Automatic loading method and device, storage medium and automatic loading control device

An automatic feeding and control device technology, which is applied in the direction of manufacturing tools, welding equipment, laser welding equipment, etc., can solve the problems of machine tool shutdown, feeding system feeding failure, etc., to ensure continuous processing and reduce the limit of the orientation state , Improve the effect of feeding success rate and feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

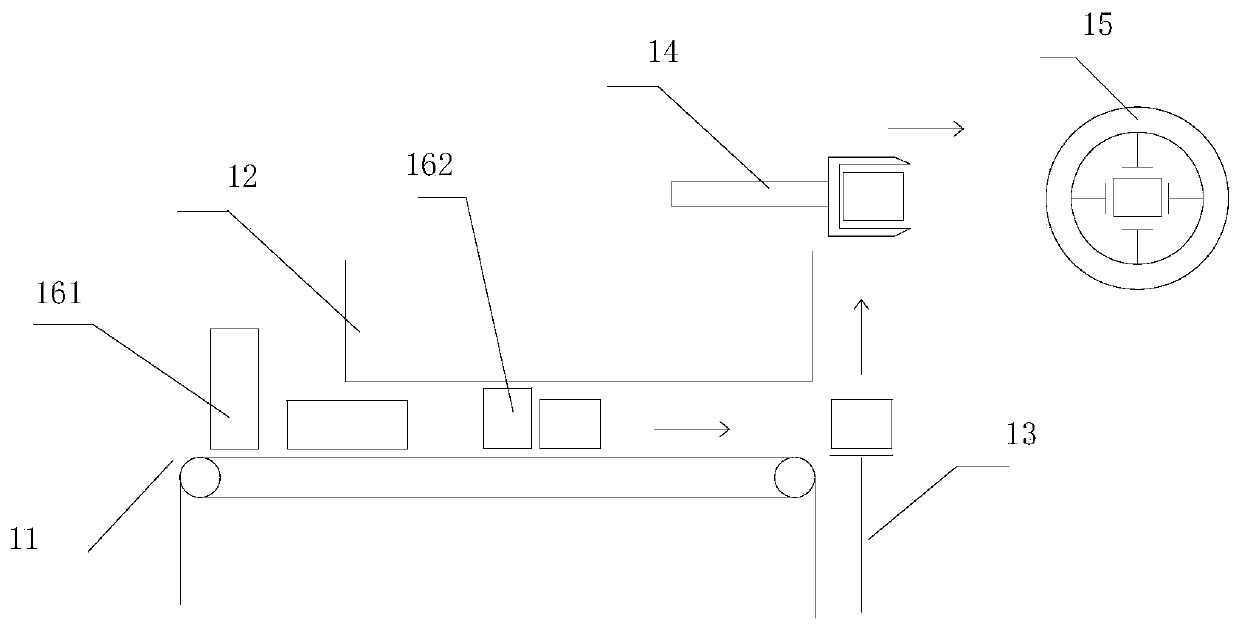

[0024] The embodiment of the present application provides an automatic feeding device, such as figure 1 As shown, the automatic feeding device includes: a transmission mechanism 11, a material distribution mechanism 12, a material lifting mechanism 13, a feeding mechanism 14, a machine tool ( figure 1 Not fully shown in, 15 is machine tool chuck), automatic feeding control device ( figure 1 Not shown in) and the measuring sensor ( figure 1 not shown), the automatic feeding control device is connected to the measuring sensor and the machine tool, and the measuring sensor is used to detect the opening of the clamping device on the feeding mechanism;

