Rotary feeding pulverized coal quantitative feeding and conveying device and method

A technology of rotating feeding and conveying device, applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problems of unstable conveying and low precision, and achieve convenient operation, simple control, and prevention of bridging and blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

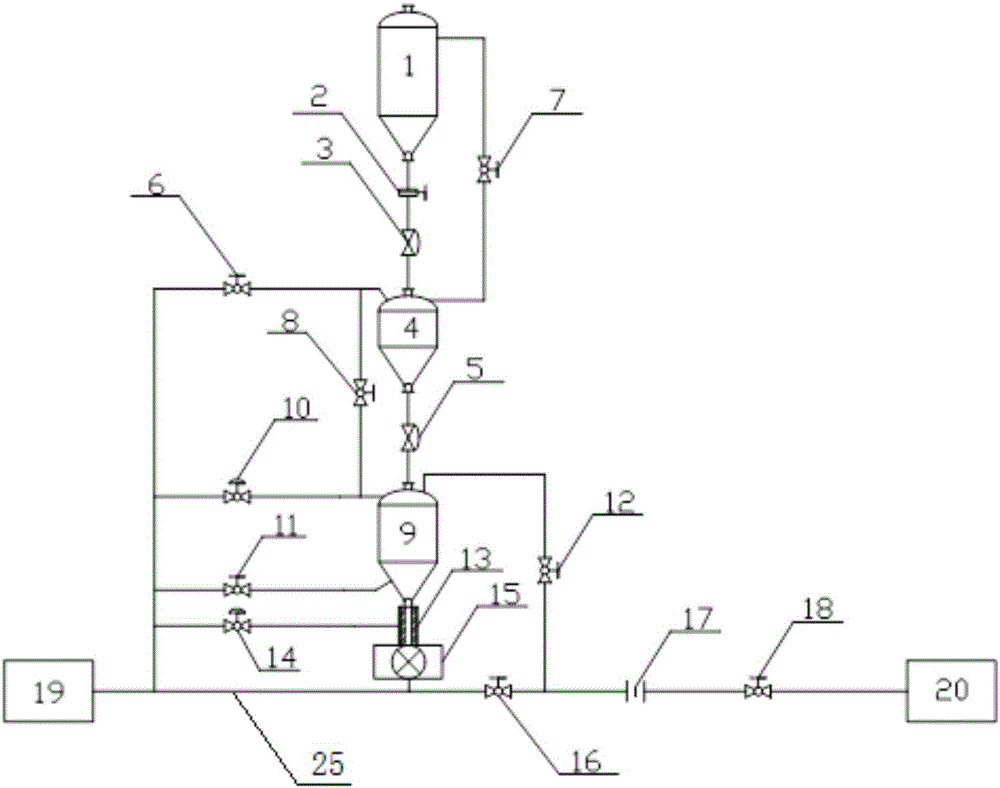

[0029] see figure 1 , the device of the present invention mainly includes three parts: a lock hopper feeding system, a pressurized feeding system and a pneumatic conveying system. Feeder 15, pulverized coal flow meter 17, gas source system 19 and related control valves.

[0030] The coal hopper 1 is a normal pressure equipment, the lower part of the coal hopper 1 is connected with the lock hopper 4 through the gate valve 2 and the feed wear-resistant disc valve 3, and the lower part of the lock hopper 4 is connected with the feed hopper 9 through the discharge wear-resistant disc valve 5, and the feeding The lower part of the hopper 9 is directly connected with the pulverized coal looser 13, the lower part of the pulverized coal looser 13 is connected with the pressurized feeder 15, the pressurized feeder 15 is connected with the delivery pipeline 25, one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com