 5;

[0024] The nozzle 2 provided at the lower end of the post-mixing injection device faces the upper surface of the workpiece 1, the upper end of the post-mixing injection device is provided with a working fluid inlet 4, and the interior of the post-mixing injection device is provided with a post-mixing chamber 3. The side wall is provided with an abrasive mixed liquid inlet 5, and the abrasive mixed liquid inlet 5 communicates...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment further describes Embodiment 1, and the precision flow control pump 6 is a peristaltic pump.

[0031] With such a setting, the precise control of the input flow rate of the peristaltic pump can be conveniently realized by controlling the speed of the peristaltic pump, and the peristaltic pump isolates the abrasive mixed liquid from the pump body through the pipeline during the feeding process, avoiding the impact of the external environment on the abrasive mixed liquid. pollution.

specific Embodiment approach 3

[0032] Embodiment 3: Based on the method of the low-pressure post-mixing fine abrasive jet precision feeding device described in Embodiment 1, the method includes the following steps:

[0033] Step 1. Prepare abrasive mixed liquid with fine abrasives and working liquid medium, and inject the abrasive mixed liquid stirring device 8 for stirring, so that the abrasive and the working liquid medium are evenly mixed, and the concentration of the abrasive mixed liquid is controlled at 50g / L-300g / between L;

[0034] Step 2, turn on the precision flow control pump 6;

[0035] Step 3: Control the speed of the precision flow control pump 6 through the computer 10, so that the speed of the precision flow control pump 6 is controlled between 50 rpm and 600 rpm;

[0036] The stirring speed of the abrasive mixed liquid stirring device 8 is controlled by the computer 10, and the stirring speed of the abrasive mixed liquid stirring device 8 is controlled between 50 rpm-300 rpm;

[0037] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com