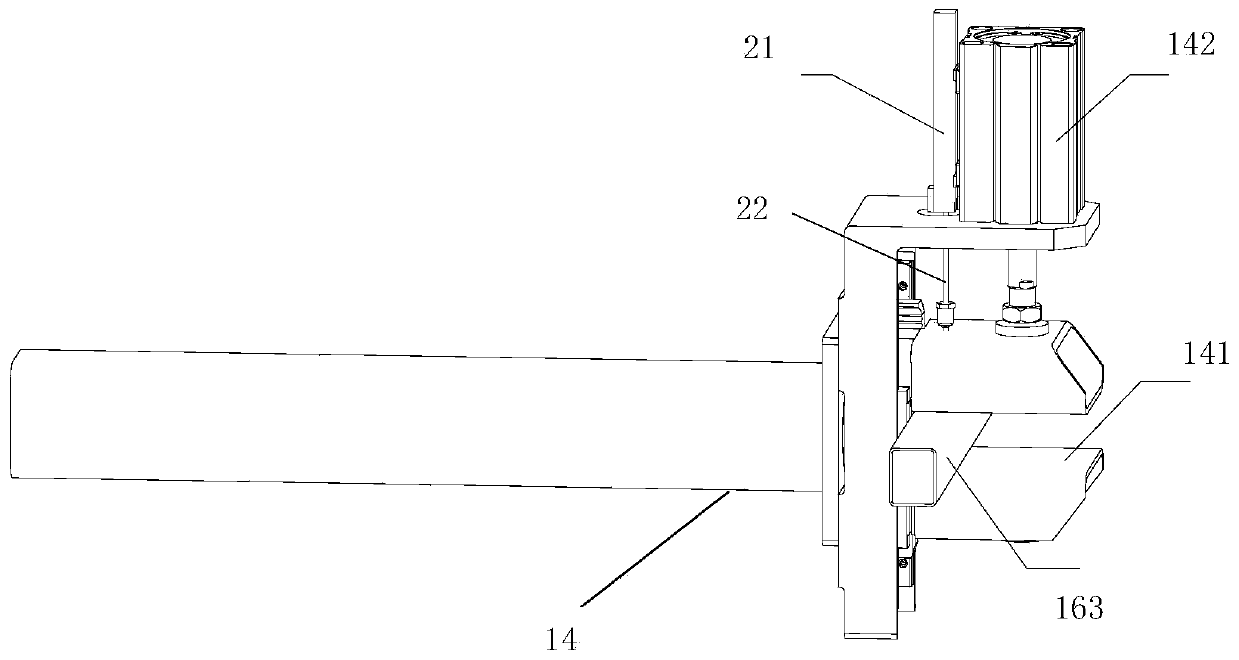

[0025] The transmission mechanism 11 is used to transport materials; the material distribution mechanism 12 is used to push down materials exceeding a certain height; the material lifting mechanism 13 is used to transfer the materials on the material distribution mechanism to the The feeding mechanism; the feeding mechanism 14 is...

no. 2 example

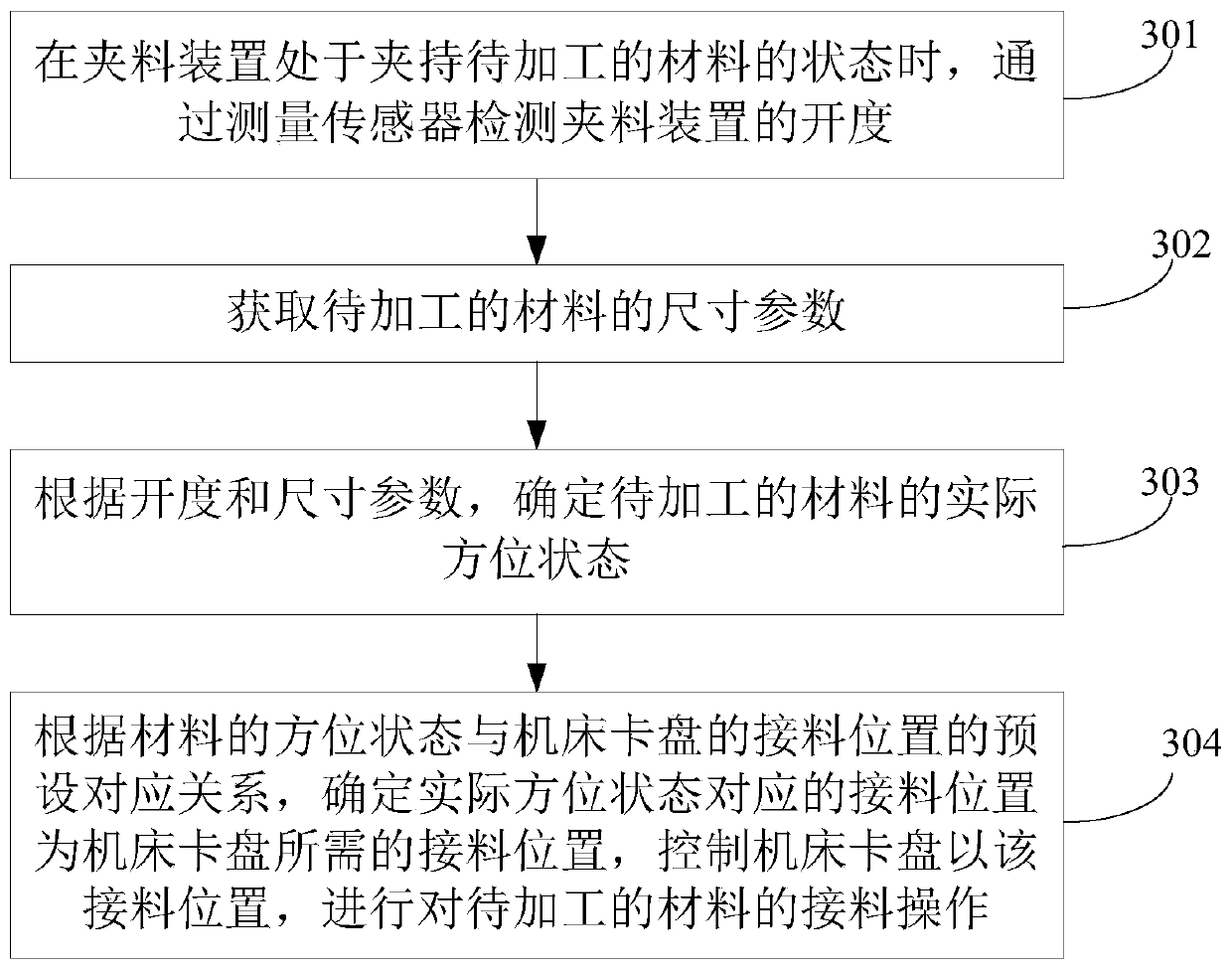

[0033]The embodiment of the present application proposes an automatic feeding method, which is applied to the automatic feeding device as in the first embodiment, see image 3 , the automatic feeding method includes:

[0034] Step 301, when the clamping device is in the state of clamping the material to be processed, the opening of the clamping device is detected by the measuring sensor;

[0035] In this embodiment, the material can be specifically a pipe, and the specification of the pipe has been expanded compared with the existing technology, including but not limited to 20*30, 40*50, 100*120 and other specifications widely used in furniture, passenger cars and agricultural machinery industries Pipes and other industries. The shape of the cross-section of the pipe is not limited, and may be circular, rectangular, square, hexagonal, etc., which is not limited in this embodiment.

[0036] In an example, when the measuring sensor is a displacement sensor, detecting the openi...

no. 3 example

[0065] see Figure 4 , this embodiment proposes an automatic feeding method, the automatic feeding method is applied as in the first embodiment and figure 1 An automatic feeding device, wherein, assuming that the measuring sensor is a displacement sensor, the automatic feeding method includes:

[0066] Step 401, start feeding;

[0067] Step 402, the pipe is transported on the transmission mechanism and passes through the material distribution mechanism;

[0068] Step 403, the pipe is transferred to the feeding mechanism by the lifting mechanism,

[0069] Step 404, the displacement sensor on the feeding mechanism detects the opening of the clamp;

[0070] Step 405, obtaining the size parameters of the pipe;

[0071] Step 406, compare the dimensional parameters of the pipe with the opening of the clamping tongs, determine whether the orientation state of the pipe is a flat state, if so, go to step 408, otherwise go to step 407;

[0072] Step 407, the chuck of the machine to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com